BX high-end three-dimensional integrated solid-liquid synchronous deeply sewage-treating device and manufacturing method

A technology of sewage treatment equipment and manufacturing method, which is applied in the direction of water treatment parameter control, biological water/sewage treatment, light water/sewage treatment, etc., which can solve the problem of single and specialized equipment and the inability to achieve one-time deep harmless treatment up to standard , high investment cost and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

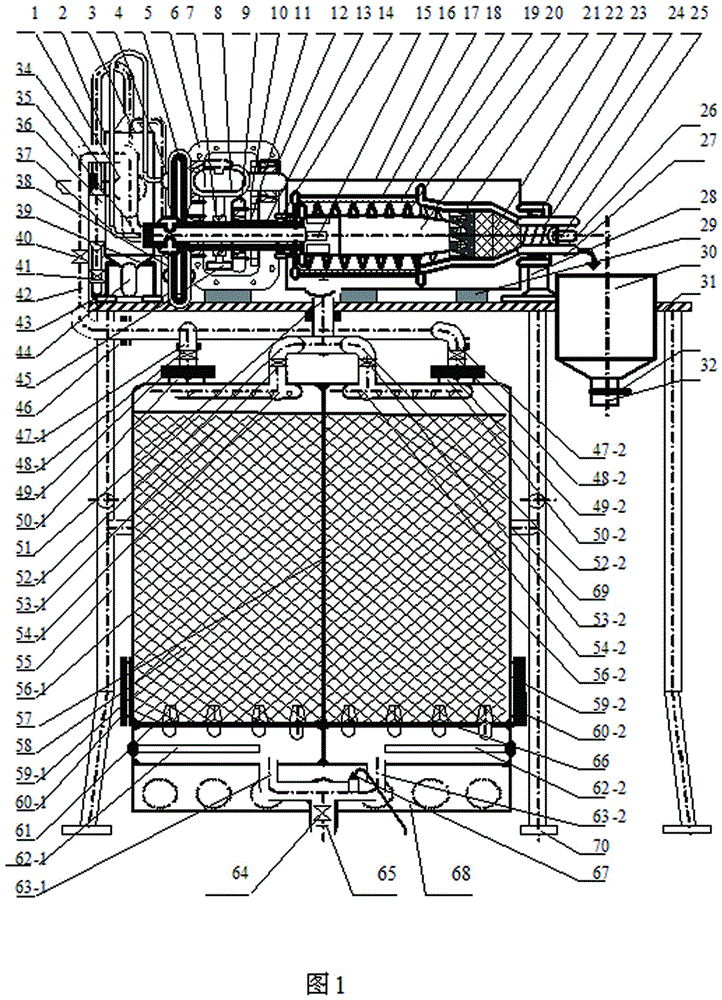

[0023] Embodiment: The BX high-end three-dimensional integrated solid-liquid synchronous deepening sewage treatment equipment and manufacturing method are based on carbon steel plate, stainless steel plate reel, cast steel, stainless steel material foundry casting, aluminum alloy, stainless steel material precision casting, plastic mold opening injection molding, After welding and mechanical processing, it has sewage inlet (1); oil-water separation chamber (2); dosing port (3); main shaft (4); pulley (5); gearbox (6); worm shaft (7); turbine (8); drum shaft bearing seat (9); gear (10); drum shaft (11); main shaft bearing seat (12); pusher shaft (13); drum and pusher bearing seat (14); Water distribution hole (15); centrifuge shell (16); drum (17); isolation layer (18); spiral blade (19); pusher (20); sludge squeezer (21); grinding type Squeeze dry body (22); bearing bracket (23); mud guide chamber (24); end shaft of pusher (25); end shaft centering sleeve (26); sludge discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com