Modification method and application of activated carbon

An activated carbon and modified technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of waste liquid pollution, complex operation process, long time-consuming, etc., and meet the requirements of high treatment efficiency and experimental conditions. Low, porosity-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of modification method of activated carbon of the present embodiment, comprises the following steps:

[0038] (1) Put 4g of coconut shell activated carbon in an oven at a temperature of 60°C. After baking for 24 hours, take it out, weigh 2g with an electronic balance, and use it for later modification (marked as AC-1). Put it into a sealed bag as a comparison sample (marked as AC-2).

[0039] (2) Air is used as the gas source, and the flow rate is 20cc / min; the working voltage of the atmospheric pressure low-temperature plasma equipment is kept at 220V, and after turning on the power, let the equipment stand still for 40 seconds, and then turn off the power.

[0040](3) Take No. AC-1 activated carbon, put it into a 50ml beaker, spread it evenly on the bottom of the beaker, and place it just below the jet outlet of the atmospheric pressure low temperature plasma equipment.

[0041] (4) Adjust the height of the equipment so that the distance between the low-temper...

Embodiment 2

[0046] A kind of modification method of activated carbon of the present embodiment, comprises the following steps:

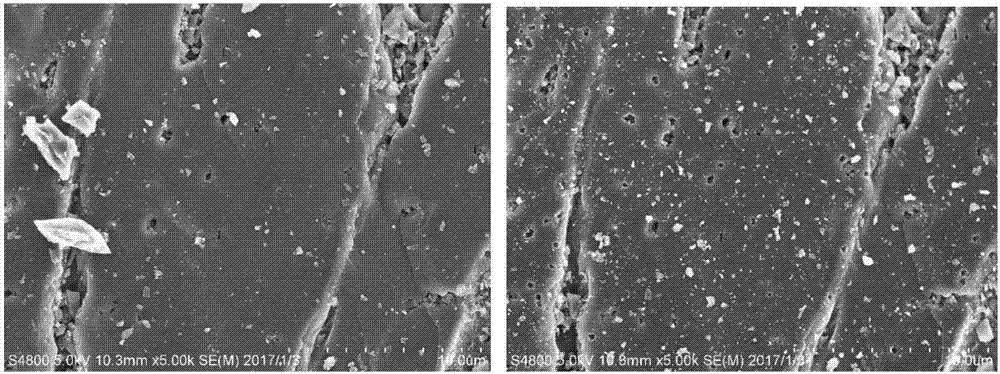

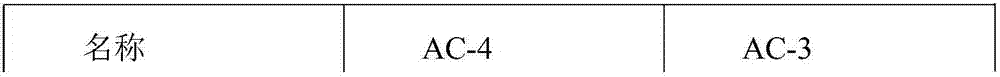

[0047] (1) Put 4g of coconut shell activated carbon in an oven, bake at a constant temperature of 60°C for 24 hours, take it out, weigh 2g with an electronic balance, (for later modification) (marked as AC-3), and pack the rest Put it into a sealed bag, (as a comparison sample) (marked as No. AC-4).

[0048] (2) Air is used as the gas source, and the flow rate is 20cc / min; the working voltage of the atmospheric pressure low-temperature plasma equipment is kept at 220V, and after turning on the power, let the equipment stand still for 40 seconds, and then turn off the power.

[0049] (3) Take No. AC-3 activated carbon, put it into a 50ml beaker, spread it evenly on the bottom of the beaker, and place it just below the jet outlet of the atmospheric pressure low temperature plasma equipment.

[0050] (4) Adjust the height of the equipment so that the distance betw...

Embodiment 3

[0056] A kind of modification method of activated carbon of the present embodiment, comprises the following steps:

[0057] (1) Put 4g of coconut shell activated carbon in an oven at a temperature of 60°C. After baking for 24 hours, take it out, weigh 2g with an electronic balance, and use it for later modification (marked as No. AC-5), and the remaining Put it into a sealed bag as a comparison sample (marked as No. AC-6).

[0058] (2) Use oxygen as the gas source with a flow rate of 30cc / min; keep the operating voltage of the atmospheric pressure low-temperature plasma equipment at 220V, turn on the power, let the equipment stand for 40s, and then turn off the power.

[0059] (3) Take No. AC-5 activated carbon, put it into a 50ml beaker, spread it evenly on the bottom of the beaker, and place it directly below the atmospheric pressure low temperature plasma equipment.

[0060] (4) Adjust the height of the equipment so that the distance between the low-temperature plasma jet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com