Preparation method of sodium alginate/L-cysteine/reduced graphene oxide magnetic hydrogel/aerogel

A cysteine, sodium alginate technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of limited adsorption performance, inability to expand, waste of resources, etc. Reduced use and preparation time, enhanced adsorption and monitoring performance, improved surface porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Take a beaker, add 200mg of graphene oxide, 1000mg of sodium alginate, 200mg of L-cysteine, 200mg of nanometer iron ferric oxide, 200mg of sodium bicarbonate and 100mL of distilled water, and stir it by ultrasonic and mechanical for 2h to form a uniform mixture.

[0031] (2) Take another beaker and prepare 200mL of 10mg / mL CaCl at a temperature of 10°C 2 Solution, drop the mixed solution prepared in step (1) into CaCl with a peristaltic pump 2 In solution, unreduced gel spheres were obtained.

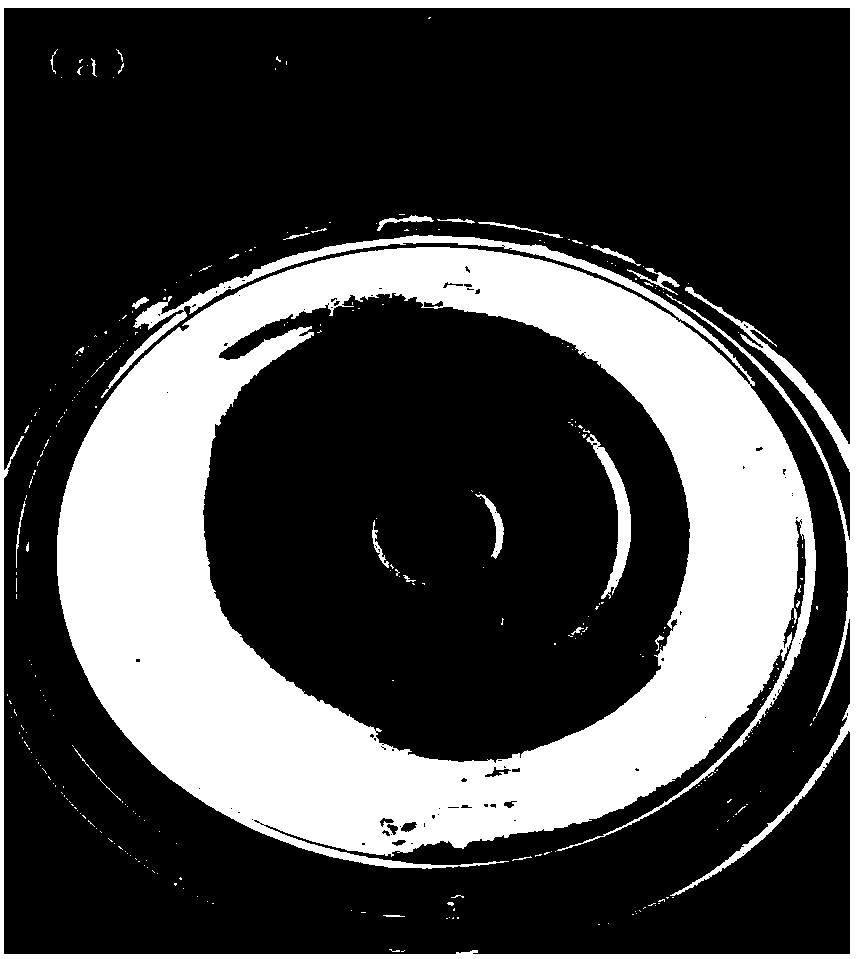

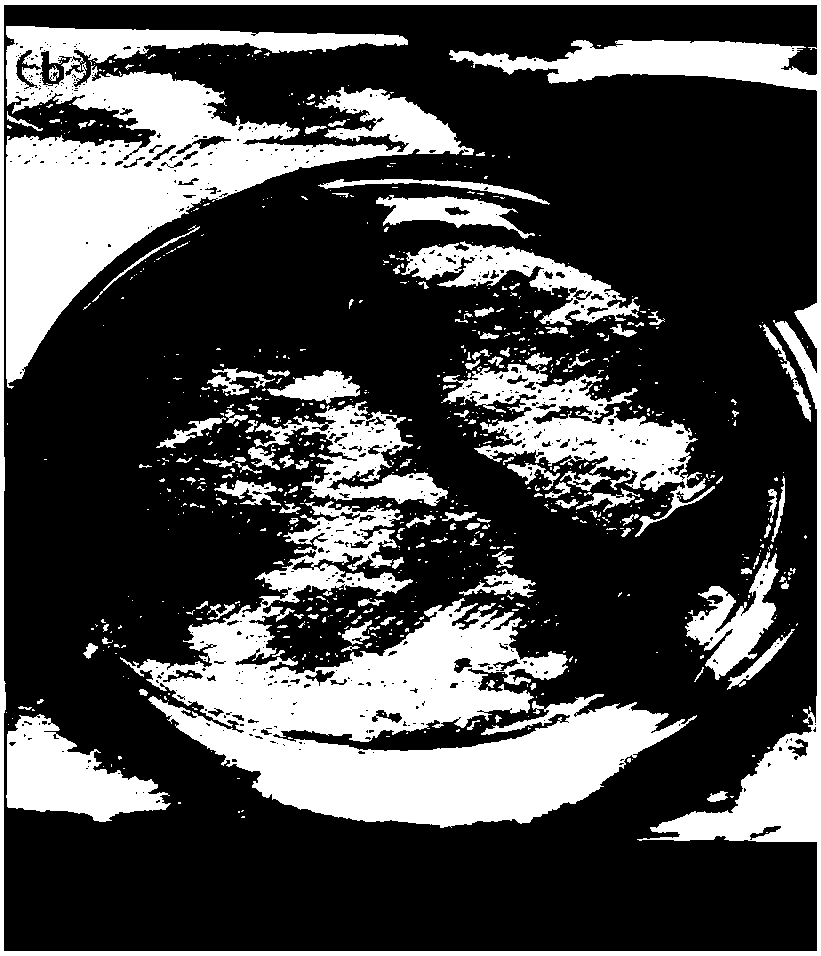

[0032] (3) After the unreduced gel balls prepared in step (2) were left to stand for 6 hours, they were placed in a water bath at 80° C. and heated for 3 hours to obtain reduced hydrogel balls. The obtained gel balls were soaked in distilled water for 6 h to remove surface impurities to obtain sodium alginate / L-cysteine / reduced graphene oxide magnetic hydrogel.

[0033] (4) Put the sodium alginate / L-cysteine / reduced graphene oxide magnetic hydrogel prepared in step (3) int...

Embodiment 2

[0038] (1) Take a beaker, add 1000mg graphene oxide, 7000mg sodium alginate, 2000mg L-cysteine, 2000mg nano ferric oxide, 2000mg sodium bicarbonate and 100mL distilled water, and stir it by ultrasonic and mechanical for 6h until a uniform solution.

[0039] (2) Take another beaker and prepare 200mL of 70mg / mL CaCl at 40°C 2 Solution, use a peristaltic pump to drop the mixed solution into CaCl 2 In solution, unreduced gel spheres were obtained.

[0040] (3) After the unreduced gel balls prepared in step (2) were left to stand for 12 hours, they were placed in a 90° C. water bath and heated for 12 hours to obtain reduced hydrogel balls. The obtained gel balls were soaked in distilled water for 12 hours to remove surface impurities to obtain sodium alginate / L-cysteine / reduced graphene oxide magnetic hydrogel.

[0041] (4) Put the prepared sodium alginate / L-cysteine / reduced graphene oxide magnetic hydrogel into a freeze dryer, and freeze it in a freezer at -40°C for 12 hours; the...

Embodiment 3

[0043] (1) Take a beaker, add 2000mg graphene oxide, 20000mg sodium alginate, 10000mg L-cysteine, 10000mg nano ferric oxide, 10000mg sodium bicarbonate and 100mL distilled water, and stir it by ultrasonic and mechanical for 10h to form homogeneous solution.

[0044] (2) Take another beaker and prepare 200mL of 200mg / mL CaCl at a temperature of 50°C 2 Solution, use a peristaltic pump to drop the mixed solution into CaCl 2 In solution, unreduced gel spheres are obtained.

[0045] (3) After the unreduced gel balls prepared in step (2) were left to stand for 24 hours, they were placed in a water bath at 100° C. and heated for 24 hours to obtain reduced hydrogel balls. The obtained gel balls were soaked in distilled water for 24 hours to remove surface impurities to obtain sodium alginate / L-cysteine / reduced graphene oxide magnetic hydrogel.

[0046] (4) Put the prepared sodium alginate / L-cysteine / reduced graphene oxide magnetic hydrogel into a freeze dryer, and freeze it in a fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com