Preparation method of spongy-structure separation membrane with adjustable pore diameter and the separation membrane prepared by the preparation method

A separation membrane and sponge-like technology, applied in the field of membrane separation, can solve the problems of closed pores, dense skin, uneven pore size, and high energy consumption of thermal methods in membrane products, and achieve high flux, uniform pore size, and high separation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

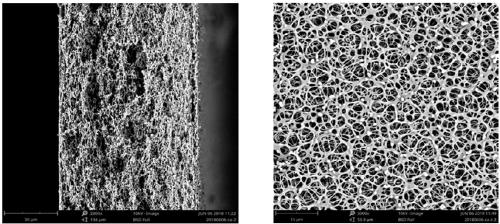

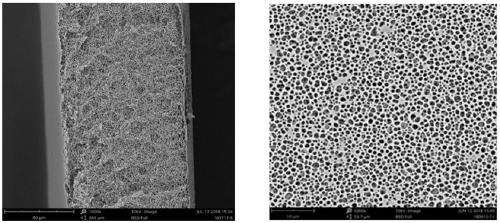

[0033] The mixture of cellulose acetate, dimethylformamide, acetone and glycerin was mixed in a mass ratio of 9:46:23:12, stirred at room temperature for 12 hours to prepare a clear and transparent solution, and allowed to stand for defoaming. Control the humidity of the scraping film atmosphere to be stable at 50-60%, set the blade gap of the flat-panel scraper to 0.40 μm, start the flat-panel scraper, and run the scraper at a speed of 100 mm / s to evenly scrape the cast film on the glass plate or On the non-woven fabric, after the scraper stops running, the separation membrane is left to stand at an ambient temperature of 50°C and a humidity of 90% for evaporation and phase separation for 180s, and then the primary film is transferred to a coagulation bath (pure water) at 25°C to generate a solution Phase inversion, then rinse the product in pure water for 48 hours, and then immerse in a mixed solution with a mass ratio of water:glycerin:SDS=79.2:20:0.8 for 5-6 days and then d...

Embodiment 2

[0035] Mix the mixture of cellulose acetate, dimethylformamide, acetone and ethylene glycol at a mass ratio of 9:50:20:21, stir at room temperature for 8 hours to prepare a clear and transparent solution, and let it stand for defoaming. Control the humidity of the scraping film atmosphere to be stable at 50-60%, set the blade gap of the flat-panel scraper to 0.40 μm, start the flat-panel scraper, and run the scraper at a speed of 100 mm / s to evenly scrape the cast film on the glass plate or On the non-woven fabric, after the scraper stops running, the separation membrane is left to stand at an ambient temperature of 75°C and a humidity of 70% to evaporate and separate phases for 120s, and then transfer the primary film to a 25°C coagulation bath (pure water) to generate a solution Phase inversion, then rinse the product in pure water for 48 hours, and then immerse in a mixed solution with a mass ratio of water:glycerin:SDS=79.2:20:0.8 for 5-6 days and then dry it in the shade. ...

Embodiment 3

[0037]Mix a mixture of polyvinylidene fluoride, dimethylacetamide, polyvinylpyrrolidone, acetone and glycerin at a mass ratio of 18:54:5:18:5, stir at 50°C for 12 hours to prepare a clear and transparent solution, and let it stand to remove Bubble. Control the humidity of the scraping film atmosphere to be stable at 50-60%, set the gap between the scrapers of the flat-panel film scraper to 0.30 μm, start the flat-panel scraper, and run the scraper at a speed of 150 mm / s to evenly scrape the cast film on the glass plate or On the non-woven fabric, after the scraper stops running, the separation membrane is left to stand at an ambient temperature of 50°C and a humidity of 95% to evaporate and separate phases for 120s, and then transfer the primary film to a coagulation bath (pure water) at 25°C to generate a solution Phase inversion, then rinse the product in pure water for 48 hours, then soak for 4 hours in a mixed solution with a mass ratio of water: glycerol: sodium bisulfite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com