Preparation method for density-controllable light bamboo-wood-based fiber plate

A fiberboard and lightweight technology, applied in the field of lightweight fiberboard, can solve problems such as increased operational complexity, prolonged hot pressing time, and difficult foaming process parameters, so as to achieve good practical application value and promotion value, improve controllability, reduce effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

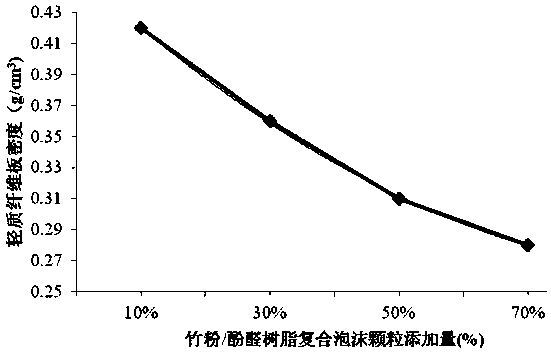

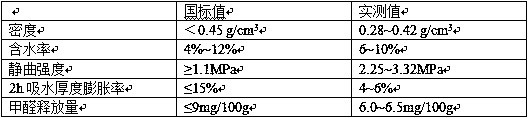

[0029] Embodiment 1: a kind of preparation method of density-controllable lightweight bamboo-based fiberboard, comprises the following steps:

[0030] 1. Preparation of thermosetting phenolic resin:

[0031] Take a certain amount of phenol and formaldehyde solution with a molar ratio of 1:1.6 in the reactor, then add a certain amount of sodium hydroxide with a molar ratio of 0.35:1 to phenol as a catalyst, heat and stir at a rate of 4°C / min Raise the temperature to 90°C, react at constant temperature for 120 minutes, add hydrochloric acid to adjust the pH value to 6.8~7.2, and vacuum dehydrate when the temperature is lowered to 70°C to obtain a thermosetting phenolic resin, which is ready for use;

[0032] 2. Preparation of bamboo powder phenolic resin composite foam particles:

[0033] 2.1, processing bamboo slices: select 3-5 year old moso bamboo, carry out slice processing by slicer, remove bamboo green and bamboo yellow, then carry out pulverization with pulverizer;

[0...

Embodiment 2

[0042] Embodiment 2: a kind of preparation method of density-controllable lightweight bamboo-based fiberboard, comprises the following steps:

[0043] 1. Preparation of thermosetting phenolic resin:

[0044] Take a certain amount of phenol and formaldehyde solution with a molar ratio of 1:1.6 in the reactor, then add a certain amount of sodium hydroxide with a molar ratio of 0.35:1 to phenol as a catalyst, heat and stir at a rate of 4°C / min Raise the temperature to 90°C, react at constant temperature for 120 minutes, add hydrochloric acid to adjust the pH value to 6.8~7.2, and vacuum dehydrate when the temperature is lowered to 70°C to obtain a thermosetting phenolic resin, which is ready for use;

[0045] 2. Preparation of bamboo powder phenolic resin composite foam particles:

[0046] 2.1, processing bamboo slices: select 3-5 year old moso bamboo, carry out slice processing by slicer, remove bamboo green and bamboo yellow, then carry out pulverization with pulverizer;

[0...

Embodiment 3

[0055] Embodiment 3: a kind of preparation method of density-controllable lightweight bamboo-based fiberboard, comprises the following steps:

[0056] 1. Preparation of thermosetting phenolic resin:

[0057] Take a certain amount of phenol and formaldehyde solution with a molar ratio of 1:1.6 in the reactor, then add a certain amount of sodium hydroxide with a molar ratio of 0.35:1 to phenol as a catalyst, heat and stir at a rate of 4°C / min Raise the temperature to 90°C, react at constant temperature for 120 minutes, add hydrochloric acid to adjust the pH value to 6.8~7.2, and vacuum dehydrate when the temperature is lowered to 70°C to obtain a thermosetting phenolic resin, which is ready for use;

[0058] 2. Preparation of bamboo powder phenolic resin composite foam particles:

[0059] 2.1, processing bamboo slices: select 3-5 year old moso bamboo, carry out slice processing by slicer, remove bamboo green and bamboo yellow, then carry out pulverization with pulverizer;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com