Polyvinylidene difluoride membrane, manufacturing method thereof, and purifying brine method thereof

A technology of polyvinylidene fluoride and thin film, which is applied in the direction of chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of reducing the life of DCMD and affecting the stability of DCMD, and achieves low cost, good salt resistance and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

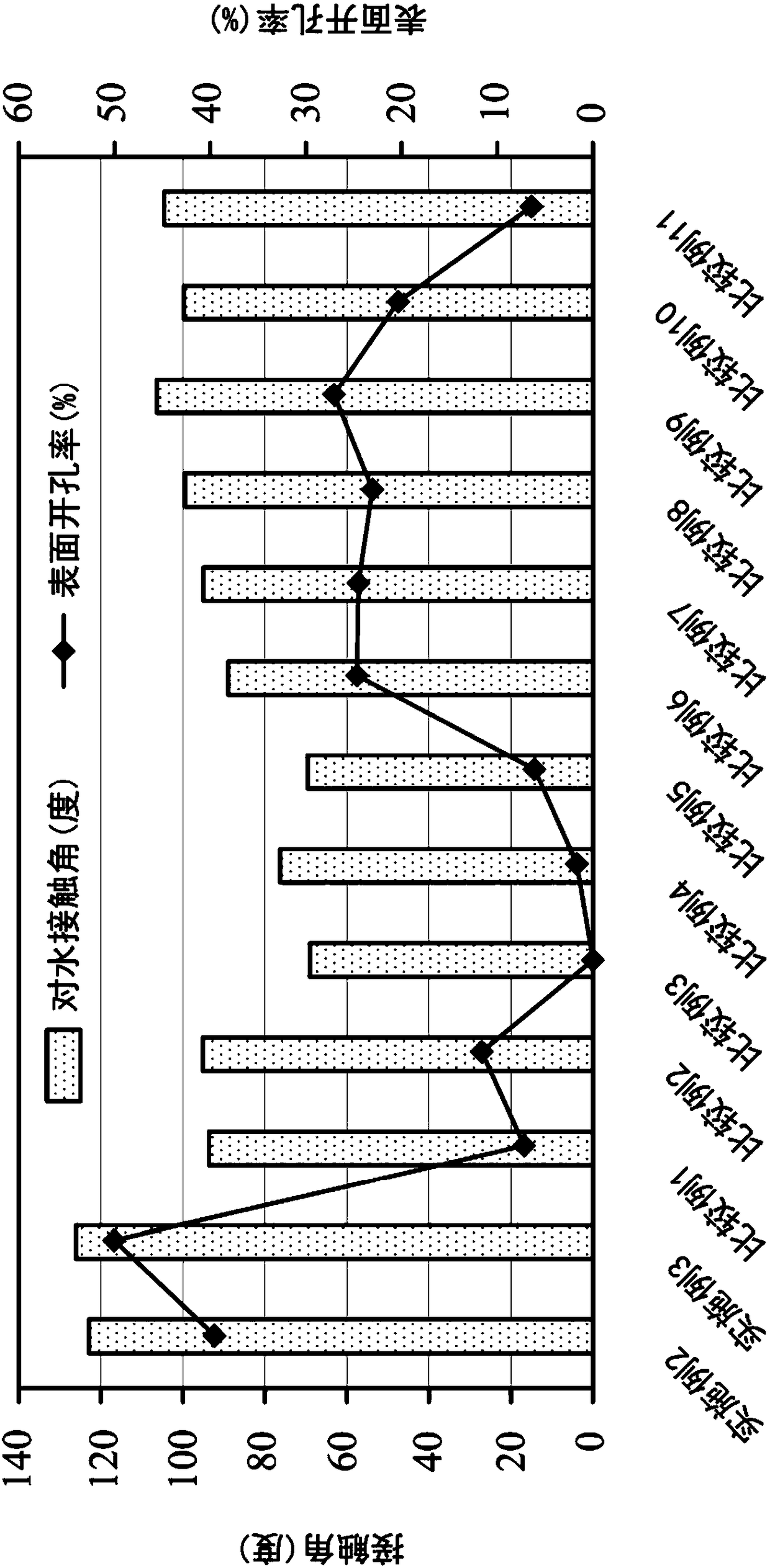

[0037] Take triethyl phosphate (TEP, triethyl phosphate, Alfa Aesar) and polyvinylidene fluoride (PVDF, melt viscosity between 35 to 60 kpoise) to prepare a 6-10wt% PVDF polymer solution, stir with a magnet at 30 Dissolve at -80°C until PVDF is completely dispersed. When the PVDF is completely dissolved, control the internal temperature and keep stirring the solution at the set temperature for more than 48 hours, then let it stand for more than 24 hours or remove the air bubbles in the dope solution with reduced pressure and vacuum.

preparation example 2

[0038] Preparation example 2 (modification of carbon nanotubes)

[0039] Disperse 10 grams of carbon nanotubes in 100 grams of 30-50wt% hydrogen peroxide and stir at 50-105°C for 3-6 hours to oxidize the surface of the carbon nanotubes, filter the reacted carbon nanotubes and After washing with deionized water until neutral, place in an oven and dry at a low temperature of 50-80°C to obtain oxidatively modified carbon nanotubes. Preparation example 3 (modification of carbon nanotubes)

preparation example 3

[0040] Disperse 10 grams of carbon nanotubes in 100 grams of 3-5M nitric acid, stir and react at 50-105°C for 3-6 hours to oxidize the surface of carbon nanotubes, filter the reacted carbon nanotubes and remove After washing with ion water to neutrality, place in an oven and dry at a low temperature of 50-80°C to obtain oxidatively modified carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com