Water-based adhesive

A water-based adhesive, water-based technology, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems of easy demulsification, poor product stability, inconvenient use of products, etc., to ensure comprehensive effects and excellent stability , The effect of improving the adhesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 7

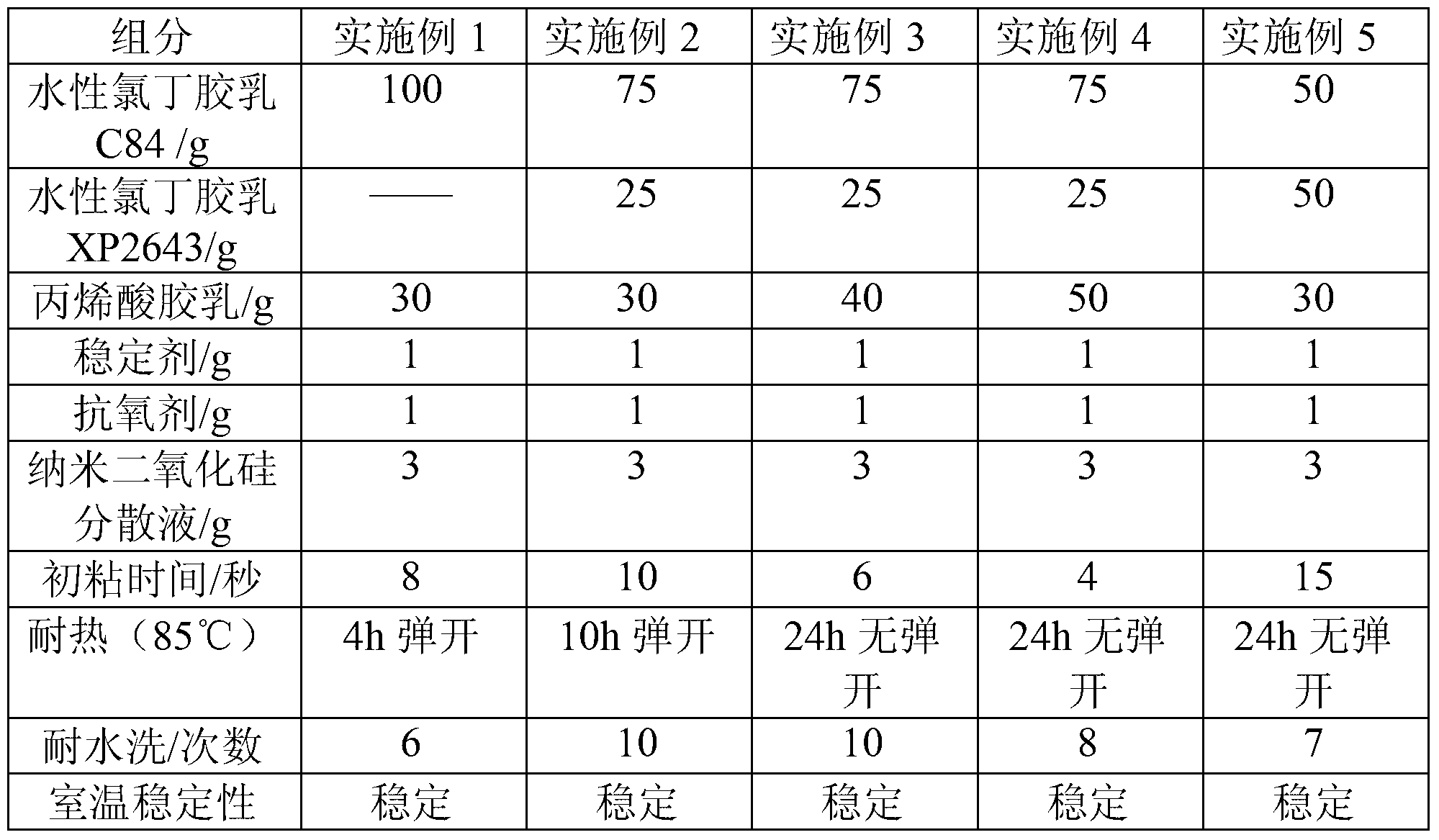

[0026] Performance comparison between this patented product and similar well-known glues at home and abroad: Table 1-4

[0027]

[0028] In contrast, compared with the well-known glues at home and abroad, the basic properties of the glue disclosed by the present invention have the advantages of faster initial adhesion, better heat resistance and water resistance; Solvent-based glue is more environmentally friendly, safe, energy-saving and economical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com