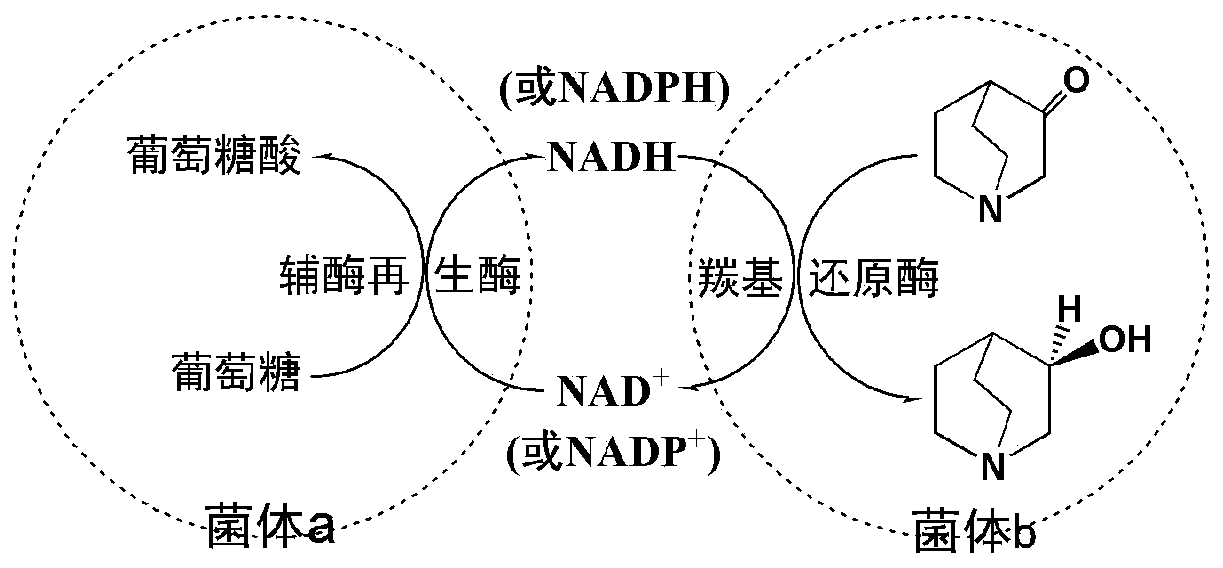

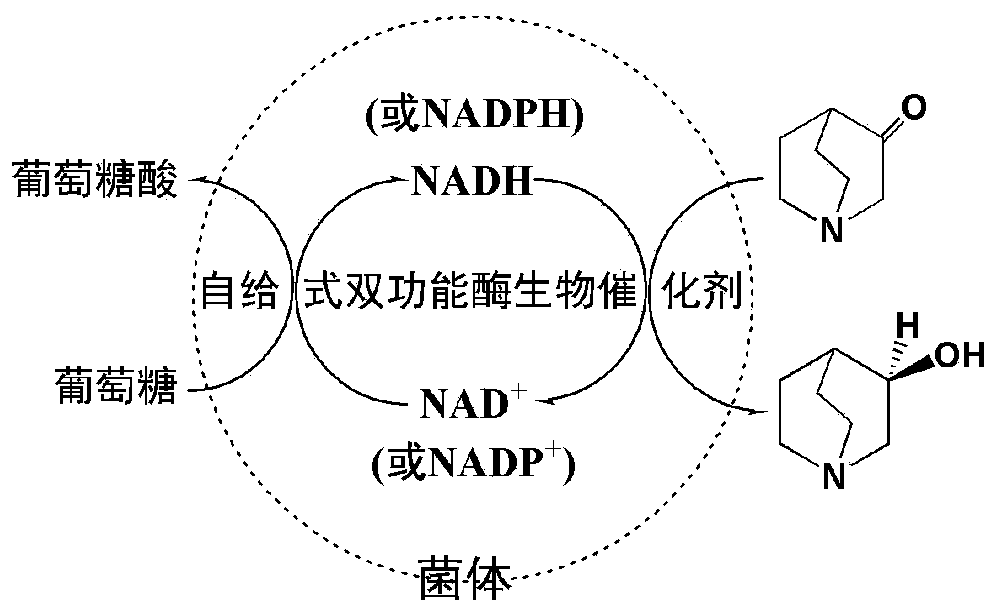

Self-feeding type dual-function biocatalyst and preparation method and application thereof

A biocatalyst, self-sufficient technology, applied in the field of bioengineering, can solve the problems of long production cycle, time-consuming, low catalytic efficiency, etc., and achieve the effects of mild process conditions, large economic benefits, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 Enzyme Activity Determination

[0047] Assay of Carbonyl Reductase Activity in a Self-Contained Bifunctional Fusion Enzyme:

[0048] Standard reaction mixture system: buffer solution (PBS, pH7.2-7.4), 3 μmol 3-quinine, 0.3 μmol NADH, appropriate amount of self-contained bifunctional biocatalyst, total volume 1mL. Changes in absorbance values were measured at λ = 340 nm. Definition of enzyme activity unit: the amount of enzyme required to convert 1 μmol NADH within 1 min at 25°C.

[0049] Determination of Coenzyme Regenerating Enzyme Activity in a Self-Contained Bifunctional Fusion Enzyme:

[0050] Standard reaction mixture system: buffer solution (PBS, pH7.2-7.4), 10 μmol glucose, 1 μmol NAD + , an appropriate amount of self-contained bifunctional biocatalyst, with a total volume of 1 mL. Changes in absorbance values were measured at ? = 340 nm. Enzyme activity unit definition: 1 μmol NAD converted within 1 min at 25°C + amount of enzyme required.

Embodiment 2

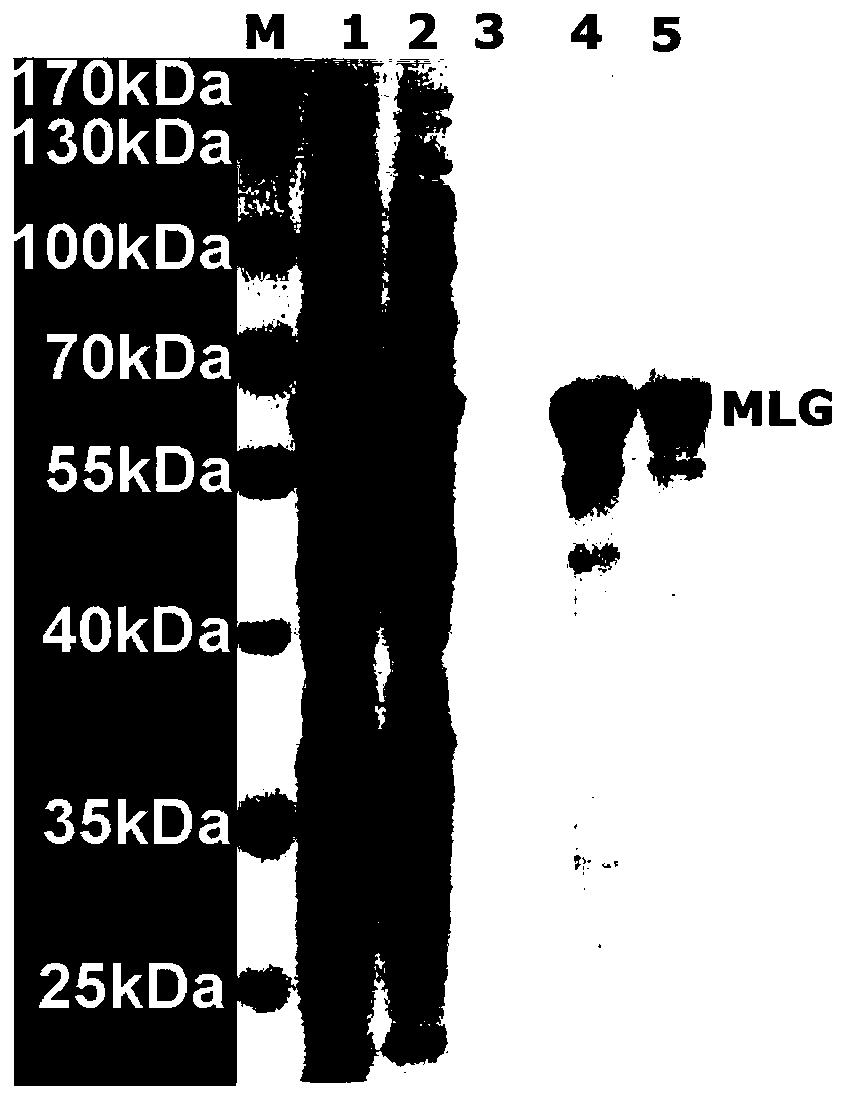

[0052] Expression of a self-sufficient bifunctional fusion enzyme

[0053] Take the expression plasmid pET28a-mlg to transform competent Escherichia coli E.coli BL21(DE3), inoculate LB solid medium (1% peptone, 0.5% yeast extract, 1% sodium chloride and 1.5 % agarose), cultured overnight at 37°C. Pick a single clone colony and inoculate it into LB liquid culture medium (1% peptone, 0.5% yeast extract and 1% sodium chloride), cultivate overnight at 37°C with a rotational speed of 150rpm. Inoculate the LB liquid medium with the culture solution at a ratio of 1:50, cultivate to OD at 37°C with a rotational speed of 150rpm 600 About 0.6-1.0. Add 0.2mM isopropyl-β-D-thiogalactoside to induce the expression of self-sufficient bifunctional fusion enzyme. The culture temperature is 25°C, the rotation speed is 150rpm, and the culture time is 36 hours. 4°C, 10,000rpm centrifuge to collect the bacteria, wash with buffer solution, and obtain self-supporting bifunctional enzyme whole-ce...

Embodiment 3

[0067] Biocatalyst catalyzed asymmetric synthesis of (R)-3-quinine alcohol:

[0068] Reaction system: 80mg biocatalyst, 5mM 3-quinine, 9mM glucose, 0.2mM NAD + , buffer solution A (10mM phosphate buffered saline, PBS, containing NaCl 137mM, KCl 2.7mM, Na 2 HPO 4 10mM, KH 2 PO 4 2mM, pH 7.2-7.4), total volume 10mL. The reaction temperature is 30°C, stirring continuously at 100rpm, and the pH is controlled at 7.5-8.0 during the reaction. The reaction is monitored by TLC, and the mobile phase is V 二氯甲烷 / V 甲醇 =9 / 1. After the biotransformation was completed, 0.1 g of trifluoroacetic acid was added to remove the protein, and the reaction mixture was centrifuged. The supernatant was adjusted to a pH greater than 12 with high-concentration NaOH, and then concentrated under reduced pressure at 80°C to 1 / 4 of the total volume. Add an equal volume of n-butanol for extraction 3 times, collect the organic phase, concentrate under reduced pressure and evaporate to dryness. Dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com