Equipment for continuously preparing high-silicon aluminum alloy through graded pressure impregnation

A high-silicon aluminum alloy, continuous technology, applied in the field of equipment for the continuous preparation of high-silicon aluminum alloys by graded pressure infiltration, can solve the problems of difficult control of the preparation process, poor mechanical properties, long production cycle, etc. Effects of layer problems, excellent machinability, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

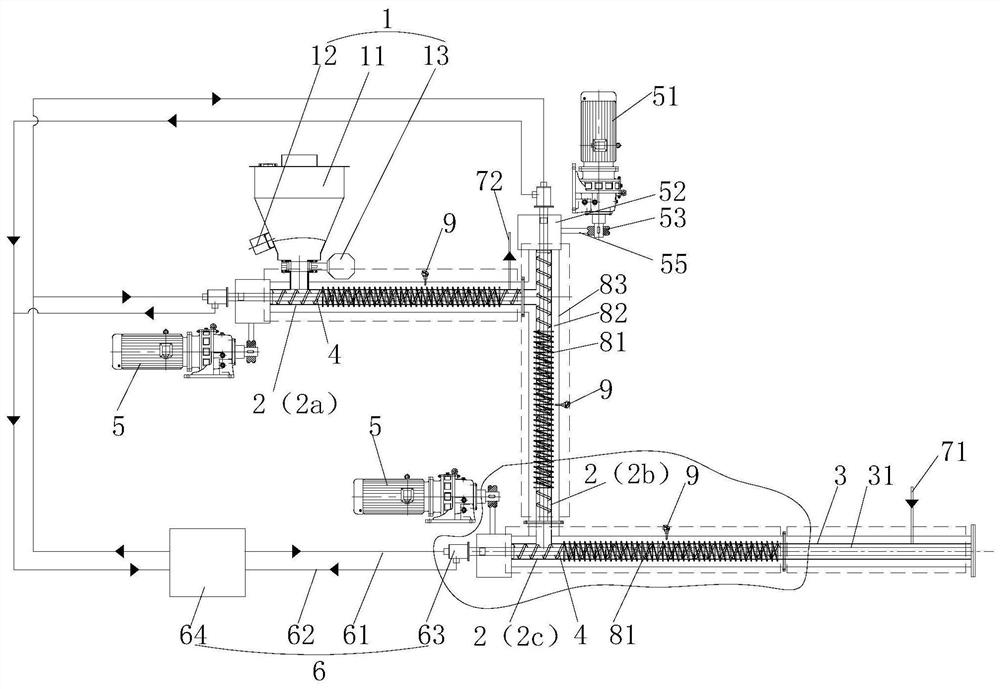

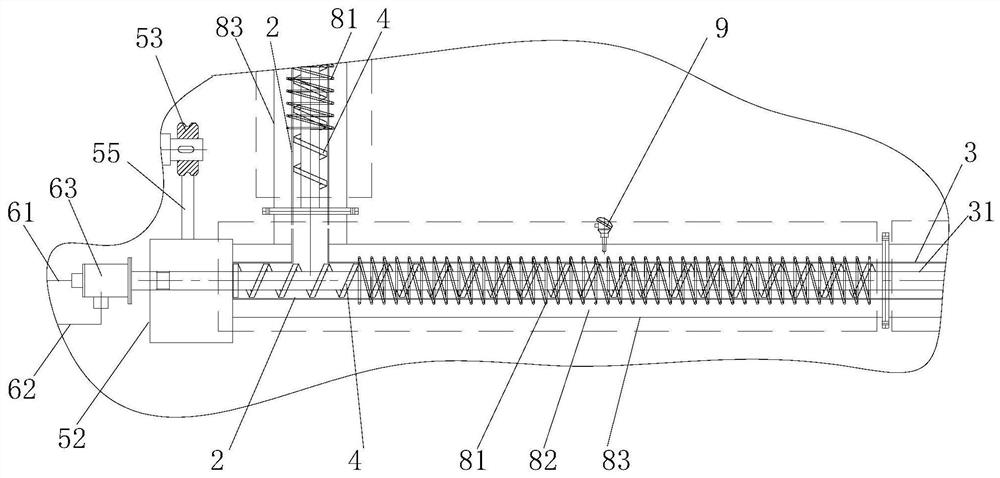

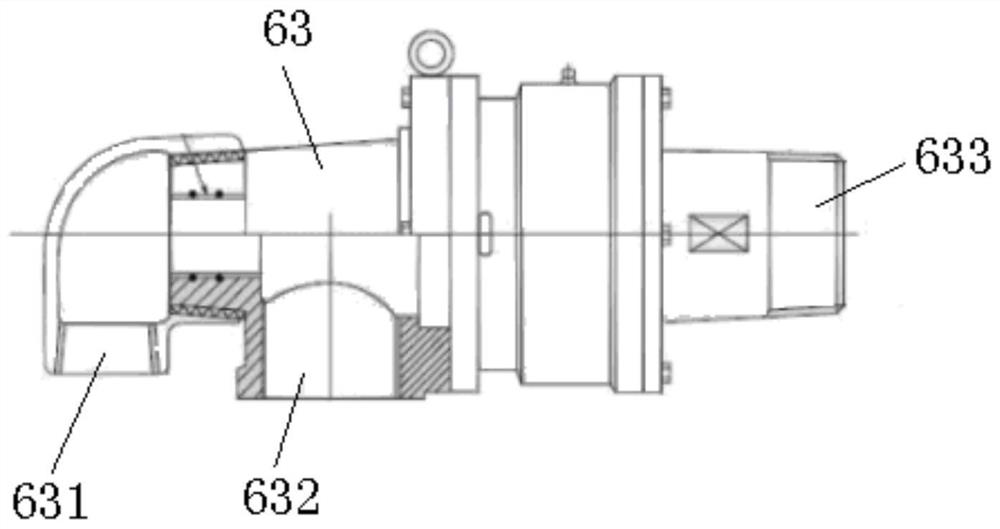

[0033] Such as figure 1 and figure 2As shown, the equipment for continuously preparing high-silicon aluminum alloys by graded pressure infiltration in this embodiment includes a feeding device 1, a cooling furnace tube 3 and at least two heating furnace tubes 2, and each heating furnace tube 2 is connected in sequence, and the The feeding device 1 is docked with the first section of the heating furnace tube 2, the cooling furnace tube 3 is connected with the last section of the heating furnace tube 2, and each section of the heating furnace tube 2 is equipped with a feeding screw 4, and the feeding screw 4 is correspondingly equipped with a rotary drive In the device 5, the pitch of the feeding screw 4 in the last section of the heating furnace tube 2 gradually decreases along the feeding direction, and the temperature in the last s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com