Device and method for eliminating electric arc additive manufacturing residual stresses through composite energy impact

A residual stress and additive manufacturing technology, used in manufacturing tools, arc welding equipment, welding equipment, etc., can solve problems such as large residual stress, and achieve the effect of improving porosity, improving overall mechanical properties, and improving residual stress elimination rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] The present invention will be further described below in conjunction with the accompanying drawings and examples in order to make a more intuitive understanding of the core points of the present invention. Further, it is within the scope of the present invention without departing from the present invention.

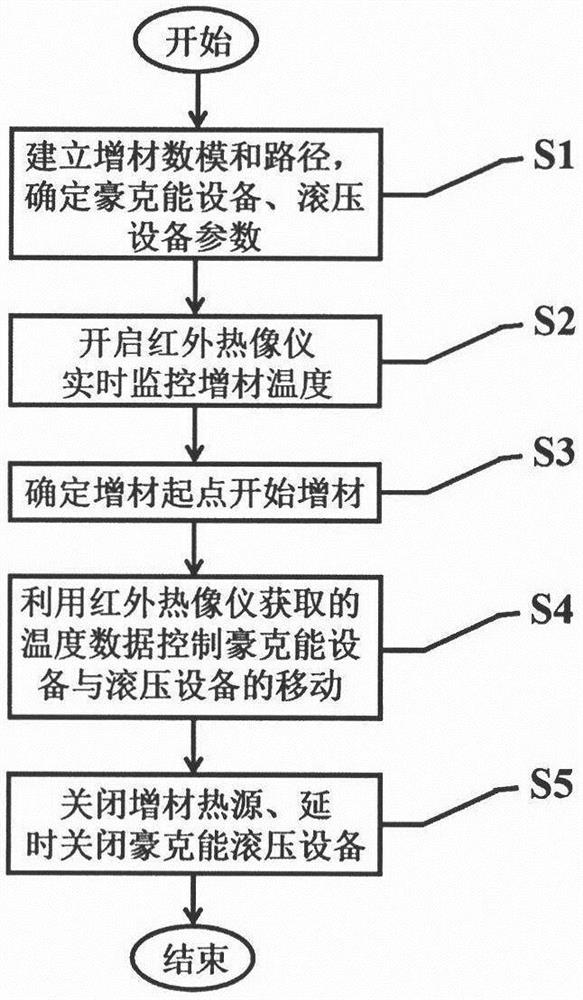

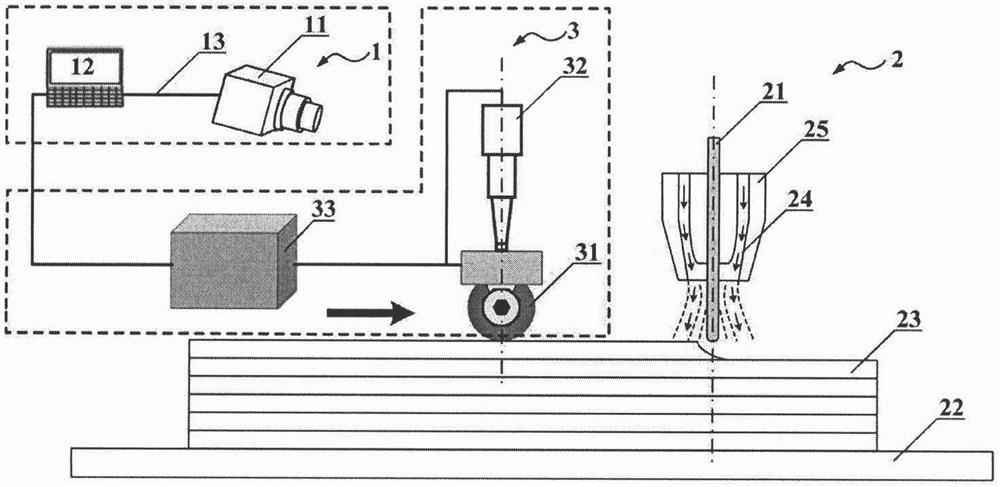

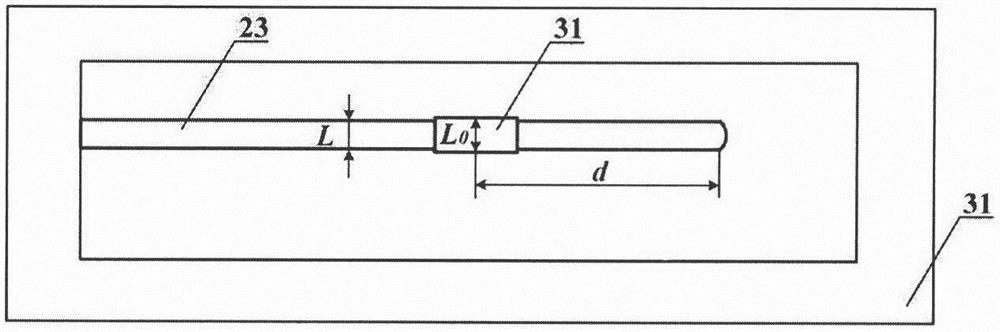

[0033] Such as figure 1 As shown in the specific implementation of the present invention, the corresponding model is first constructed according to the demand, and since the accuracy of the arc adding material is low, the processing reservation of 2 mm is added to the entire model when the model is constructed. The digitally introduced into the hierarchical slice software, planning the additive path, and determines the related parameters of the Guanoke energy vibration impact and the rolling device according to the material characteristics of the add metal metal and the height of the additive. Before the start of the additive, the infrared thermal imager is focused on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com