Patents

Literature

42results about How to "Improve formability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

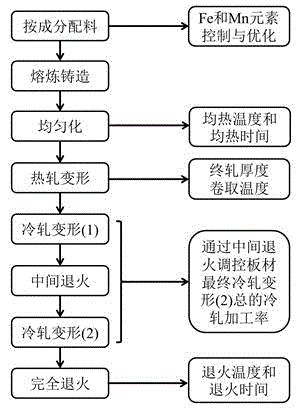

Aluminum alloy sheet material for vehicles and preparation method thereof

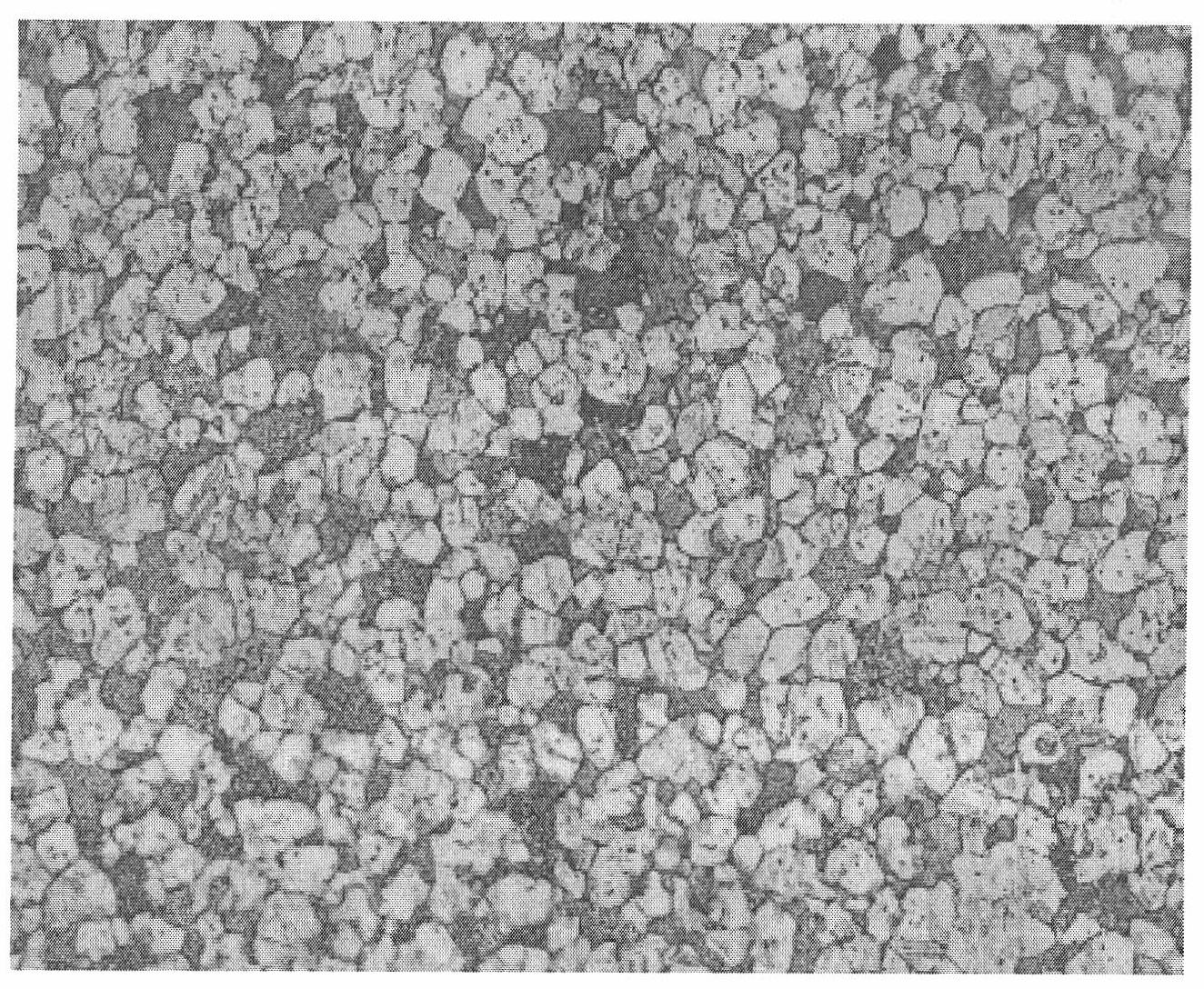

InactiveCN104894442AUniform recrystallized structureImprove formabilityChemical compositionAluminium alloy

The invention discloses an aluminum alloy sheet material for vehicles and a preparation method thereof. The aluminum alloy sheet material comprises 4.5-5.5wt% of Mg, 0.15-0.35wt% of Mn, 0.10-0.30wt% of Fe, less than or equal to 0.15wt% of Si, less than or equal to 0.10wt% of Ti, less than or equal to 0.10wt% of Cu, less than or equal to 0.10wt% of Zn, less than or equal to 0.10wt% of Cr and the balance Al and unavoidable impurities. The preparation method orderly comprises material blending, melting casting, uniformization, hot rolling deformation, primary cold rolling deformation, intermediate annealing, secondary cold rolling deformation and complete annealing. Through the design and optimization of alloy components and preparation processes, the 5XXX-series aluminum alloy sheet material with high formability and a low cost is prepared by the existing conventional plate and strip production line.

Owner:SHANDONG NANSHAN ALUMINUM

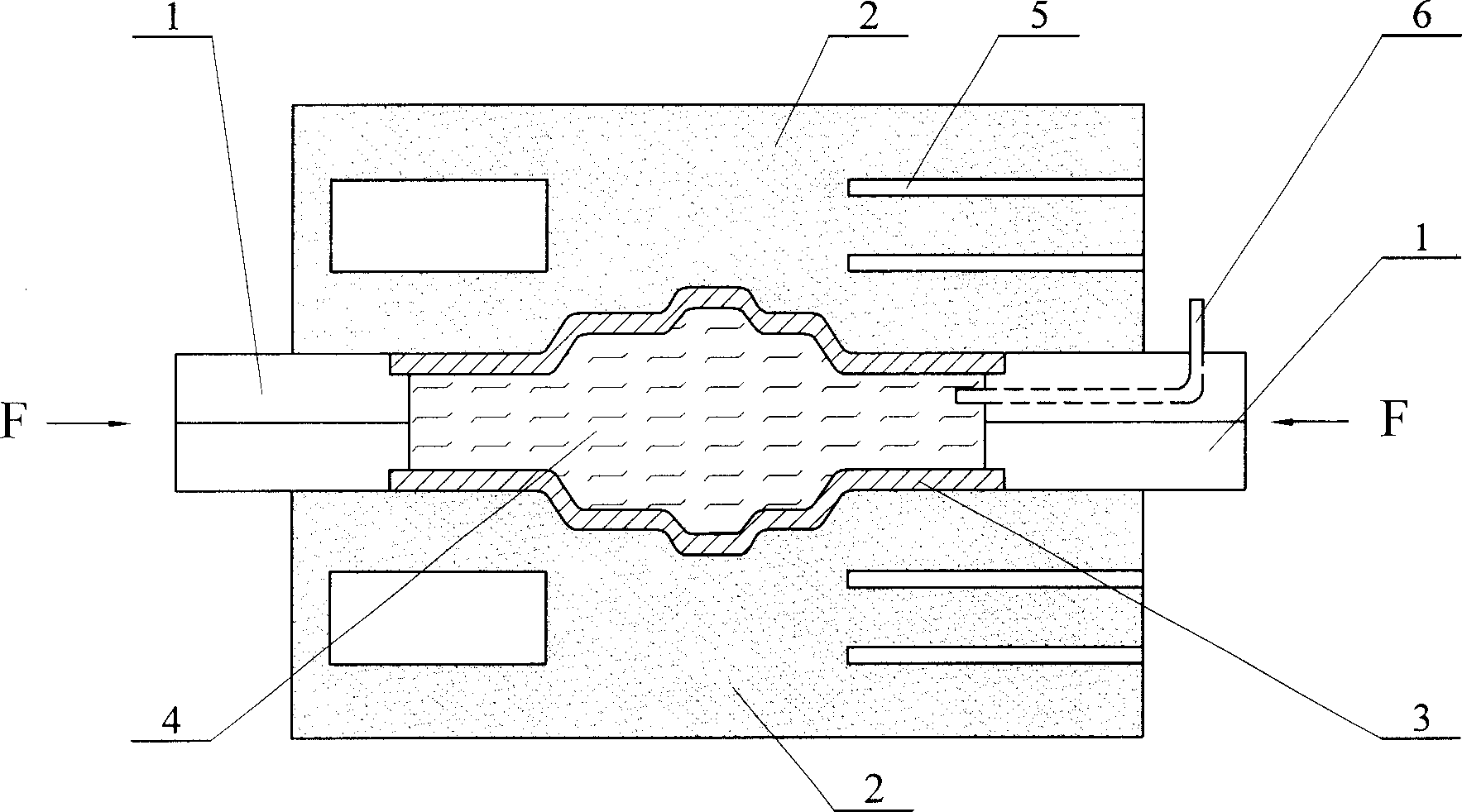

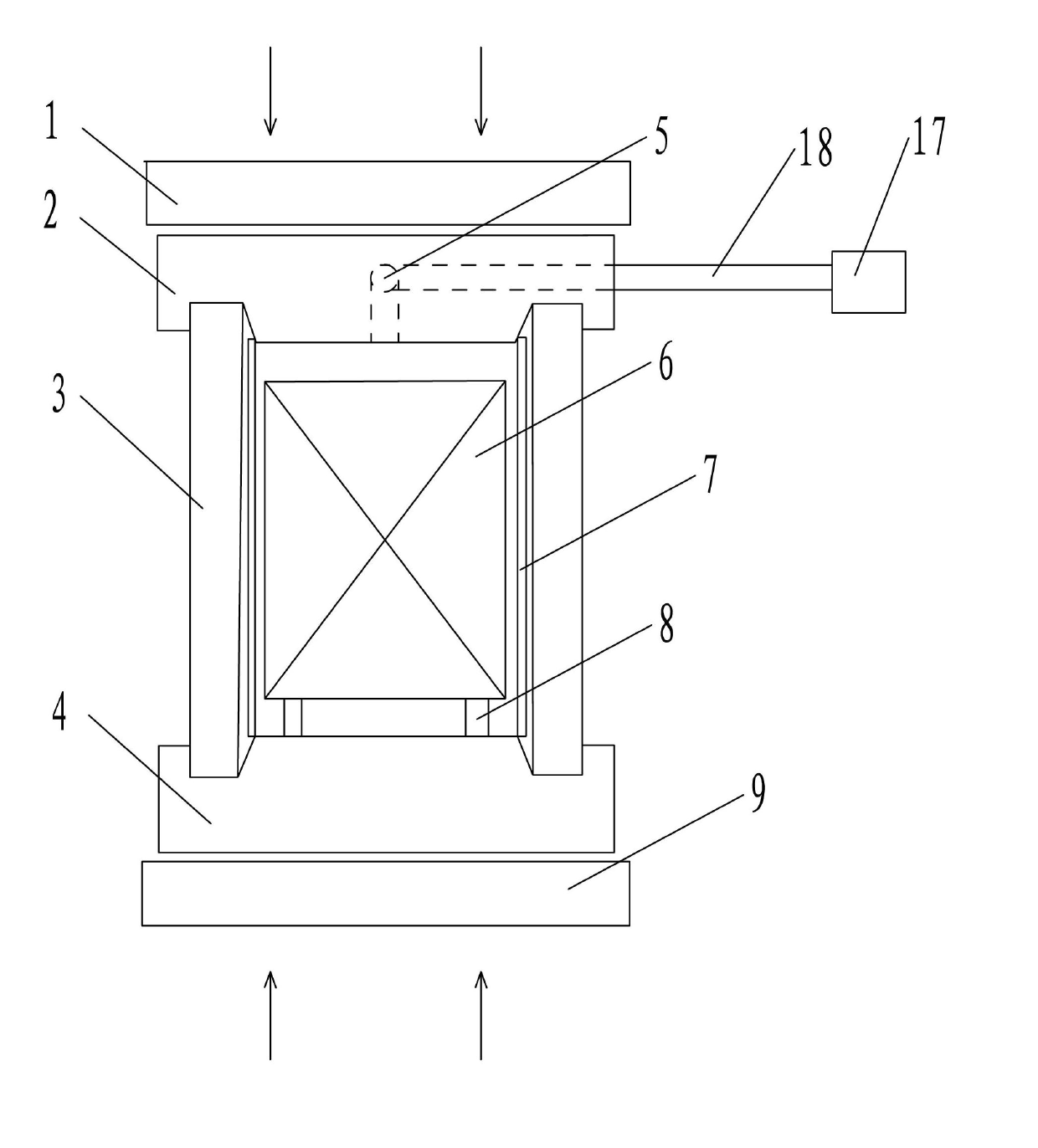

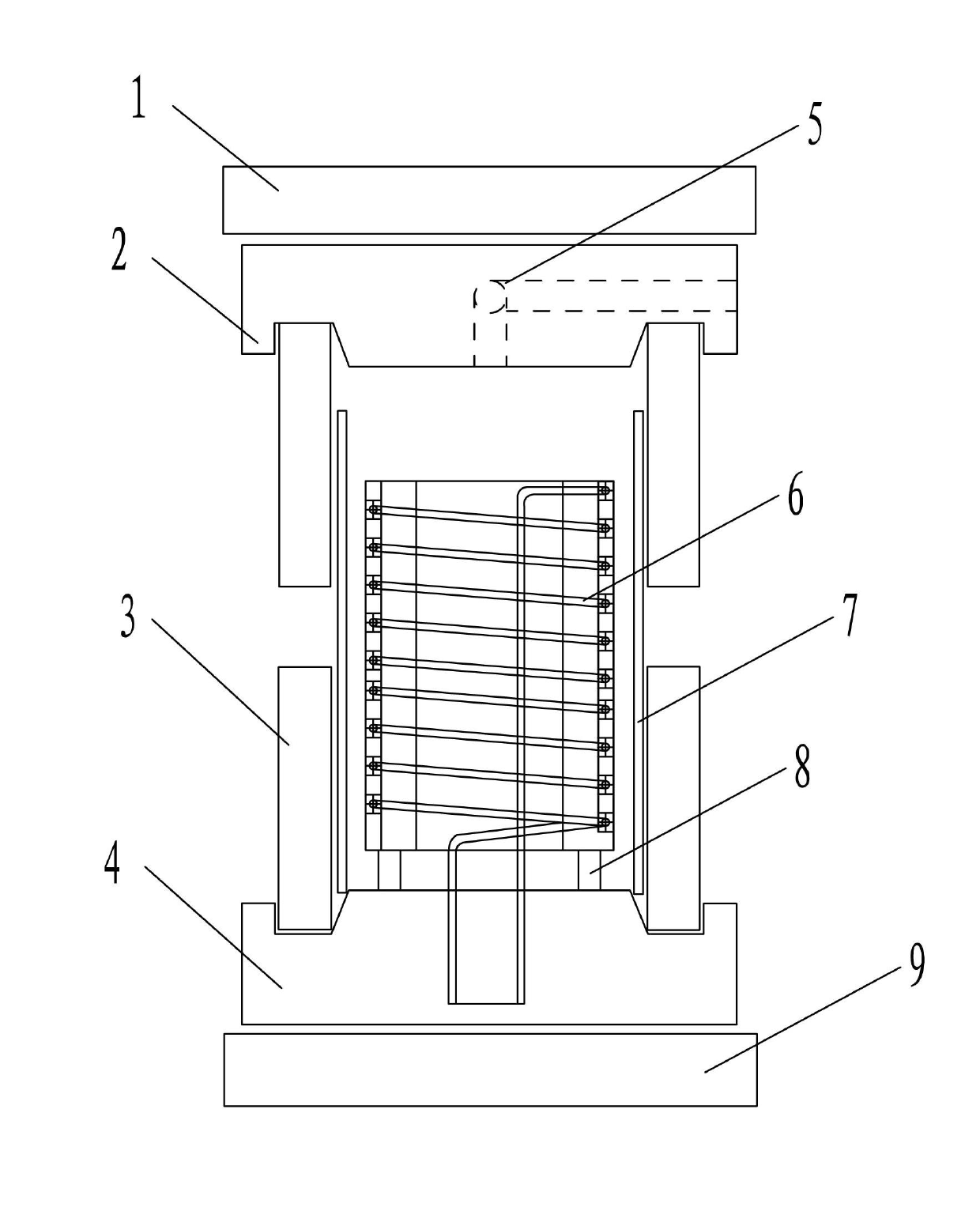

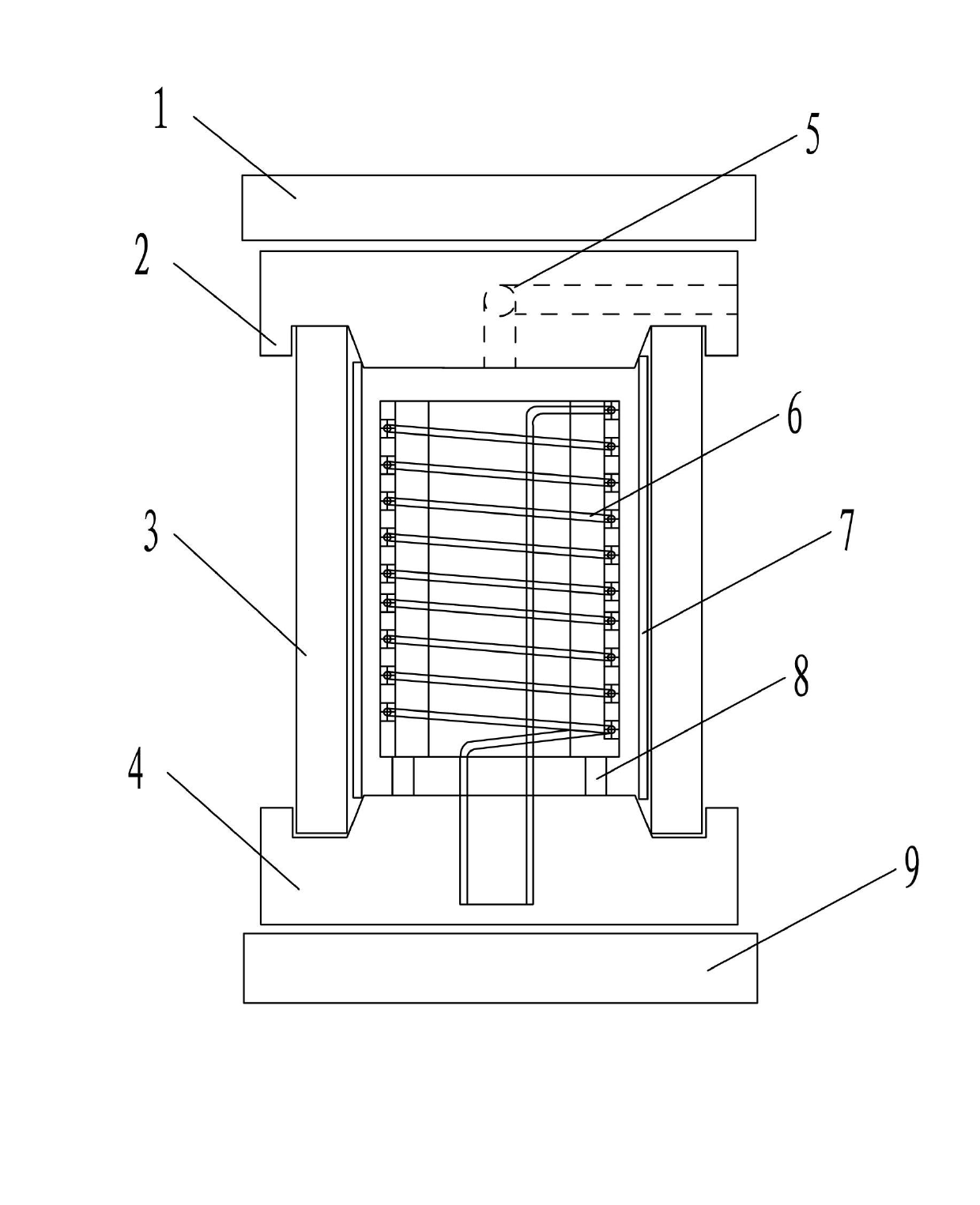

Thermal internal high pressure formation method for light alloy tube (or pipe)

A hot-state internal high pressure method for manufacturing the light alloy pipe includes such steps as heating die set to 150-500 deg.C, putting a pipe blank in the die set, closing die set, making the punch heads in contact with both ends of pipe blank, sealing the contact positions, filling hot-state liquid medium at 150-500 deg.C in the pipe blank, and applying pressure to deform the pipe blank to obtain light alloy pipe. Its advantages are light weight and high rigidity.

Owner:天津哈工永兴科技有限公司

Electro-hydraulic forming device for pipe fitting and forming method

The invention discloses an electro-hydraulic forming device for a pipe fitting and a forming method. The electro-hydraulic forming device comprises a bulging die, a power source, a water pipe, a water storage tank, an aqueous medium, a metal wire, a positive electrode and a negative electrode. The metal wire is made to penetrate through the installed positive electrode, the pipe fitting to be formed and the negative electrode in sequence, and the positive electrode and the negative electrode are installed in the two ends of the pipe fitting respectively. Water is injected into the sealed pipe fitting. High-energy pulses are transmitted to the metal wire through a wire, in this way, the size of the metal wire is increased rapidly after the metal wire is gasified due to heating, impact waves are generated in the medium around the metal wire, the impact waves act on the pipe fitting, the required pipe fitting is obtained through bulging through electro-hydraulic forming based on discharging of the metal wire. The forming performance of materials is improved, the rebound rate is reduced, the forming precision of the pipe fitting is improved, in this way, a part with the forming quality and precision meeting requirements is obtained, and the pipe fitting is promoted to burgle.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

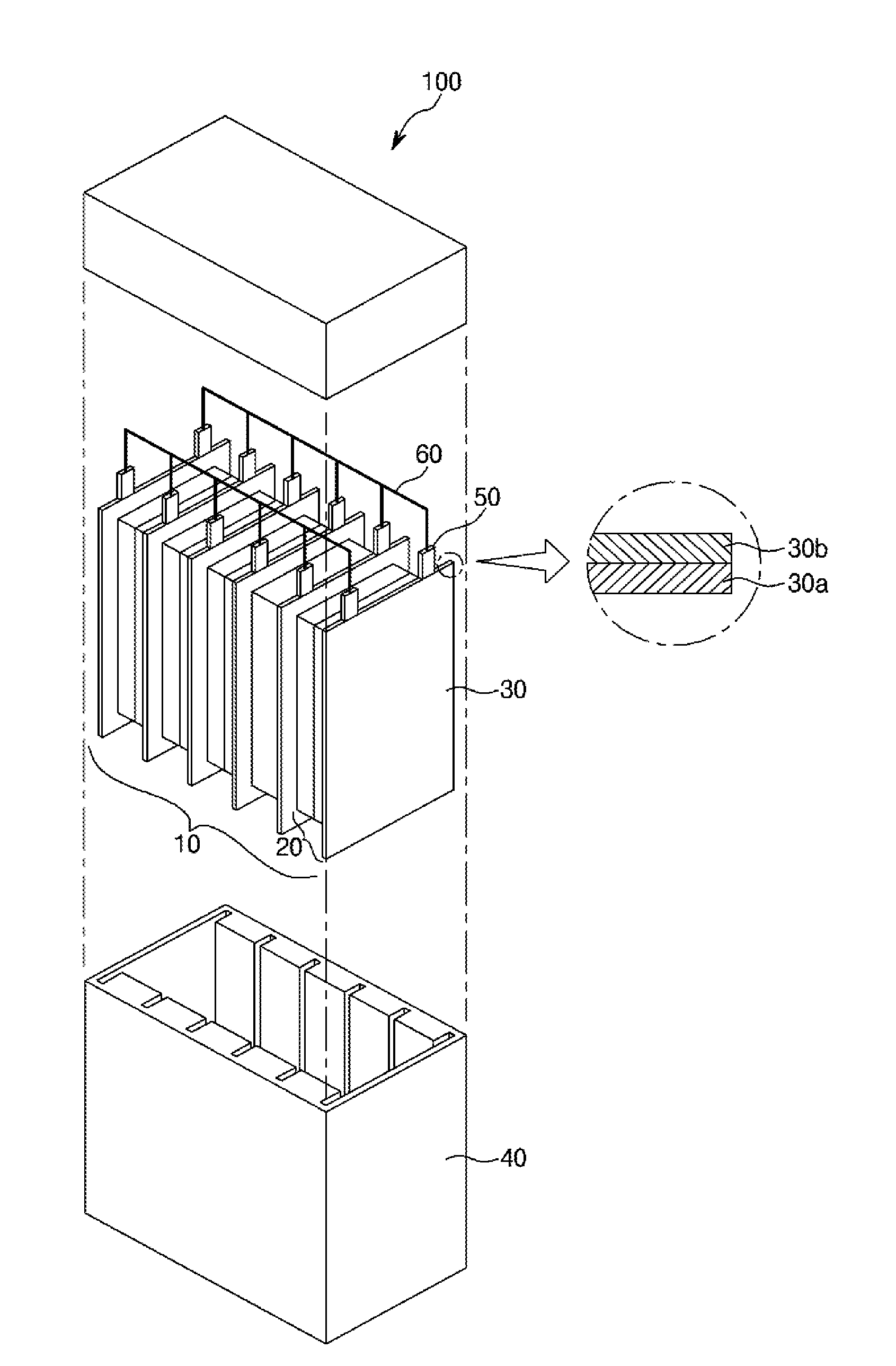

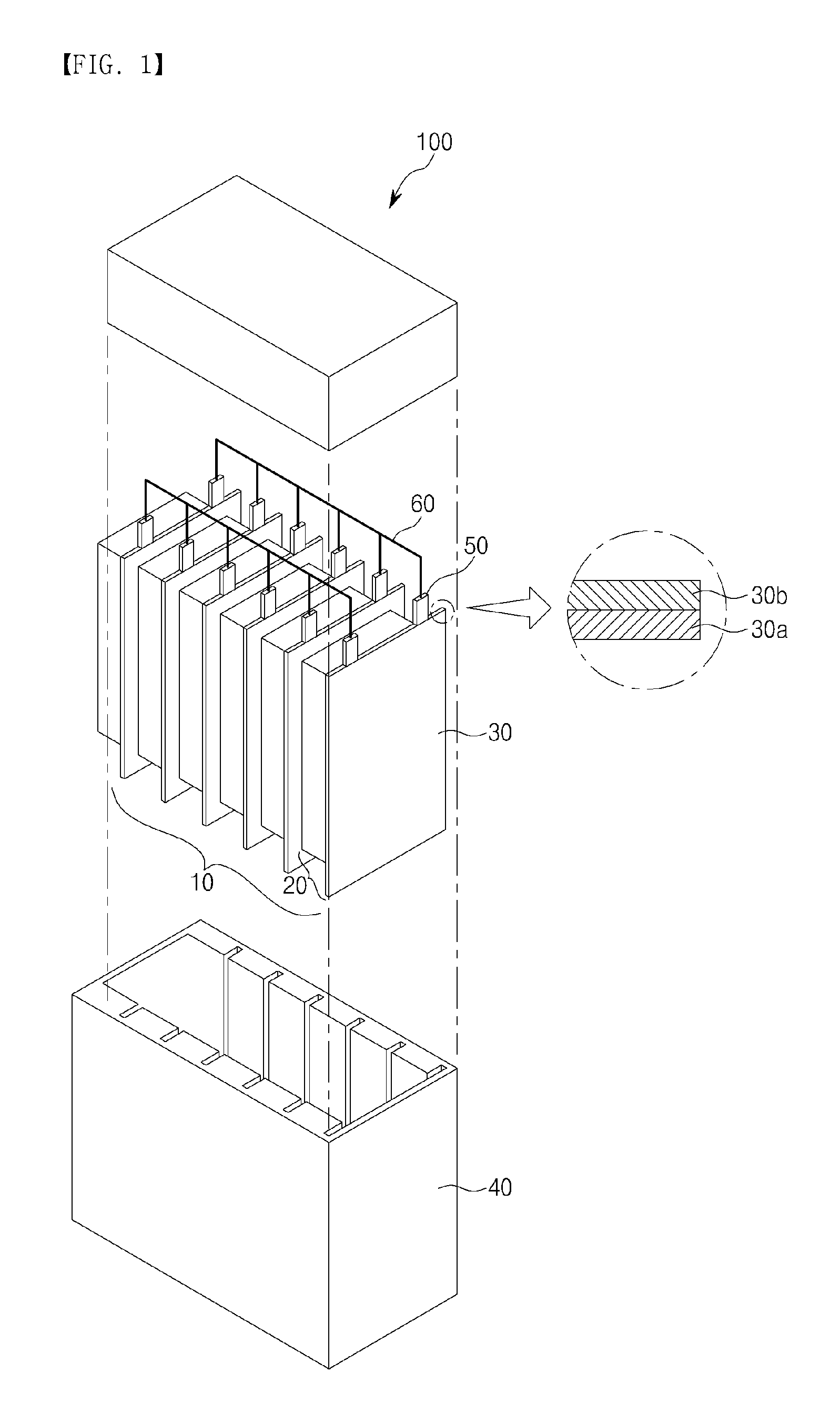

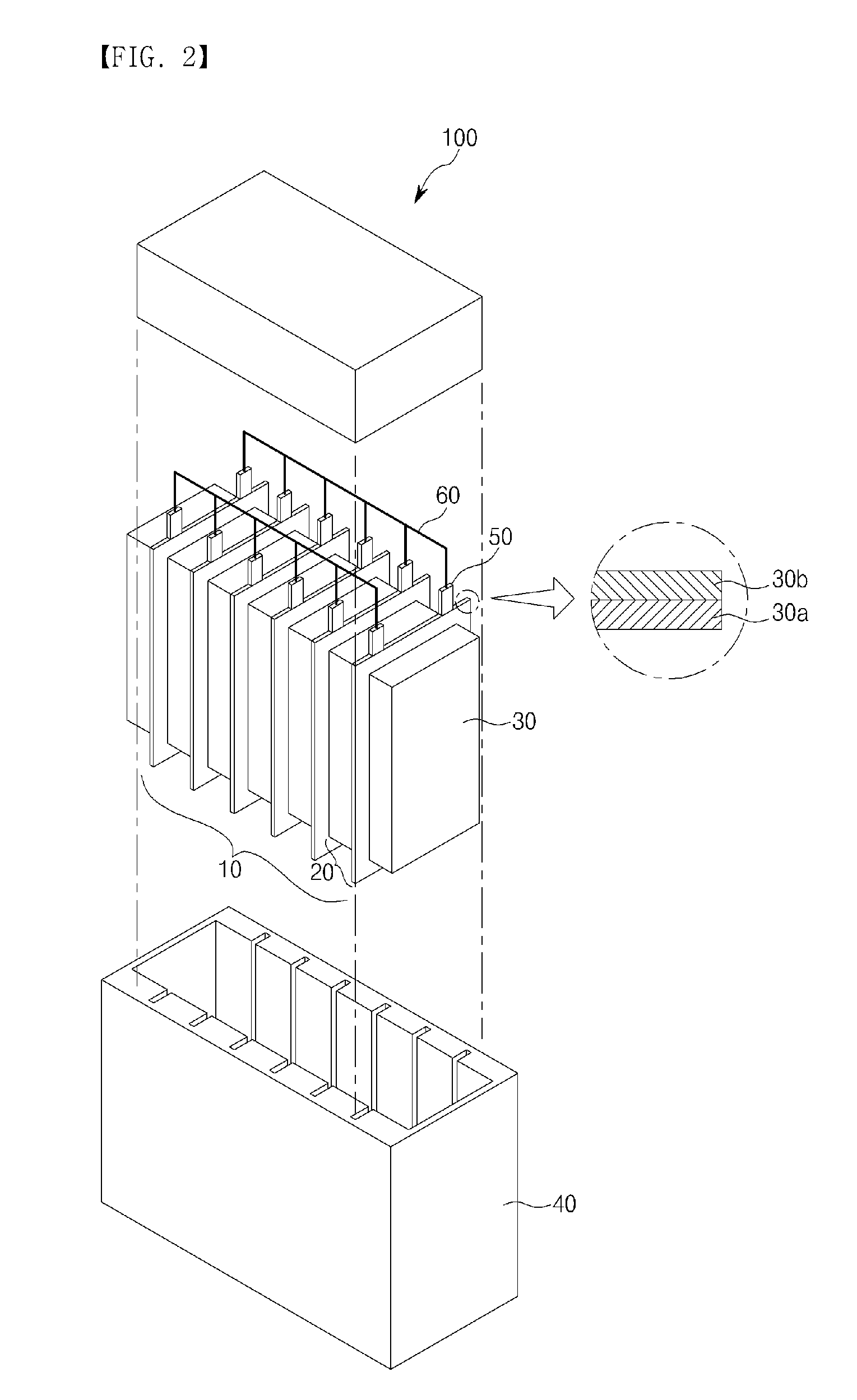

Pouch type lithium secondary battery

ActiveUS20120015226A1Good insulation propertiesImprove formabilityCell electrodesFinal product manufactureElectrical and Electronics engineeringMoisture

A pouch type lithium secondary battery including a medium- or large-sized battery module includes: a jelly-roll type electrode assembly; a resin-type first packing material that is formed of a two-layer structure having an inner resin layer and an outer resin layer, and for packing the jelly-roll type electrode assembly in the form of a unit cell; and a metal-type second packing material that integrally packs and contains two or more unit cells packed in the first packing material in the form of a module, and prevents moisture and gas penetration by a sealed structure. The pouch type lithium secondary battery is applicable particularly to medium- and large-sized batteries for EVs, p-HEVs, HEVs, and so on.

Owner:LG ENERGY SOLUTION LTD

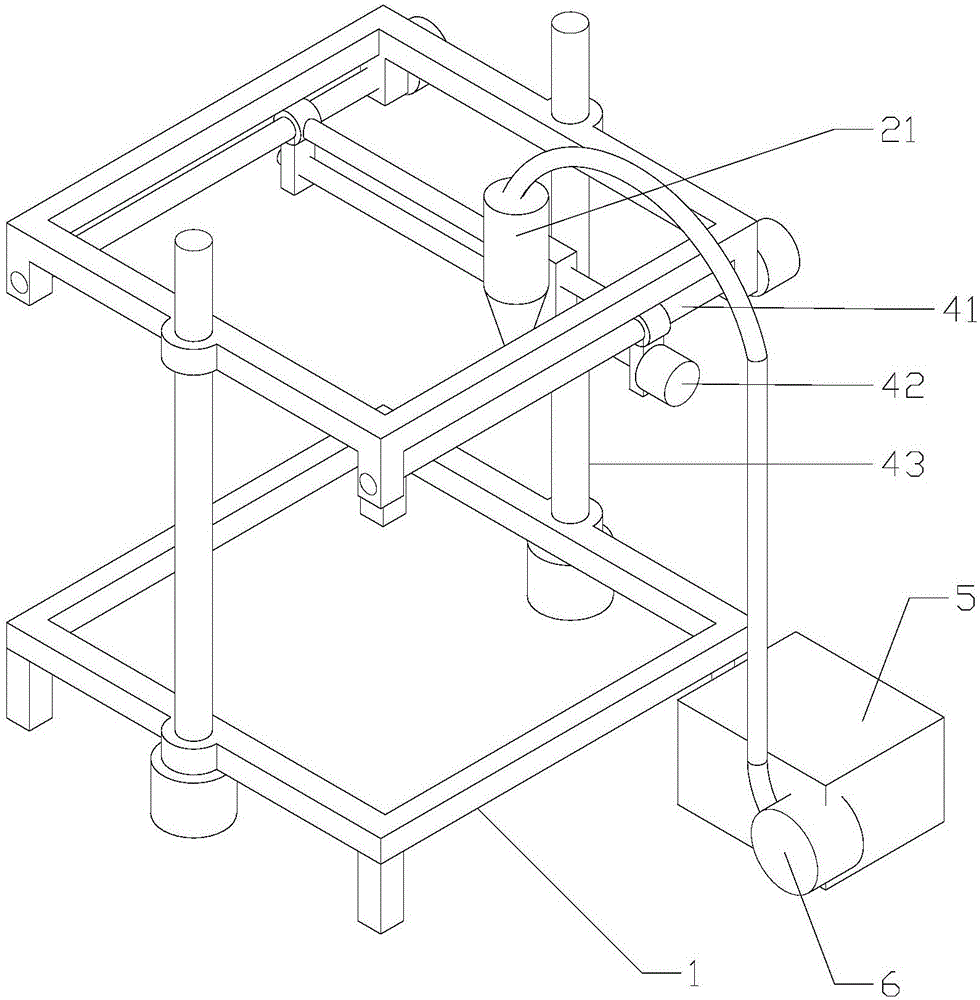

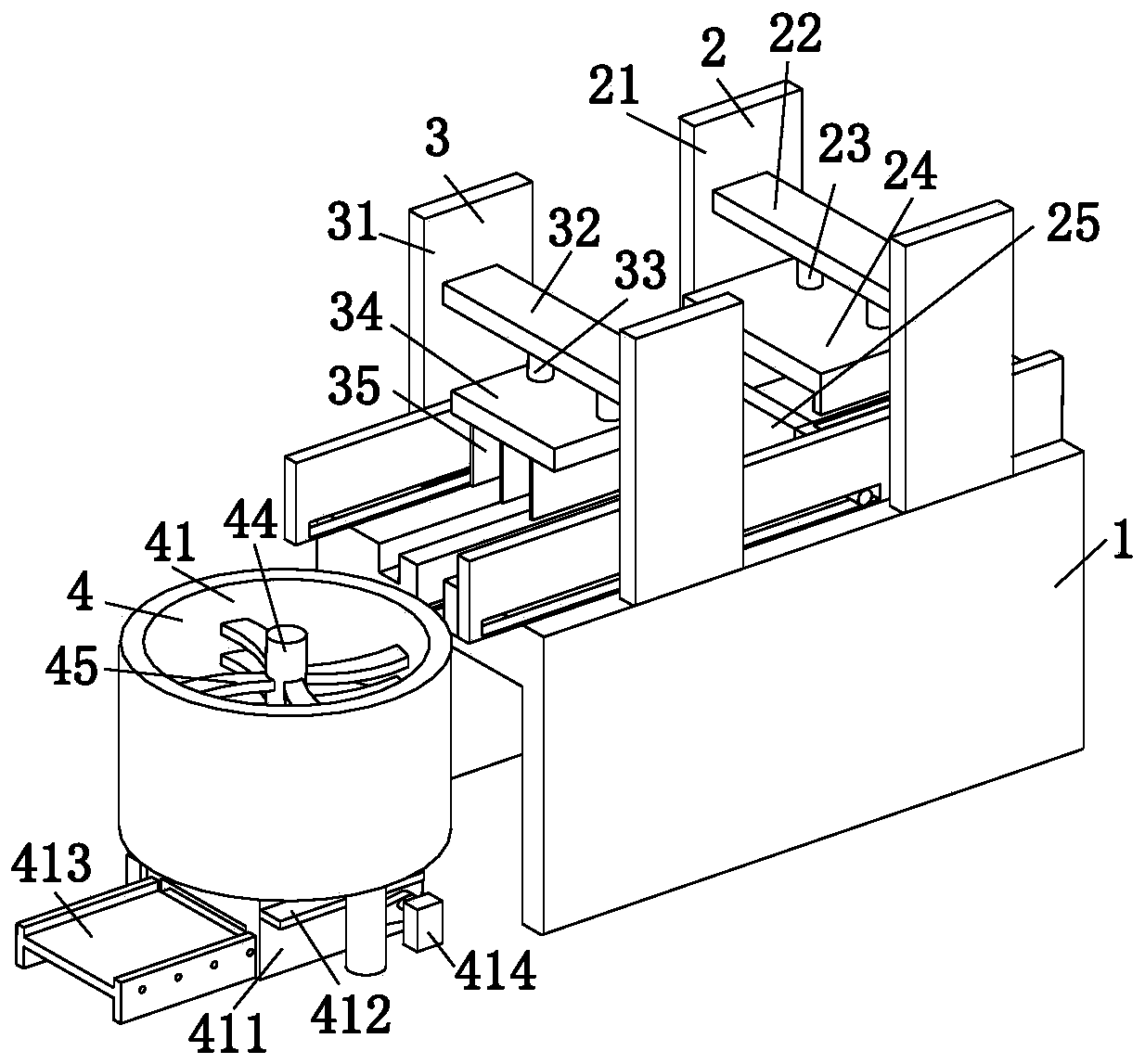

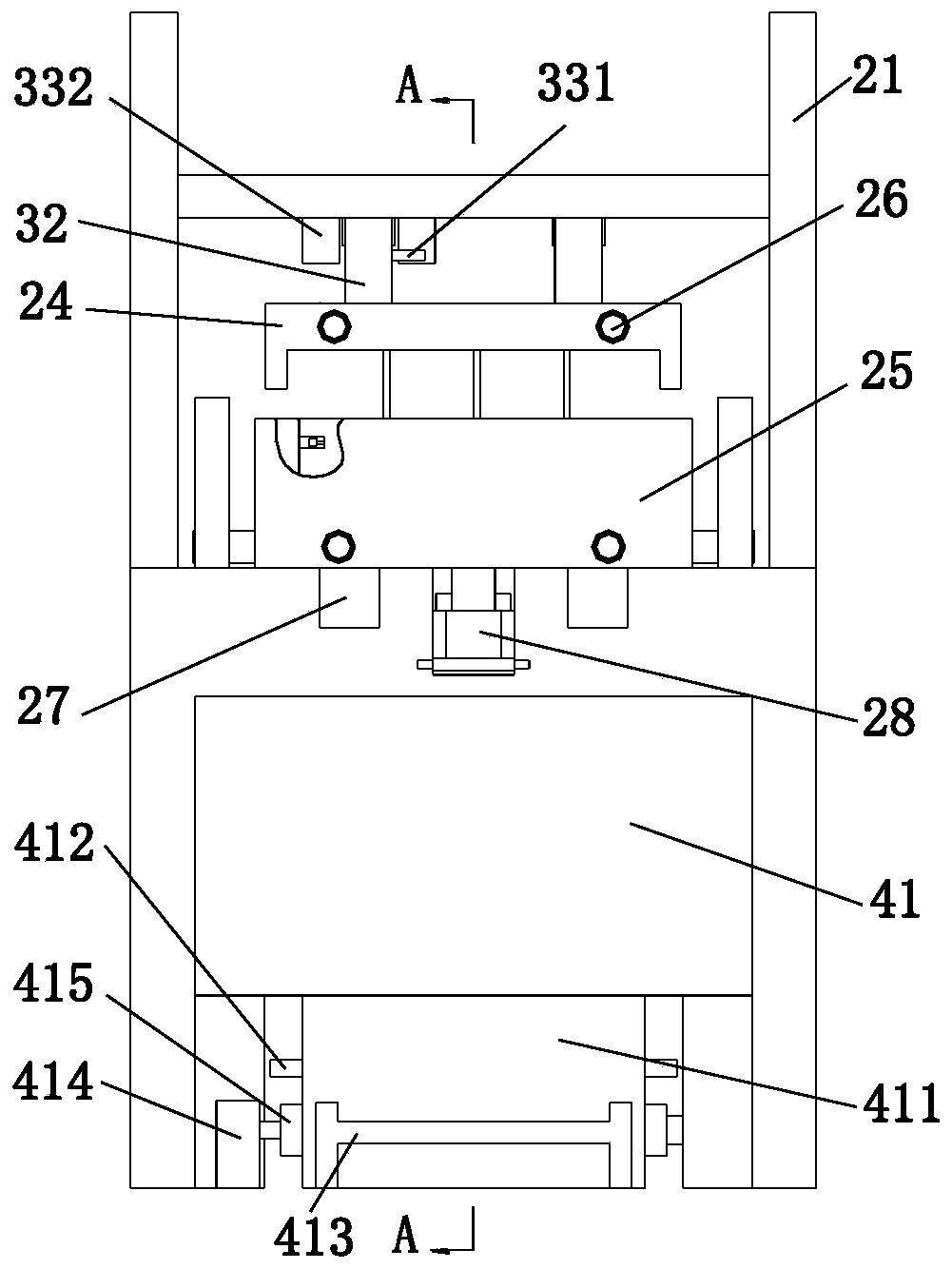

3D printer for cement product

InactiveCN106738190AImprove formabilityGood molding effectAdditive manufacturing apparatusCeramic shaping apparatusEngineeringControl system

The invention discloses a 3D printer for a cement product. The 3D printer for the cement product comprises a rack, an extrusion device, a keel filling device, a drive device and a control system, wherein the drive device is arranged on the rack; the drive device comprises an X-axis lead screw mechanism, a Y-axis lead screw mechanism and a Z-axis lead screw mechanism; the Z-axis lead screw mechanism drives the X-axis lead screw mechanism and the Y-axis lead screw mechanism to move up and down; the extrusion device comprises a shell body internally containing a cement accommodating cavity, and a cement extrusion port formed in the bottom of the shell body; the cement extrusion port mutually communicates with the cement accommodating cavity through a screw pump; and the shell body is arranged on the X-axis lead screw mechanism or the Y-axis lead screw mechanism. The 3D printer for the cement product is capable of remarkably improving the formability of cement by filling a keel through the keel filling device during printing, thereby solving the technical problem that an existing 3D printer cannot directly print a cement product.

Owner:重庆知德文化传播有限公司

Environmentally-friendly lead-free free-machining zinc white copper and preparation method thereof

The invention discloses an environmentally-friendly lead-free free-machining zinc white copper and a preparation method thereof. The zinc white copper comprises the following components in percentage by weight: 27.0-44.0% of zinc, 6.0-25.0% of nickel, 0.05-2.5% of silicon, 0.03-0.1% of cerium, 0.03-1.5% of phosphorus and the balance of copper and inevitable impurity, wherein lead content in the impurity is less than 0.01%. The preparation method comprises the steps of smelting, horizontal continuous casting, cold machining, heat treating and the like. The copper alloy of the invention also has high strength (sigma b=700-750 MPa) and favorable machining performance which is more than 70% of lead brass C36000. Hot extrusion shaping and horizontal continuous casting shaping can be adopted; the zinc white copper has favourable cold and hot pressure processing performance, is an environmentally-friendly novel material, can completely replace lead and zinc white copper to prepare various free-machining elements, can be processed into copper alloy products, such as lines, rods, plates, strips, sections, tubes, cast and the like, can be widely applied to the manufacturing industry, such as pen points, eyeglass accessories, instrument accessories and the like and is an ideal substitute for lead and zinc white copper.

Owner:NINGBO POWERWAY ALLOY MATERIAL

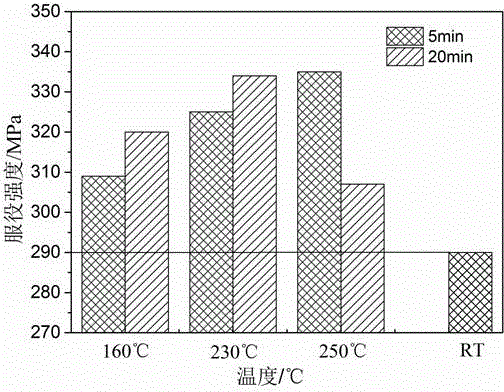

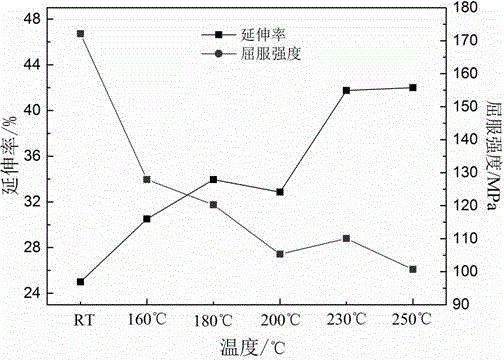

Forming method for improving forming performance of 6XXX series aluminum alloy plate

The invention relates to a forming method for a 6XXX series aluminum alloy plate for an automobile body. The method includes the steps that dies are installed on stamping equipment, and the female die and the male die are adjusted to be aligned, wherein a heating element is arranged inside the stamping female die, and a cooling device is arranged inside the male die; the 6XXX series aluminum alloy plate of which the thickness is 0.8 mm-1.5 mm and the heat treatment state is T4 is placed on the stamping female die, then the stamping female die is heated to 160 DEG C-250 DEG C, the male die is kept at the indoor temperature, and the heat preservation process is controlled to last for 3 min-15 min; after heat preservation, a punching machine program is started, warm forming treatment is performed, and the whole stamping process is controlled to last for 5 min-25 min; after forming is finished, the position of a pressing head is kept unchanged, pressure maintaining is performed on the plate, and the pressure maintaining process lasts for 5 min or less; the formed plate is taken out and air-cooled to the indoor temperature, and then warm forming treatment is completed. By means of the method, the forming performance and service strength performance of the aluminum alloy plate can be collaboratively improved.

Owner:CENT SOUTH UNIV

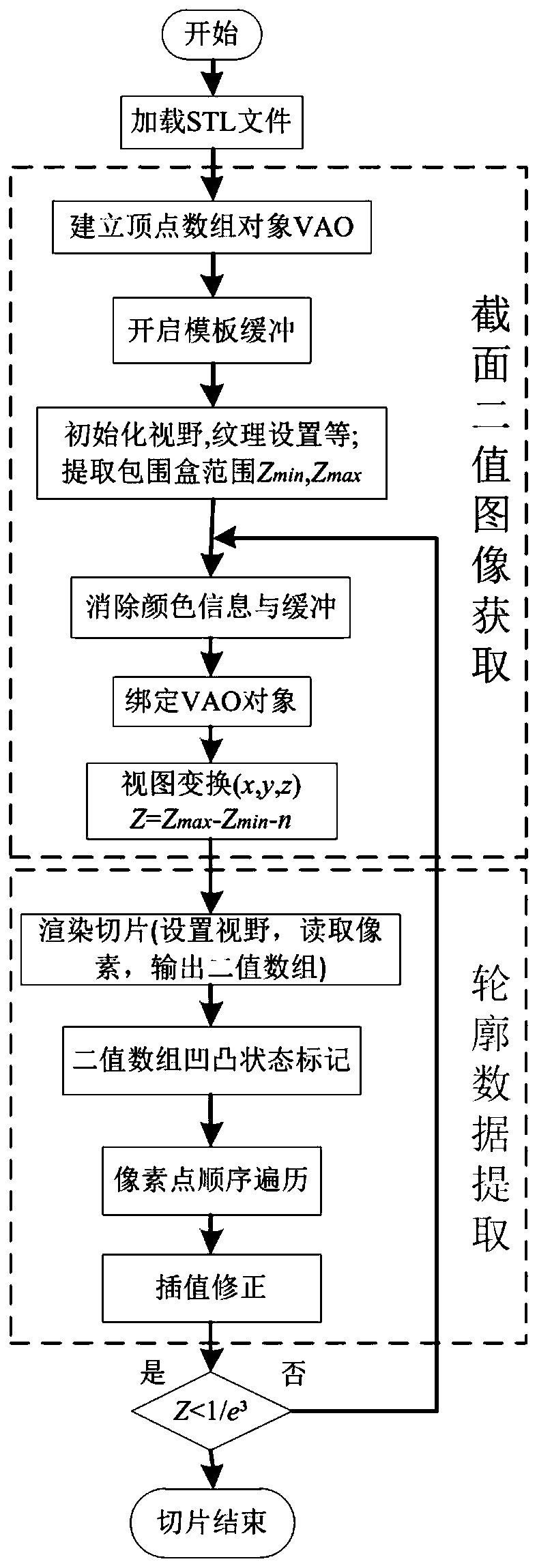

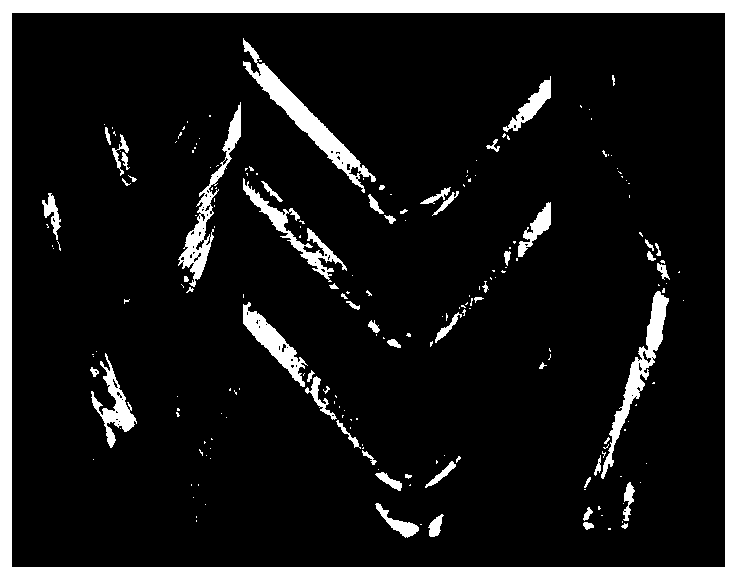

EBM variable direction forming dynamic slicing method cooperated with 840D numerical control system

ActiveCN110355365AImprove formabilityReduce computing timeProgramme controlGeometric CADStl fileThree dimensional model

The invention discloses an EBM variable direction forming dynamic slicing method cooperated with an 840D numerical control system. The EBM variable direction forming dynamic slicing method comprises the steps of establishing a vertex array object VAO, adjusting a projection matrix to the slicing height during rendering of a three-dimensional model and outputting a two-dimensional section binary image through a reverse ray tracing algorithm; acquiring data of a contour line from the binary image through a two-dimensional contour extraction method, outputting coordinates of an end-to-end closedcontour, connecting all adjacent coordinates into straight lines and connecting all the straight lines end to end to form a closed curve; and dividing the contour data into a straight line part and acurve part with the starting point of the small straight lines with the included angle of 140 degrees as the segmentation point when the triangle tolerance is one, removing neighbor points, repeated points and internal points of the same straight lines, conducting segmentation fitting on a slicing data curve through a NURBS curve and then conducting dynamic slicing through the 840D numerical control system. Through the EBM variable direction forming dynamic slicing method, the computing time and conversion errors of STL files are reduced, and meanwhile, the phenomenon of over-accumulation of straight line inflection points is reduced.

Owner:XI AN JIAOTONG UNIV

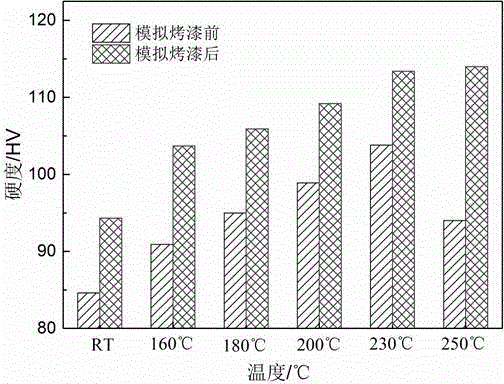

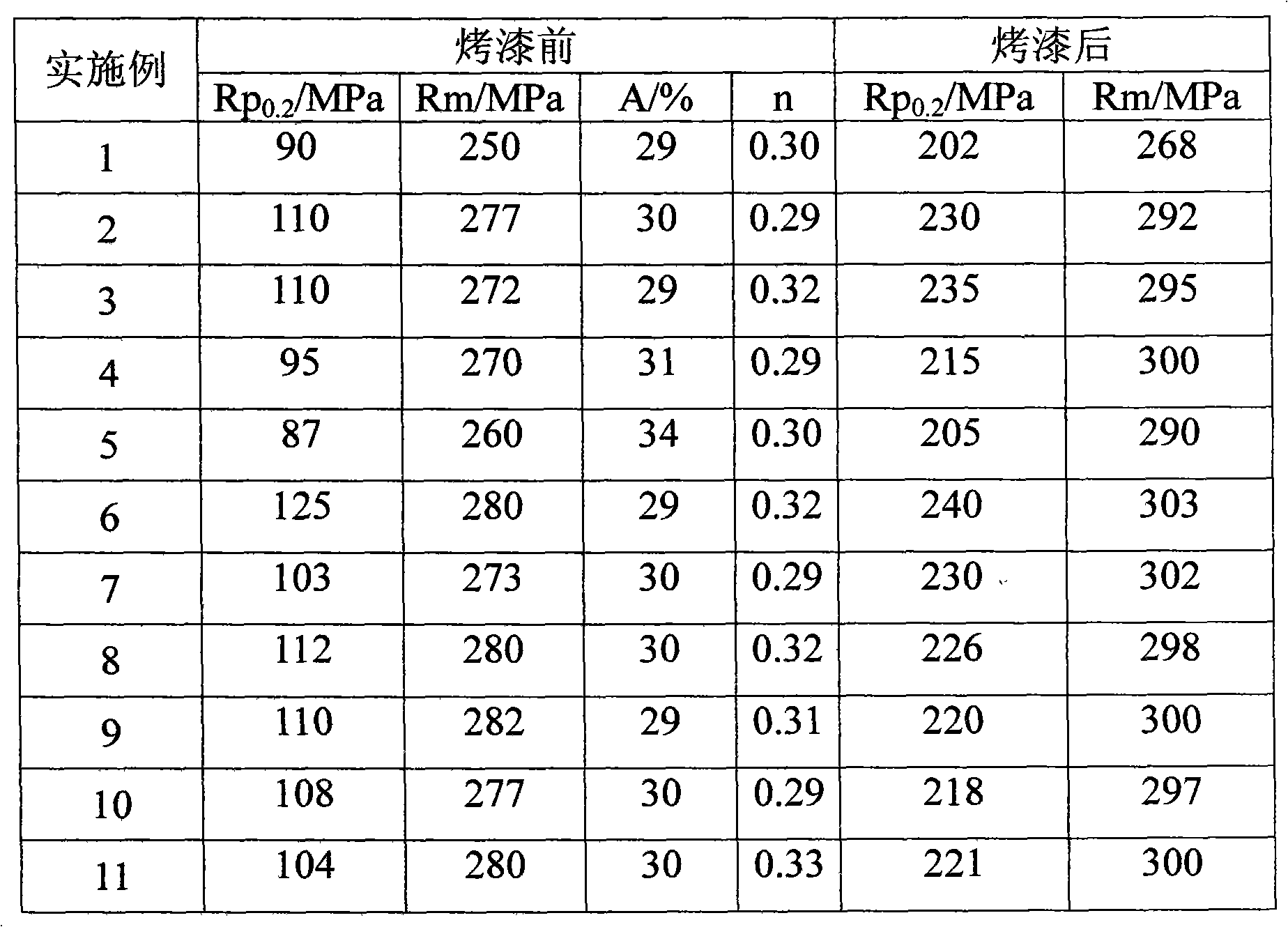

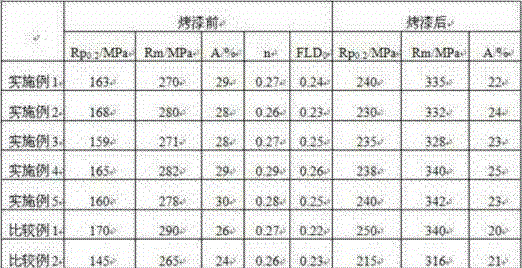

Aluminium alloy with high forming property for automobile body plate

The invention discloses an aluminium alloy with high forming property for an automobile body plate, comprising the following chemical constituents in percentage by weight: 0.50-1.20wt% of Si, 0.35-0.70wt% of Mg, 0.01-0.20wt% of Cu, 0.05-0.20wt% of Mn, less than or equal to 0.10wt% of Cr, 0.01-0.25wt% of Zn, less than or equal to 0.15wt% of Ti, 0.05-0.15wt% of Fe and the balance of Al. The aluminium alloy material of the invention has lower yield strength before baking finish, which is favourable for stamping shaping; and after baking finish, the yield strength is improved. The material has higher forming property and simultaneously satisfies the requirements of the impact resistance of the automobile body plate.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

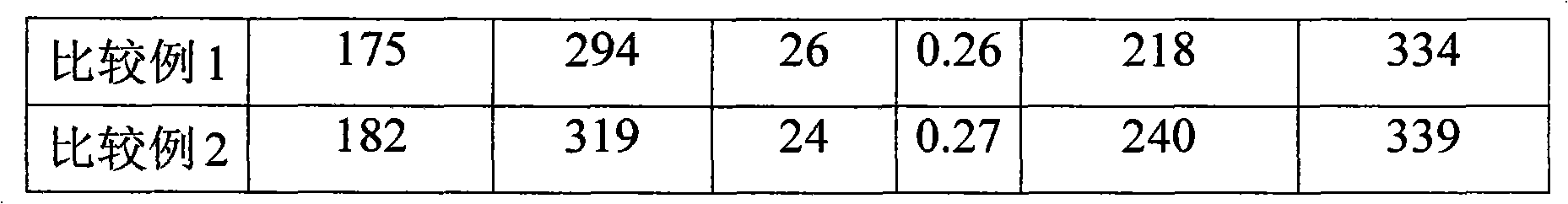

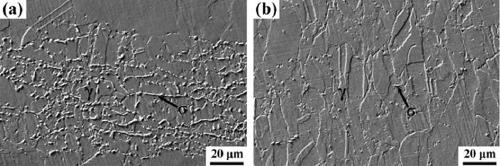

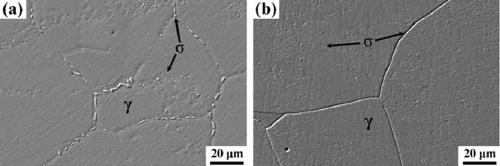

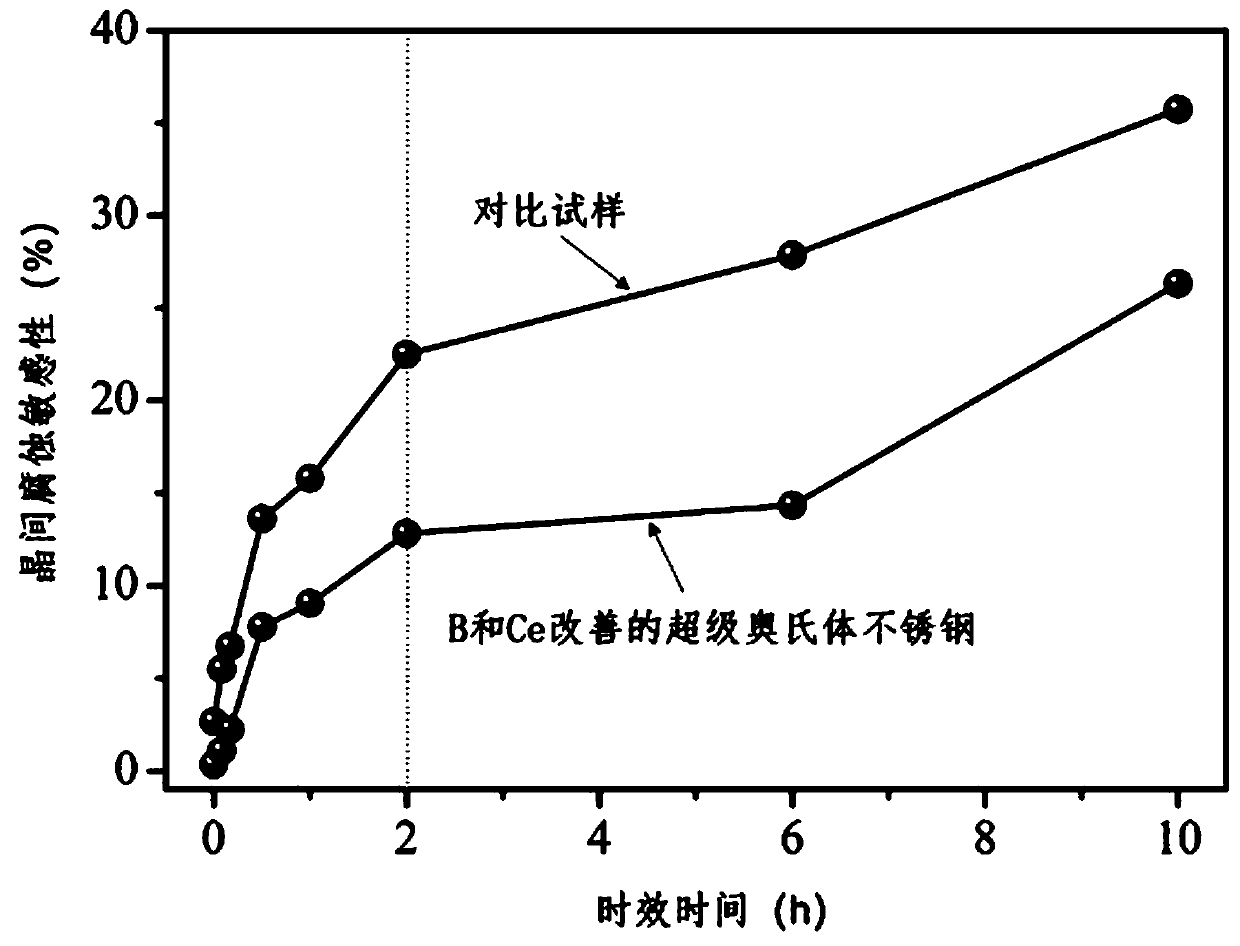

Method for reducing sigma phase precipitation and improving intergranular corrosion resistance of 6Mo superaustenitic stainless steel by adding B and Ce

The invention belongs to the technical field of superaustenitic heatproof steel preparation and application and provides a method for reducing sigma phase precipitation and improving intergranular corrosion resistance of 6Mo superaustenitic stainless steel by adding B and Ce. The stainless steel comprises, by mass, 0-0.02 of C, 0-0.6 of Si, 0-1.00 of Mn, 0-0.03 of P, 0-0.005 of S, 19-21 of Cr, 17.0-19.0 of Ni, 6.0-6.5 of Mo, 0.5-1 of Cu, 0.18-0.25 of N, 0-0.006 of B, 0-0.01 of Ce and the balance Fe and other inevitable impurity elements; and by adding the B and the Ce, grain boundary sigma phase precipitation of the of superaustenitic heatproof steel is effectively reduced, and the intergranular corrosion resistance is improved.

Owner:TAIYUAN UNIV OF TECH

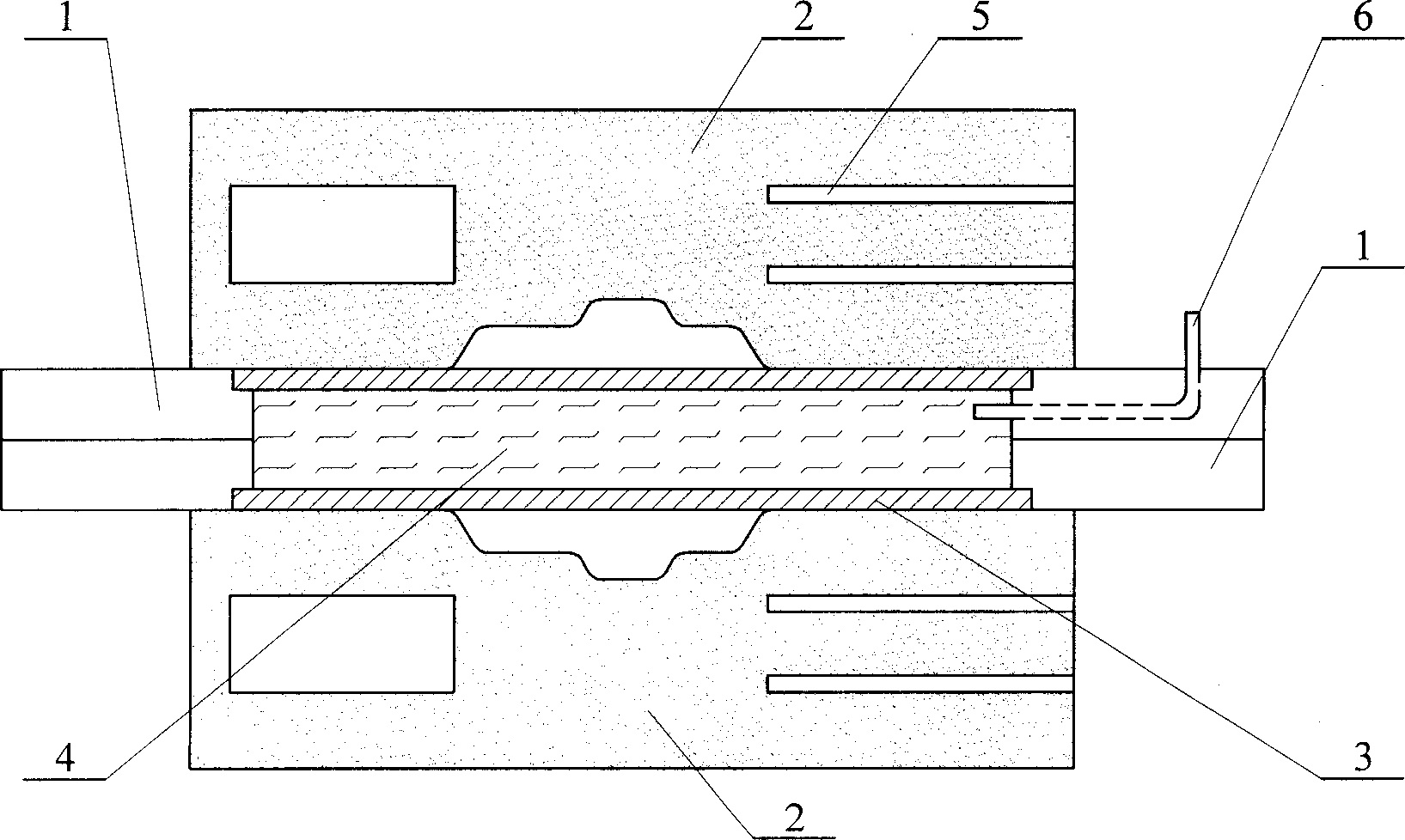

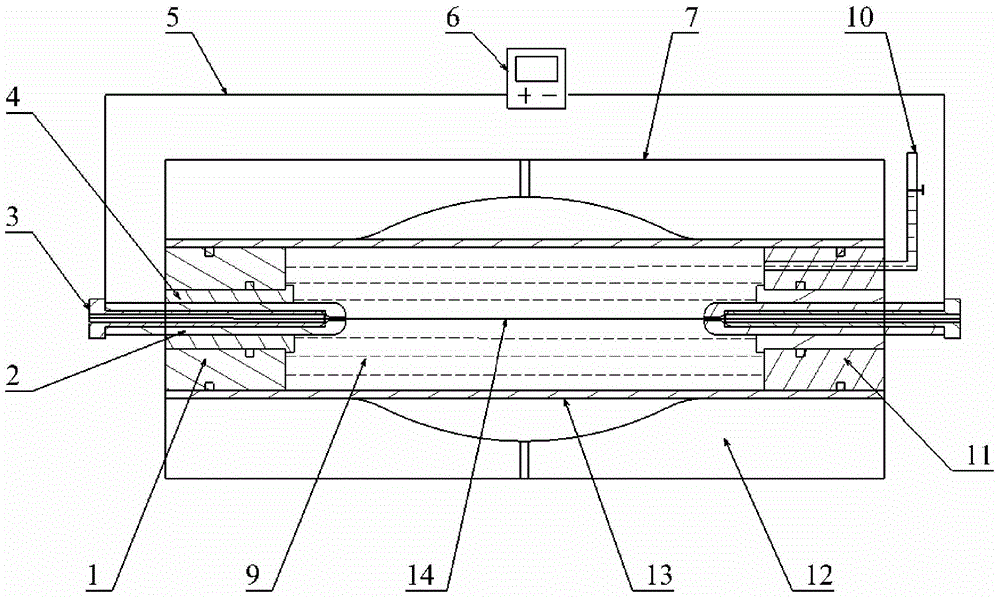

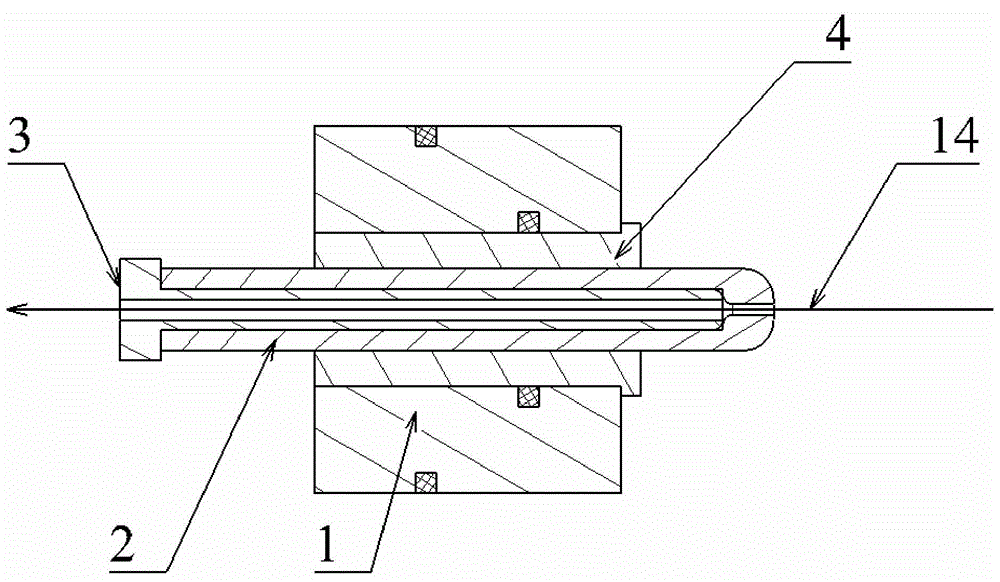

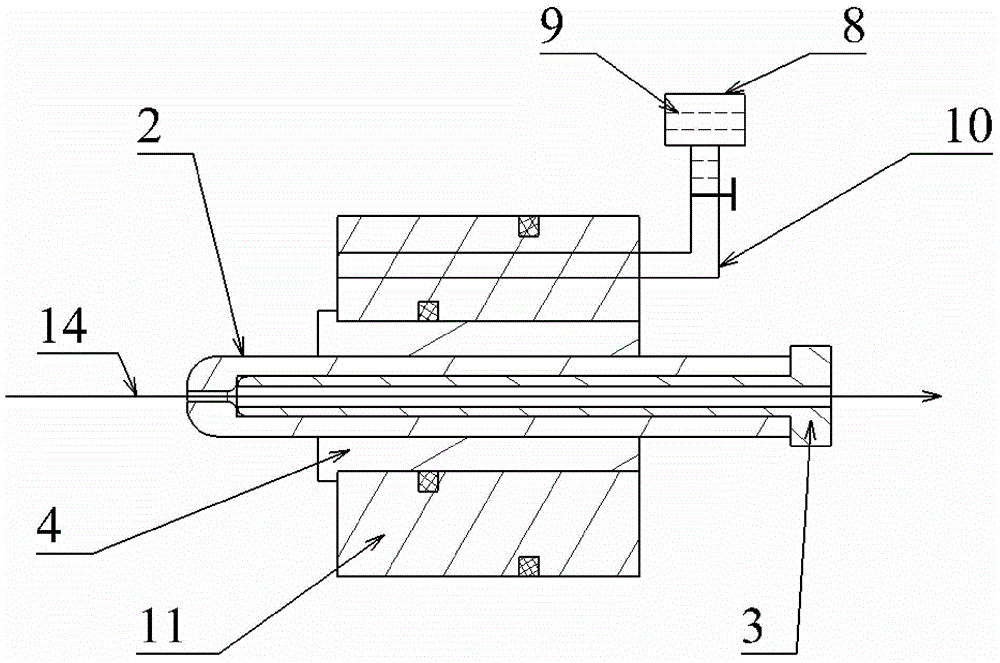

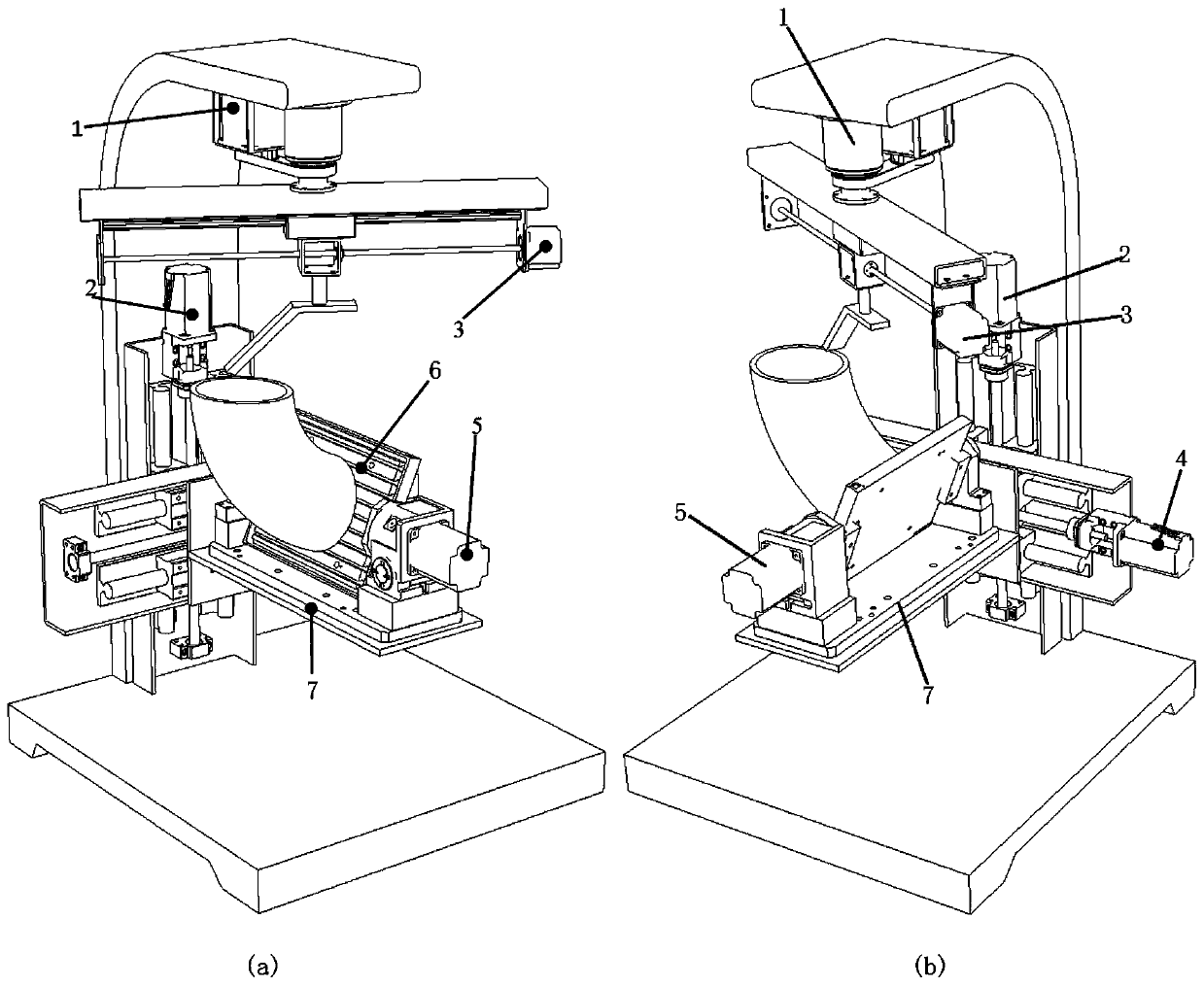

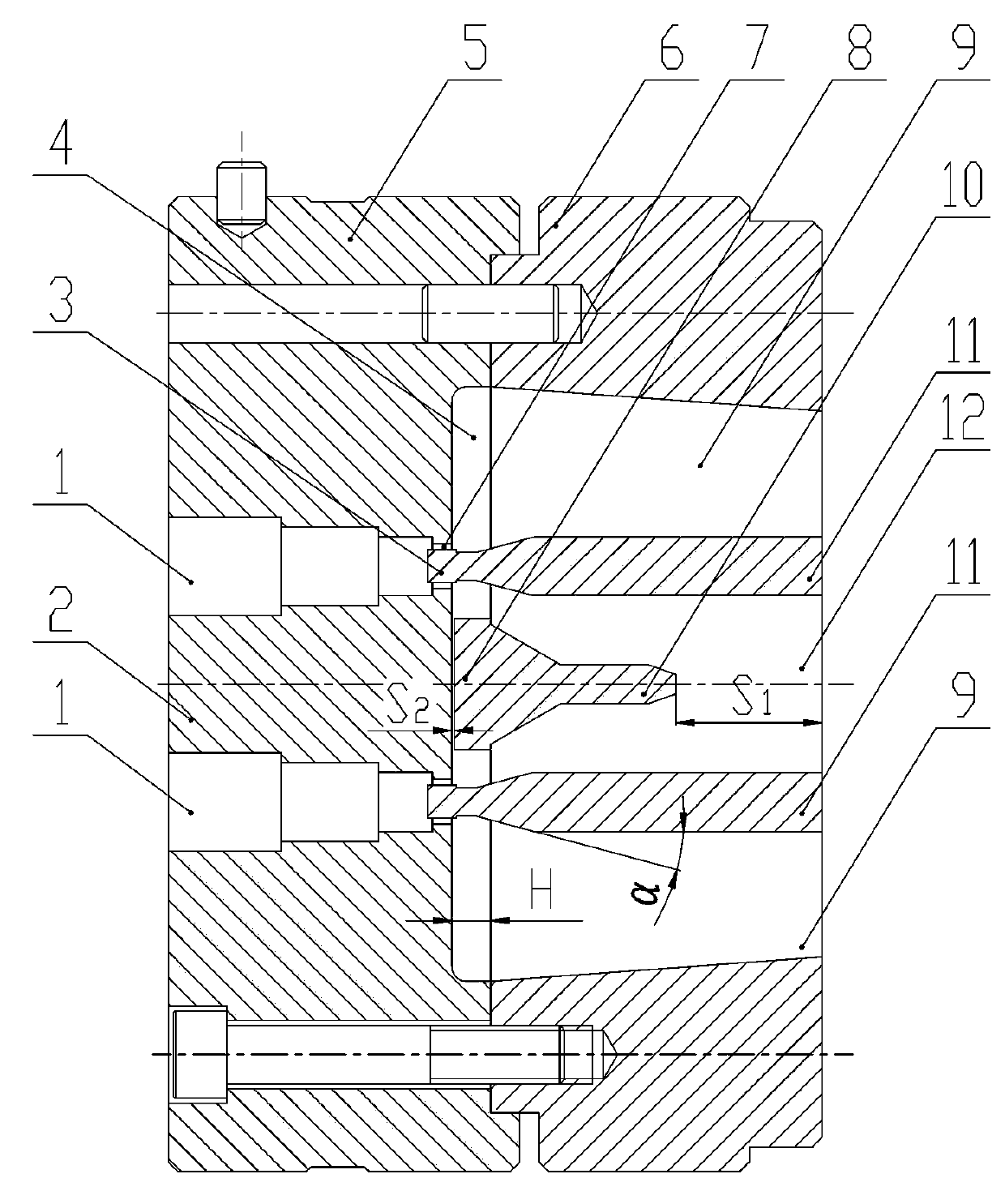

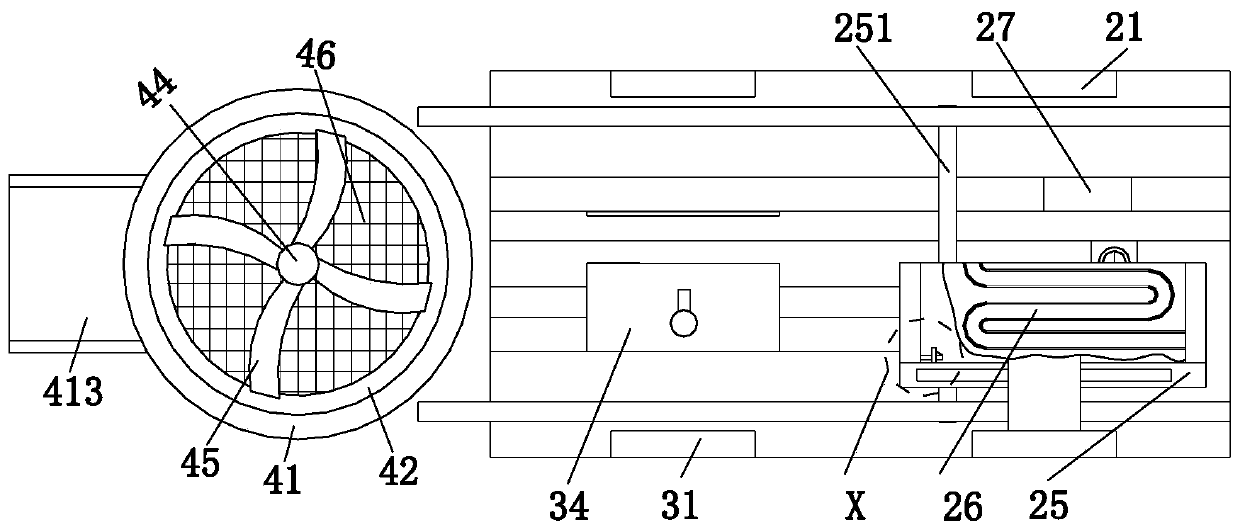

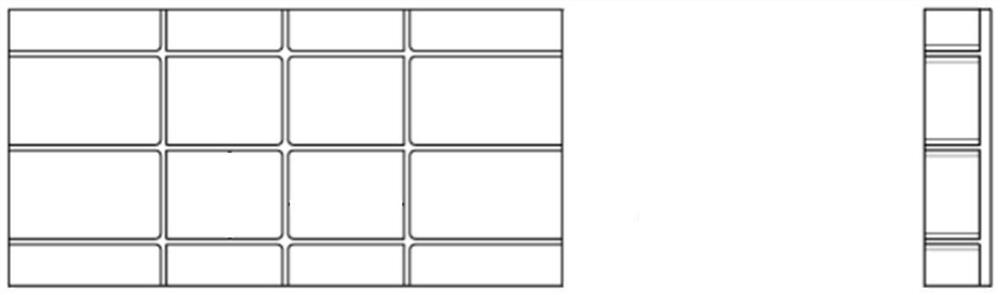

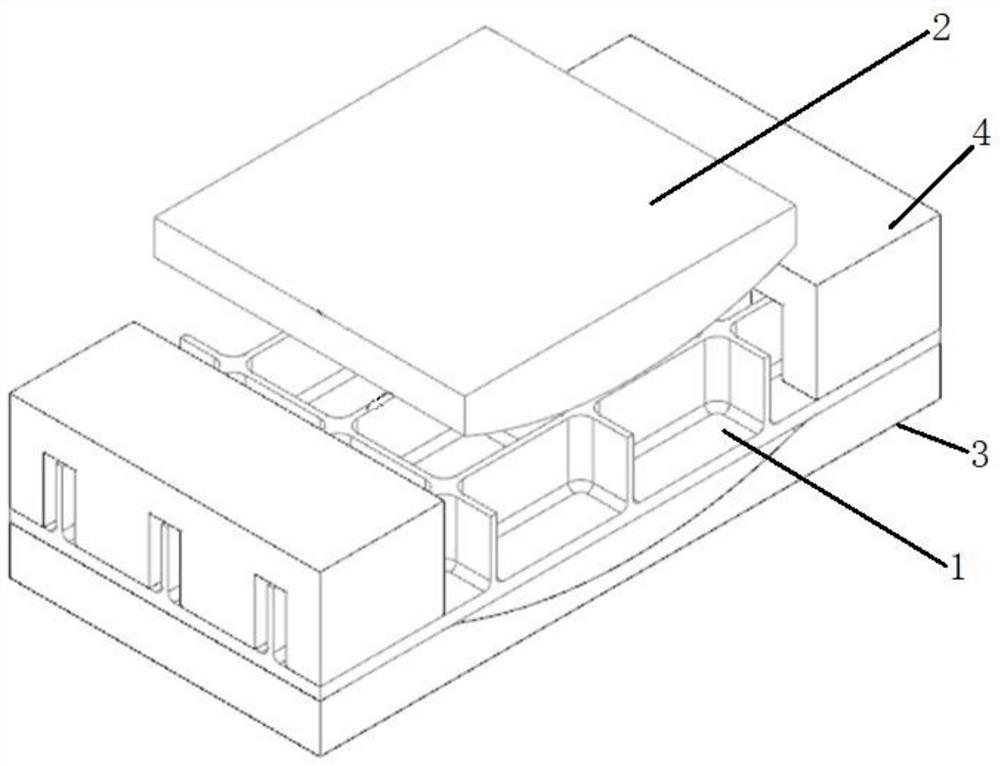

Internal heating and pressurizing pipe distortion rectification device and method

InactiveCN102672007AReduce manufacturing costImprove formabilityShaping toolsDistortionHigh intensity

The invention discloses an internal heating and pressurizing pipe distortion rectification device and an internal heating and pressurizing pipe distortion rectification method, relates to a pipe distortion rectification device and a pipe distortion rectification method, and aims to solve the problem that the shape and size of a die are easily changed to influence a distortion rectification effect if distortion is rectified after a pipe billet and the die are simultaneously heated when the distortion of a strong-strength pipe is rectified. According to the device, an upper sliding block, an upper die holder and a lower die holder are sequentially arranged on a lower tabletop from top to bottom; a die insert is inserted between the upper and lower die holders; a support block is arranged on the lower tabletop in the die insert; a heating source is arranged on the support block; and an air vent communicated with an inner cavity of the die insert is reserved in the upper die holder. The method comprises the following steps of: placing a pipe billet of which the distortion is to be rectified on the lower die holder in a sealed way; heating the pipe billet; introducing high-pressure gas into the pipe billet; bulging the pipe billet of which the distortion is to be rectified, and gradually attaching the pipe billet to the inner cavity of the distortion rectification insert to finish the distortion rectification; and after the distortion rectification is finished, relieving the high-pressure gas, taking the distortion-rectified pipe billet out, and cutting undistorted areas at the two ends to finish the distortion rectification of the pipe. The device and the method are used for the distortion rectification of the pipe.

Owner:HARBIN INST OF TECH

Thermal processing method for improving aluminum alloy stamping forming

The invention discloses a thermal processing method for improving aluminum alloy stamping forming. The method comprises the following steps of: before stamping forming, treating an aluminum section at the temperature of 230-330 DEG C for 1-20 minutes; transferring the aluminum section into water of 0-50 DEG C within 20 sections; cooling; and completing stamping forming within 8 hours. According to the method, the stamping forming of an aluminum alloy workpiece is improved, and the technical problems of high technical requirement, difficulty in controlling, high cost, high material improving cost and poor popularity are solved. In the method, a thermal treatment process is added before stamping forming, so that the forming performance of the aluminum alloy section is improved. The method disclosed by the invention has a simple principle, wide popularity and low energy consumption, and is easy to operate; the rejection rate of the aluminum alloy section during stamping forming can be effectively controlled, and the yield of the stamping forming of the aluminum alloy section is greatly increased.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Wire mesh flexible composite fabric for surface modification and preparation method of wire mesh flexible composite fabric

InactiveCN102965602AImprove formabilityImproved formabilitySurface modificationNickel Chromium Alloys

The invention relates to a wire mesh flexible composite fabric for surface modification and a preparation method of the wire mesh flexible composite fabric. The wire mesh flexible composite fabric comprises wolfram carbide (WC) or WC-cobalt (Co), mechanically alloyed nickel-chromium alloy powder, a forming agent and a binding agent. The wire mesh flexible composite fabric for surface modification is made through roll forming. By adopting a mechanical alloying technology, a nanocrystalline technology and a wire mesh technology, the preparation forming property of the flexible fabric is greatly improved, the thickness of the flexible fabric is extremely controlled, and the design idea of gradient coatings of more than two layers can be realized, so that the stress is reduced and the welding texture and the welding property are improved. The WC coating with excellent performance is prepared.

Owner:NANCHANG INST OF TECH

Al-Zn-Mn alloy profile for rail transit vehicle body and preparation method thereof

The invention belongs to the technical field of metal materials and machining thereof, discloses an Al-Zn-Mn alloy profile for a rail transit vehicle body and a preparation method thereof, and relatesto the technical field of aluminum alloy machining. The alloy comprises the following chemical components of, by mass, 4.4-4.6 % of Zn, 0.1-0.15% of Cu, 0.3-0.4% of Mn, 0.16-0.24% of Cr, 0.04-0.08% of Ti, 0.12-0.20 of Zr, less than or equal to 0.12% of Fe, less than or equal to 0.06% of Si, and the balance Al, wherein the ratio of the mass percentage of the Zn to the mass percentage of the Mg is3.2 to 3.5. The Al-Zn-Mn alloy material prepared through the preparation method has high toughness, corrosion resistance, anti-fatigue and weldable characteristics, and can meet the running requirements of the high-speed rail transit vehicle body.

Owner:广西南南铝加工有限公司

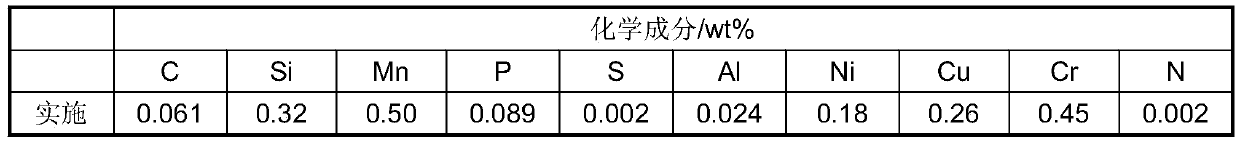

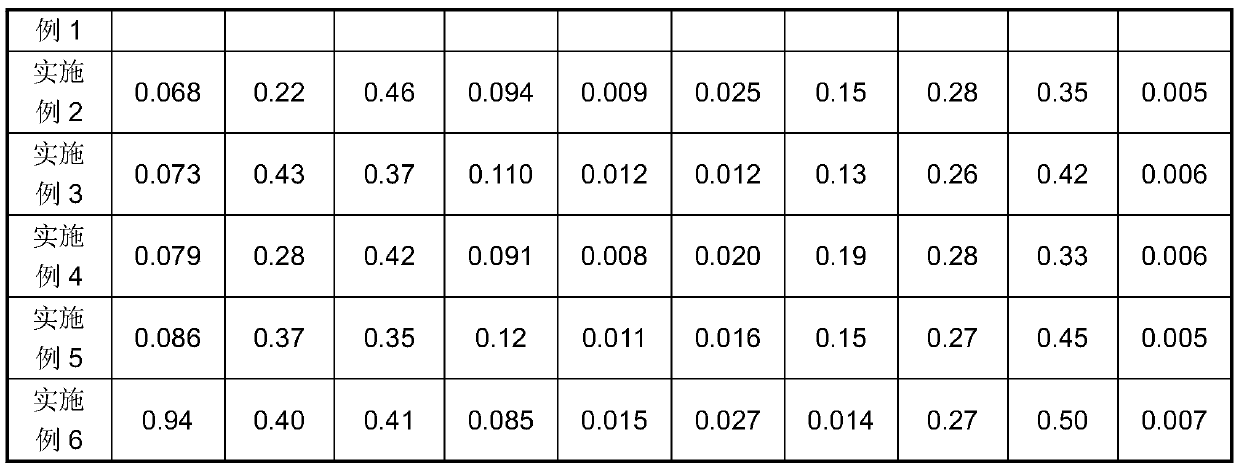

Batch annealing process-based cold rolled weathering resistant steel and manufacturing method thereof

InactiveCN110699602AImprove formabilityExcellent stamping performanceAtmospheric corrosionFormability

The invention discloses batch annealing process-based cold rolled weathering resistant steel and a manufacturing method thereof. The cold rolled weathering resistant steel comprises the following chemical components in percentage by weight: 0.06-0.10 % of C, 0.25-0.45 % of Si, 0.35-0.50 % of Mn, 0.080-0.120 % of P, not greater than 0.015 % of S, 0.008-0.030 % of Als, 0.12-0.20 % of Ni, 0.25-0.30 %of Cu, 0.30-0.50 % of Cr, not greater than 0.0080 % of N and the balance Fe and inevitable impurities. According to the cold rolled weathering resistant steel, by reasonable chemical component design, and by hot rolling process control, an acid rolling process and a batch annealing process, the cold rolled weathering resistant steel of which the surface quality grade is above the FB grade, the strip shape is good, the material yield strength is higher than 310-350 MPa, the tensile strength is higher than 450-500 MPa and the yield ratio is not greater than 0.75 is obtained, and the cold rolledweathering resistant steel has high stamping formability, an excellent welding property and high atmospheric corrosion resistance.

Owner:MAANSHAN IRON & STEEL CO LTD

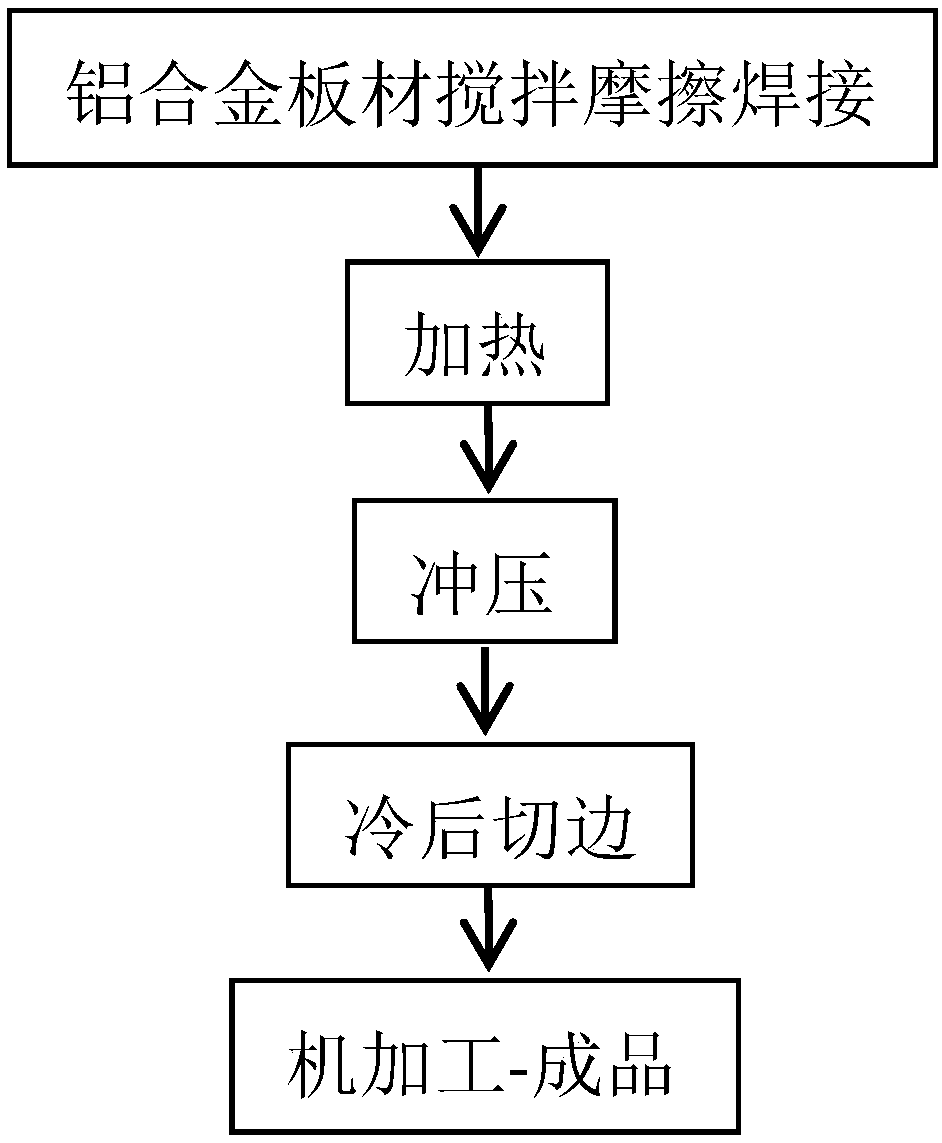

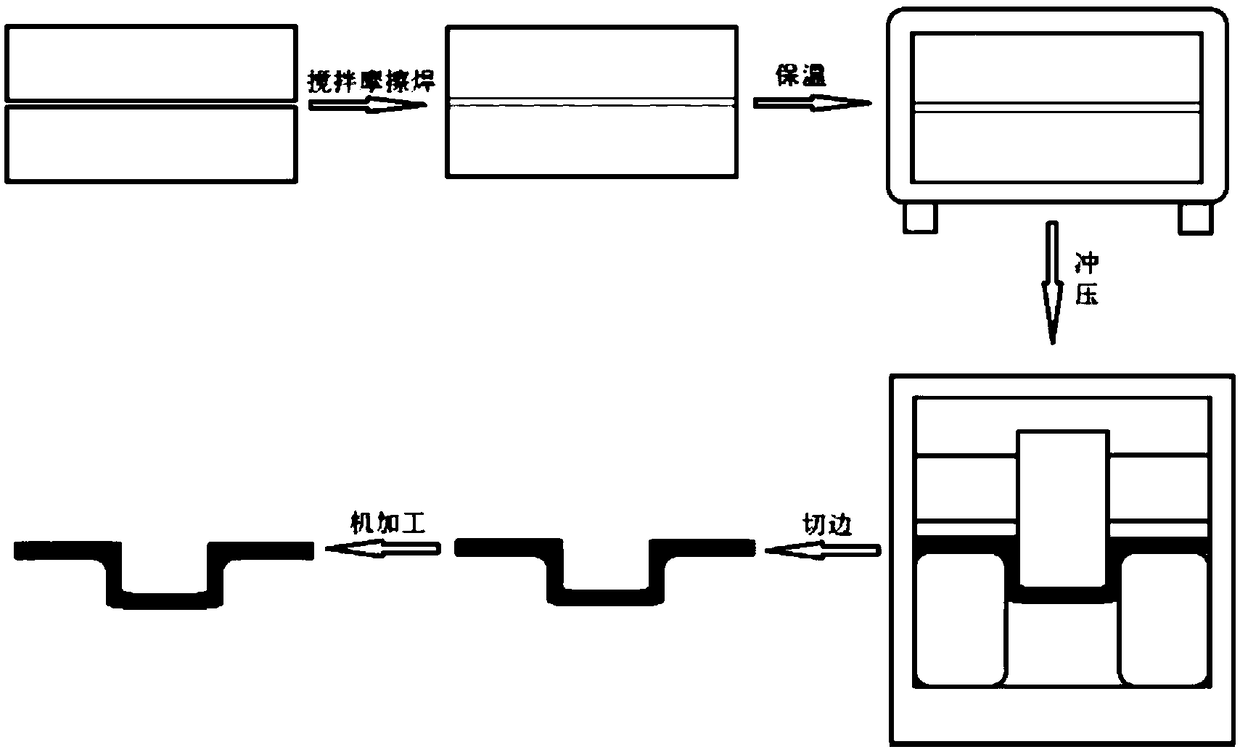

Aluminum alloy splicing welding plate forming technology

ActiveCN108655668AImprove formabilityReduce deformation resistance and springbackHot stampingAbnormal grain growth

The invention discloses an aluminum alloy splicing welding plate forming technology by friction stir welding. The technology comprises the following steps that S1, at least two aging hardening state aluminum alloy plates are subjected to friction stir welding; S2, a splicing welding plate is placed in a heating furnace to be subjected to short-time insulation treatment with the holding temperaturelower than the abnormal grain growth temperature of a joint welding joint; S3, the splicing welding plate is rapidly transferred to a stamping die after the insulation treatment and is subjected to stamping forming, and quenching pressure maintaining in a stamping die; S4, the stamped splicing welding plate is subjected to trimming treatment after cooling; and S5, the cut splicing welding plate is subjected to machining treatment and thus a finished product is obtained. A traditional hot stamping technology is simplified greatly, the production efficiency is improved, the cost is lowered, AGGis avoided and the strength of a stamped part is ensured.

Owner:WUHAN UNIV OF TECH

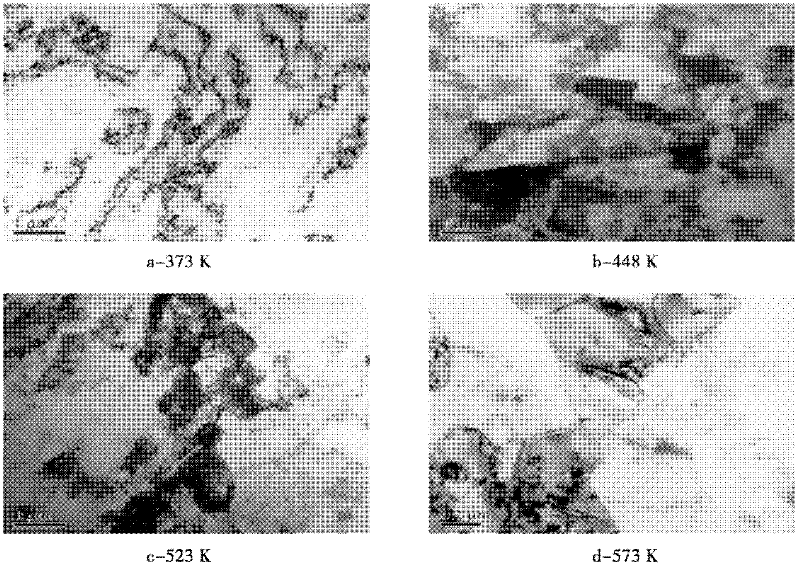

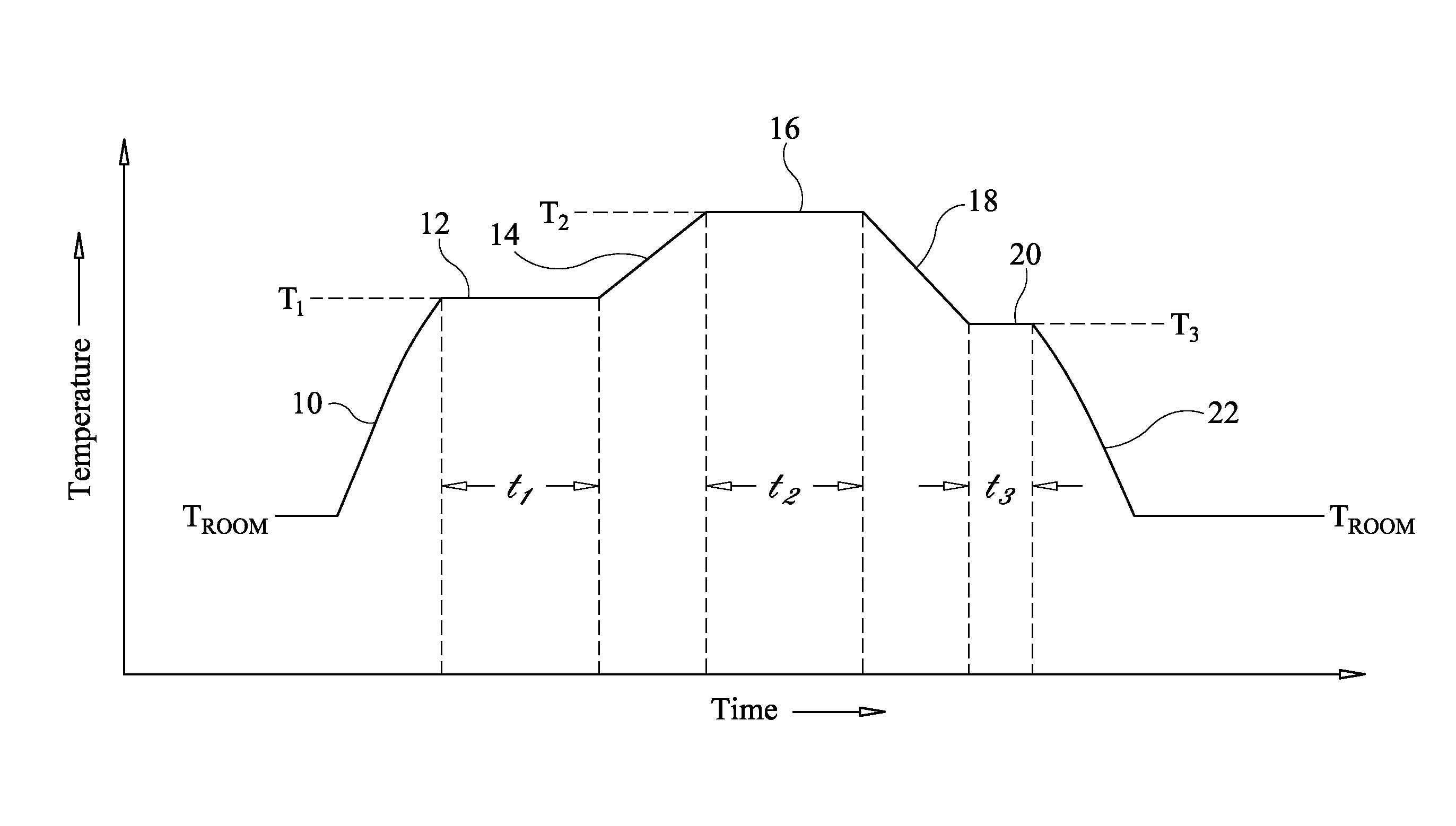

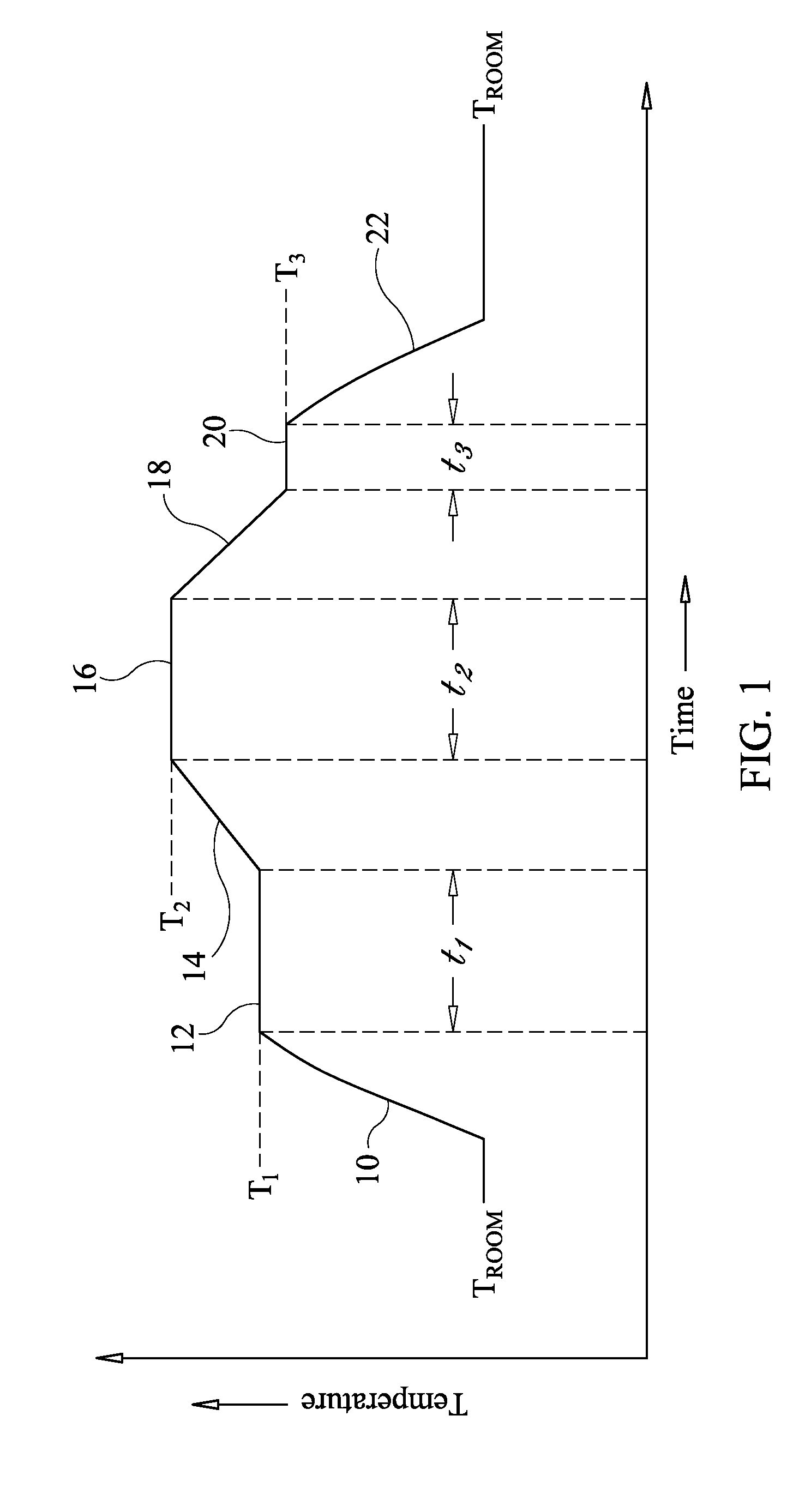

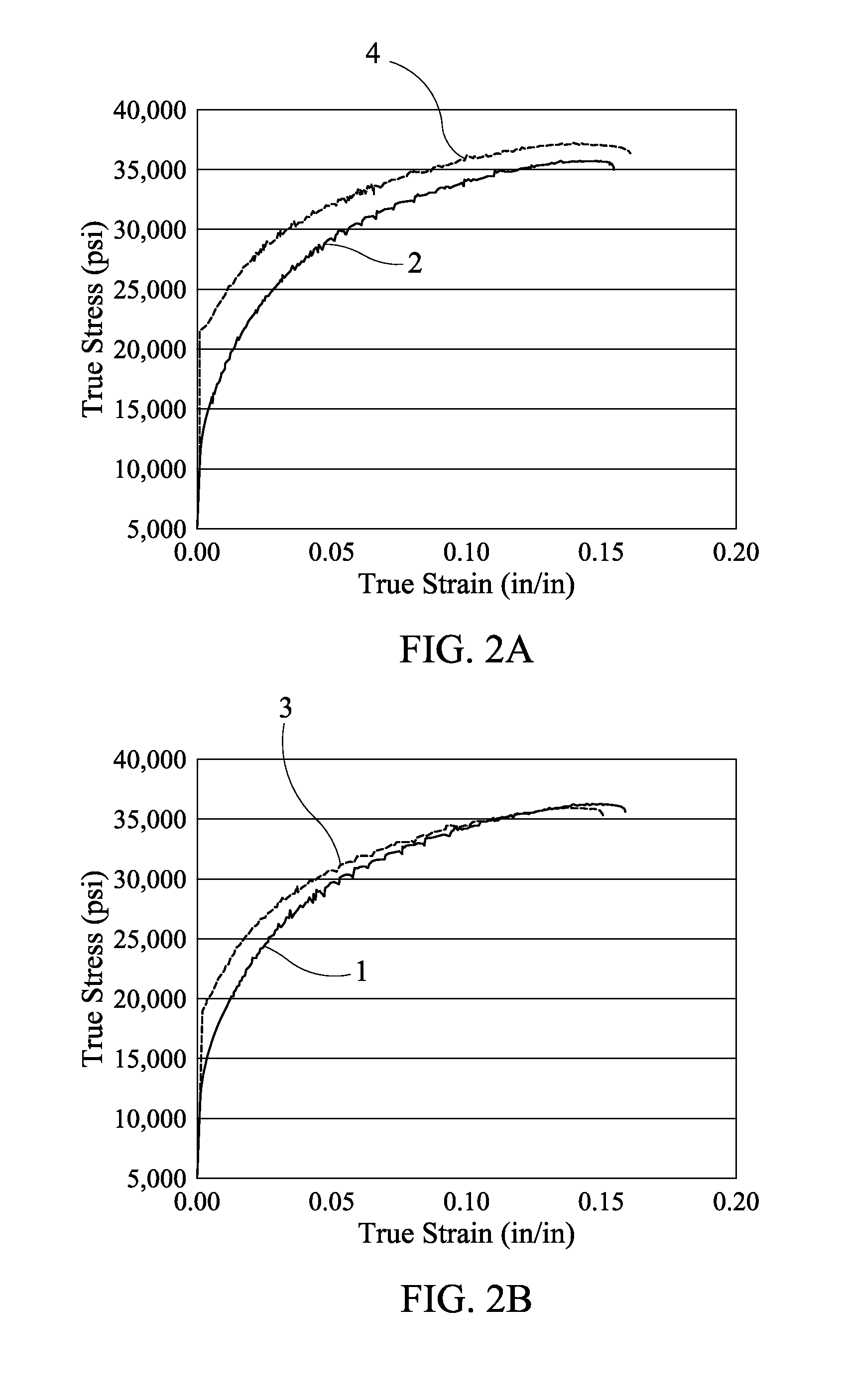

Method of heat treating aluminum—lithium alloy to improve formability

A method is provided for heat treating aluminum-lithium alloys to improve their formability. The alloy is heated to a first temperature, maintained at the first temperature for a first time period, heated at the conclusion of the first time period to a second temperature, maintained at the second temperature for a second time period, actively cooled at the conclusion of the second time period to a third temperature, maintained at the third temperature for a third time period, and then passively cooled at the conclusion of the third time period to room temperature.

Owner:NASA

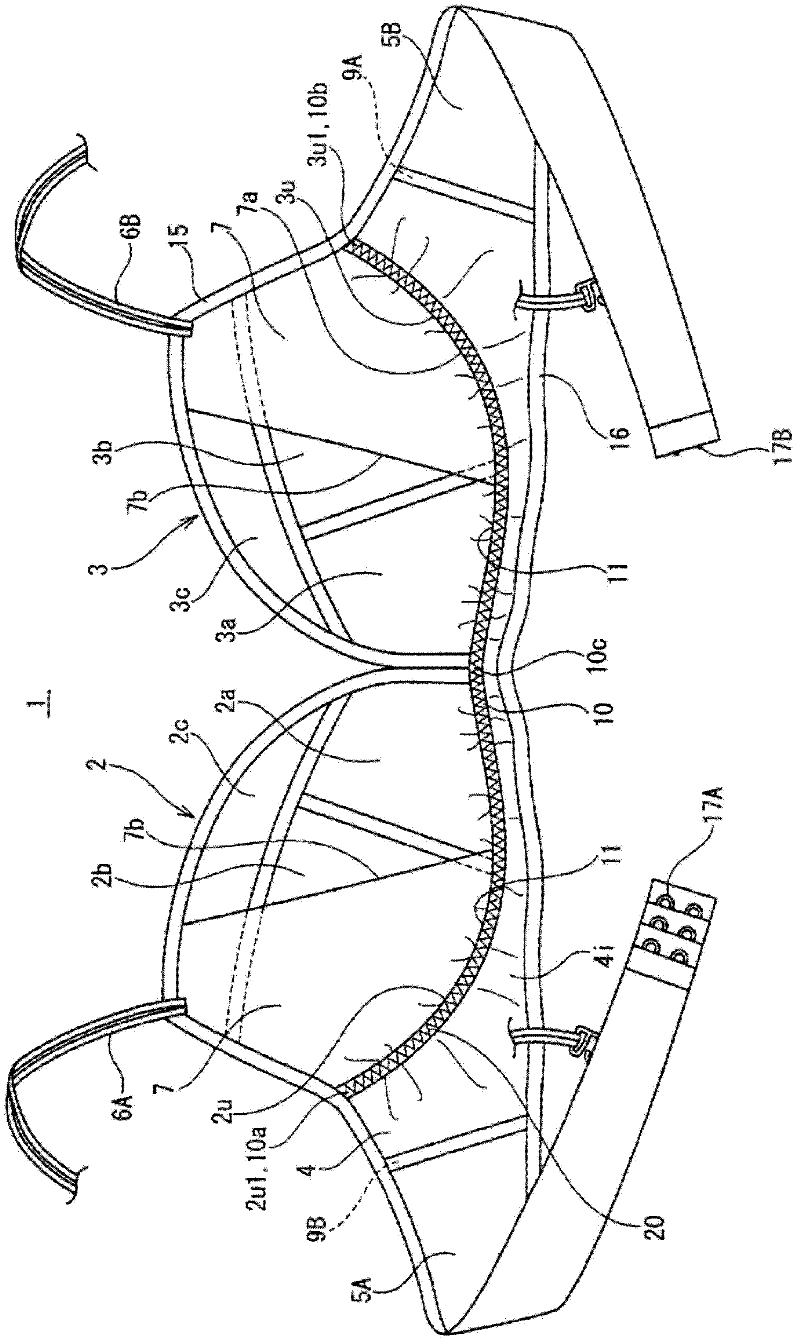

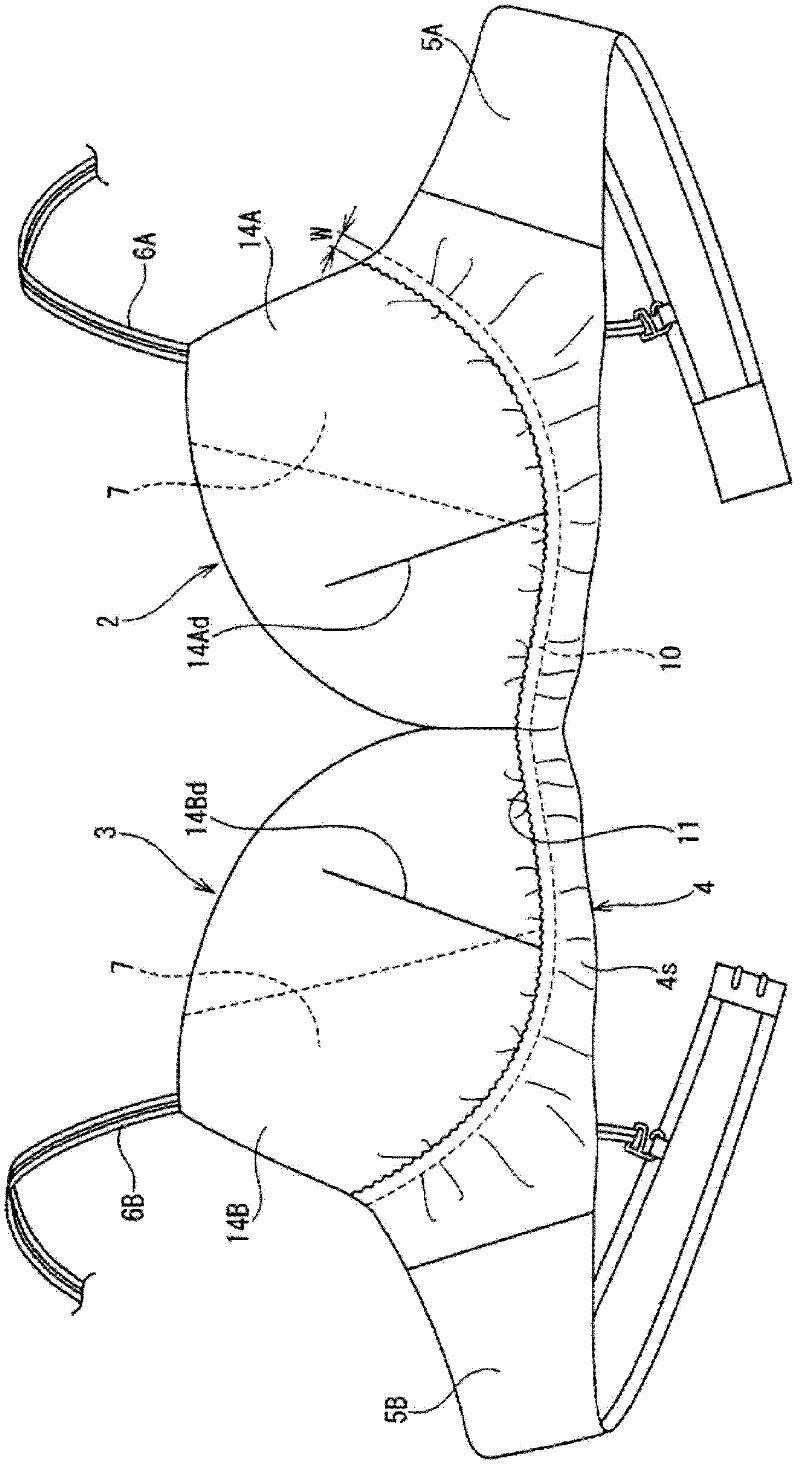

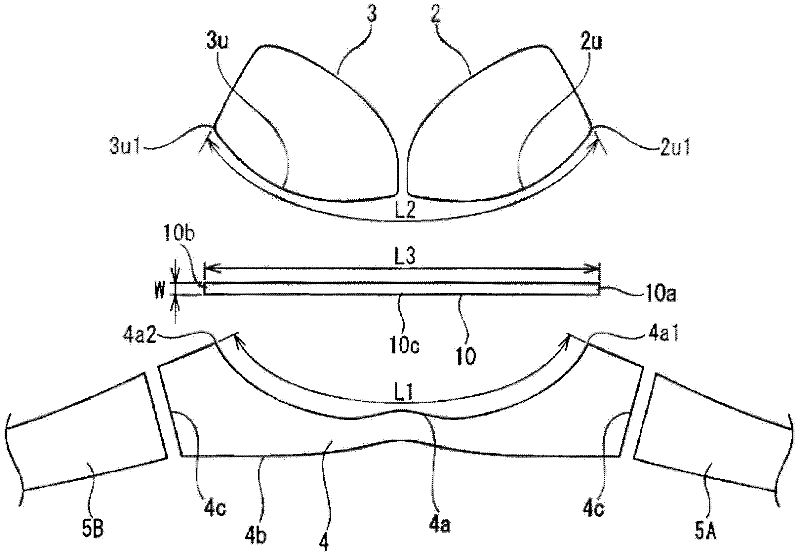

Clothing with cup parts

Disclosed is a clothing with cup parts which has excellent breast-shaping properties in spite of being non-wire. In the clothing, the marginal edges of the fabrics (2, 3) in the right and left cups along the verge's line and the marginal edge of a support fabric (4), which is joined together with the marginal ends of the fabrics in the right and left cups, are sewed on a stretch tape (10) with making gathers (11). When worn, the gathered parts of the fabrics in the cups can be three-dimensionally shaped due to the tension of the aforesaid stretch tape.

Owner:WACOAL

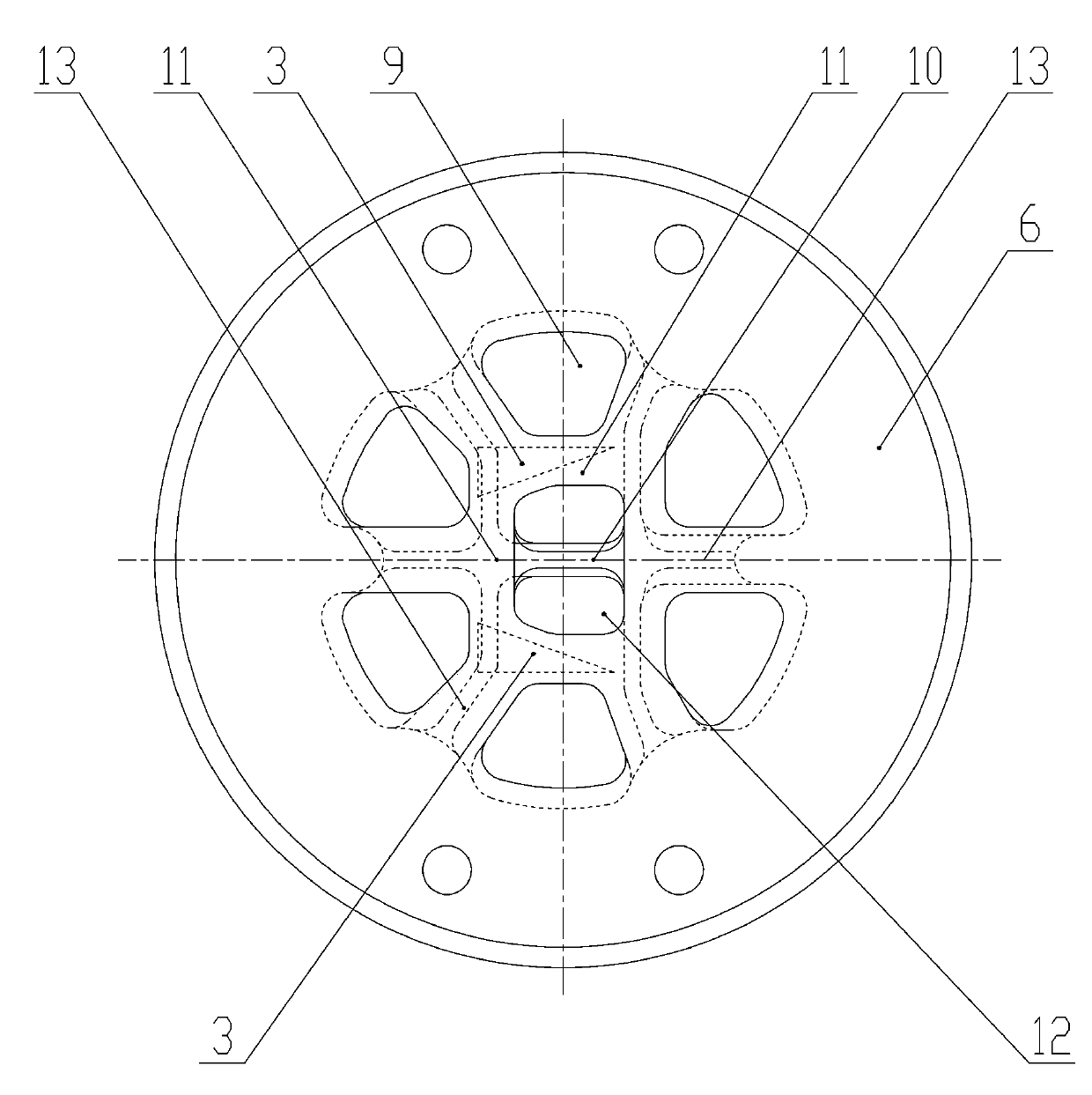

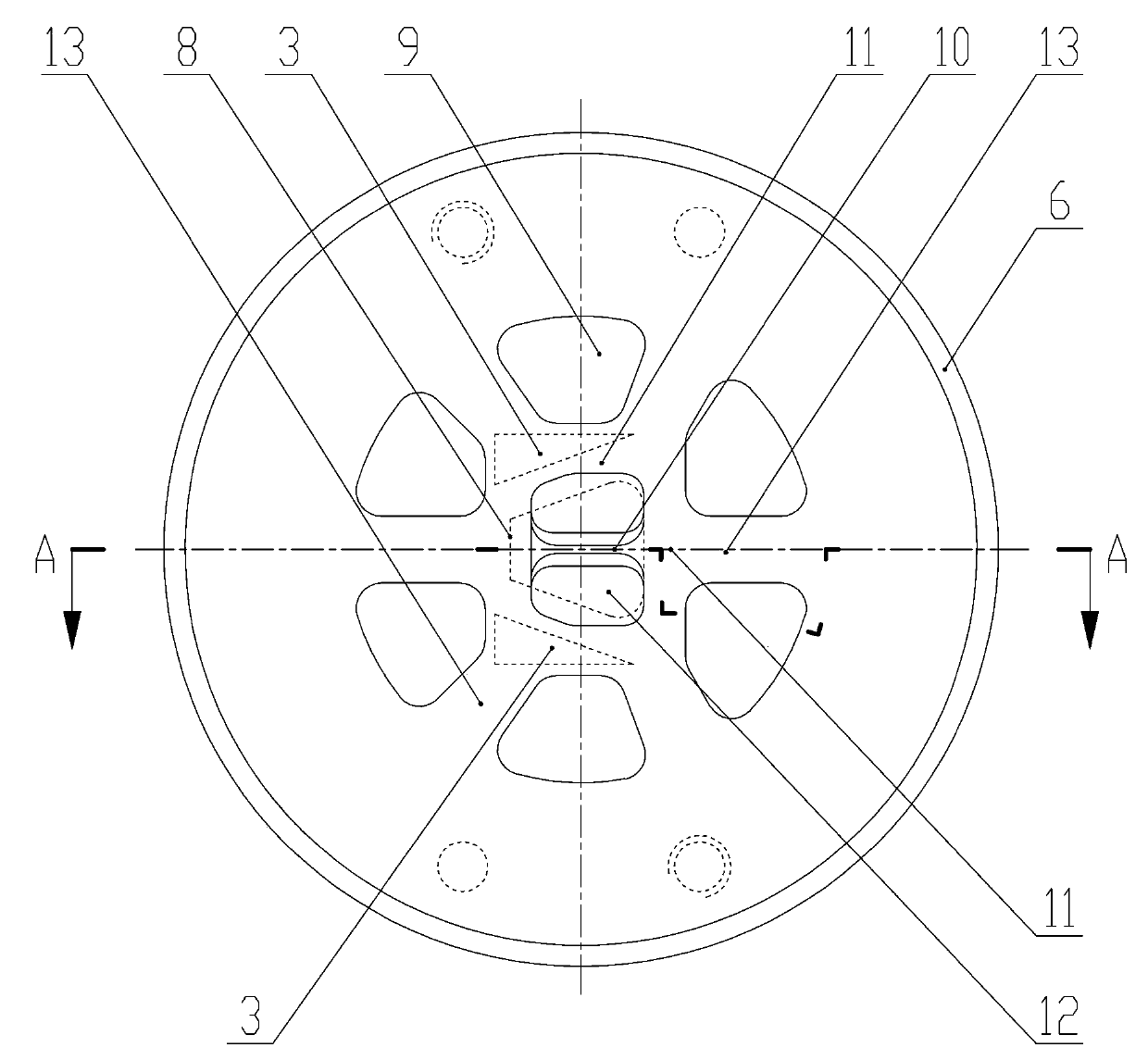

Hot extrusion mould for producing aluminum roller shutter door guide groove

The invention discloses a hot extrusion mould for producing an aluminum roller shutter door guide groove. The hot extrusion mould is formed by an upper mould body and a lower mould body in an abutting joint mode, a welding chamber is arranged on the feeding face of the lower mould body, cavities and discharging holes are formed between the welding chamber and the discharging end of the lower mould body, and a cantilever beam is arranged at the central position of the lower mould body; six outer bridge sites and four inner bridge sites are arranged on the feeding face of the upper mould body, six circumferential flow dividing holes and one central flow dividing hole are formed between the outer bridge sites and the inner bridge sites, mould cores stretching into the cavities of the lower mould body are arranged at the positions, arranged on the inner bridge sites, of the top and the bottom of the central flow dividing hole, an auxiliary bridge is arranged in the central flow dividing hole, one end of the auxiliary bridge is arranged inside the central flow dividing hole, and the other end of the auxiliary bridge is provided with a fake male head which stretches out of the central flow dividing hole and directly faces the cantilever beam of the lower mould body. According to the hot extrusion mould, the stability of the material flow is improved well, the direct impact of the material flow of the central flow dividing hole to the cantilever beam of the lower mould body can be avoided, the service life of the mould is prolonged, forming of bars is stable, the size of the bars is precise, and the mould is mainly used for producing aluminum roller shutter door guide groove class cantilever bars.

Owner:DAYE TIANGONG MOLD

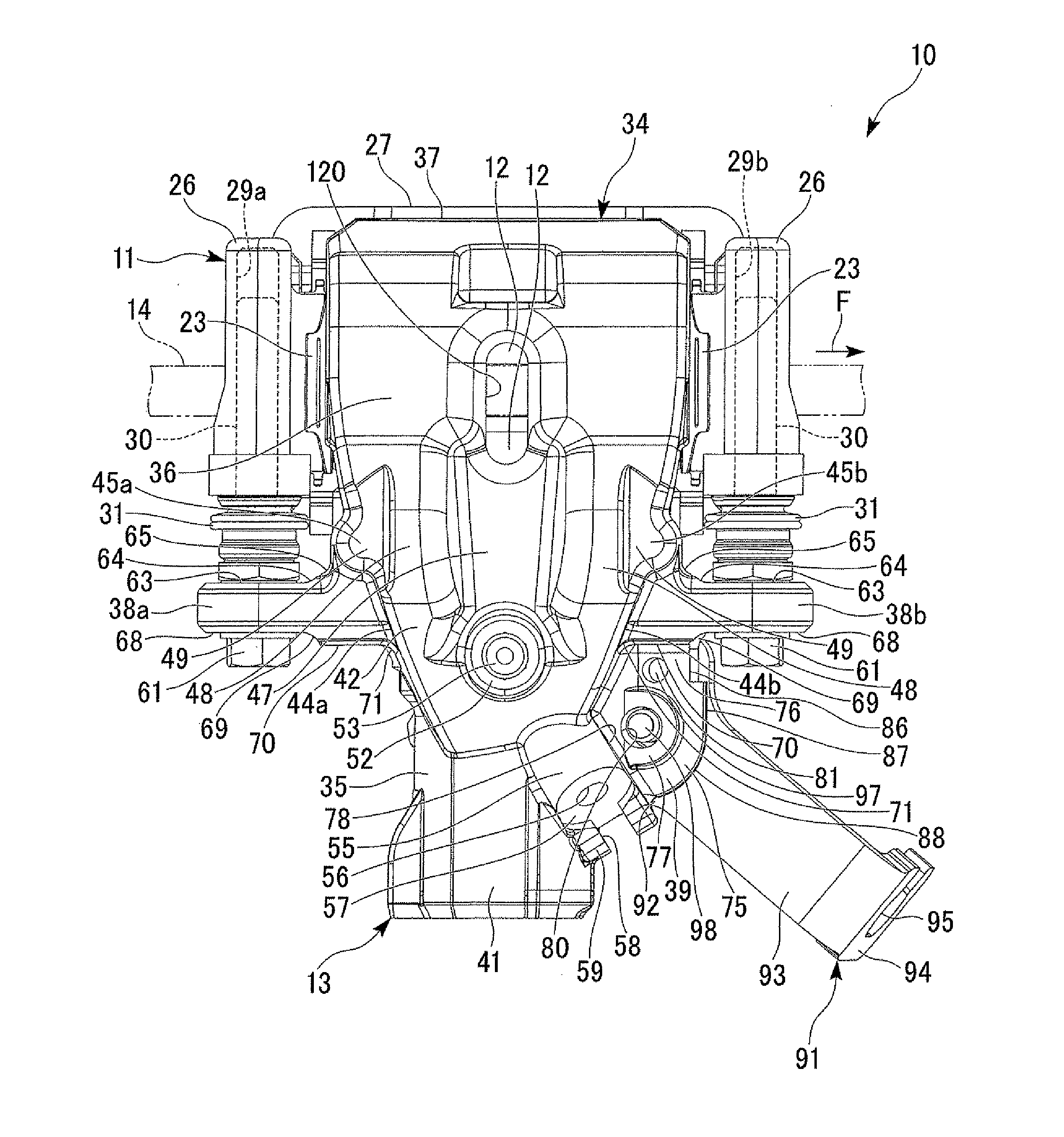

Disk brake

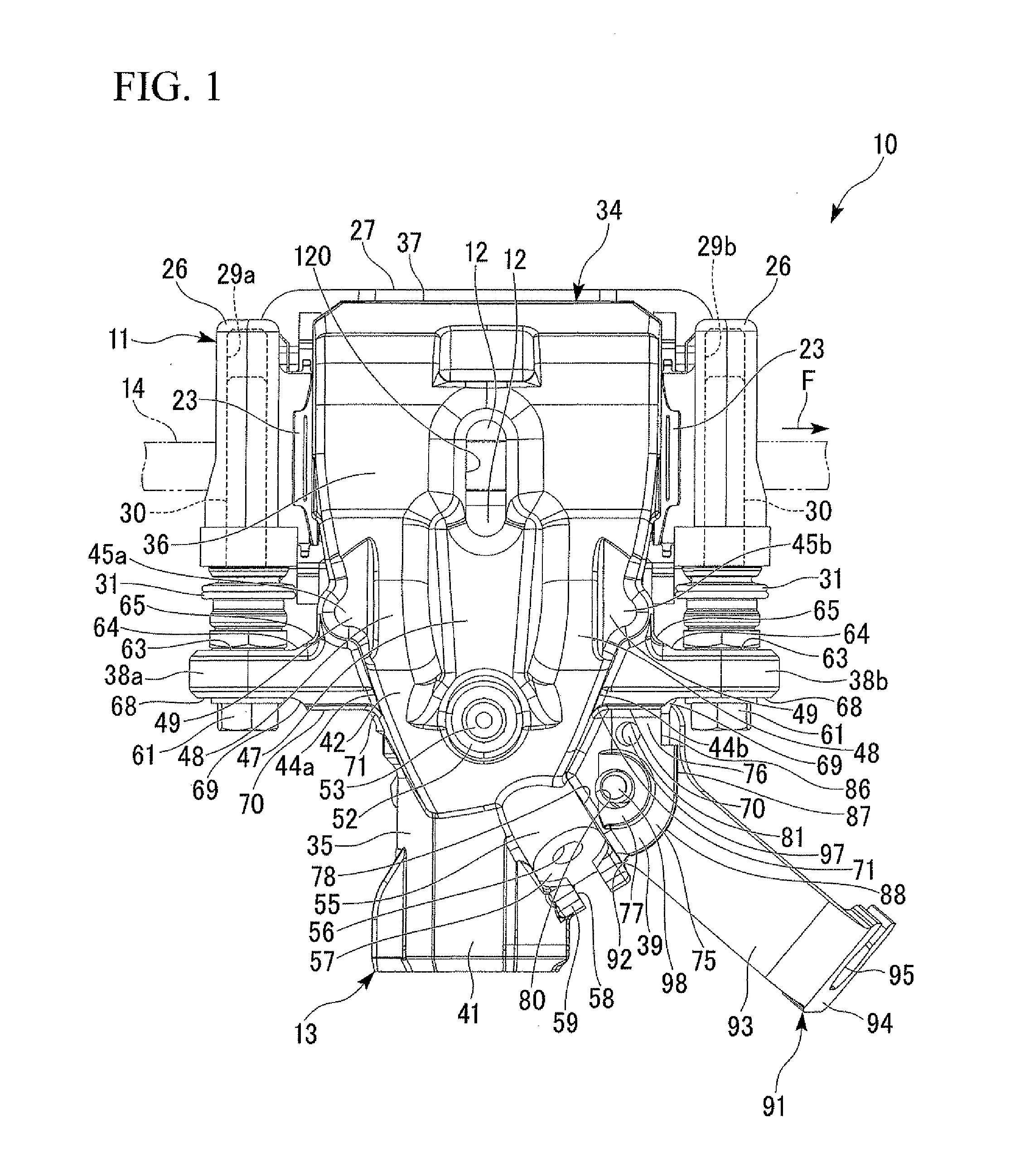

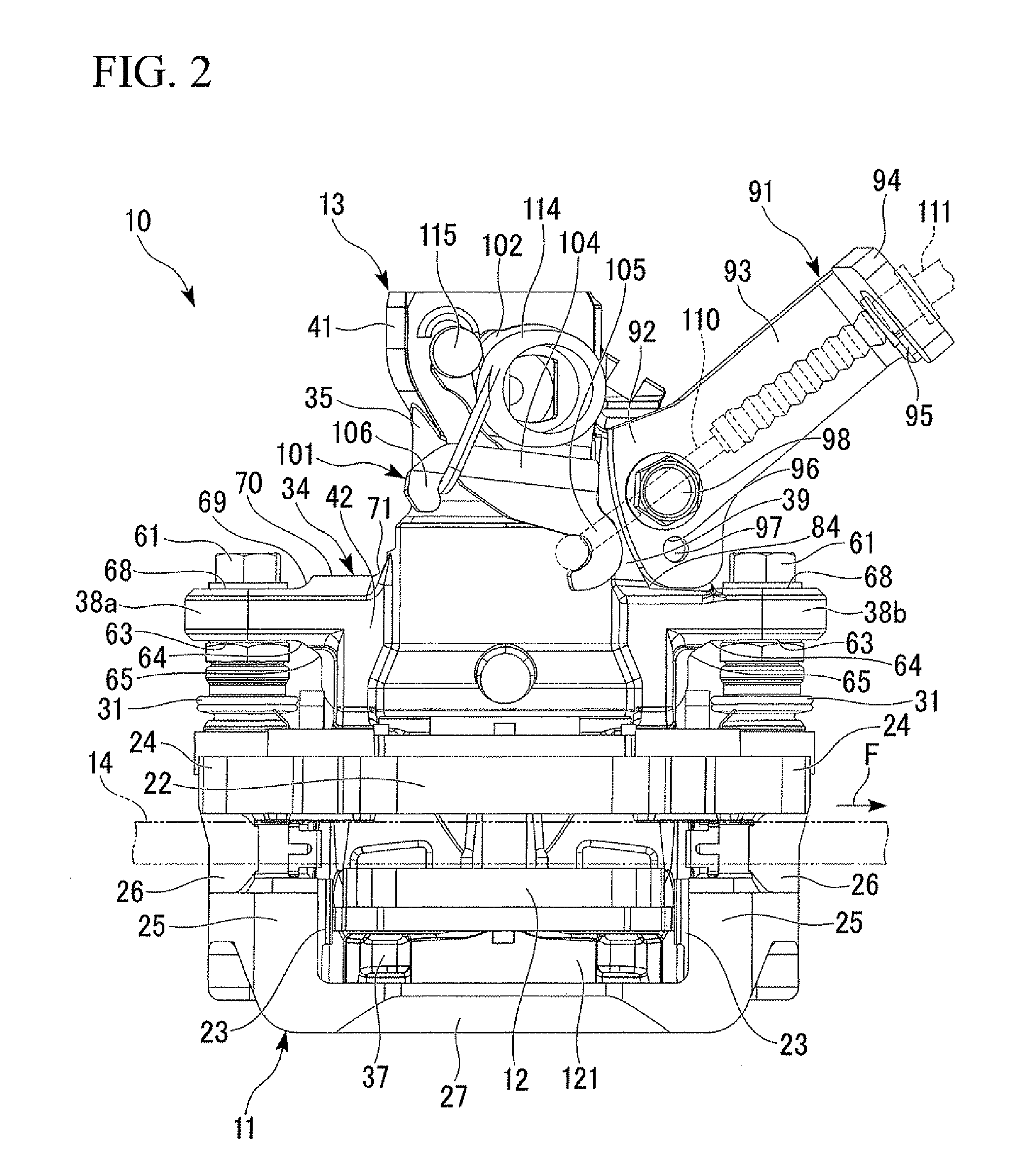

ActiveUS20110290597A1Improve formabilityGood molding effectFluid actuated brakesBrake actuating mechanismsDisc brakePiston

Provided is a disk brake having a caliper. The caliper includes a cylinder part disposed at one side in a disk axial direction and having a bore for accommodating a piston, a pair of arm parts extending to both sides of the cylinder part in a disk rotational direction and having ends to which sliding pins are fixed, and a guide attachment part configured to couple the one arm part to the cylinder part and to which a cable guide member is fixed, which are integrally formed with each other. A thickness of the guide attachment part in a disk diameter direction and a thickness of the one arm part in the disk diameter direction at least partially overlap in the disk axial direction.

Owner:HITACHI ASTEMO LTD

Vertical sludge cleaning treatment machine for river channel dredging

InactiveCN110698024AIncrease profitImprove formabilitySievingSludge treatment by de-watering/drying/thickeningEngineeringEnvironmental geology

The invention relates to a vertical sludge cleaning treatment machine for river channel dredging. The vertical sludge cleaning treatment machine comprises a workbench, a drying device, a block cuttingdevice and a crushing device, wherein the drying device is installed at the right end of the upper end face of the workbench in a sliding fit mode; the block cutting device is arranged on the left side of the drying device and is connected with the upper end face of the workbench in a sliding fit mode; and the crushing device is arranged on the left side of the workbench. According to the vertical sludge cleaning treatment machine for river channel dredging, river sludge is cleaned and reutilized by adopting the design concept of multi-stage treatment, so the waste is turned into the valuable, and the utilization rate and the forming degree of sludge are improved; and dried sludge blocks are crushed and refined by adopting the crushing device, so the crushed sludge blocks can be easily mixed with other substances during subsequent use.

Owner:谢诚浩

Electric auxiliary bending forming process method for high-temperature titanium alloy grid rib wall plate

The invention discloses an electric auxiliary bending forming process method for a high-temperature titanium alloy grid rib wall plate. The method comprises the following steps that a high-temperaturetitanium alloy thick plate is milled into a planar grid rib wall plate; two electrodes connected with a pulse current generator are used for conducting contact edge pressing on the two ends of the planar grid rib wall plate respectively; the pulse current generator carries out self-resistance heating on the planar grid rib wall plate through the electrodes; a bending male die is controlled to move downwards to bend the planar grid rib wall plate; and after the planar grid rib wall plate is formed into a designed geometrical shape, the pulse current generator is shut down. According to the electric auxiliary bending forming process method, the idea of pulse current auxiliary forming is applied to the overall forming process of the high-temperature titanium alloy grid rib wall plate, the formability of the high-temperature titanium alloy grid rib overall wall plate is expected to be improved through the material self-resistance heating effect and the electroplastic effect, and the integrated and accurate control over the formability of the high-temperature titanium alloy grid rib overall wall plate is achieved through the electric field-thermal field-force field cooperative control.

Owner:HEFEI UNIV OF TECH

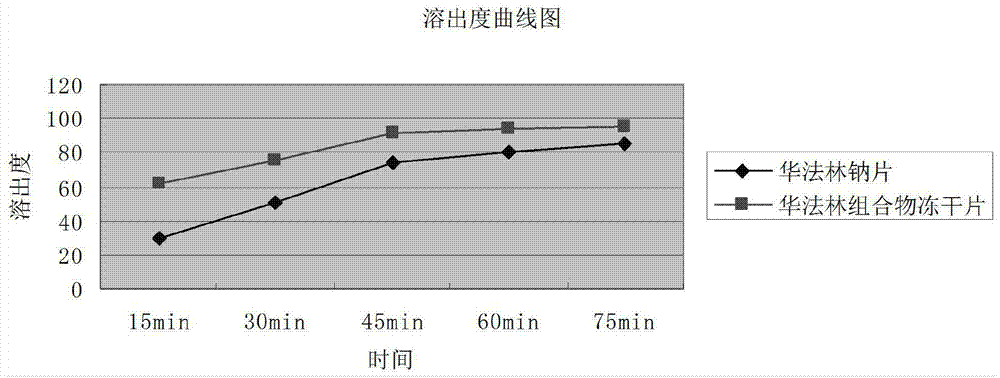

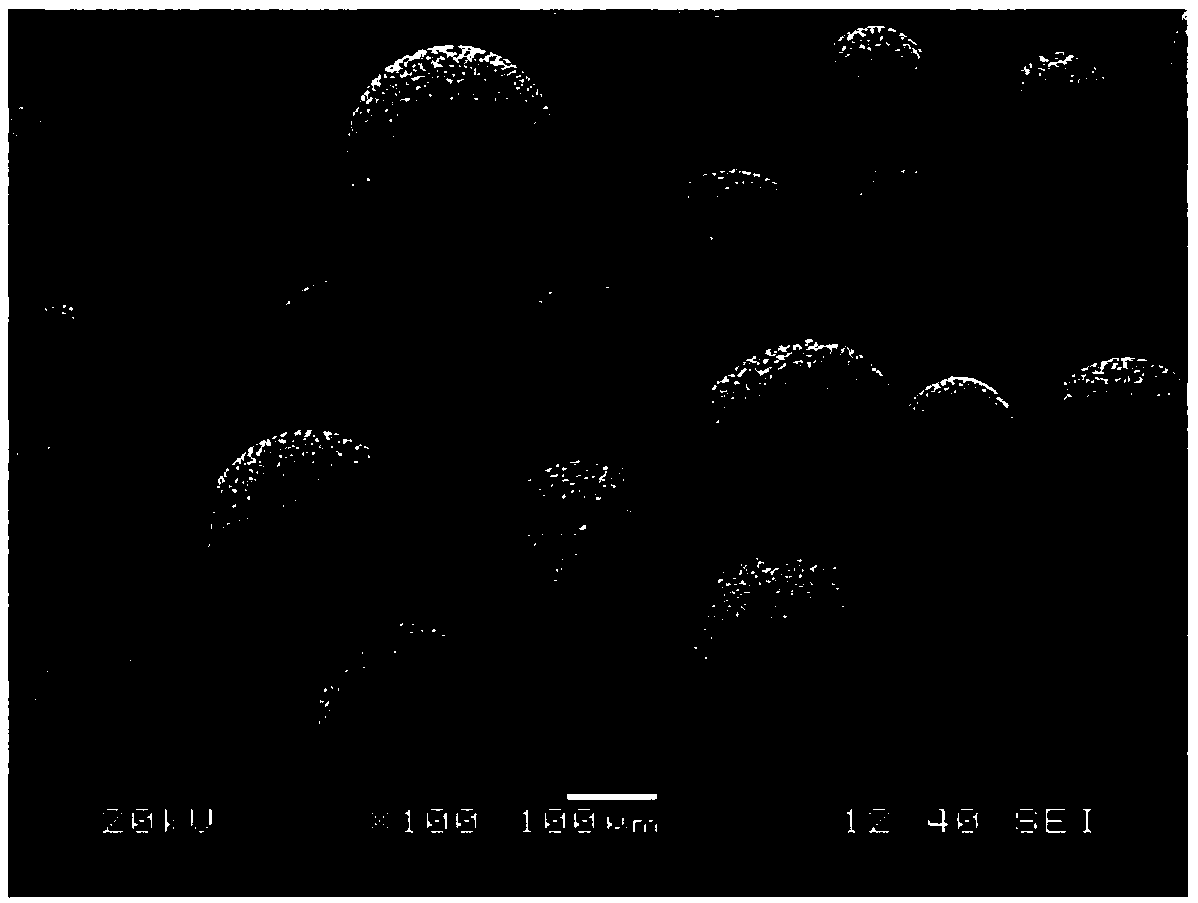

Lyophilized tablet prepared from warfarin composition and preparation method thereof

InactiveCN104490832AImprove formabilityHigh dissolution ratePill deliveryPharmaceutical non-active ingredientsCorn starchSucrose

The invention provides a lyophilized tablet prepared from a warfarin composition and a preparation method thereof and belongs to the technical of medicines and medicine production. The lyophilized tablet is prepared from warfarin, starch and sucrose, wherein the starch and the sucrose serve as adjuvants. By heating the common corn starch, the binding and disintegrating effects of the starch in the lyophilized tablet can be improved, and the formability of the lyophilized tablet can be improved. The adjuvants for preparing the lyophilized tablet only comprise the starch and the sucrose. The lyophilized tablet is prepared by decreasing temperature twice and increasing temperature twice, and the twice temperature decrease and twice temperature increase can ensure that the lyophilized tablet can be well formed, the dissolution rate of the lyophilized tablet can be increased and the bioavailability of the lyophilized tablet can be improved. The lyophilized tablet overcomes the defects of the ordinary tablet prepared from warfarin, is prepared by adopting a few kinds of and a small amount of adjuvants compared with the tablet prepared from warfarin, has high dissolution rate and high bioavailability, has a good clinical treatment effect and can be used for clinical treatment safely.

Owner:HAINAN WEI KANG PHARMA QIANSHAN

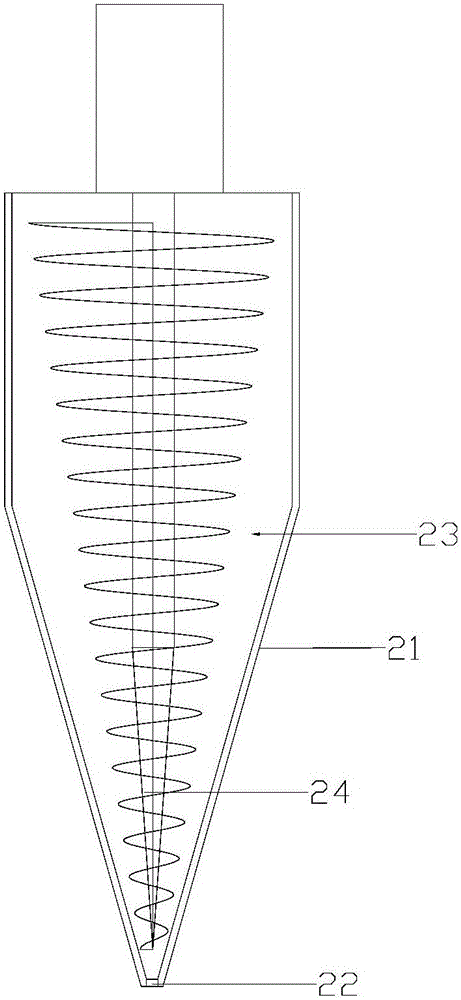

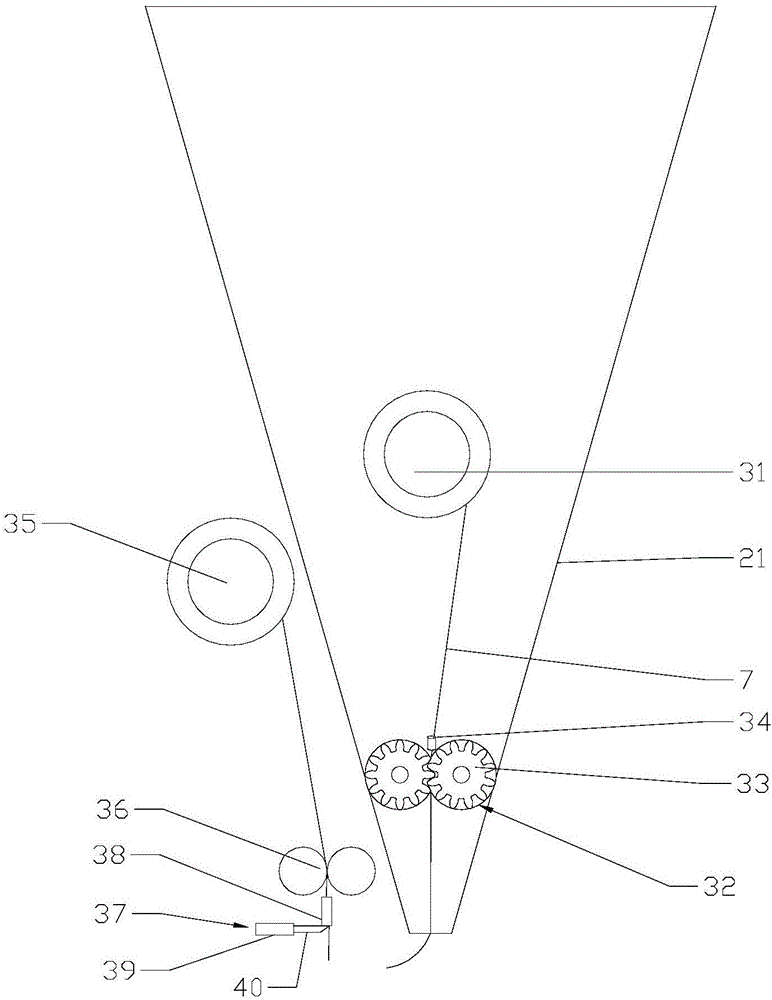

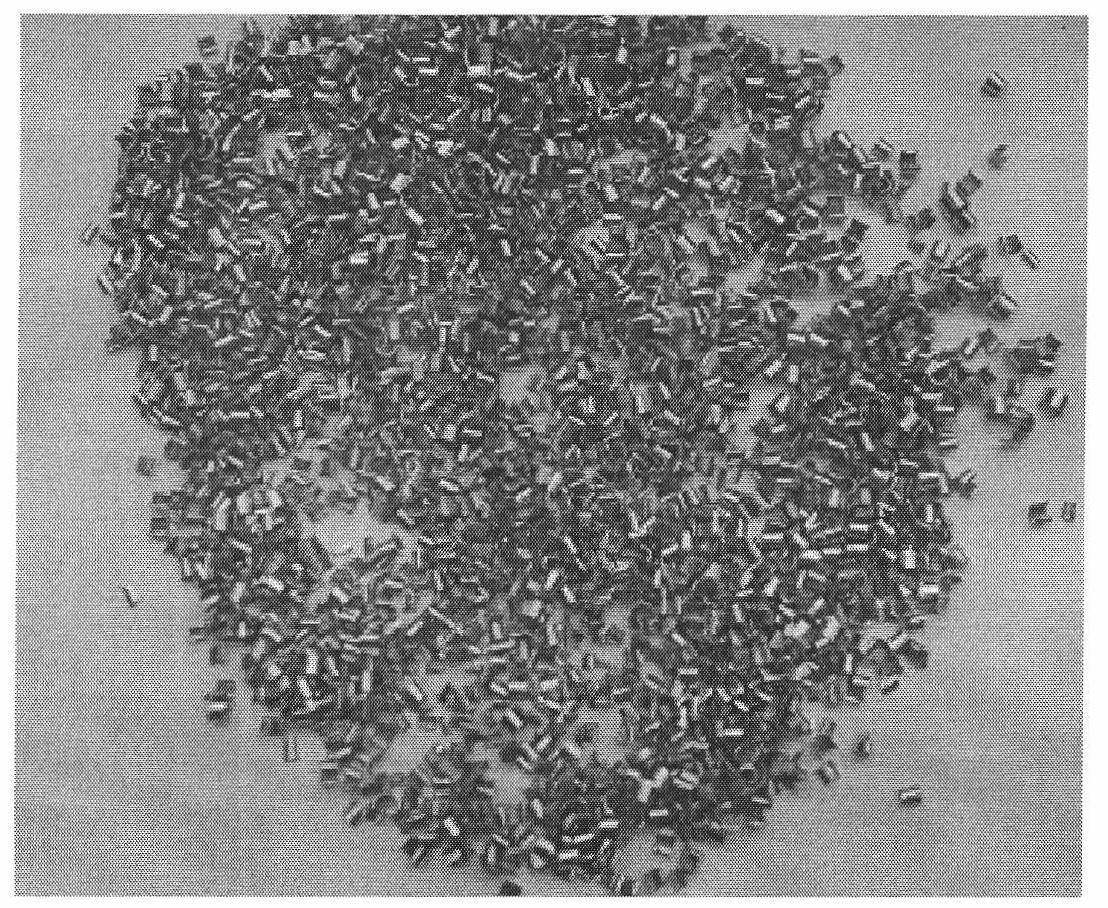

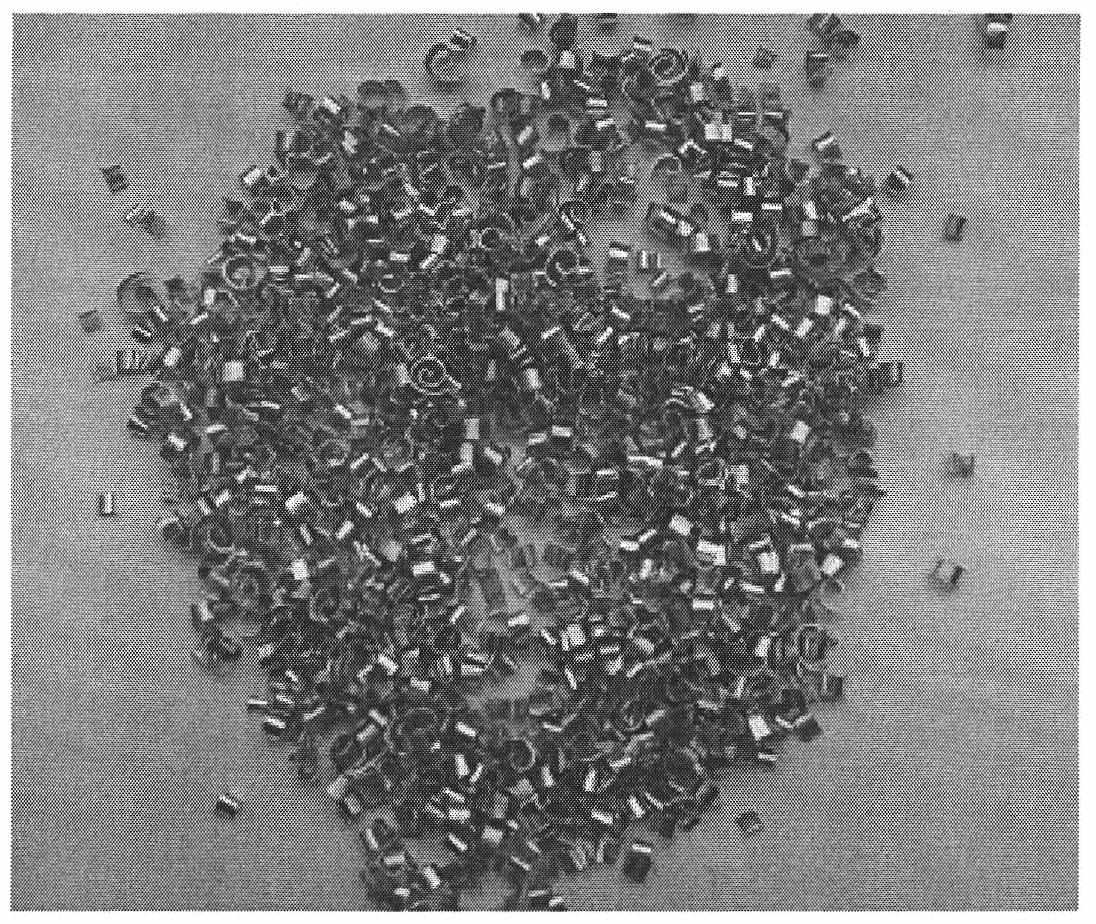

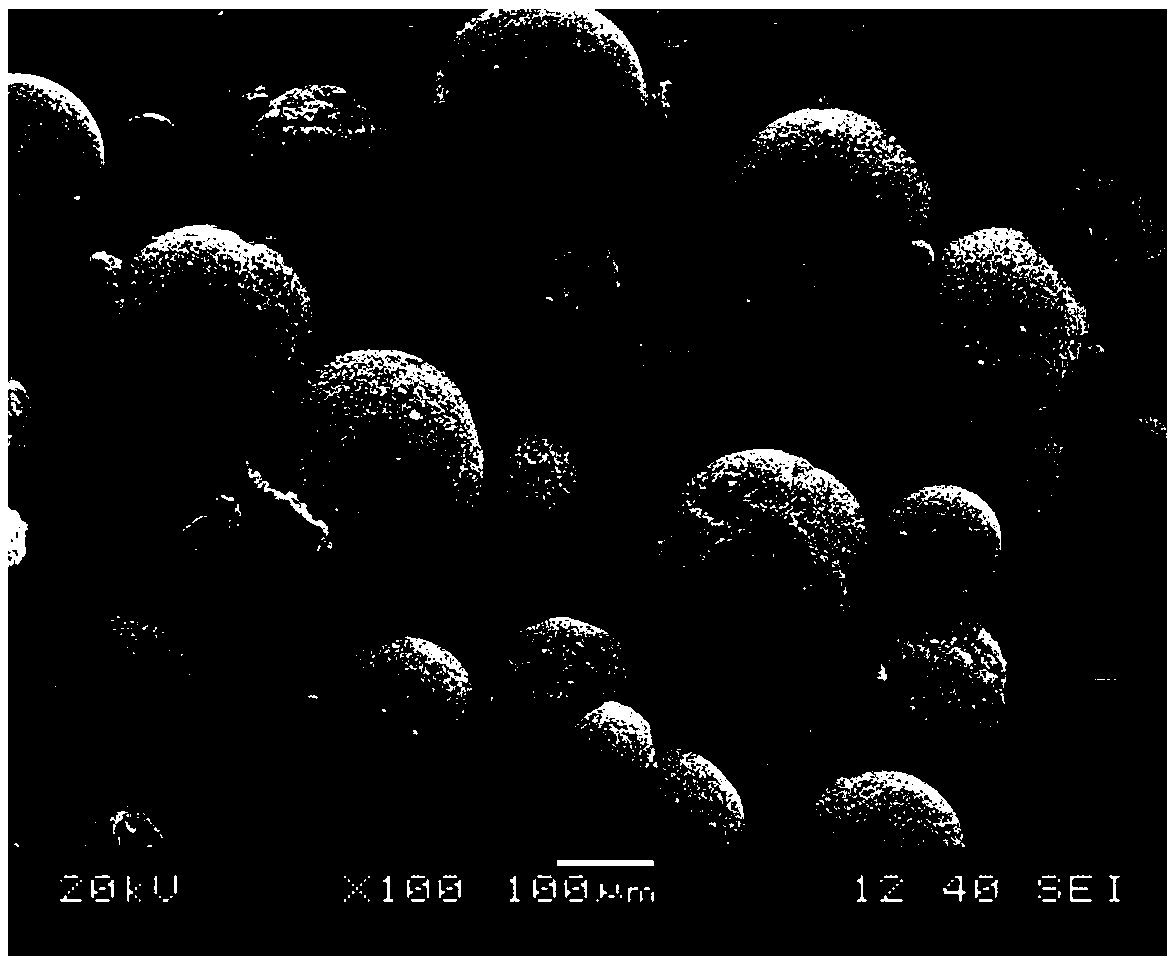

A two-fluid granulation method of soft magnetic composite powder for molding inductors

InactiveCN109102979AImprove formabilityHigh inductance and high stabilityTransportation and packagingMetal-working apparatusMagnetic powderAdhesive

The invention discloses a two-fluid granulation method of soft magnetic composite powder for molding inductors, belonging to the technical field of metal soft magnetic powder material preparation. Themethod comprises the following steps in particular: (1) pretreatment of soft magnetic metal powder; (2) preparation of adhesive; (3) fully stirring and mixing the pretreated soft magnetic metal powder and the adhesive to obtain two-fluid granulating slurry; (4) spray granulation of the original granulation slurry. The soft magnetic powder prepared by the method of the invention has high sphericity, low moisture content, good bulk density and fluidity, and improves product performance and production efficiency.

Owner:安徽博微新磁科技有限公司

Heat treatment method of aluminum alloy for automotive body

InactiveCN105986207AImprove formabilityHigh paint strength and formabilityQuenchingSolution treatment

The invention relates to a heat treatment method of an aluminum alloy for an automotive body. The heat treatment method comprises the following steps of: carrying out homogenizing annealing heat treatment, and then carrying out hot rolling, intermediate annealing and cold rolling machining to form sheet metal; carrying out solution treatment on the aluminum alloy sheet metal at 500-600 DEG C, carrying out rapid quenching till temperature is lower than 110 DEG C, and then carrying out pre-ageing treatment within 20 minutes, wherein according to the pre-ageing treatment process, pre-ageing is carried out for 3-10s at 150-200 DEG C, or pre-ageing is carried out for 0.3-10 hours at 50-90 DEG C. The heat treatment method comprises the following steps of: carrying out homogenizing annealing heat treatment, and then carrying out hot rolling, intermediate annealing and cold rolling machining to form sheet metal; carrying out solution treatment on the aluminum alloy sheet metal at 540-565 DEG C, carrying out rapid quenching till temperature is lower than 100 DEG C, and then carrying out pre-ageing treatment within 30 minutes, wherein according to the pre-ageing treatment process, pre-ageing is carried out for 1-10s at 180-220 DEG C, or pre-ageing is carried out for 0.2-12 hours at 60-100 DEG C. After the aluminum alloy is subjected to the pre-ageing treatment, the property of the aluminum alloy is stable in a room temperature placement process, and before baking finish, the aluminum alloy has good forming property.

Owner:重庆金亚模具制造有限公司

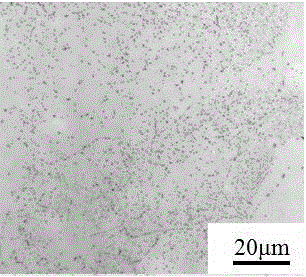

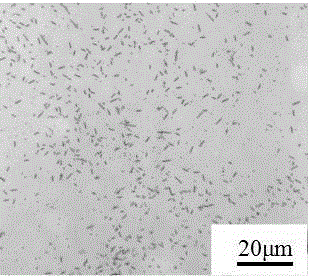

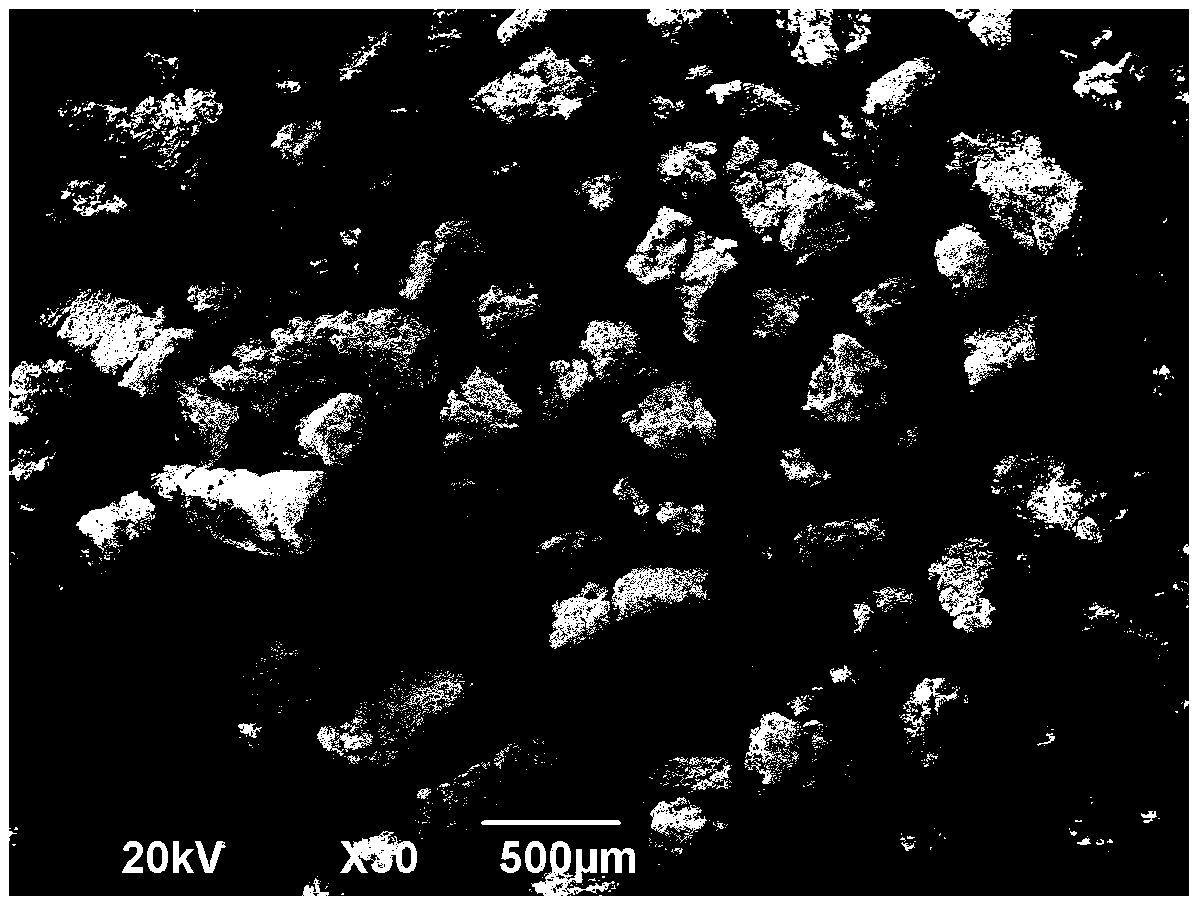

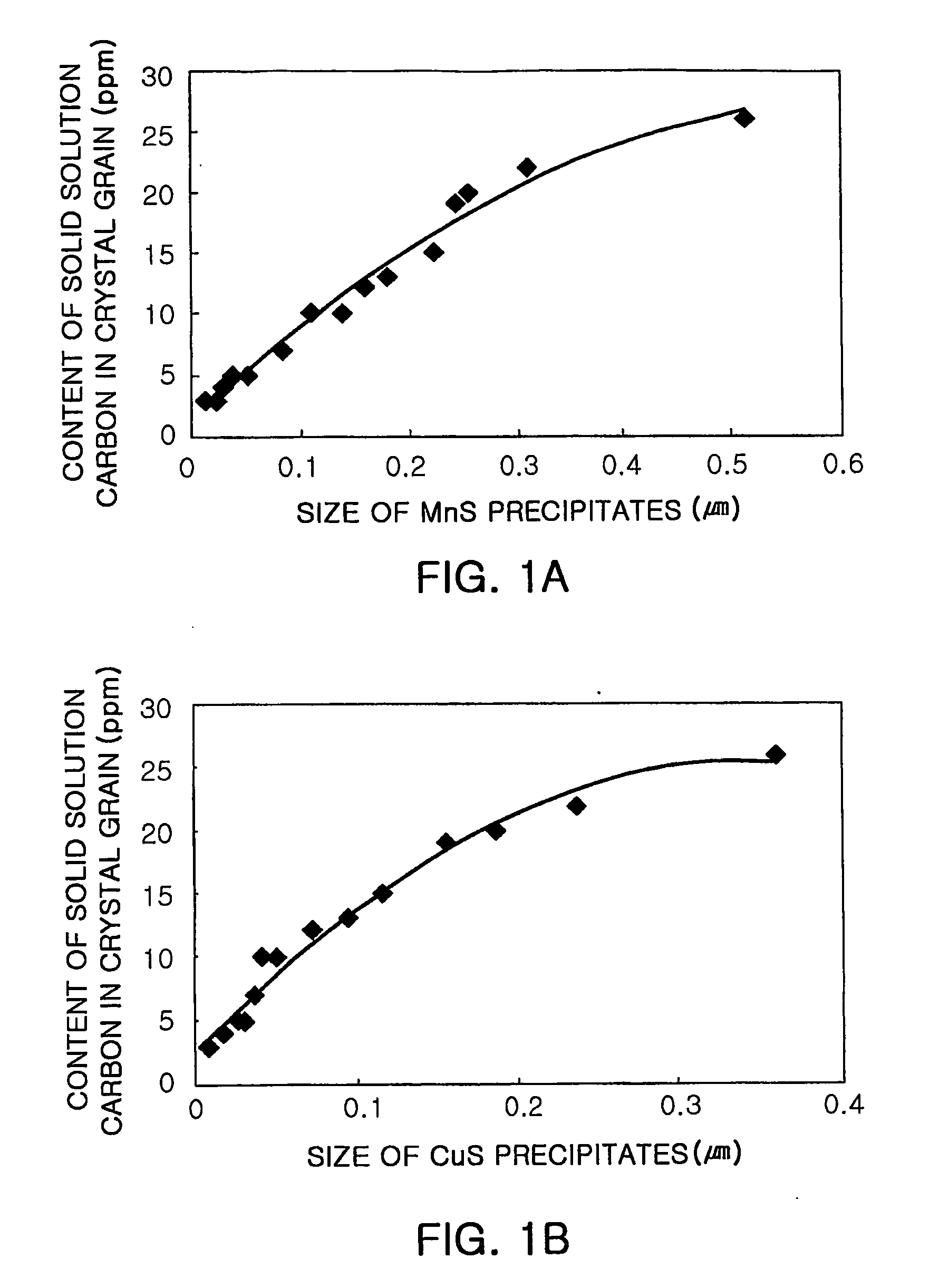

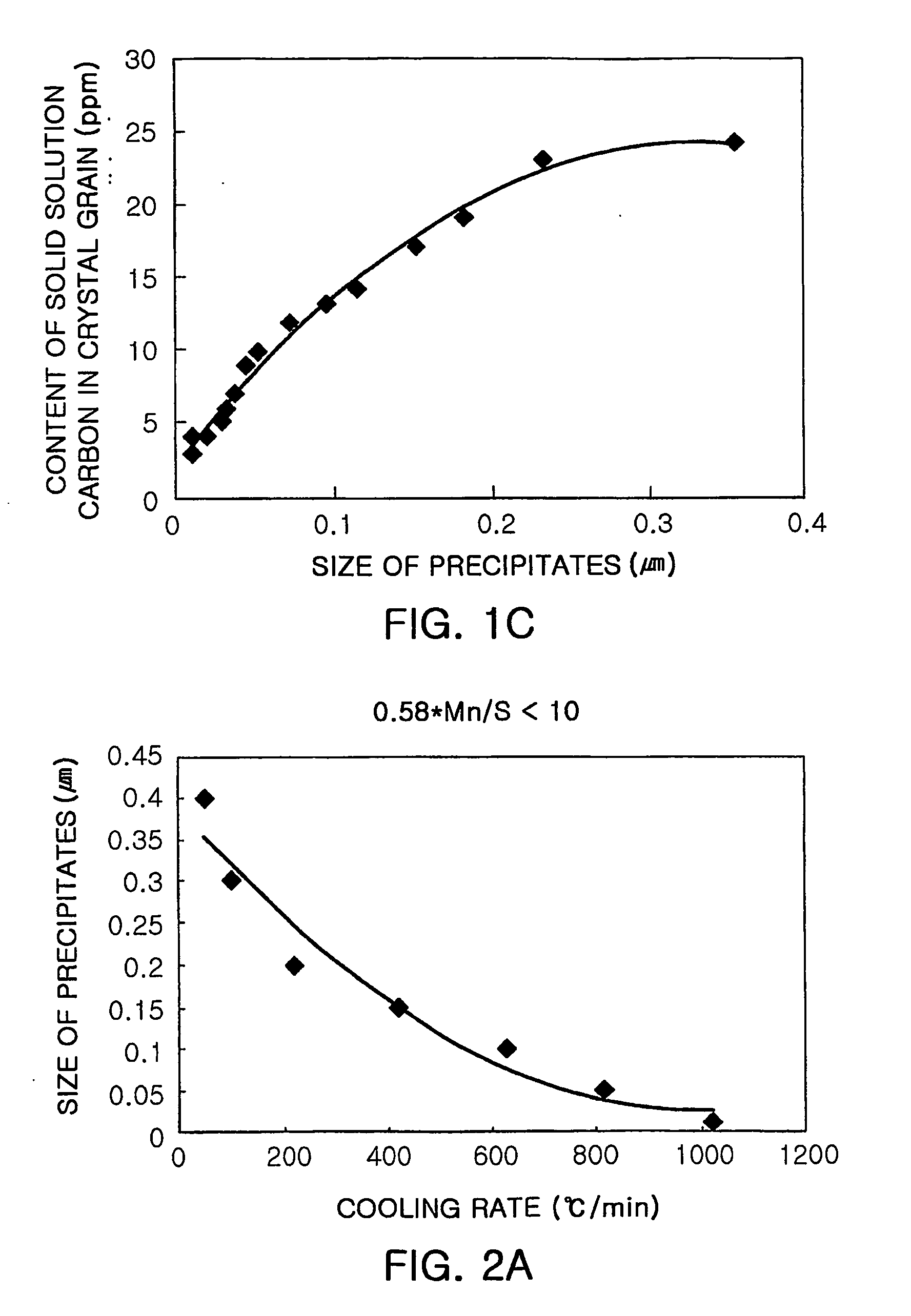

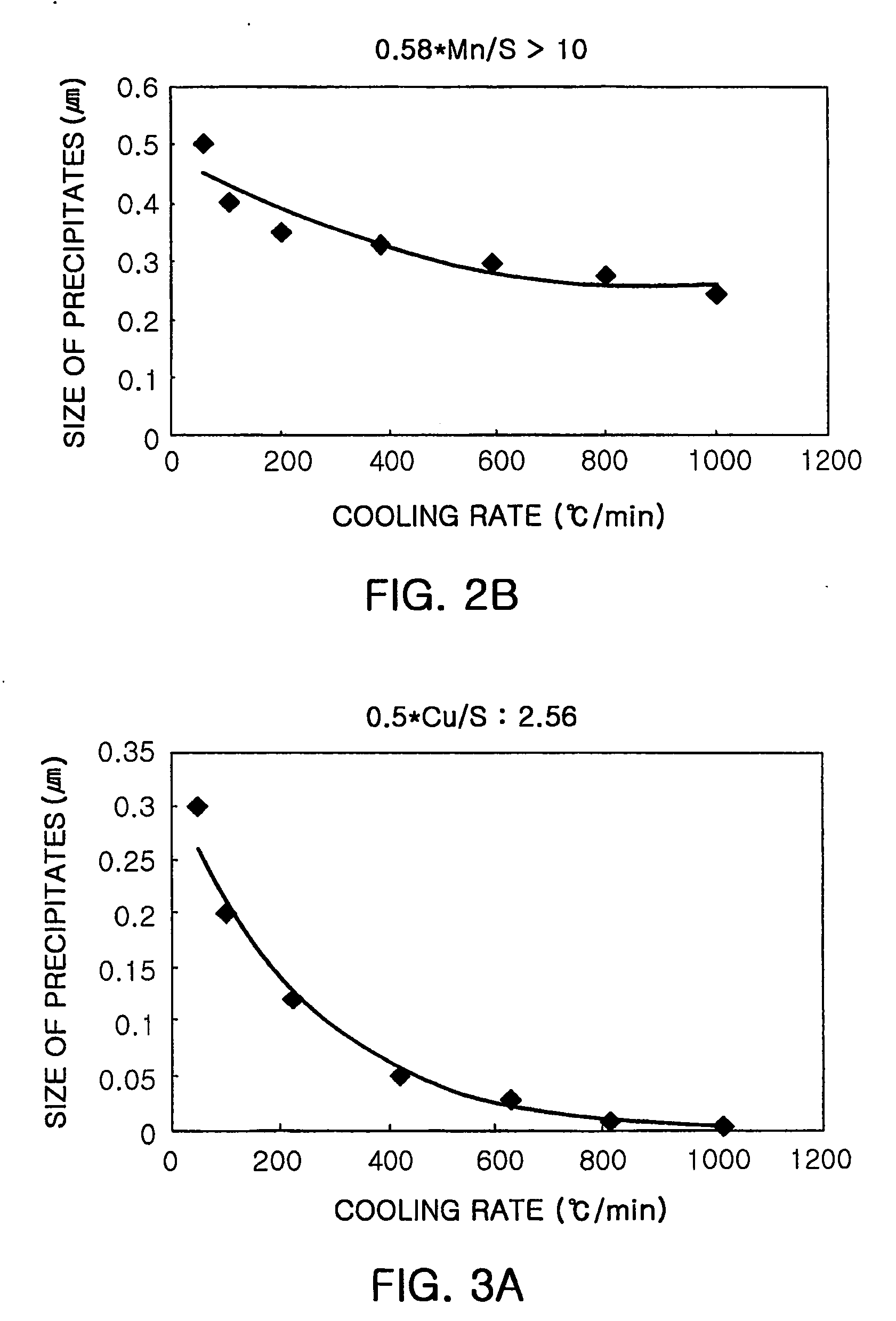

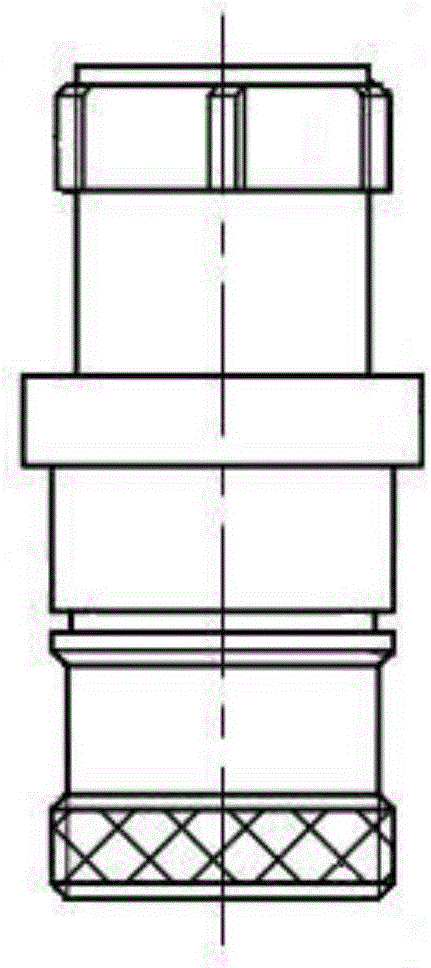

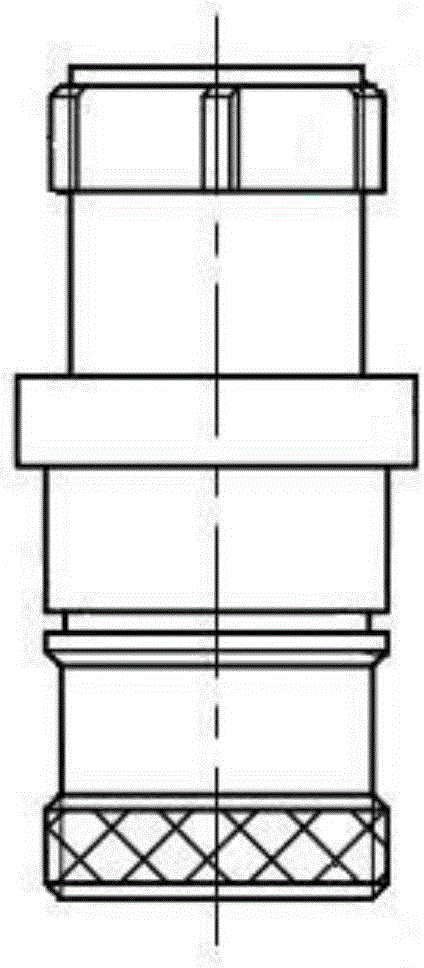

Cold Rolled Steel Sheet Having Aging Resistance and Superior Formability, and Process for Producing the Same

ActiveUS20090020196A1Improve formabilityEnsure aging resistanceFurnace typesHeat treatment furnacesCrystalliteDuctility

A cold rolled steel sheet, and a method of manufacturing the same, designed to have aging resistance and excellent formability suitable for use in automobile bodies, electronic appliances, and the like. The cold rolled steel sheet comprises in weight %: 0.003% or less of C, 0.003˜0.03% of S, 0.01˜0.1% of Al, 0.02% or less of N, 0.2% or less of P, at least one of 0.03˜0.2% of Mn and 0.005˜0.2% of Cu, and a balance of Fe and other unavoidable impurities. When the steel sheet comprises one of Mn and Cu, the composition of Mn, Cu, and S satisfies at least one relationship: 0.58*Mn / S≦10 and 1≦0.5*Cu / S≦10, and when the steel sheet comprises both Mn and Cu, the composition of Mn, Cu, and S satisfies the relationship: Mn+Cu≦0.3 and 2≦0.5*(Mn+Cu) / S≦20. Participates of MnS, CuS, and (Mn, Cu)S in the steel sheet have an average size of 0.2 μm or less. Since carbon content in a solid solution state in a crystal grain is controlled by fine precipitates of MnS, CuS, or (Mn, Cu)S, the steel sheet has enhanced aging resistance and formability, and has excellent yield strength and strength-ductility.

Owner:POHANG IRON & STEEL CO LTD

Machining process for spline shell

The invention discloses a machining process for a spline shell and relates to the field of preparation of automatic spare parts. The process comprises the steps that firstly, a blank is treated, specifically, A, drilling is conducted, B, the outer diameter is subjected to rough turning, specifically, the front end and the rear end of the blank are subjected to rough turning, and enough cutting allowances are reserved, C, three outside protrusions are milled, specifically, the three protrusions are milled on the outer diameter of the front end of the blank, and D, the outer diameter and the inner diameter of the front end are subjected to finish turning; secondly, the outer diameter is subjected to knurling, specifically, the outer diameter of the rear end of the blank is subjected to outside knurling through a special machine independently; thirdly, finish machining is conducted, specifically, A, the outer diameter is subjected to rough turning, and a rotary groove is turned in the outer diameter, and B, the inner diameter and the outer diameter of the rear end are subjected to finish turning; and fourthly, two key grooves are punched in the inner wall of a shaft hole through a special machine independently.

Owner:苏州昭沃五金科技有限公司

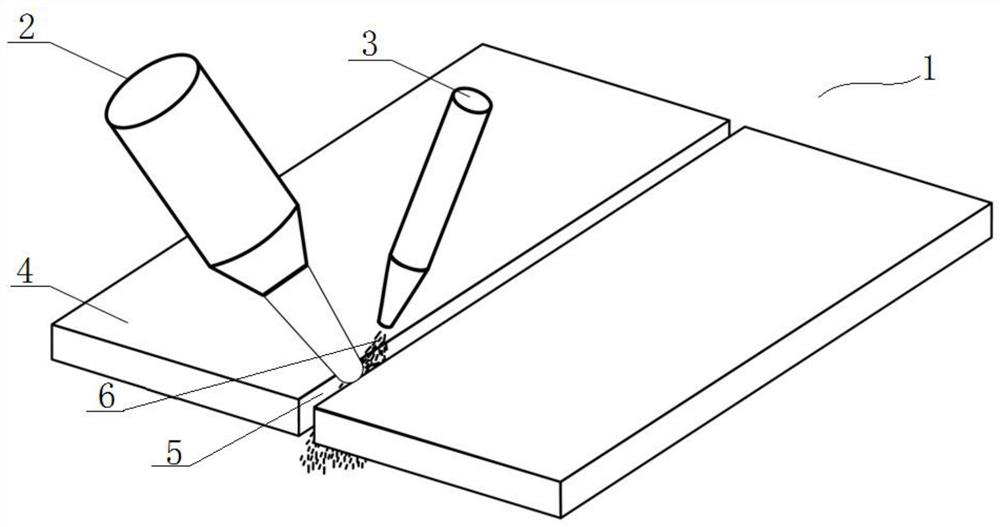

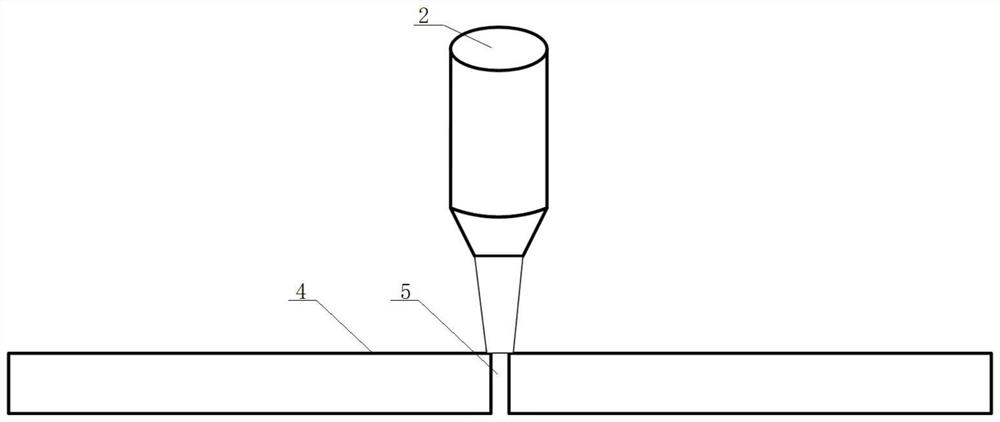

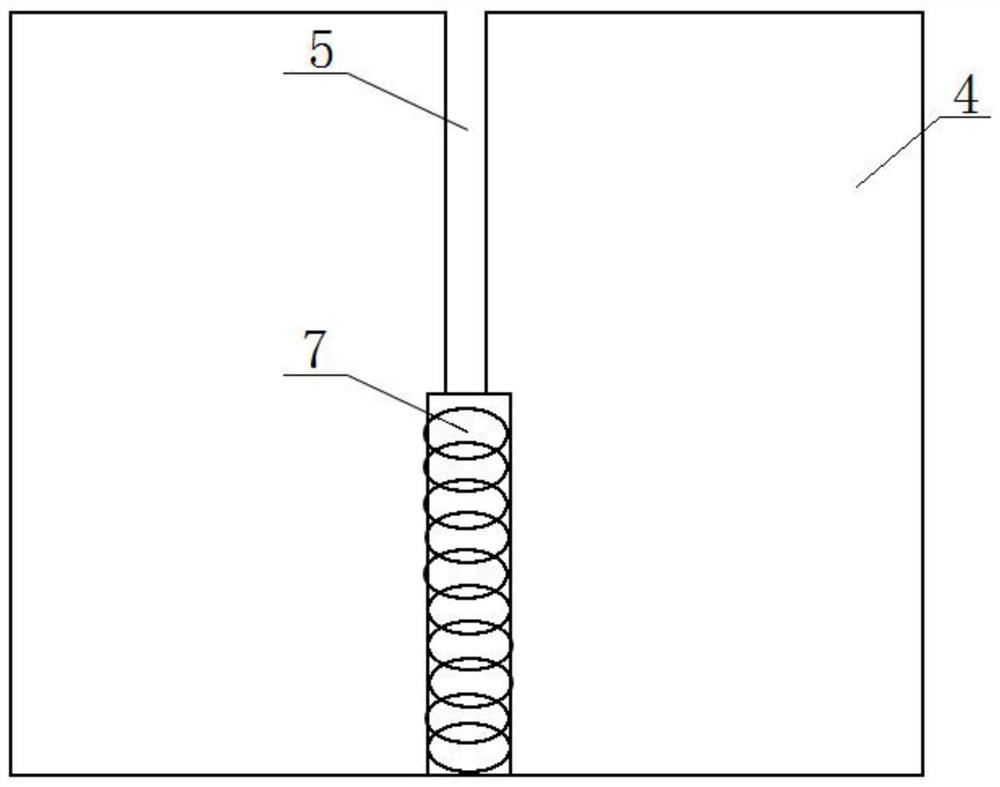

Synchronous powder feeding and laser penetration welding method and system

PendingCN113146043AReduce volume fractionImprove formabilityWorkpiece edge portionsLaser beam welding apparatusWeld seamMicrostructure

The invention discloses a synchronous powder feeding and laser penetration welding method. It is characterized in that to-be-welded plates are arranged at intervals to form an I-shaped groove; when the I-shaped groove is filled with alloy powder, the to-be-welded plates on the two sides and the alloy powder filled into the I-shaped groove are irradiated through light spots formed by laser, so that synchronous melting and common solidification of the to-be-welded plates and the alloy powder filled into the I-shaped groove are achieved, and an in-situ alloying welding seam is formed, and the microstructure of a joint is regulated and controlled through in-situ alloying, so that the volume fraction of the brittle phase Al4C3 is effectively reduced, the formability of the welded joint is optimized, the tensile strength of the welded joint is greatly improved, and the welding efficiency and the joint quality are improved. The invention further provides a synchronous powder feeding laser penetration welding system, the structure is simple and reasonable, the microstructure of the joint can be regulated and controlled through the in-situ alloying, the welding efficiency and the quality of the joint are improved, and practicability is high.

Owner:HUAZHONG UNIV OF SCI & TECH

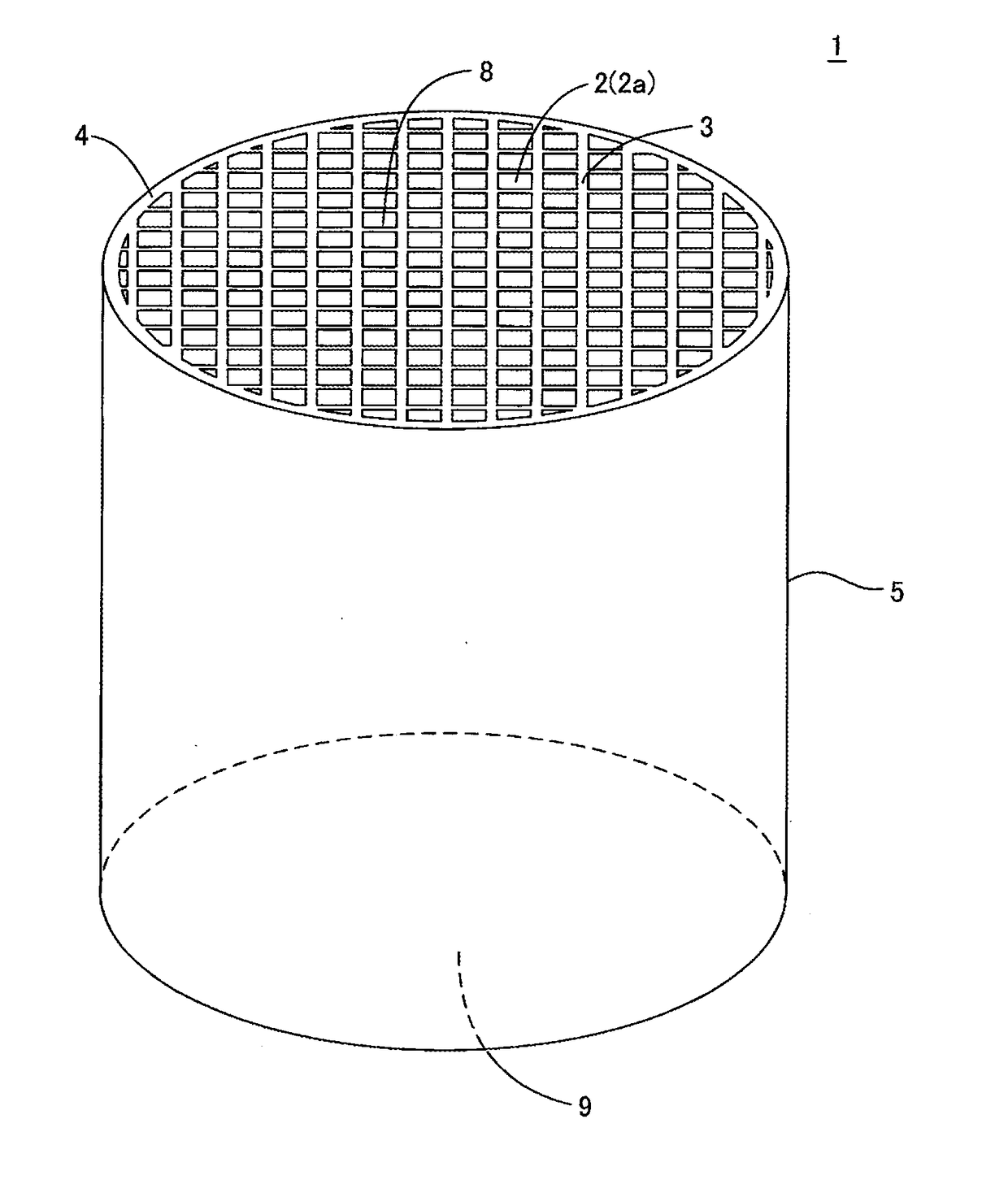

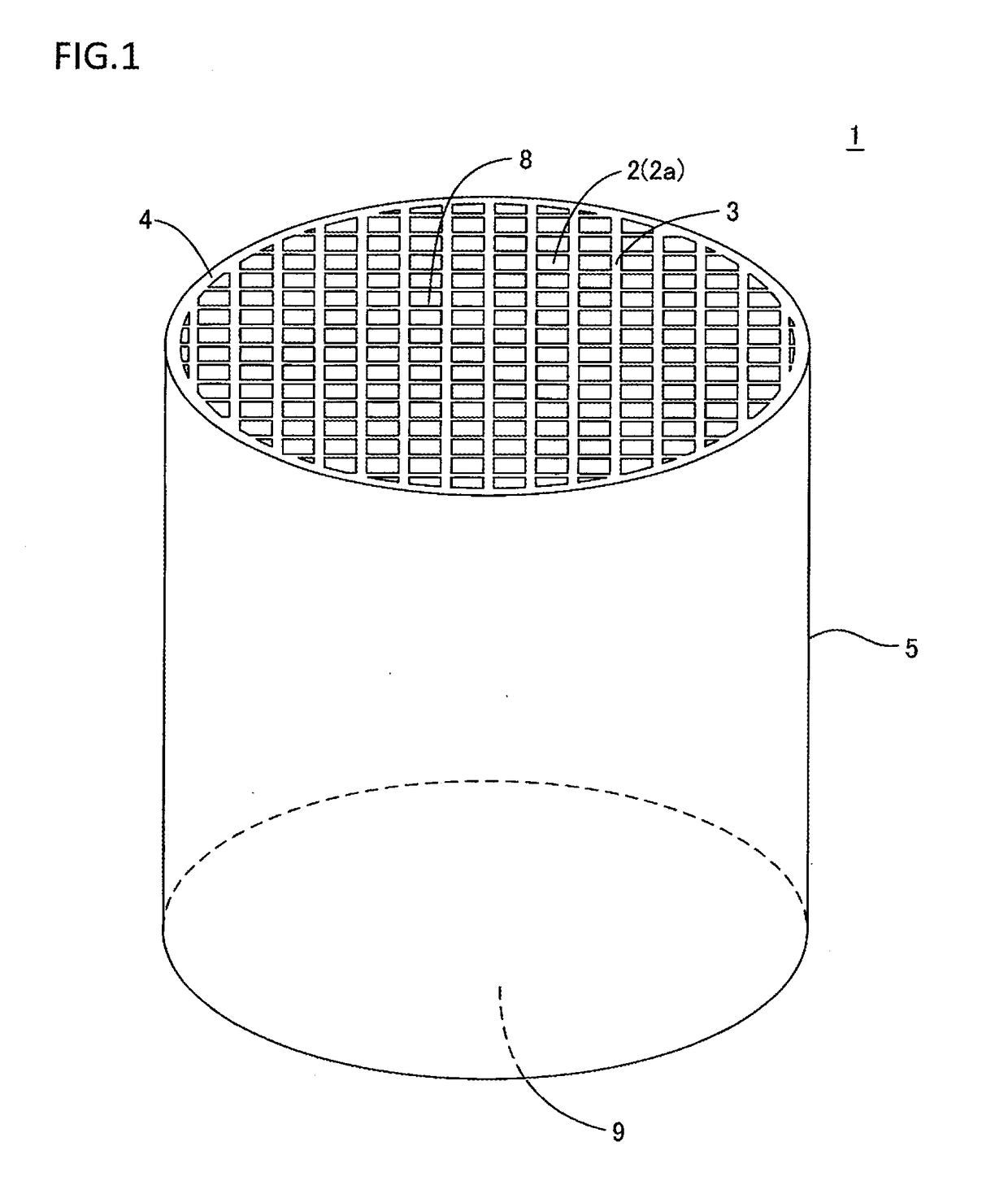

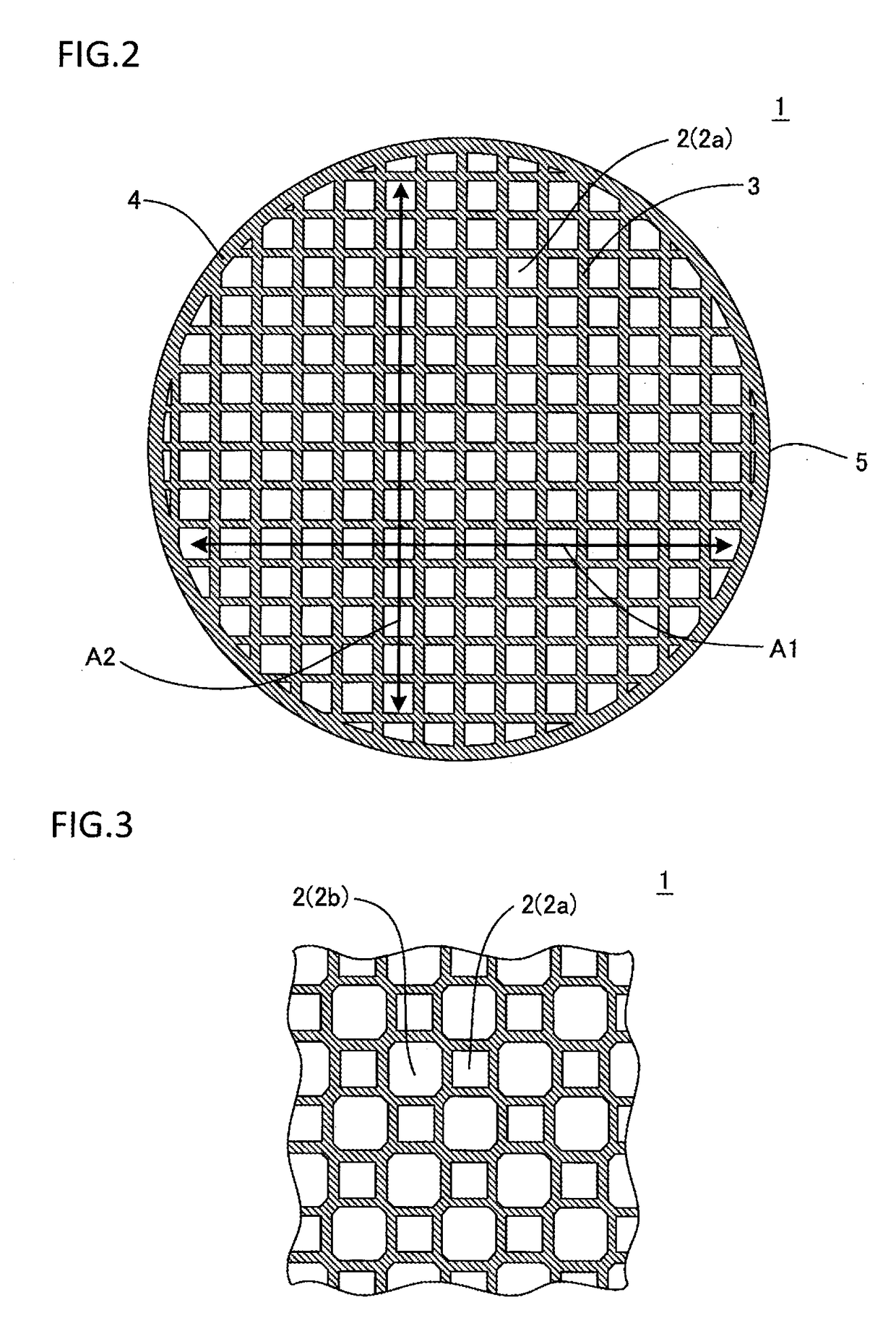

Manufacturing method of honeycomb structure, and honeycomb structure

ActiveUS20180215672A1Improve formabilityProduction cost be not raiseGas treatmentMolecular sieve catalystsCordieriteSlurry coating

A manufacturing method of a honeycomb structure includes a forming step of forming a honeycomb formed body by use of a kneaded material containing a cordierite forming raw material, a slurry coating step of coating a coating layer forming slurry which contains a cordierite forming raw material on four regions in a rotation area when each of two straight lines passing through the center of gravity of the cross section and extending in a diagonal direction of main quadrangular cells is rotated in a range of ±x° of the center of gravity in a circumferential surface, and a firing step of firing the honeycomb formed body on which the slurry is coated. The value x is in a range of 7 to 45, and the slurry is adjusted so that the coating layer has a porosity higher than that of the honeycomb structure body as much as 5% or more.

Owner:NGK INSULATORS LTD

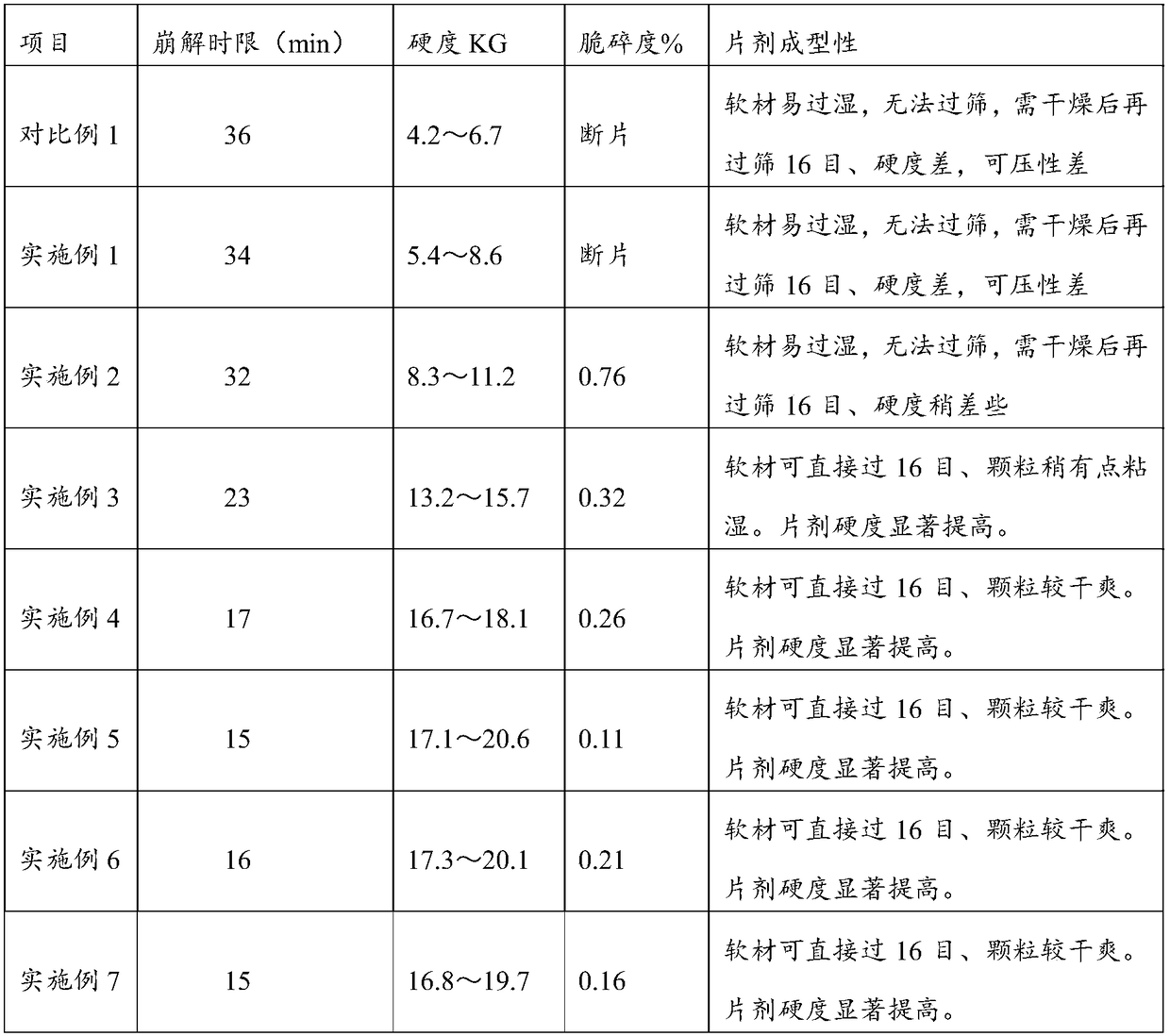

Preparation method of tablet containing grease components at high dosage

ActiveCN108904455AHigh hardnessImprove formabilityPharmaceutical non-active ingredientsPill deliveryChemistryTableting

The invention belongs to the technical field of health-care products, and in particular relates to a preparation method of a tablet containing grease components at a high dosage. The preparation method of the tablet containing the grease components at a high dosage comprises the following steps: 1, mixing a grease active substance, a first part of silicon dioxide and a binding agent and implementing pelletizing, and implementing sieving and drying so as to obtain oil-containing granules, wherein in terms of mass percentage of the grease active substance, grease accounts for 30-50%; and 2, mixing the oil-containing granules, a second part of silicon dioxide, an adsorbent, a filling agent, a disintegrant, functional raw materials and a lubricating substance, and implementing tabletting, so that the tablet containing the grease components at the high dosage is prepared. According to the preparation method of the tablet containing the grease components at the high dosage, technical shortcomings of the prior art that it is difficult to conduct tabletting on grease components at a high dosage can be effectively overcome.

Owner:BY HEALTH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com