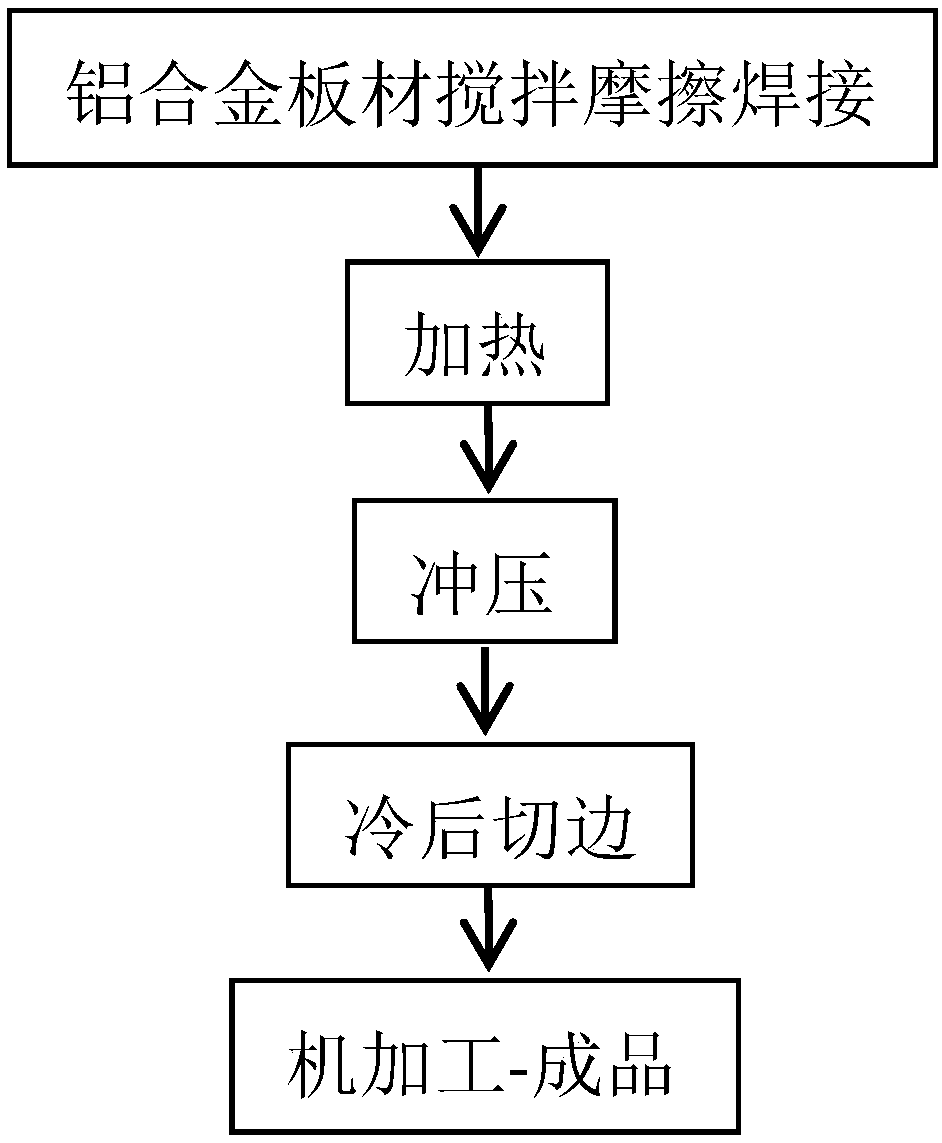

Aluminum alloy splicing welding plate forming technology

A technology for forming and processing aluminum alloy sheets, which is applied in the field of material processing, can solve the problems of AGG, many times of heating, and long holding time in welds, etc., to simplify the traditional hot stamping process, reduce deformation resistance and springback, The effect of improving formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

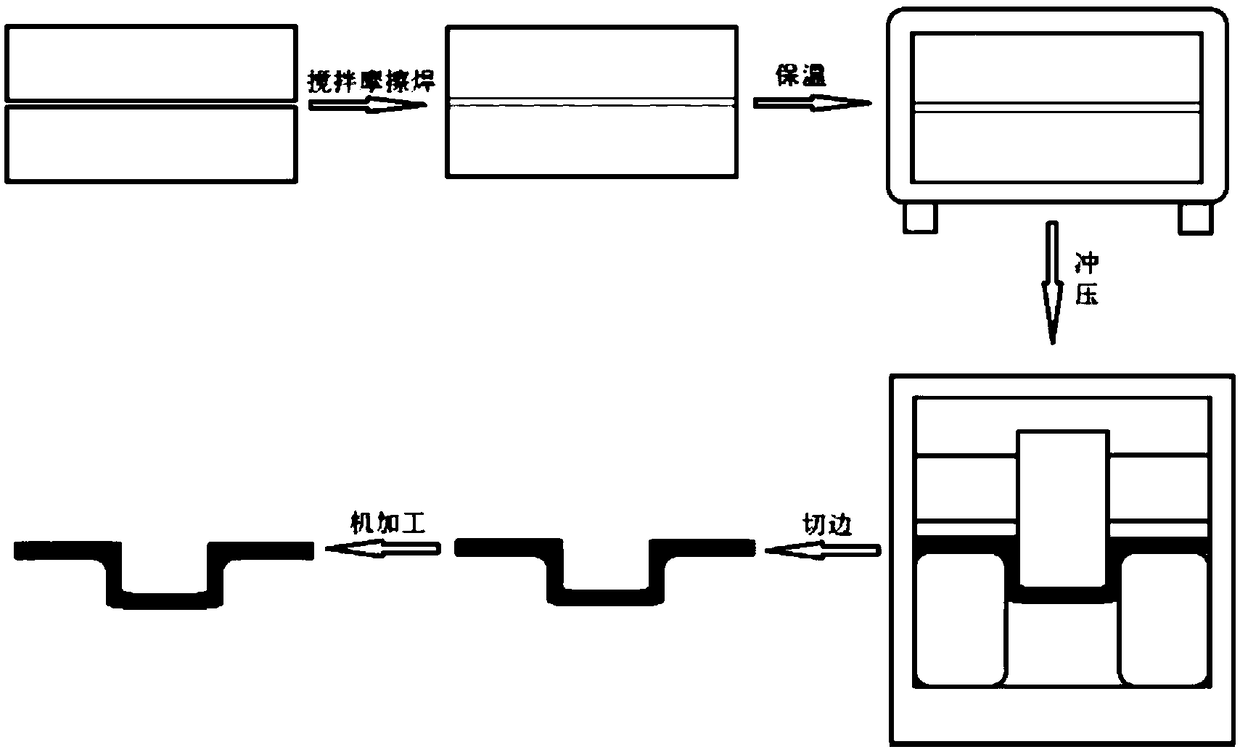

[0044] Tailor welding and forming of 2024 aluminum alloy plates by the present invention comprises the following steps:

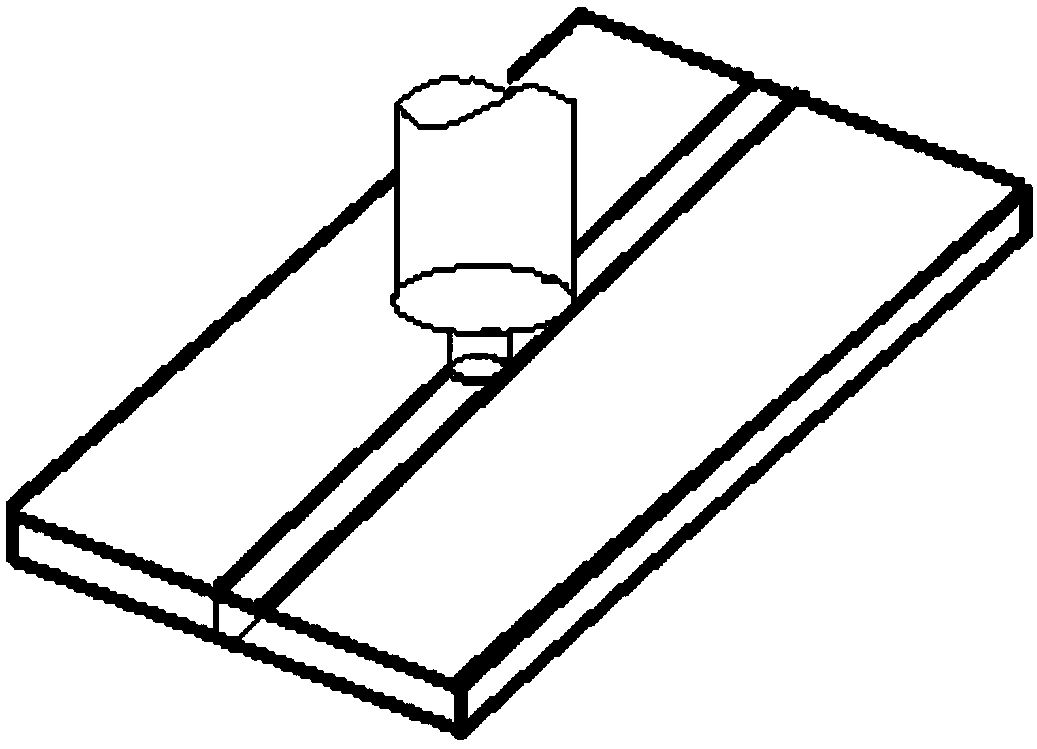

[0045] The first step is to carry out friction stir welding of two 2024 aluminum alloy plates, the welding speed is 100mm / min, and the rotation speed of the stirring head is 800r / min;

[0046]The second step is to put the plates obtained after welding in the first step into the furnace for heat preservation, the temperature is 450°C, and the heat preservation time is 5 minutes;

[0047] The third step is to quickly transfer the heat-preserved tailored welded blank to the stamping die for stamping treatment, and quench and hold the pressure in the die for 10 seconds;

[0048] The fourth step is to perform cold trimming on the stamped sheet;

[0049] The fifth step is to carry out machining to obtain the finished product.

Embodiment 2

[0051] Adopting the present invention to carry out tailor welding forming to 7075 aluminum alloy plate, comprises the following steps:

[0052] The first step is to carry out friction stir welding of two 7075 aluminum alloy plates, the welding speed is 100mm / min, and the rotation speed of the stirring head is 800r / min;

[0053] The second step is to put the plates obtained after welding in the first step into the furnace for heat preservation, the temperature is 300 ° C, and the heat preservation time is 5 minutes;

[0054] The third step is to quickly transfer the heat-preserved tailored welded blank to the stamping die for stamping treatment, and quench and hold the pressure in the die for 10 seconds;

[0055] The fourth step is to perform cold trimming on the stamped sheet;

[0056] The fifth step is to carry out machining to obtain the finished product.

Embodiment 3

[0058] Tailor welding and forming of 7075 and 2024 heterogeneous aluminum alloy plates using the present invention comprises the following steps:

[0059] The first step is to perform friction stir welding of 7075 and 2024 aluminum alloy plates, wherein 7075 is placed on the forward side, 2024 is placed on the backward side, the welding speed is 50mm / min, and the rotation speed of the stirring head is 1000r / min;

[0060] The second step is to put the plates obtained after welding in the first step into the furnace for heat preservation, the temperature is 350°C, and the heat preservation time is 5 minutes;

[0061] The third step is to quickly transfer the heat-preserved tailored welded blank to the stamping die for stamping treatment, and quench and hold the pressure in the die for 10 seconds;

[0062] The fourth step is to perform cold trimming on the stamped sheet;

[0063] The fifth step is to carry out machining to obtain the finished product.

[0064] From the above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com