3D printer for cement product

A technology for 3D printers and cement products, which is used in manufacturing tools, ceramic molding machines, and additive processing. It can solve the problem of not being able to directly print cement products, and improve the formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with accompanying drawing and embodiment:

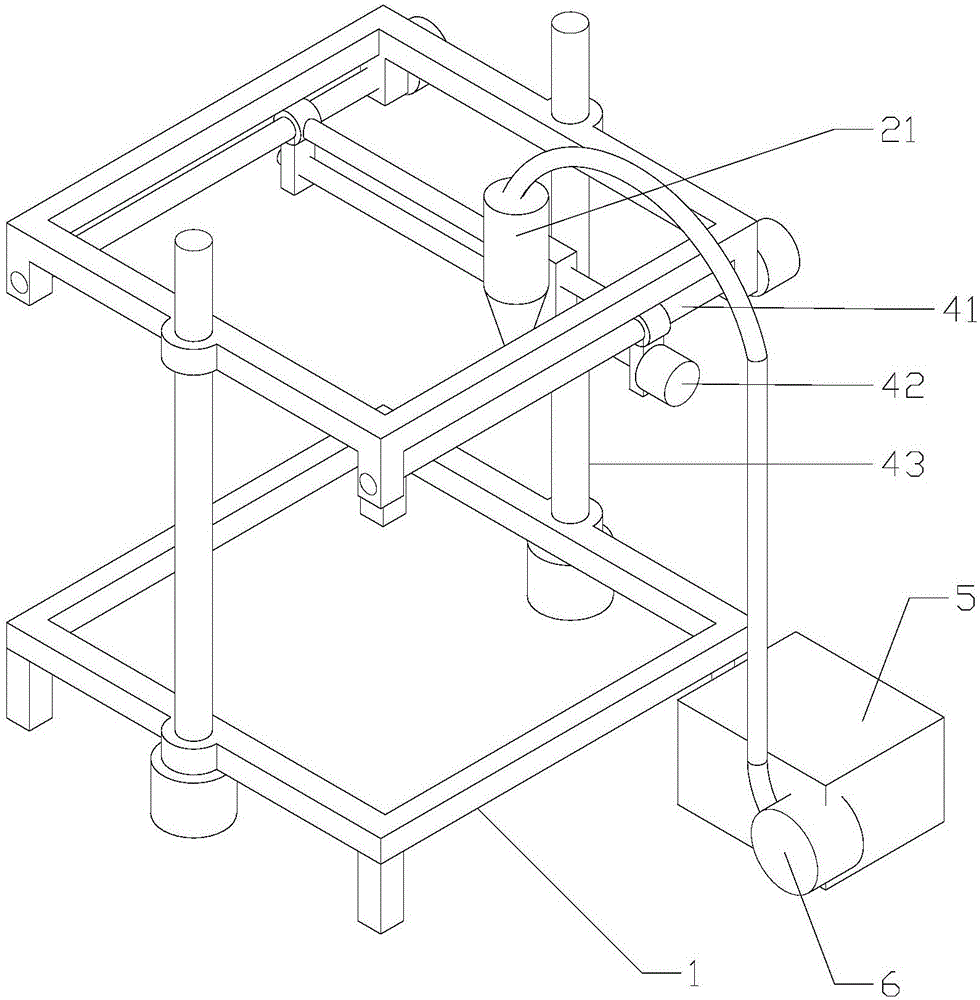

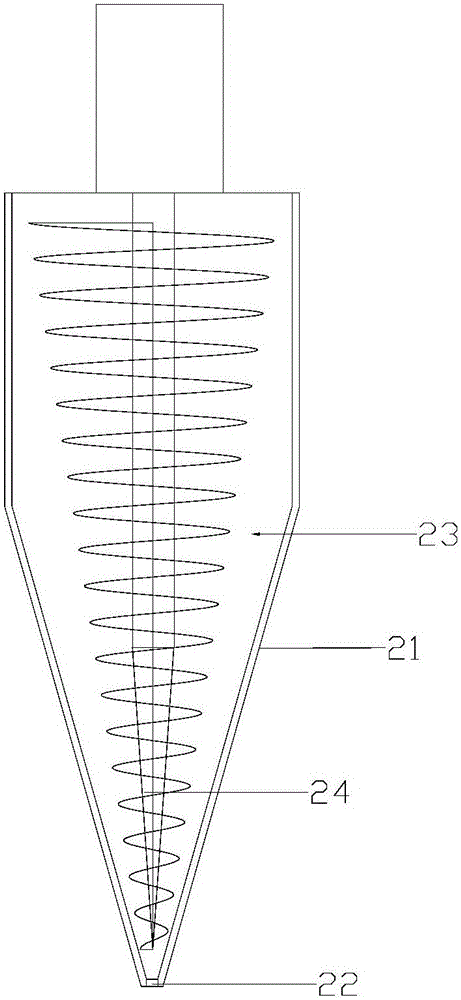

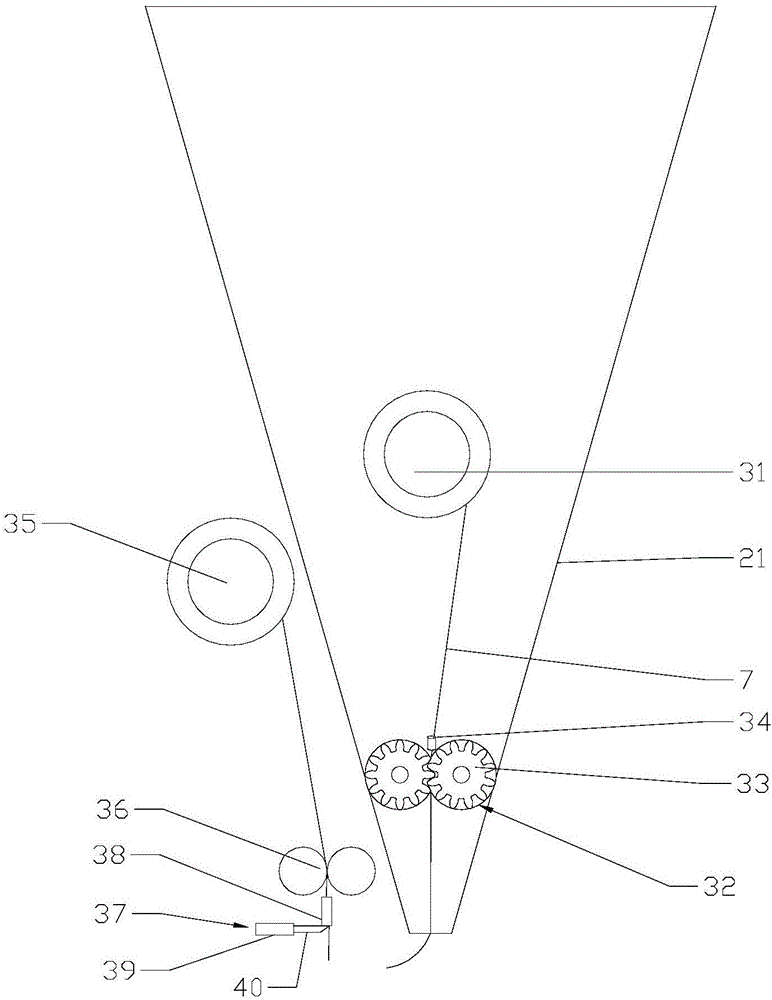

[0017] like Figure 1-3 As shown, the cement product 3D printer in this embodiment includes a frame 1, an extrusion device, a keel filling device, a driving device and a control system, and the driving device is arranged on the frame 1, and the driving device includes an X-axis A screw mechanism 41, a Y-axis screw mechanism 42 and a Z-axis screw mechanism 43, the Z-axis screw mechanism 43 drives the X-axis screw mechanism 41 and the Y-axis screw mechanism 42 to move up and down, and the extrusion device includes The casing 21 containing the cement containing chamber 23, the cement extrusion port 22 arranged at the bottom of the casing 21, the cement extrusion port 22 and the cement containing chamber 23 communicate with each other through a screw pump 24, and the casing 21 It is arranged on the X-axis screw mechanism 41 or the Y-axis screw mechanism 42; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com