Aluminum alloy sheet material for vehicles and preparation method thereof

A technology for aluminum alloy plates and alloy plates, which is applied in the field of aluminum alloys, can solve the problems of increasing raw material costs and equipment investment costs, unreasonable production process design, and large production energy consumption, so as to achieve high production efficiency, reduce raw material costs, and improve production efficiency. The effect of recycling waste aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

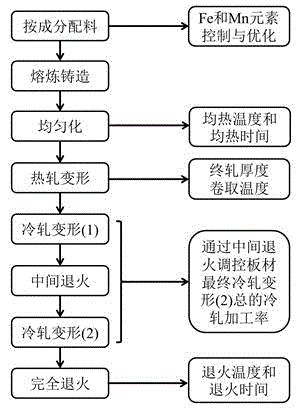

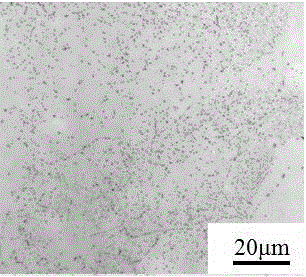

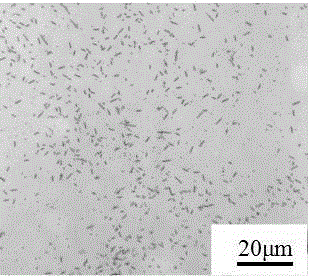

[0036] For reference example alloy ingot 4F171 and alloy ingot 1E298 of the present invention, cut the ingot sample at 1 / 4 of the thickness direction of the ingot after sawing and pinching the head and tail to carry out the laboratory exploration of the homogenization process, and use the air circulation furnace to carry out the uniform process heat treatment , the heating rate is 15-40 ℃ / h, water quenching after soaking and heat preservation. Using an optical microscope, under the same corrosion conditions, the soaked Al 6 (FeMn) dispersed phase for tissue observation. The soaking system of 4F171 ingot samples is 480°C / 2h and 480°C / 24h, and the metallographic photos are respectively figure 2 and image 3 . While the soaking system of 1E298 ingot samples is 480°C / 2h, 530°C / 2h, 530°C / 4h and 530°C / 8h, the Al 6 (FeMn) dispersed phase metallographic structure observation results are as follows Figure 4-7 shown.

Embodiment 2

[0038] Using the alloy ingot 1E298 of the present invention, after sawing and milling, use a pusher heating furnace to perform homogenization treatment. The treatment process is: differential temperature heating, ingot heating rate 15-40 ℃ / h, homogenization temperature 530 ℃, heat preservation 2 After 2 hours, the furnace is cooled to the hot rolling start temperature of 470-490 ℃, and the heat preservation is 2 hours for direct hot rolling. The 1+4 hot continuous rolling production line is used for hot rolling of the plate, and the hot rough rolling is carried out to the thickness of the middle plate. The thickness of the continuous finish rolling plate is 5.5 mm, and the coiling temperature of the plate is 339-350 ℃. After the hot-rolled coils were cooled to room temperature, they were cold-rolled and deformed to a thickness of 0.8 mm by a single-stand 6-high CVC cold-rolling mill. The air circulation furnace was used to explore the complete annealing process. The treatment ...

Embodiment 3

[0040] The alloy ingot 4F171 of the reference example was homogenized by a pusher heating furnace after sawing and milling. The treatment process was: differential temperature heating, the ingot heating rate was 15-40 ℃ / h, the homogenization temperature was 480 ℃, and the heat preservation was 2 h Afterwards, it is directly hot-rolled, and the 1+4 hot continuous rolling production line is used for hot-rolling of the plate. The thickness of the middle plate is 28 mm, and the thickness of the plate is 6.0 mm after 4 consecutive hot-rolled finishes. The coiling temperature of the plate is 337-349 ℃ . After the hot-rolled coils were cooled to room temperature, they were cold-rolled and deformed to a thickness of 0.8 mm by a single-stand 6-high CVC cold-rolling mill. A conventional horizontal annealing furnace is used for complete annealing, and the treatment process is as follows: the heating and cooling rate of the coil is 15-40 °C / h, the complete annealing temperature is 330 °C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com