High-corrosion-resistant magnesium-aluminum-zinc alloy plated steel plate, and two-step annealing preparation method and application thereof

A technology of alloy coating and high corrosion resistance, which is applied in the direction of metal material coating process, coating, manufacturing tools, etc., to achieve the effect of coarse grain size, fast heating rate and uniform recrystallization structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The embodiment of the present invention provides a two-step annealing preparation method for a high corrosion-resistant magnesium-aluminum-zinc alloy coated steel plate, comprising:

[0035] The preliminary formed steel plate after continuous casting and rolling is subjected to bell furnace pre-annealing, electrolytic degreasing, vertical annealing furnace annealing and surface galvanizing in sequence.

[0036] The two-step annealing preparation method of high corrosion-resistant magnesium-aluminum-zinc alloy coated steel plate provided by the embodiment of the present invention adopts BAF bell-type furnace pre-annealing + vertical annealing furnace annealing after continuous casting and rolling, and the bell-type annealing furnace has a slow heating rate , the steel strip has the characteristics of small superheat during the heating and cooling process, and the vertical annealing furnace has the characteristics of fast heating rate and high heating temperature. The comb...

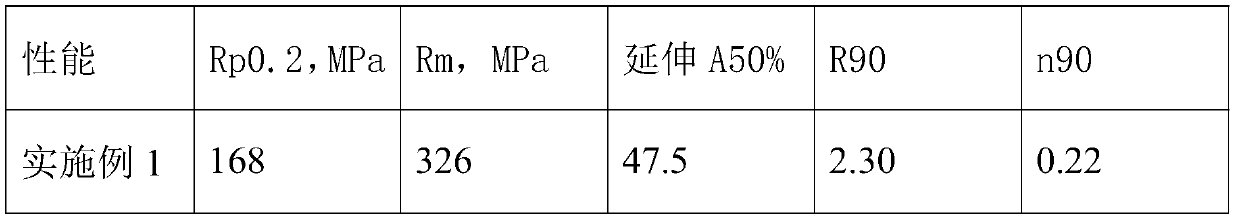

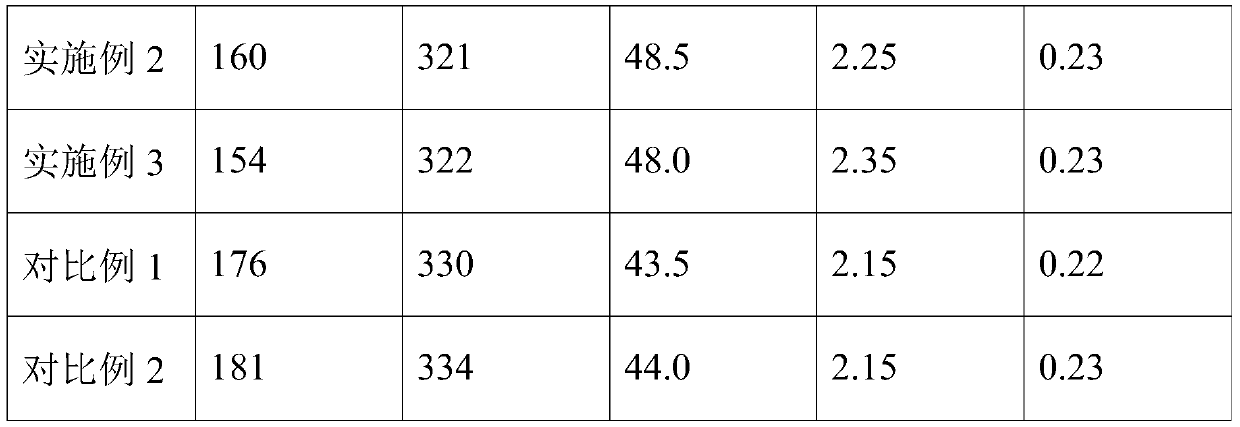

Embodiment 1

[0061] The embodiment of the present invention provides a two-step annealing preparation method of high corrosion resistance magnesium-aluminum-zinc alloy coated steel plate, the specific process is as follows:

[0062] Blast furnace molten iron smelting, converter molten steel smelting, LF molten steel refining treatment, RH molten steel refining treatment, CSP thin slab continuous casting and rolling, pickling cold continuous rolling, bell furnace pre-annealing, electrolytic degreasing, vertical annealing furnace annealing, zinc pot coating Plating, post-plating cooling, skin pass and straightening, passivation, drying, electrostatic oiling and coiling.

[0063] After RH molten steel refining treatment, the refined substrate is obtained, and the chemical composition is as follows in terms of mass percentage: [C]: 0.0050Wt%; [Si]: 0.18Wt%; [Mn]: 0.17Wt%; [P]: 0.0150Wt% ; [S]: 0.0100Wt%; [Als]: 0.0462Wt%; [Ti+Nb]: 0.0775Wt%.

Embodiment 2

[0072] The embodiment of the present invention provides a two-step annealing preparation method of high corrosion resistance magnesium-aluminum-zinc alloy coated steel plate, the specific process is as follows:

[0073] Blast furnace molten iron smelting, converter molten steel smelting, LF molten steel refining treatment, RH molten steel refining treatment, CSP thin slab continuous casting and rolling, pickling cold continuous rolling, bell furnace pre-annealing, electrolytic degreasing, vertical annealing furnace annealing, zinc pot coating Plating, post-plating cooling, skin pass and straightening, passivation, drying, electrostatic oiling and coiling.

[0074] After RH molten steel refining treatment, the refined substrate is obtained, and the chemical composition is as follows in terms of mass percentage: [C]: 0.0047Wt%; [Si]: 0.20Wt%; [Mn]: 0.20Wt%; [P]: 0.0099Wt% ; [S]: 0.0085Wt%; [Als]: 0.030Wt%; [Ti+Nb]: 0.088Wt%.

[0075] CSP thin slab continuous casting and rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com