Method for reducing sigma phase precipitation and improving intergranular corrosion resistance of 6Mo superaustenitic stainless steel by adding B and Ce

A technology of austenitic stainless steel and compound addition, which is applied in the field of preparation and application of super austenitic heat-resistant steel, can solve the problems of intergranular corrosion of materials, achieve the effect of reducing sensitivity and enhancing formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Preparation of B, Ce microalloyed super austenitic stainless steel

[0021] Adopt 50kg induction furnace to smelt the super austenitic stainless steel of the present invention, mark the furnace number as 1-3#, smelt the contrast sample that does not add B and Ce simultaneously, concrete steps are as follows:

[0022] (1) Smelt in a 50Kg vacuum induction furnace according to the alloy composition ratio shown in Table 1, and cast it into a 120×100×500mm ingot in a vacuum state, and take it out of the mold after the ingot is air-cooled;

[0023] (2) Use a resistance heating furnace to keep the ingot at 1200°C for 16 hours, air-cool it to room temperature, raise the temperature of the ingot to 1250°C with the furnace and hold it for 30 minutes, and then roll it on a Φ550 hot rolling mill to a thickness of 12mm steel plate.

[0024] Table 1: Composition List

[0025]

Embodiment 2

[0026] Example 2: B and Ce-improved 6Mo-type super austenitic heat-resistant steel precipitate distribution in as-rolled samples

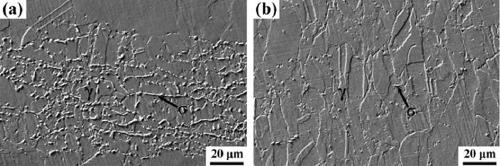

[0027] Cut 15mm × 15mm samples from the super austenitic stainless steel plate prepared in Example 1, grind, polish and metallographically corrode, after adding B and Ce, the Sigma phase in the super austenitic heat-resistant steel hot-rolled sample The content is significantly reduced, and the precipitated phase is more dispersed. Such as figure 1 As shown, the addition of 0.002% B and 0.006% Ce (No. 2 sample) significantly reduces the Sigma phase content in the hot-rolled microstructure of the comparison sample. The super austenitic stainless steel with combined addition of B and Ce can significantly inhibit the precipitation of the second phase compared with the sample without addition.

Embodiment 3

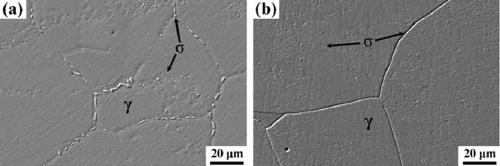

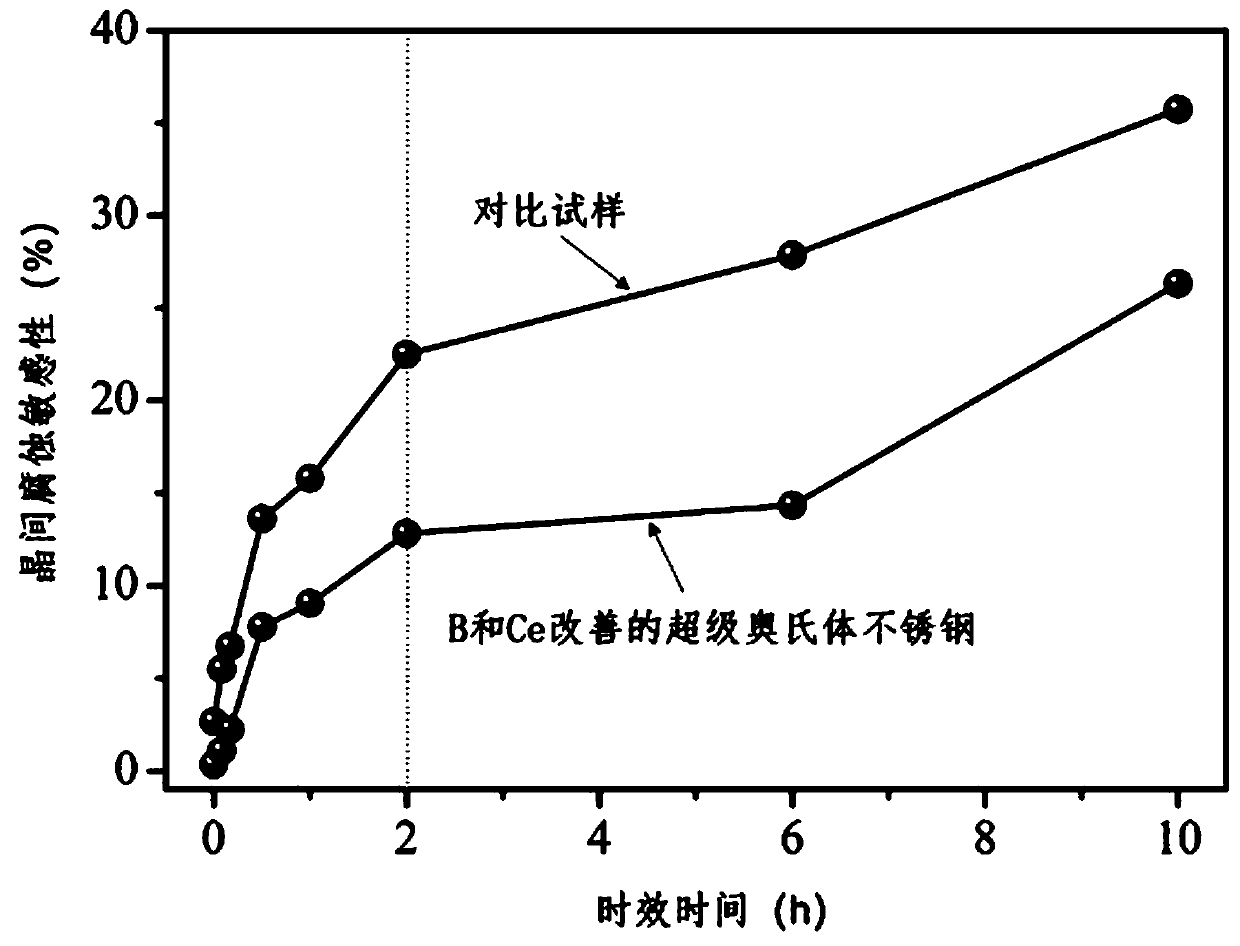

[0028] Example 3: Precipitated phase distribution of 6Mo-type super austenitic heat-resistant steel improved by B and Ce after aging

[0029] Solution treatment: cut a 15mm×15mm sample from the super austenitic stainless steel sheet prepared in Example 1, heat up the box furnace to 1220°C, place the sample in a box furnace at 1220°C for 1 hour and heat it for solid solution treatment for 1 hour, then quickly Water cooling; all solid solution treatments are carried out in an inert atmosphere environment, and then the box furnace is heated to 950°C, and then the sample is placed in the box furnace at 950°C for 10min, 30min, 1h, and 10h for aging treatment After water cooling, all aging treatments are carried out in an inert atmosphere environment.

[0030] After grinding, polishing and corrosion, using metallographic microscope, scanning electron microscope and transmission electron microscope to analyze and characterize, it can be found that as the aging time prolongs in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com