Environmentally-friendly lead-free free-machining zinc white copper and preparation method thereof

A free-cutting, zinc-nickel-nickel technology, which is applied in the field of free-cutting zinc-nickel-nickel alloy and its preparation, can solve problems such as poor interdiffusion ability of atoms, weakening of grain boundary atom bonding, and reduction of copper alloy grain boundary energy, so as to improve material performance and The uniformity of the structure, the refinement of the grain, and the effect of improving the cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with specific embodiment:

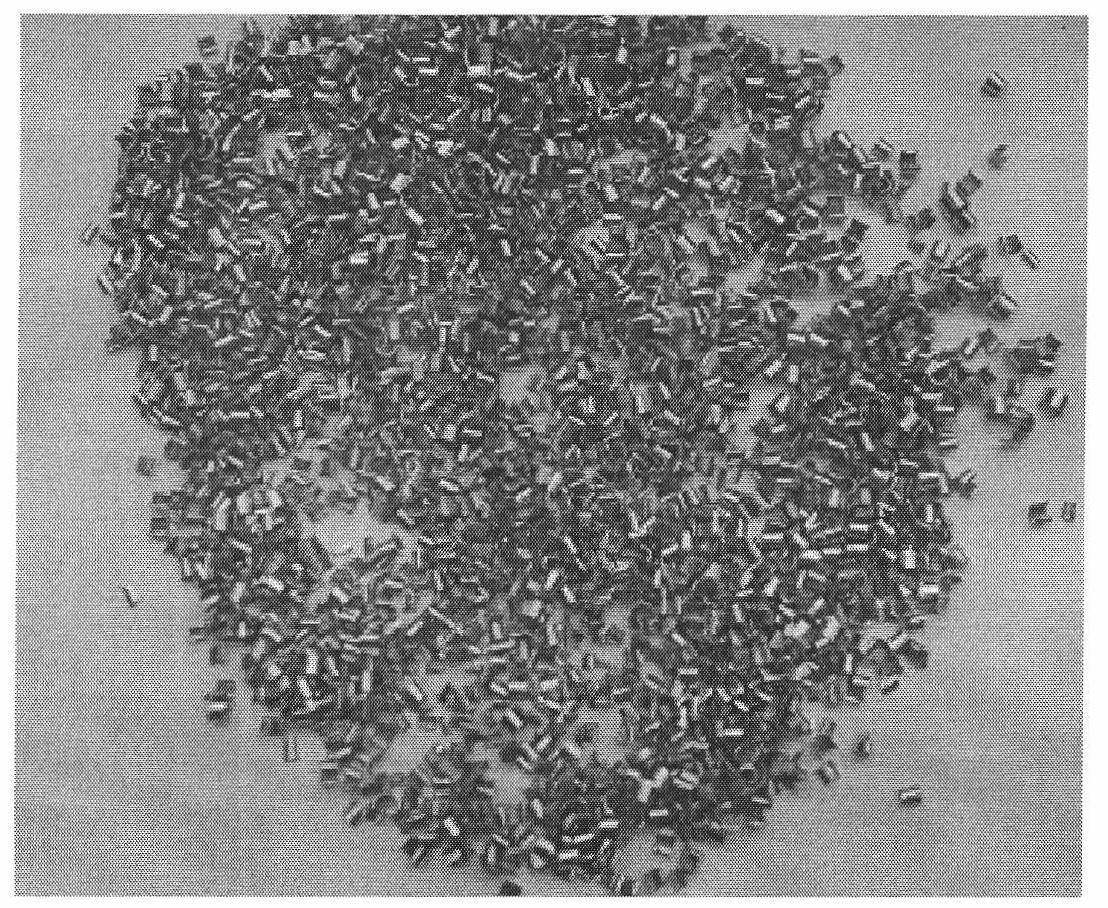

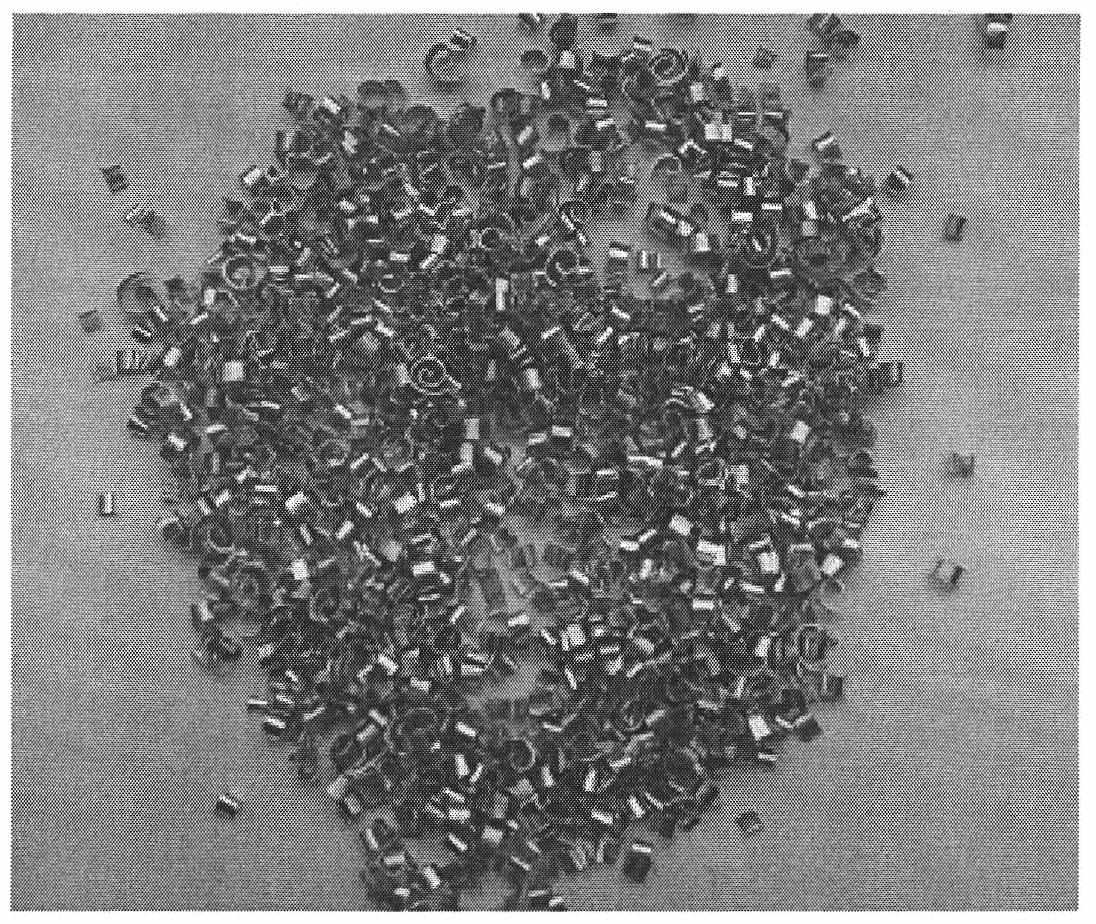

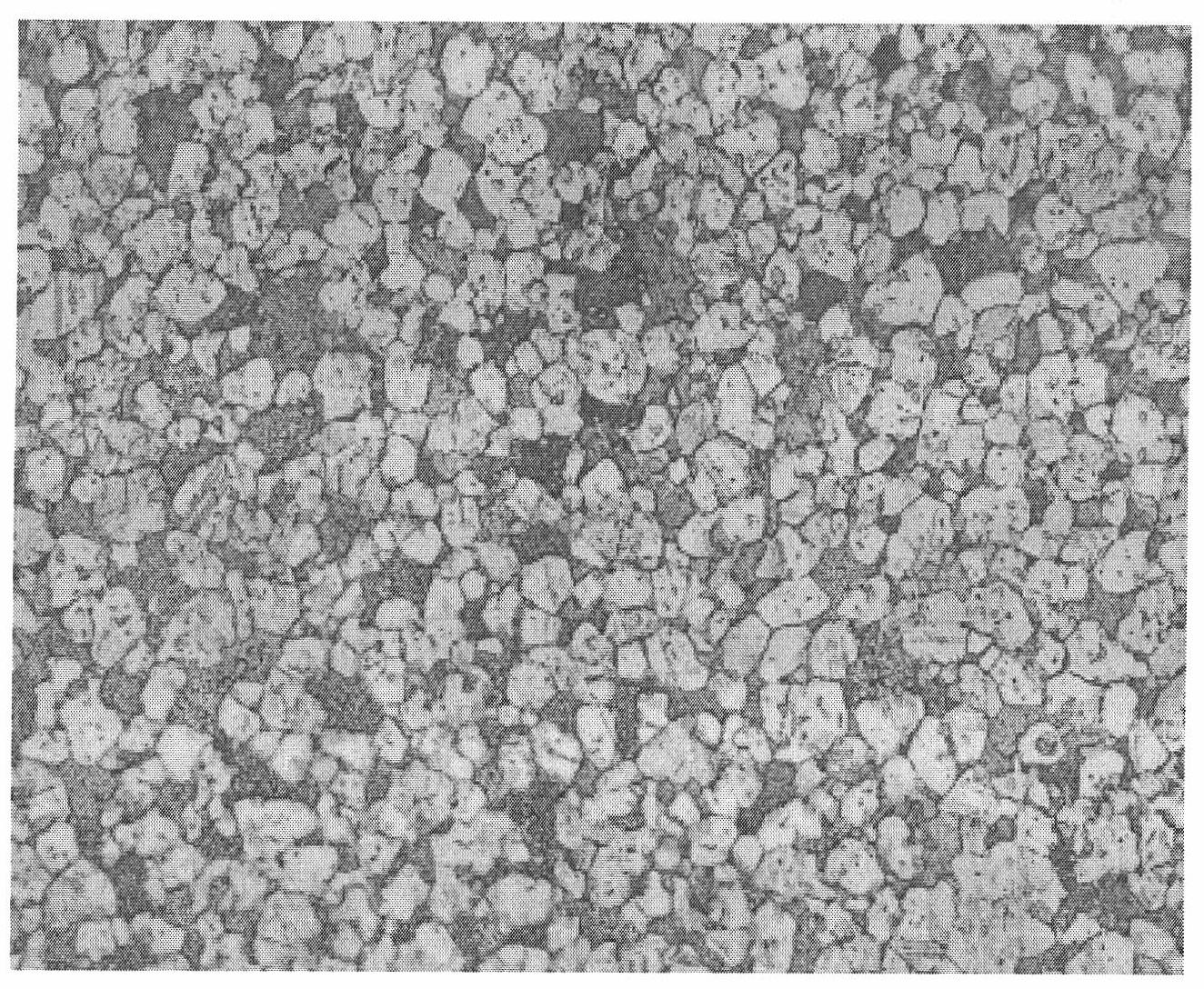

[0026] Examples 1 to 16 of the present invention (the specific alloy composition and properties are as shown in Table 1) adopt conventional copper, zinc, nickel, silicon, phosphorus and other elements as raw materials, and under industrial scale conditions, they are melted by an induction furnace, and the smelting temperature 1280℃~1350℃, and then carry out horizontal continuous casting into lead-free zinc white copper billet. The casting temperature is 1150℃~1230℃. If hot extrusion is required, the extrusion temperature is 750℃~850℃, and then cold working , the cold processing rate is between 0 and 50%, and the final heat treatment is performed at a temperature of 580°C to 700°C and a heat treatment time of 2.5h to 4.5h, so as to prepare products of different specifications and states.

[0027] The process route of lead-free free-cutting zinc-nickel-nickel copper of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com