Dust-removing antistatic filter material and preparation method thereof

An antistatic and filter material technology, which is applied in separation methods, chemical instruments and methods, and filtration separation, can solve the problems of complex structure of antistatic filter materials, unfavorable gas circulation, and reduced dust removal effect, so as to achieve convenient dust removal efficiency and reduce dust removal. The effect of small resistance and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

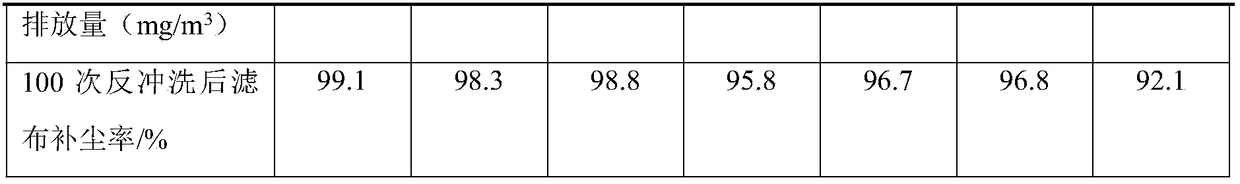

Examples

Embodiment 1

[0028] Step 1: The polytetrafluoroethylene fibers and glass fibers with a volume ratio of 8:2 are carded, twisted and plyed into warps with a wire diameter of 0.15-0.2 mm; the polyester fibers with a volume ratio of 8:2 and metal conductive fibers are respectively carded and then twisted and woven into weft threads with a wire diameter of 0.2-0.3mm;

[0029] Step 2: Weave the warp and weft threads obtained in step 1 through a loom to obtain a base fabric, the warp thread density is 15-20 threads / cm, and the weft thread density is 10-15 threads / cm;

[0030] Step 3: 30 parts of polyurethane, 35 parts of silicone resin, 15 parts of perfluoroalkyl ethyl acrylate, 6 parts of activated carbon, 4 parts of magnesium hydroxide, 3 parts of antimony oxide, tert-butyl hydroquinone derivative ( 7 parts of DTBHO) and 14 parts of silicone oil were mixed and stirred evenly, heated to 50°C and kept warm, and the base cloth obtained in step 2 was soaked for 5 hours;

[0031] Step 4: Take out t...

Embodiment 2

[0035] Step 1: The polytetrafluoroethylene fibers and glass fibers with a volume ratio of 8:2 are carded, twisted and plyed into warps with a wire diameter of 0.15-0.2 mm; the polyester fibers with a volume ratio of 8:2 and metal conductive fibers are respectively carded and then twisted and woven into weft threads with a wire diameter of 0.2-0.3mm;

[0036] Step 2: Weave the warp and weft threads obtained in step 1 through a loom to obtain a base fabric, the warp thread density is 15-20 threads / cm, and the weft thread density is 10-15 threads / cm;

[0037] Step 3: 35 parts of polyurethane, 40 parts of silicone resin, 20 parts of perfluoroalkyl ethyl acrylate, 7 parts of activated carbon, 5 parts of magnesium hydroxide, 4 parts of antimony oxide, tert-butylhydroquinone derivative ( 8 parts of DTBHO) and 15 parts of silicone oil were mixed and stirred evenly, heated to 60°C and kept warm, and the base cloth obtained in step 2 was soaked for 3 hours;

[0038] Step 4: Take out th...

Embodiment 3

[0042] Step 1: The polytetrafluoroethylene fibers and glass fibers with a volume ratio of 7:3 are carded, twisted and plyed into warps with a wire diameter of 0.15-0.2mm; the polyester fibers with a volume ratio of 7:3 and metal conductive fibers are respectively carded and then twisted and woven into weft threads with a wire diameter of 0.2-0.3mm;

[0043] Step 2: Weave the warp and weft threads obtained in step 1 through a loom to obtain a base fabric, the warp thread density is 15-20 threads / cm, and the weft thread density is 10-15 threads / cm;

[0044]Step 3: 20 parts of polyurethane, 20 parts of silicone resin, 10 parts of perfluoroalkyl ethyl acrylate, 5 parts of activated carbon, 3 parts of magnesium hydroxide, 2 parts of antimony oxide, tert-butylhydroquinone derivative ( 5 parts of DTBHO) and 10 parts of silicone oil were mixed and stirred evenly, heated to 40°C and kept warm, and the base cloth obtained in step 2 was soaked for 6 hours;

[0045] Step 4: Take out the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com