Preparation method of anti-ultraviolet anti-static fabric

An anti-ultraviolet and anti-static technology, applied in the direction of electrospinning, filament/thread forming, non-woven fabrics, etc., can solve the problems of weakening and disappearing of anti-ultraviolet and anti-static properties, to speed up the dissipation of static electricity, reduce Remarkable effect of specific resistance and antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

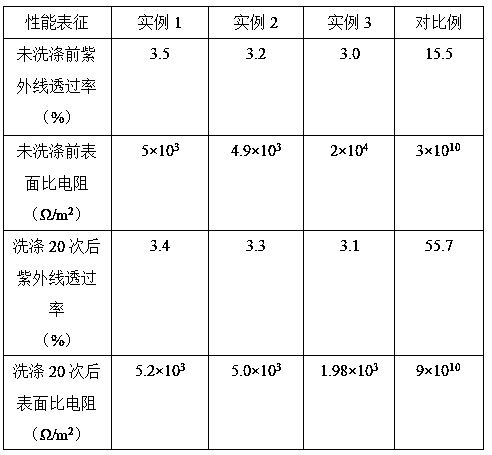

Examples

Embodiment Construction

[0020] In parts by weight, weigh 20-30 parts of polyvinyl alcohol, 50-60 parts of deionized water, 10-15 parts of ATO powder, 8-12 parts of zinc oxide, and 1-5 parts of sodium lauryl sulfate, Mix polyvinyl alcohol and deionized water, stir for 2-3 hours at a temperature of 85-95°C and a stirring speed of 100-200r / min to obtain a mixed solution, cool to room temperature, add ATO powder, zinc oxide and dodecyl Sodium sulfate, continue to stir for 30-50 minutes, and ultrasonically disperse for 10-15 minutes to obtain a spinning solution; carry out electrospinning on the spinning solution, with a spinning voltage of 60-70kV, a generator speed of 10-20r / min, and a spinning distance of 180 ~200mm, the speed of the receiver is 1~5m / min, using non-woven fabric as the receiving source to obtain the fiber film, heat-treating the fiber film at a temperature of 200-220°C for 10-20min, and plasma treatment at 200-220W for 1 ~3min to obtain the modified fiber membrane, put the modified fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com