Method for preparing anti-aging plastic woven bag ribbon-like filament

A plastic woven bag, anti-aging technology, applied in the field of woven bags, can solve the problem of insignificant anti-aging performance, achieve excellent anti-ultraviolet aging performance, good anti-aging performance, and reduce surface polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

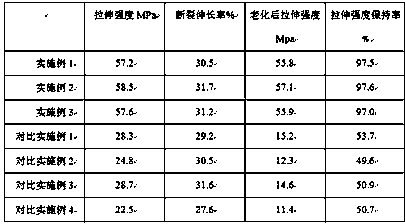

Examples

Embodiment 1

[0019] A preparation method for anti-aging plastic woven bag flat wire, comprising the following steps:

[0020] (1) Take 20 parts by weight of high-density polyethylene, 10 parts of modified aluminum borate whiskers, and 3 parts of polyethylene wax, heat and melt at 138 ° C, stir at 150 rpm for 20 minutes, extrude and granulate, and obtain modified High-density polyethylene masterbatch;

[0021] (2) Put 20 parts of modified high-density polyethylene masterbatches obtained in step (1) together with 40 parts of isotactic polypropylene, 50 parts of isotactic polyethylene, and 10 parts of polyvinyl chloride into a high-speed mixer. , Stir at 1500rpm for 5 minutes, add 10 parts of trimethylsiloxysilicate, 5 parts of microcrystalline wax, 15 parts of modified composite fiber, 3 parts of anti-aging agent, continue stirring for 5 minutes, then heat up to 160 ° C for melting , after being extruded into a film, cooled, and cut into embryo filaments, it is stretched into flat filaments...

Embodiment 2

[0030] A preparation method for anti-aging plastic woven bag flat wire, comprising the following steps:

[0031] (1) Take 25 parts by weight of high-density polyethylene, 12 parts of modified aluminum borate whiskers, and 4 parts of polyethylene wax, heat and melt at 140 ° C, stir at 180 rpm for 25 minutes, extrude and granulate, and obtain modified High-density polyethylene masterbatch;

[0032] (2) Put 25 parts of modified high-density polyethylene masterbatches obtained in step (1) together with 50 parts of isotactic polypropylene, 60 parts of isotactic polyethylene, and 12 parts of polyvinyl chloride into a high-speed mixer. , Stir at 1550rpm for 8 minutes, add 13 parts of trimethylsiloxysilicate, 8 parts of microcrystalline wax, 20 parts of modified composite fiber, 4 parts of anti-aging agent, continue stirring for 7 minutes, then heat up to 165 ° C for melting , after being extruded into a film, cooled and cut into embryo filaments, it is stretched into flat filaments ...

Embodiment 3

[0041] A preparation method for anti-aging plastic woven bag flat wire, comprising the following steps:

[0042] (1) Take 30 parts by weight of high-density polyethylene, 15 parts of modified aluminum borate whiskers, and 4 parts of polyethylene wax, heat and melt at 143 ° C, stir at 200 rpm for 30 minutes, extrude and granulate, and obtain modified High-density polyethylene masterbatch;

[0043] (2) Put 30 parts of modified high-density polyethylene masterbatch obtained in step (1) into a high-speed mixer together with 60 parts of isotactic polypropylene, 80 parts of isotactic polyethylene, and 15 parts of polyvinyl chloride. , Stir at 1600rpm for 10min, add 15 parts of trimethylsiloxysilicate, 10 parts of microcrystalline wax, 30 parts of modified composite fiber, 6 parts of anti-aging agent, continue stirring for 10 minutes, then heat up to 170°C for melting , after being extruded into a film, cooled and cut into embryo filaments, it is stretched into flat filaments throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com