Antistatic protective clothing fabric and preparation method thereof

A technology of antistatic protection and antistatic agent, which is applied in the field of protective clothing, can solve problems such as easy interference with electronic equipment, failure of electronic equipment, and impact on work, and achieve the effects of accelerating dissipation, improving wearing comfort, and improving antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

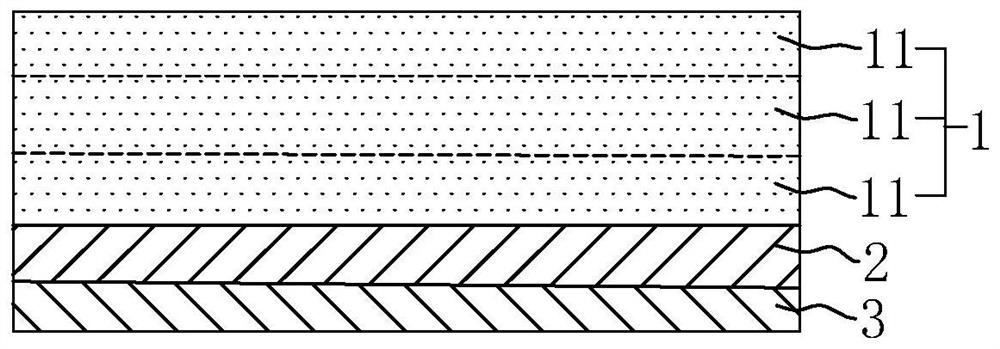

[0044] An antistatic protective clothing fabric, as shown in the figure, sequentially includes a non-woven base layer 1, a partition layer 2 and a film layer 3 from the inside to the outside. The unit area weight of base layer 1 is 41g / m 2 , the partition layer 2 is formed by interweaving blended yarns and organic conductive fibers, the content of organic conductive fibers in the partition layer 2 is 0.5%, and the weight per unit area of the partition layer 2 is 9g / m 2 , the film layer 3 is a TPEE breathable film.

[0045] Wherein, the resin that makes nonwoven fabric 11 is polypropylene resin, and the mass ratio of each component in nonwoven fabric 11 is ordinary fiber: cotton: ice silk=4:1:2, and the specific surface area of nonwoven fabric 11 is 85m 2 / g, the porosity is 80%.

[0046]In addition, an antistatic agent and a moisture-wicking agent are attached to the base layer 1 of the non-woven material. The antistatic agent is polyoxyethylene laurate. The antistatic a...

Embodiment 2

[0051] An antistatic protective clothing fabric, as shown in the figure, sequentially includes a non-woven base layer 1, a partition layer 2 and a film layer 3 from the inside to the outside. The unit area weight of base layer 1 is 40g / m 2 , the partition layer 2 is formed by interweaving blended yarns and organic conductive fibers, the content of organic conductive fibers in the partition layer 2 is 1%, and the weight per unit area of the partition layer 2 is 6g / m 2 , the film layer 3 is a TPEE breathable film.

[0052] Wherein, the resin that makes nonwoven fabric 11 is polypropylene resin, and the mass ratio of each component in nonwoven fabric 11 is ordinary fiber: cotton: ice silk=4:1:2, and the specific surface area of nonwoven fabric is 75m 2 / g, the porosity is 85%.

[0053] In addition, an antistatic agent and a moisture-wicking agent are attached to the base layer 1 of the non-woven material. The antistatic agent is polyoxyethylene laurate. The antistatic agent...

Embodiment 3

[0059] An antistatic protective clothing fabric, as shown in the figure, sequentially includes a non-woven base layer 1, a partition layer 2 and a film layer 3 from the inside to the outside. The unit area weight of base layer 1 is 38g / m 2 , the partition layer 2 is formed by interweaving blended yarns and organic conductive fibers, the content of organic conductive fibers in the partition layer 2 is 0.8%, and the weight per unit area of the partition layer 2 is 8g / m 2 , the film layer 3 is a TPEE breathable film.

[0060] Wherein, the resin that makes nonwoven fabric 11 is polypropylene resin, and the mass ratio of each component in nonwoven fabric 11 is common fiber: cotton: ice silk=4:1:2, and the specific surface area of nonwoven fabric 11 is 110m 2 / g, the porosity is 95%.

[0061] In addition, an antistatic agent and a moisture-wicking agent are attached to the base layer 1 of the non-woven material. The antistatic agent is polyoxyethylene laurate. The antistatic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Weight per unit area | aaaaa | aaaaa |

| Weight per unit area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com