Industrial dust removing device

A dust removal device and industrial technology, applied in the direction of dispersed particle filtration, filtration separation, textile and paper making, etc., can solve the problems of washing out and affecting the service life of filter materials, and achieve accelerated charge dissipation, simple structure, quick installation and replacement convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

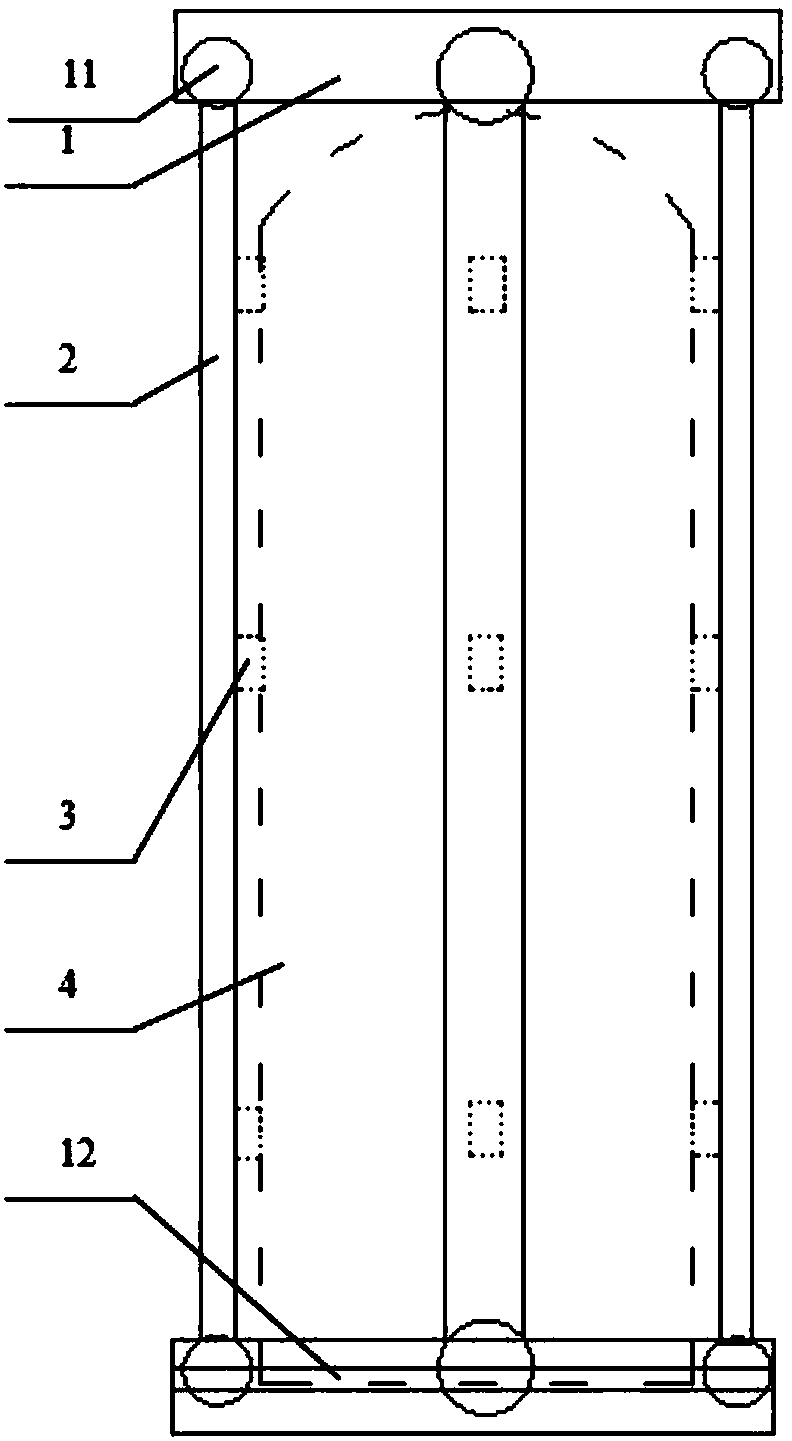

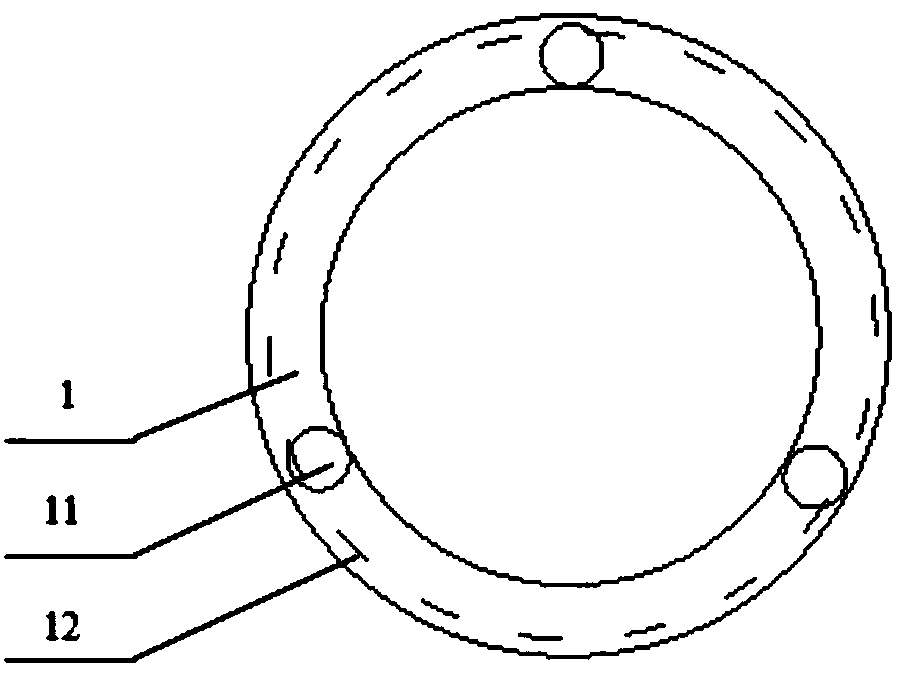

[0032] Such as Figure 1 to Figure 3 As shown, the industrial dust removal device includes a frame 1 and a detachable filter bag 4 installed in the frame 1. The two ends of the frame are provided with vibration motors 11 and power lines connected to external power sources. The vibration motors 11 at both ends are connected by connecting rods 2. The connecting rod 2 is provided with a protrusion 3 in contact with the outer surface of the filter bag 4. After the vibration motor 11 is powered on, the vibration is transmitted to the protrusion 3 through the connecting rod 2, and the filter bag 4 that is in contact with the upper part of the protrusion 3 is tapped. Make the dust on the surface of the filter bag 4 fall into the ash hopper in time to ensure the dust removal effect of the filter bag in the later stage.

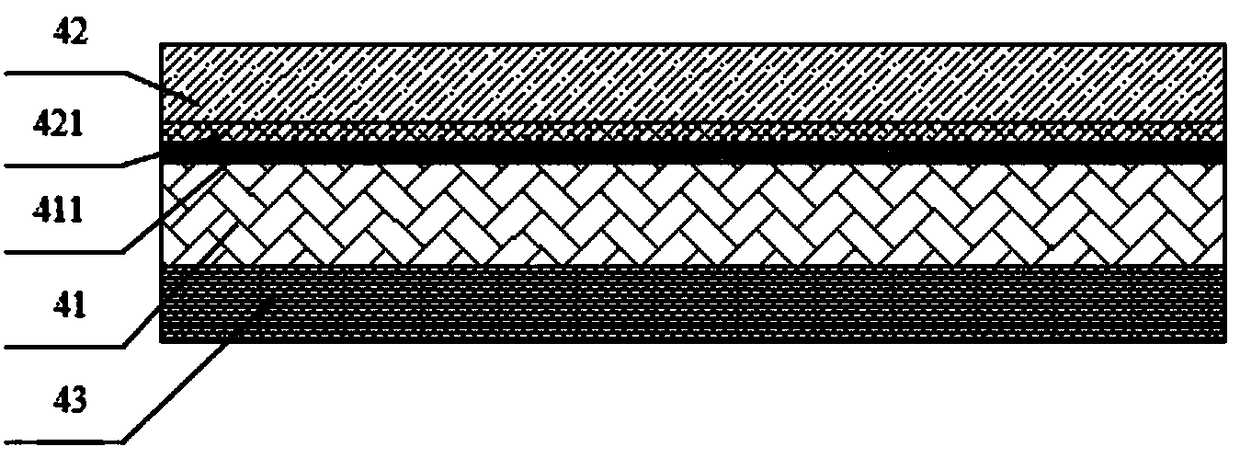

[0033] Such as image 3 As shown, one end of the filter bag 4 is opened as an air inlet, and one end is sewn together. The filter bag includes a base cloth layer 41 ...

Embodiment 2

[0044] This dedusting device is identical in structure with embodiment 1, but the preparation method of filter bag is different:

[0045] Step 1: The polytetrafluoroethylene fibers and glass fibers with a volume ratio of 8:2 are carded, twisted and plyed into warps with a wire diameter of 0.15-0.2 mm; the polyester fibers with a volume ratio of 8:2 and metal conductive fibers are respectively carded and then twisted and woven into weft threads with a wire diameter of 0.2-0.3mm;

[0046] Step 2: Weave the warp and weft threads obtained in step 1 through a loom to obtain a base fabric, the warp thread density is 15-20 threads / cm, and the weft thread density is 10-15 threads / cm;

[0047] Step 3: 35 parts of polyurethane, 40 parts of silicone resin, 20 parts of perfluoroalkyl ethyl acrylate, 7 parts of activated carbon, 5 parts of magnesium hydroxide, 4 parts of antimony oxide, tert-butylhydroquinone derivative ( 8 parts of DTBHO) and 15 parts of silicone oil were mixed and stirr...

Embodiment 3

[0054] This dedusting device is identical in structure with embodiment 1, but the preparation method of filter bag is different:

[0055] Step 1: The polytetrafluoroethylene fibers and glass fibers with a volume ratio of 7:3 are carded, twisted and plyed into warps with a wire diameter of 0.15-0.2mm; the polyester fibers with a volume ratio of 7:3 and metal conductive fibers are respectively carded and then twisted and woven into weft threads with a wire diameter of 0.2-0.3mm;

[0056] Step 2: Weave the warp and weft threads obtained in step 1 through a loom to obtain a base fabric, the warp thread density is 15-20 threads / cm, and the weft thread density is 10-15 threads / cm;

[0057] Step 3: 20 parts of polyurethane, 20 parts of silicone resin, 10 parts of perfluoroalkyl ethyl acrylate, 5 parts of activated carbon, 3 parts of magnesium hydroxide, 2 parts of antimony oxide, tert-butyl hydroquinone derivative ( 5 parts of DTBHO) and 10 parts of silicone oil were mixed and stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com