Antistatic composite material, preparation method, antistatic shell and purifier

A composite material and composite material layer technology, applied in the field of electrostatic protection, can solve the problems affecting the safety of operators, dust collection on the outer surface of the shell, poor antistatic effect, etc., so as to improve the dust collection efficiency, improve the antistatic performance, increase the The effect of compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

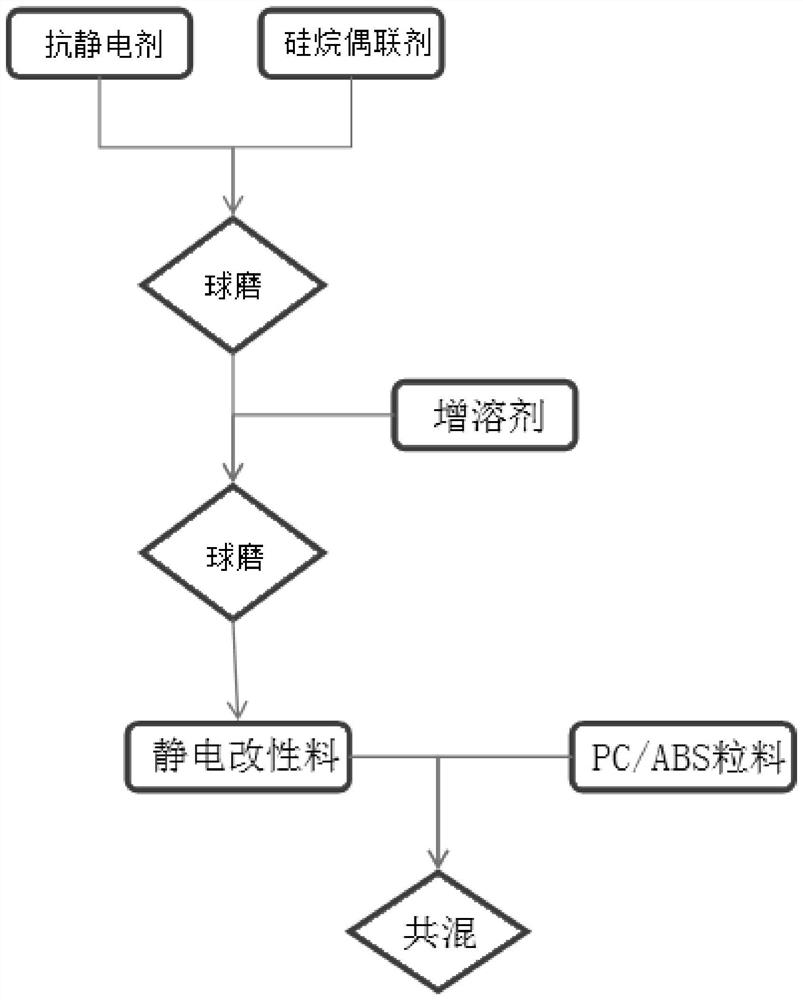

[0044] On the other hand, the present invention also provides the preparation method of the above-mentioned antistatic composite material, comprising the following steps: mixing the antistatic agent and the silane coupling agent for the first grinding to obtain the first abrasive; The solubilizer is added to the resin, and the second grinding is carried out to obtain the second grinding material; the second grinding material is added to the resin for blending, and then molded after injection molding to obtain an antistatic composite material. Further, the rotation speed of the first grinding is not less than 1000r / min, and the time is not less than 2h. Preferably, the rotation speed of the first grinding is 2000r / min-4000r / min, the time is 2h-5h, and the temperature is 20- 30°C. Further, the rotation speed of the second grinding is not less than 1000r / min, and the time is not less than 1h. Preferably, the rotation speed of the first grinding is 1500r / min-3500r / min, the time is...

Embodiment 1

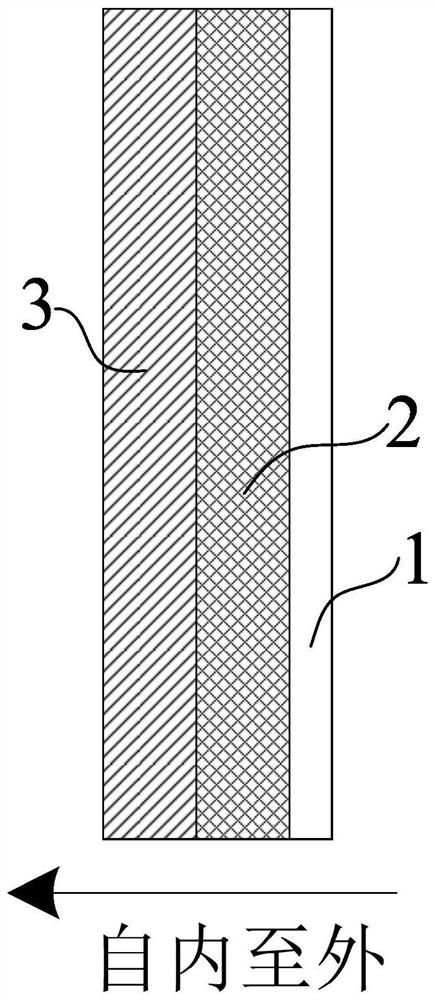

[0054] This embodiment provides an antistatic shell, such as figure 1 As shown, from the inside to the outside, it includes a polytetrafluoroethylene layer 1, an antistatic composite material layer 2 and a resin layer 3; wherein the thickness of the polytetrafluoroethylene layer 1 is 0.4mm, and the resistivity of the polytetrafluoroethylene layer is 10 15 Ω cm; the thickness of the antistatic composite material layer 2 is 4mm, and the resistance of the antistatic composite material layer 2 is 10 7 Ω; resin layer is PC / ABS blended resin, and the thickness of described PC / ABS blended resin is 3mm;

[0055] In the above-mentioned antistatic casing, first, one side of the polytetrafluoroethylene layer 1 is activated by acidification to form an active surface on the polytetrafluoroethylene layer 1; then, the polytetrafluoroethylene layer 1 and the antistatic composite material layer 2 are made of glued together so that the active surface of the polytetrafluoroethylene layer 1 is ...

Embodiment 2

[0059] This embodiment provides an antistatic shell, such as figure 1 As shown, from the inside to the outside, it includes a polytetrafluoroethylene layer 1, an antistatic composite material layer 2 and a resin layer 3; wherein the thickness of the polytetrafluoroethylene layer 1 is 0.3 mm, and the resistivity of the polytetrafluoroethylene layer is 10 13 Ω cm; the thickness of the antistatic composite material layer 2 is 5 mm, and the resistance of the antistatic composite material layer 2 is 10 9 Ω; resin layer is PC / ABS blended resin, and the thickness of described PC / ABS blended resin is 2mm;

[0060] In the above-mentioned antistatic casing, first, one side of the polytetrafluoroethylene layer 1 is activated by plasma fontization to form an active surface on the polytetrafluoroethylene layer 1; then, the polytetrafluoroethylene layer 1 is combined with the antistatic composite material Layer 2 is composited together by integral molding, so that the active surface of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com