Non-evapotranspiration type thin film getter and preparation method thereof

A non-evaporative, getter technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of limiting the service life of components, maintaining the vacuum degree of the cavity, etc., to extend the service life, increase the Inhalation capacity, the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

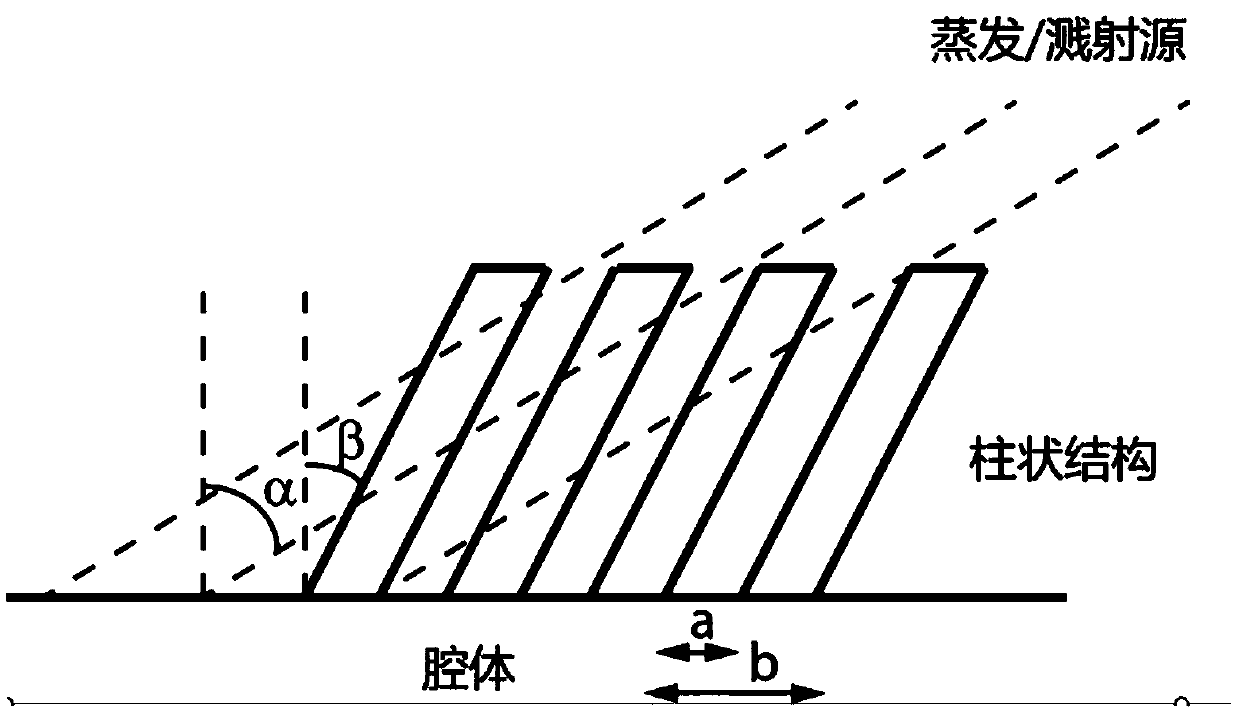

[0039] Ti films were deposited on silicon wafers with inclination angles of 50° and 70° respectively, and columnar films with inclination angles of 29° and 46° were deposited. The inclination angle conforms to the theoretical formula tanα=2×tanβ, and the theoretical values of the β angles should be 31° and 54° respectively. After testing, the porosity of the film is 25% and 55%, respectively, which indicates that the oblique-angle deposition method of this embodiment can deposit a porous film.

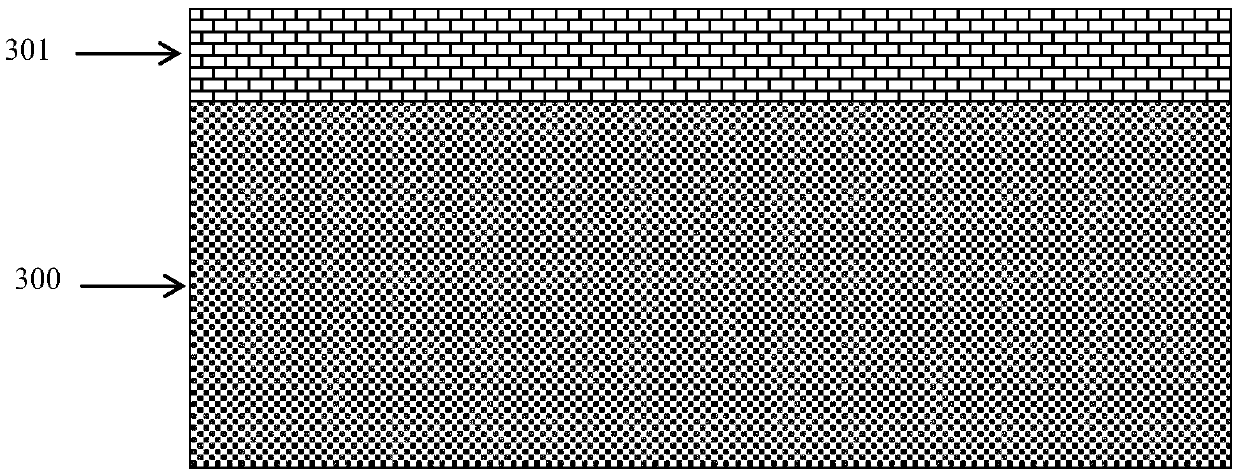

[0040] Then, a gold layer is covered on the surface of the film to obtain a film structure such as image 3 shown. Among them, 300 is a columnar porous thin film getter, and 301 is a 10-50 thick nanometer protective layer covered on the surface of the thin film getter. The structure is dense. The protective layer can prevent the surface of the getter from being polluted when it is not activated.

[0041] Under the activation conditions of 300°C and 1h, the above-mentioned film gett...

Embodiment 2

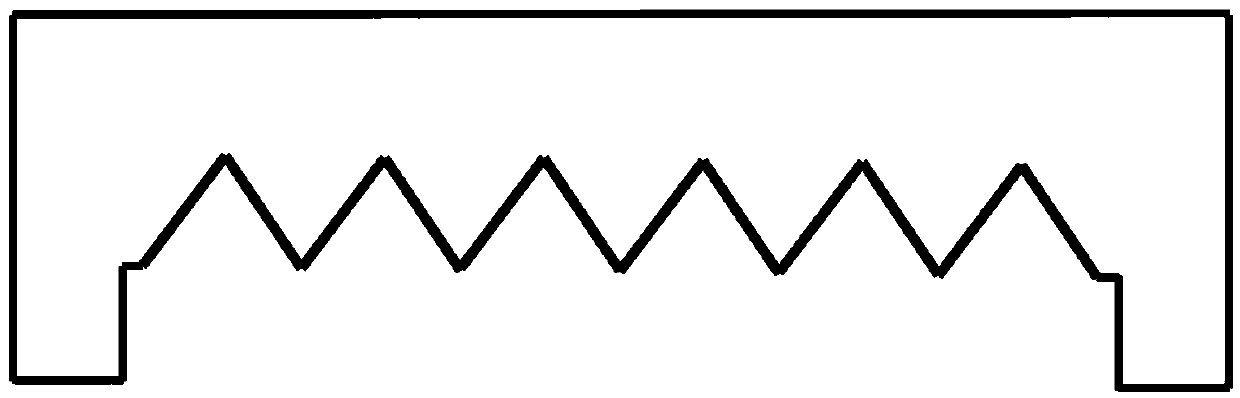

[0043] Before depositing the film, the cavity is wet-etched to etch out such as figure 2 The cavity is inclined at an angle of 54.7°. Next, a thin film is deposited in the cavity to obtain a porous columnar thin film. After testing, its air-absorbing capacity is about 20 times that of the non-columnar film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com