Production method of film solar cell and electro-deposition device thereof

A technology for solar cells and production methods, applied in electrodes, circuits, electrical components, etc., can solve the problems of complex production process and high production cost of solar thin-film cells, and achieve the effects of saving processes, reducing waste and avoiding occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] This embodiment provides a method for producing a thin-film solar cell, comprising the following steps:

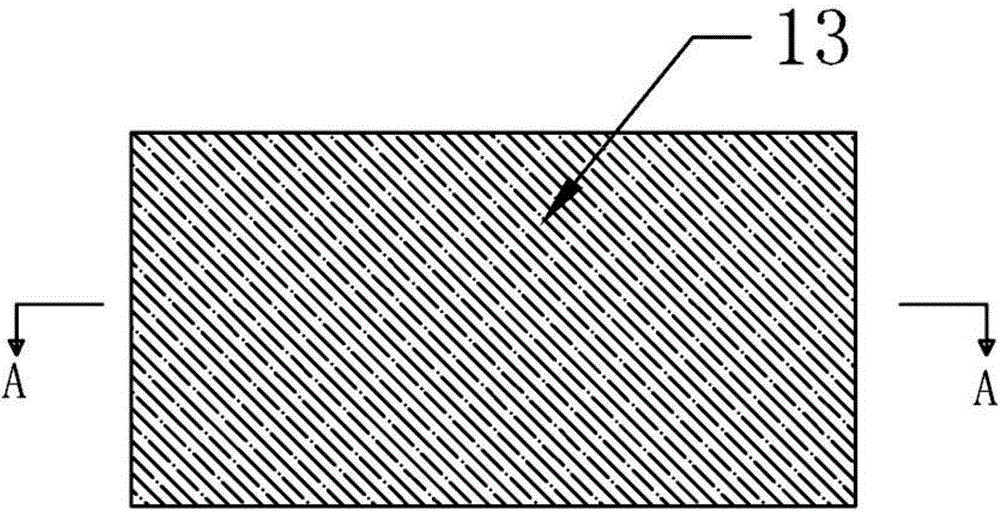

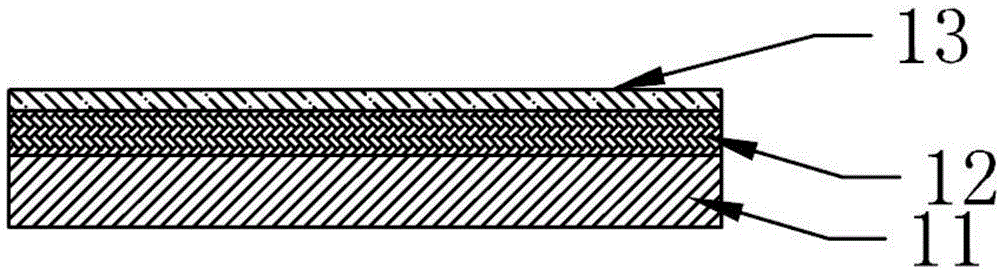

[0090] (a) if Figure 1b As shown, a transparent conductive layer 12 is formed on a glass substrate 11 .

[0091] (b) if Figure 1a and 1b As shown, a window layer 13 is formed on the transparent conductive layer 12, and the window layer 13 is a cadmium sulfide (CdS) layer.

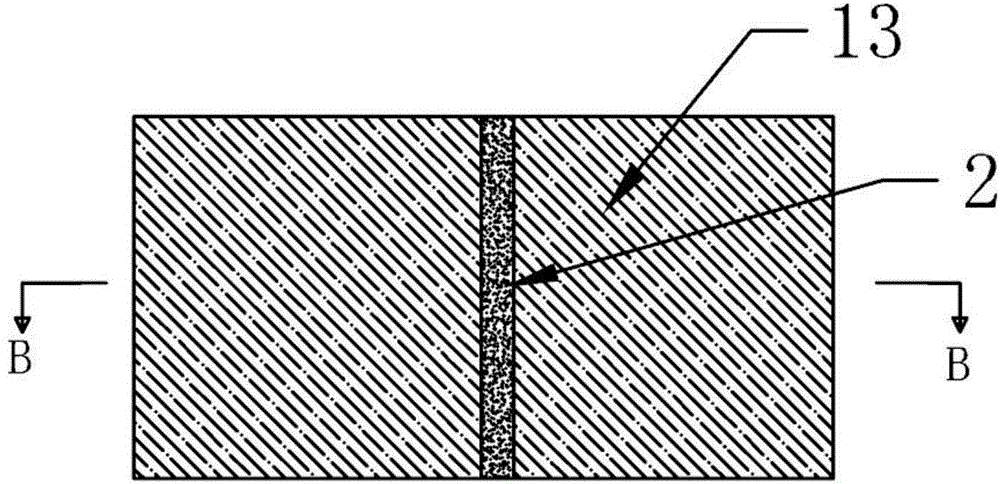

[0092] (c) if Figure 1c and 1dAs shown, the strip contact electrode 2 penetrates the window layer 13 and makes ohmic contact with the transparent conductive layer 12, the contact surface between the strip contact electrode 2 and the transparent conductive layer 12 is strip-shaped, and the strip contact surface The cross section of the strip contact electrode 2 perpendicular to the direction of the contact long side is rectangular, and the long side of the strip contact electrode 2 is a straight line.

[0093] (d) if Figure 1e As shown, on the transparent conductive layer 12 in step (c),...

Embodiment 2

[0106] This embodiment provides a method for producing a thin-film solar cell, the specific method is the same as that in Embodiment 1, the only difference is that the cross-section of the elongated contact electrode 2 perpendicular to the direction in which the elongated contact electrode 2 contacts the long side is circular, Specific as Figure 2d-2j shown.

[0107] Such as Figure 8a and Figure 8b As shown, in the electrodeposition tank, when the absorber layer 14 is electrodeposited on the window layer 13 and simultaneously fills the first groove P1, the elongated contact electrode 2 is connected and energized at the end.

[0108] As an alternative embodiment, in the production method of the thin film solar cell described in this embodiment, the cross-section of the elongated contact electrode perpendicular to the direction of the long side of the elongated contact electrode is trapezoidal

Embodiment 3

[0110] The production method of the thin-film solar cell described in this embodiment, the specific embodiment is the same as embodiment 1, the difference is:

[0111] In step (c), the elongated contact electrode 2 penetrates the window layer 13 and makes ohmic contact with the transparent conductive layer 12, and the contact surface between the elongated contact electrode 2 and the transparent conductive layer 12 is elongated, Such as Figure 3c As shown, the long side of the strip contact electrode 2 is a curve; as Figure 3d As shown, the cross section of the elongated contact electrode 2 perpendicular to the direction of the long side of the contact is trapezoidal, and the end of the elongated contact electrode 2 is connected with electricity.

[0112] In step (h), the back electrode layer is formed after filling the vacancy of the elongated contact electrode of the semi-finished product obtained in step (g). Formed by deposition, the second contact electrode is in ohmic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com