Preparation method of flexible supercapacitor positive electrode material

A technology for supercapacitors and positive electrode materials, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, hybrid capacitor collectors, etc., can solve problems such as poor conductivity, achieve good flexibility and mechanical stability, high yield, The effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

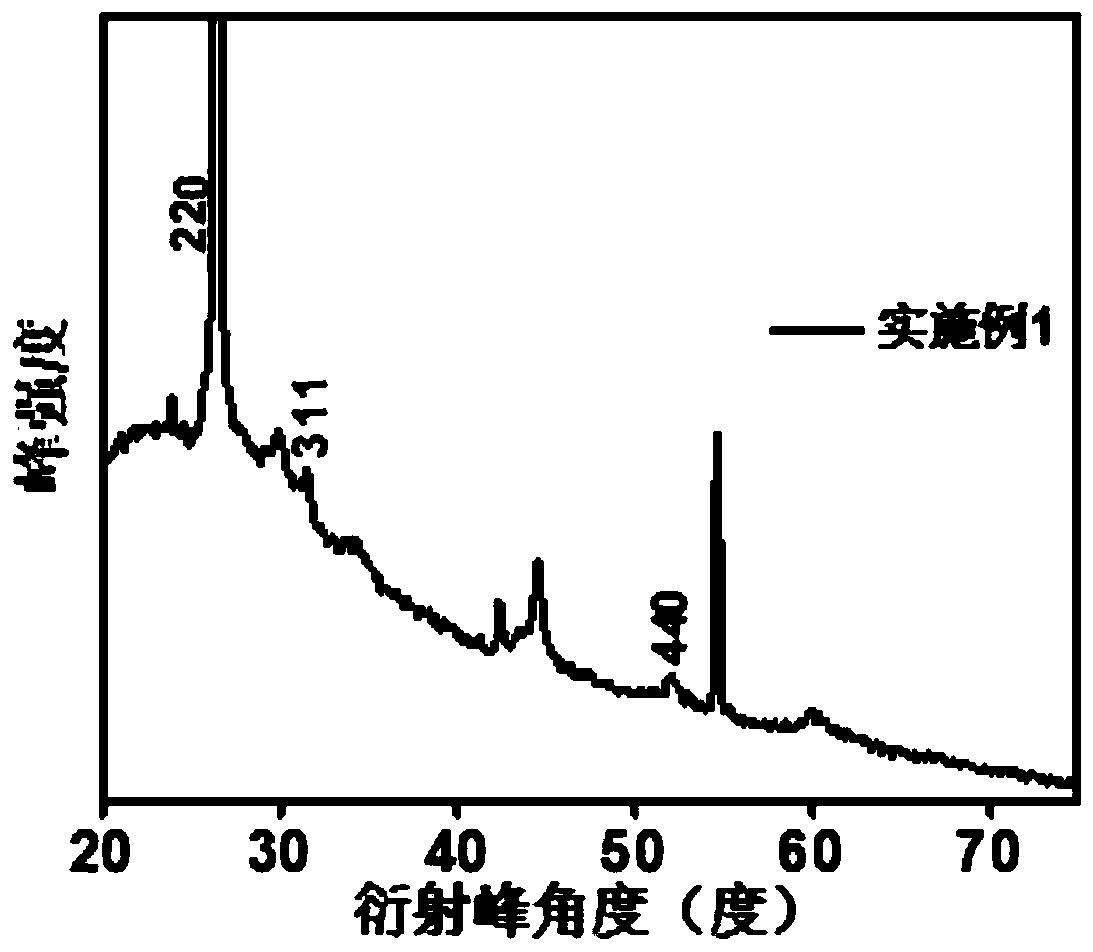

Embodiment 1

[0040] The nickel-cobalt-sulfur / graphene composite material chooses to use the electrodeposition method, and the nickel-cobalt-sulfur sample is deposited on the graphene foam by the electrochemical method of cyclic voltammetry to form a fluffy porous composite material. First, clean the prepared graphene foam with a length of 2 cm and a width of 1 cm with acetone, ethanol and deionized water. 0.12g of cobalt chloride hexahydrate, 0.17g of nickel chloride hexahydrate and 0.4505g of thiourea were dissolved in 100mL of deionized water, stirred, and dissolved to form an electrolyte. Electrodeposition was performed using cyclic voltammetry in a three-electrode system. The platinum sheet electrode is used as the counter electrode, the silver / silver chloride is used as the reference electrode, and the graphene foam is clamped by the multifunctional electrode clip as the working electrode. The voltage window is -1.2V to 0.2V, and the cycle is 4 cycles, and the sweep rate is 5mV s -1 ...

Embodiment 2

[0046] The nickel-cobalt-sulfur / graphene composite material chooses to use the electrodeposition method, and the nickel-cobalt-sulfur sample is deposited on the graphene foam by the electrochemical method of cyclic voltammetry to form a fluffy porous composite material. First, clean the prepared graphene foam with a length of 2 cm and a width of 1 cm with acetone, ethanol and deionized water. 0.12g of cobalt chloride hexahydrate, 0.17g of nickel chloride hexahydrate and 0.4505g of thiourea were dissolved in 100mL of deionized water, stirred, and dissolved to form an electrolyte. Electrodeposition was performed using cyclic voltammetry in a three-electrode system. The platinum sheet electrode is used as the counter electrode, the silver / silver chloride is used as the reference electrode, and the graphene foam is clamped by the multifunctional electrode clamp as the working electrode. The voltage window is -1.2V to 0.2V, and the cycle is 8 cycles, and the sweep speed is 5mV s -...

Embodiment 3

[0049] The nickel-cobalt-sulfur / graphene composite material chooses to use the electrodeposition method, and the nickel-cobalt-sulfur sample is deposited on the graphene foam by the electrochemical method of cyclic voltammetry to form a fluffy porous composite material. First, clean the prepared graphene foam with a length of 2 cm and a width of 1 cm with acetone, ethanol and deionized water. Take 0.29g of cobalt chloride hexahydrate and 0.4505g of thiourea and dissolve them in 100mL of deionized water, stir and dissolve to form an electrolyte. Electrodeposition was performed using cyclic voltammetry in a three-electrode system. The platinum sheet electrode is used as the counter electrode, the silver / silver chloride is used as the reference electrode, and the graphene foam is clamped by the multifunctional electrode clip as the working electrode. The voltage window is -1.2V to 0.2V, and the cycle is 4 cycles, and the sweep rate is 5mV s -1 . The graphene foam on which the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com