Rubber-metal spherical hinge provided with hard stop catch on end face

A ball hinge and stopper technology, applied in the direction of elastic shock absorbers, etc., can solve the problems of high manufacturing cost, complicated process realization, uneven radial stiffness, etc., and achieve the effect of easy manufacturing, lower manufacturing cost and guaranteed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

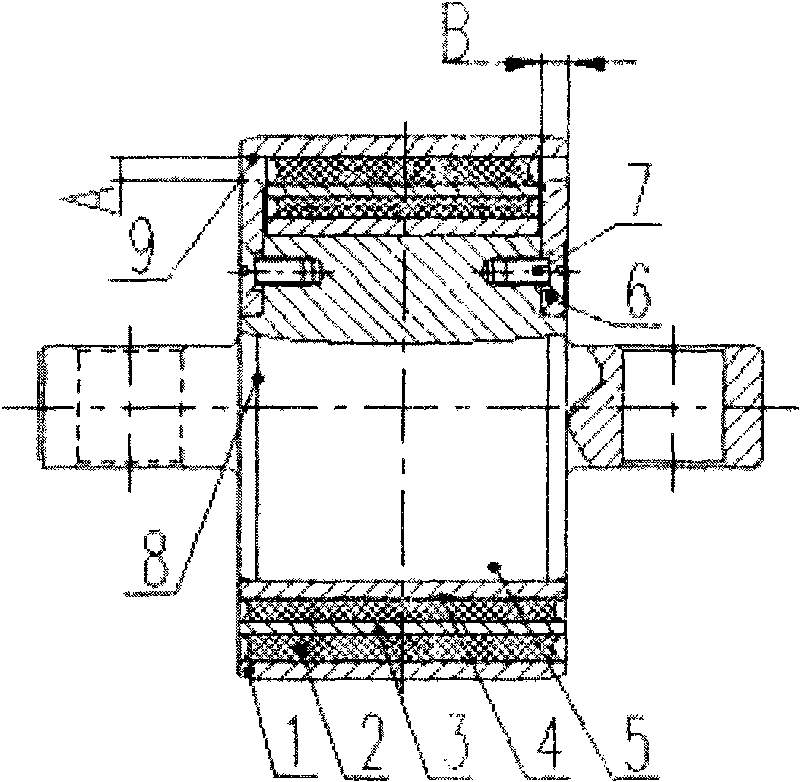

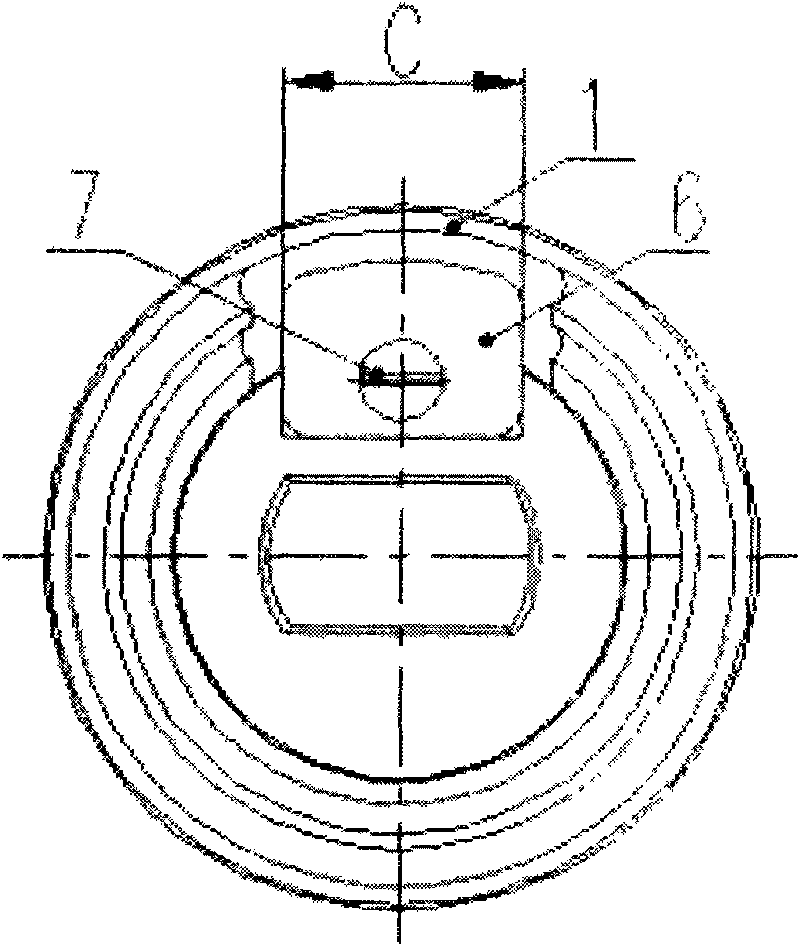

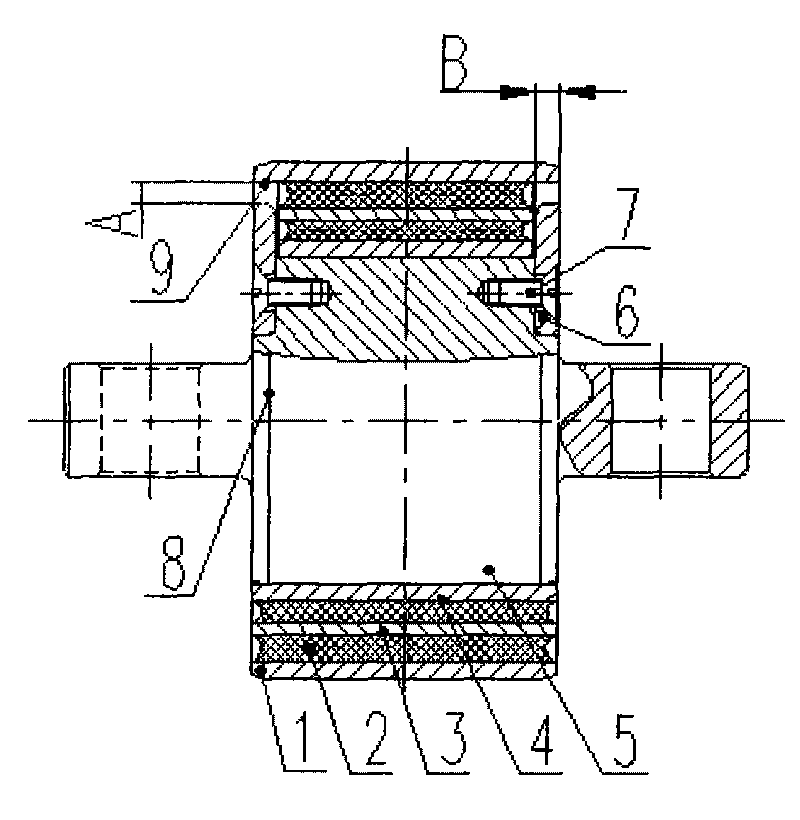

[0015] The accompanying drawings show an embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings.

[0016] It can be seen from the accompanying drawings that the present invention is a metal sleeve-hard stopper-rubber combined ball joint, which places the hard stopper on the end face of the mandrel, and installs it through fasteners after the ball joint is made. On the two ends of the elastic damping part of the spherical hinge mandrel, and ensure that there is an axial gap between the top of the hard stop and the outer shell of the elastic damping part, when the outer shell of the elastic damping part moves radially relative to the hard stop When the gap is exceeded, it is limited.

[0017] The ball joint with a radial limit device includes a metal outer sleeve 1, an elastic rubber body 2, a spacer 3, a metal inner sleeve 4, a mandrel 5, a radial hard stop 6 and a fastener 7 of the ball joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com