Spray nozzle device, in particular for spraying a cast strand

A technology for spraying nozzles and casting billets, which is applied to spraying devices, liquid spraying devices, etc., can solve problems such as mutual influence, and achieve the effect of easy matching and simplified processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

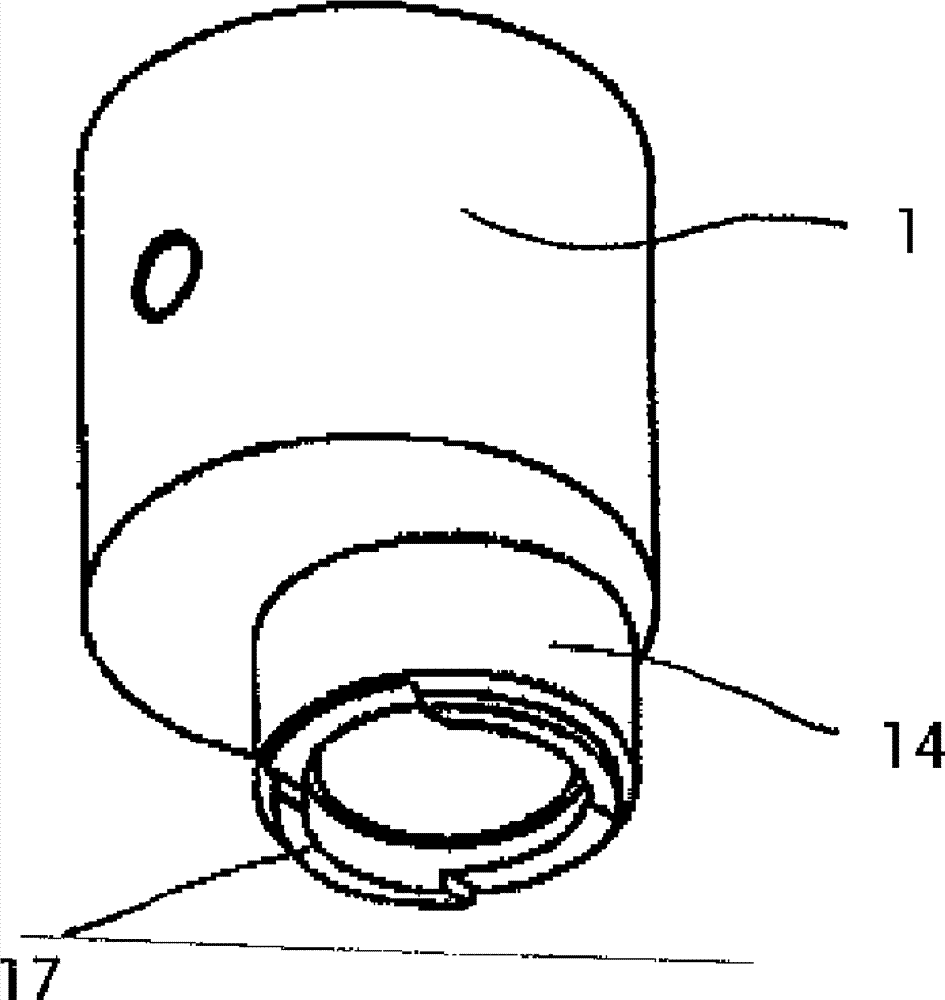

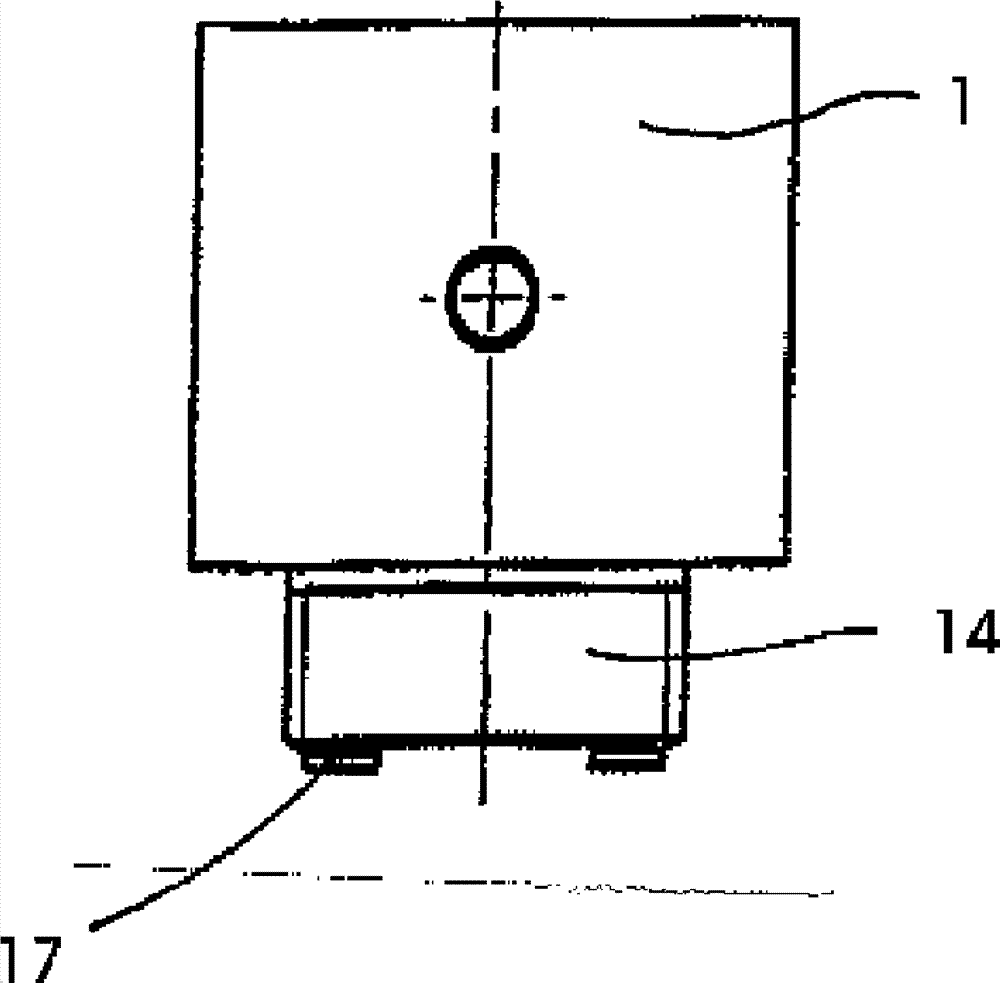

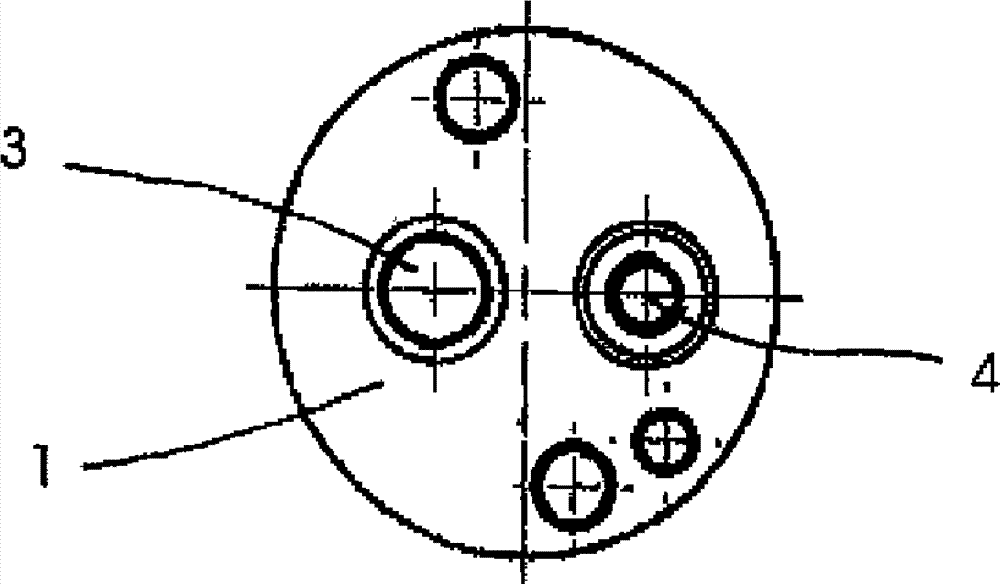

[0020] according to Figure 1 to Figure 4 The spray nozzle unit is used to spray the strand with an air / water mixture in order to cool the strand during casting. The mixing body 1 has a mixing chamber 2 which is provided with an air inlet 3 , a water inlet 4 and a nozzle outlet 5 .

[0021] The mixing chamber 2 of the mixing body 1 is designed in a cylindrical shape. The length of the mixing chamber is approximately twice its internal diameter. The air inlet 3 is arranged in an air inlet nozzle 6 whose top 7 protrudes into the upper region of the mixing chamber. The air inlet nozzle 6 is aligned coaxially to the mixing chamber 2 , and the outer diameter of the air inlet nozzle 6 is here smaller than half the inner diameter of the mixing chamber. In this region, the air inlet nozzle 6 is provided with air outlet bores 9 exiting from the air inlet nozzle in a radial direction approximately transverse to the longitudinal axis of the mixing chamber, which are distributed unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com