Ball grinder available for solid state reaction of powder

A solid-state reaction and ball mill technology, applied in grain processing, etc., can solve problems such as uneven particle size, limited mechanical energy, and easy fatigue and fracture, and achieve excellent physical and chemical properties, high degree of automation, and continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

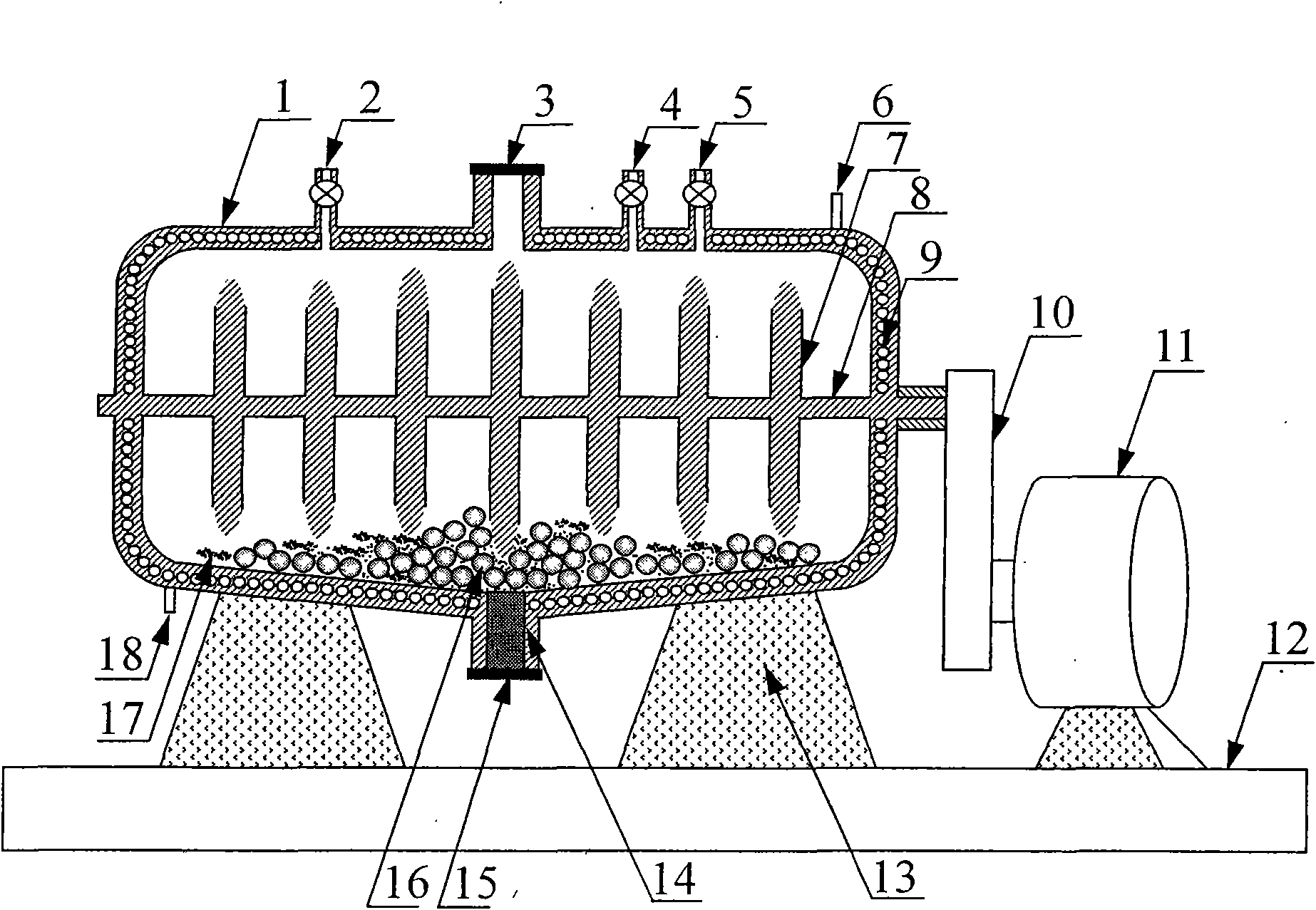

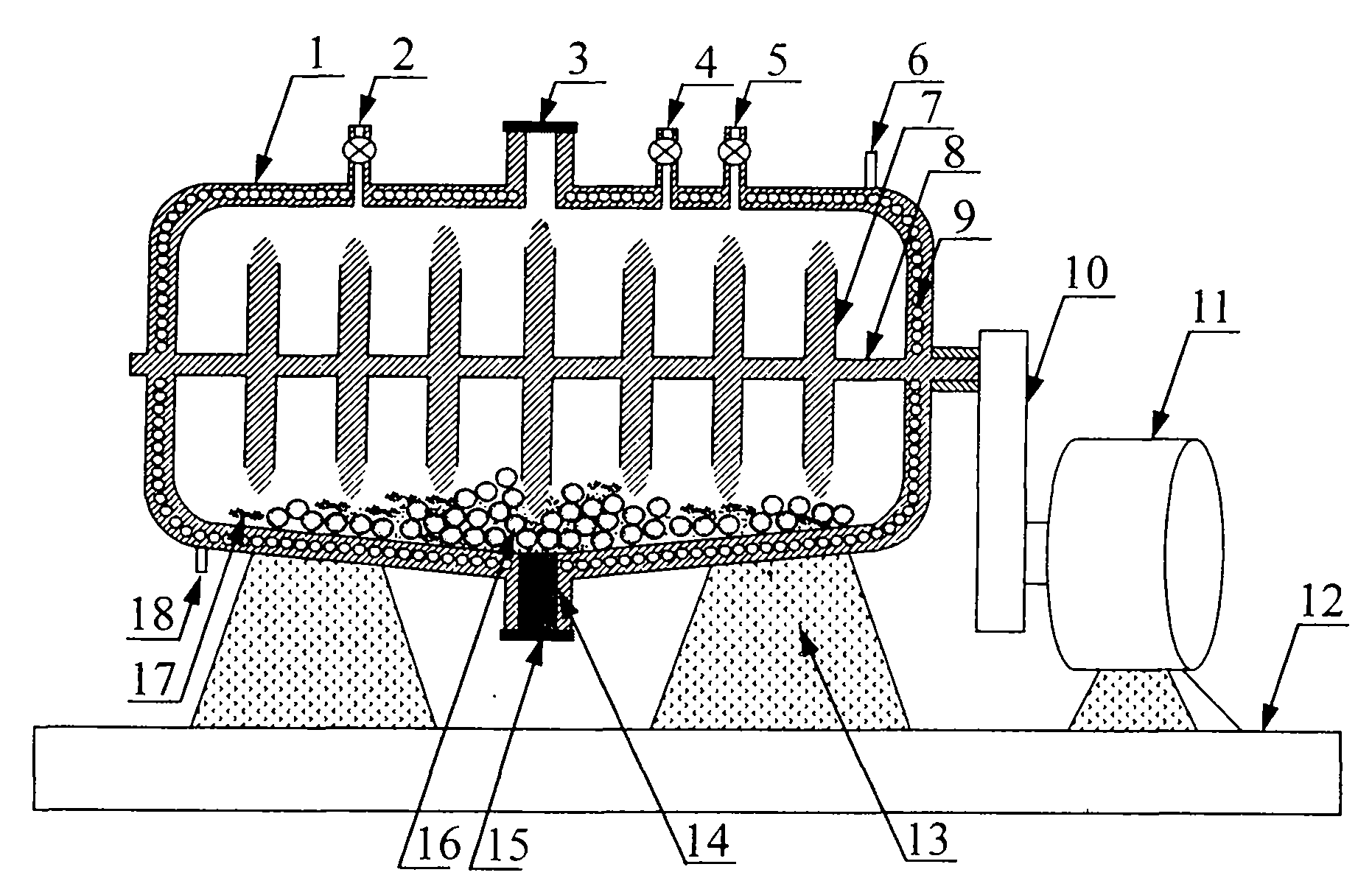

[0020] Preparation of perovskite type LaMnO with ball mill of the present invention 3 Composite oxide, wherein the diameter of the ball mill cylinder is 1 meter, the length of the cylinder is 2 meters, the slope of the bottom of the cylinder is 20 degrees, and the number of paddles is 8. According to the molecular formula LaMnO, the oxides of lanthanum and manganese 3 Weigh, mix, and transfer to the grinding tank with the atomic molar ratio shown in , the amount of material added is 10 kg; place stainless steel balls about 5 times the weight of the mixed material; start the motor, and run at a frequency of 1000 times per minute , so that the steel ball produces high-speed irregular motion, and squeezes and kneads the material. The process is dry grinding, and the grinding process continuously replenishes air into the grinding jar. Use circulating water as cooling medium to control the grinding temperature in the range of 3 Composite oxide, the specific surface area can reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com