Anti-blocking control system for coal spray branch pipes of distributor of coal spray system of blast furnace

A control system and blast furnace coal injection technology, applied in the field of control, can solve problems such as damaged furnace conditions, asymmetry, irregular branch pipe purging, etc., and achieve the effects of improving automation level, reducing work intensity, and reducing clogging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

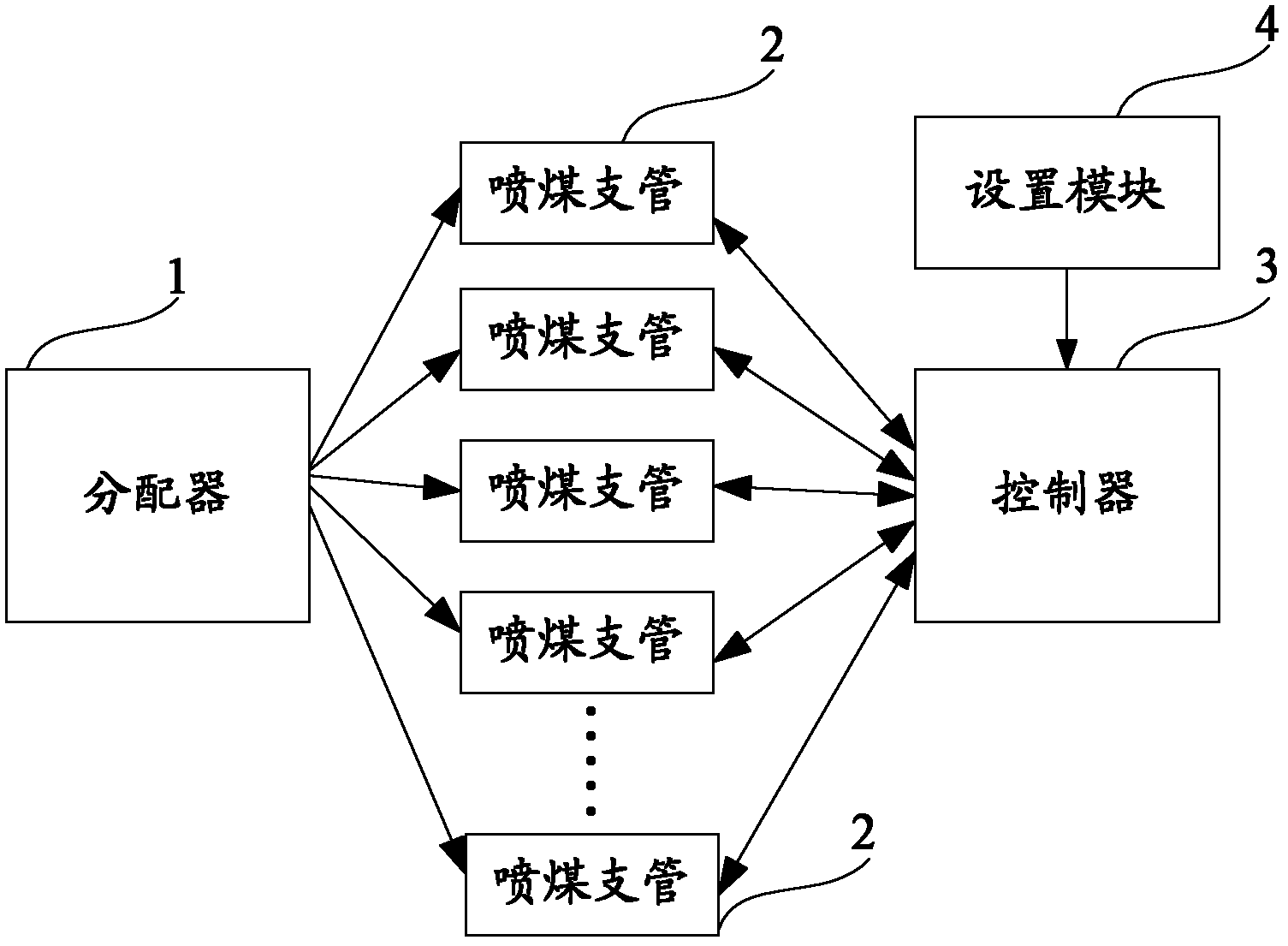

[0027] Such as figure 1 As shown, a blast furnace coal injection system distributor coal injection branch pipe anti-blocking control system provided by the embodiment of the present invention includes a distributor 1, a plurality of coal injection branch pipes 2, a controller 3, a setting module 4, an alarm module and a plurality of measuring Block instrument. The distributor 1 distributes the pulverized coal from the coal injection main pipe to a plurality of coal injection branch pipes 2 . Under the control of the controller 3, multiple coal injection branch pipes 2 are purged by means of cyclic purge during the cycle purge period. Wherein, the number of coal injection branch pipes 2 is 16-40, which can be set according to actual needs. The setting module 4 sets the cycle purge period and the purge time of each coal injection branch pipe. For example, the number of purging cycles is set to be 20 times. The purge time of each coal injection branch pipe is 10-60 seconds. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com