Novel liquid distributor

A liquid distributor and a new type of technology, applied in gas treatment, separation method, dispersed particle separation, etc., can solve the problems of poor operation stability of spray system, poor gas-liquid contact effect, low operation elasticity, etc., and avoid prolonged contact time. , the effect of low blocking probability and high operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described below in conjunction with accompanying drawing.

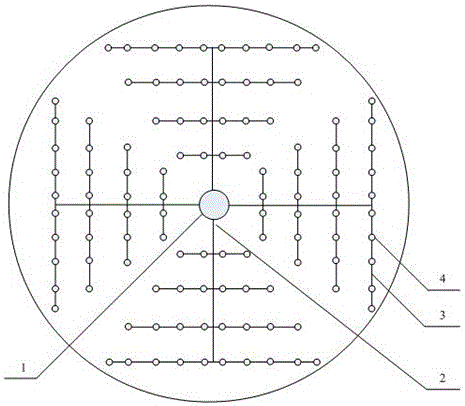

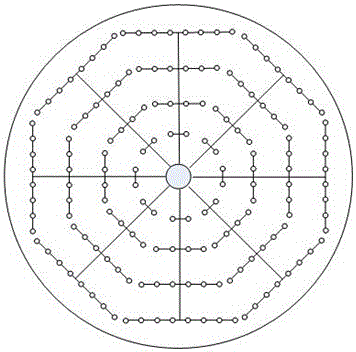

[0018] Such as figure 1 , 2 As shown, a high-efficiency water distributor for sulfur-containing waste gas is characterized in that the water distributor is composed of two layers of systems, and the central water inlet 1 of each layer of the system is divided into four main distribution pipes 2, four main distribution pipes The main pipe 2 is evenly distributed, and each main distribution main pipe 2 is divided into a distribution branch pipe 3, and each distribution branch pipe 3 is divided into eight branches. The four main fabric main pipes 2 of the system are projected into a 45° phase-to-phase misalignment;

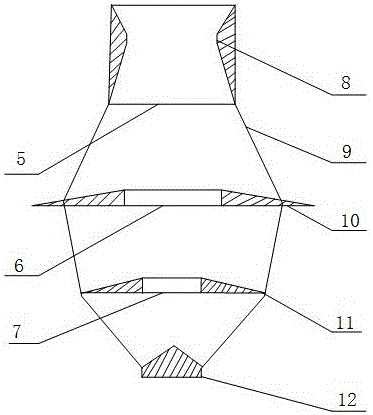

[0019] Such as image 3 As shown, the three-splash external thread nozzle 4 is composed of a water inlet 5, an upper shower hole 6, a middle shower hole 7, a Venturi inlet 8, a tendon 9, an upper splash tray 10, and a middle splash tray 11. , The lower splash dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com