Spinning workshop dust collector

A technology for vacuum cleaners and workshops, applied in the direction of vacuum cleaners, suction filters, suction nozzles, etc., can solve problems such as vacuum cleaner motor damage, achieve the effects of preventing overheating and burning, avoiding overload, and solving the effects of vacuum cleaner motor damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

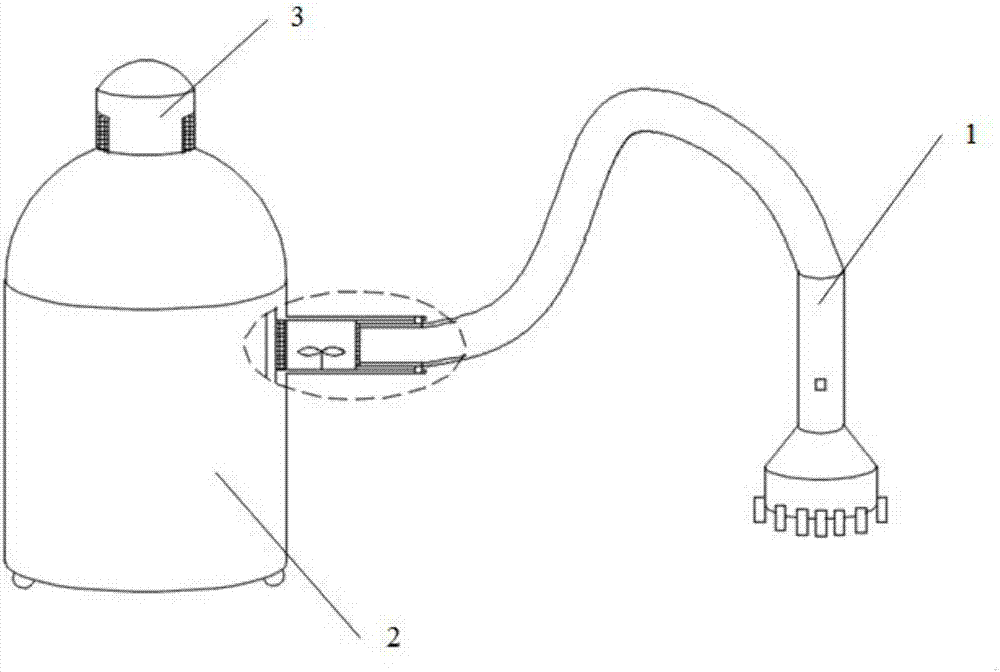

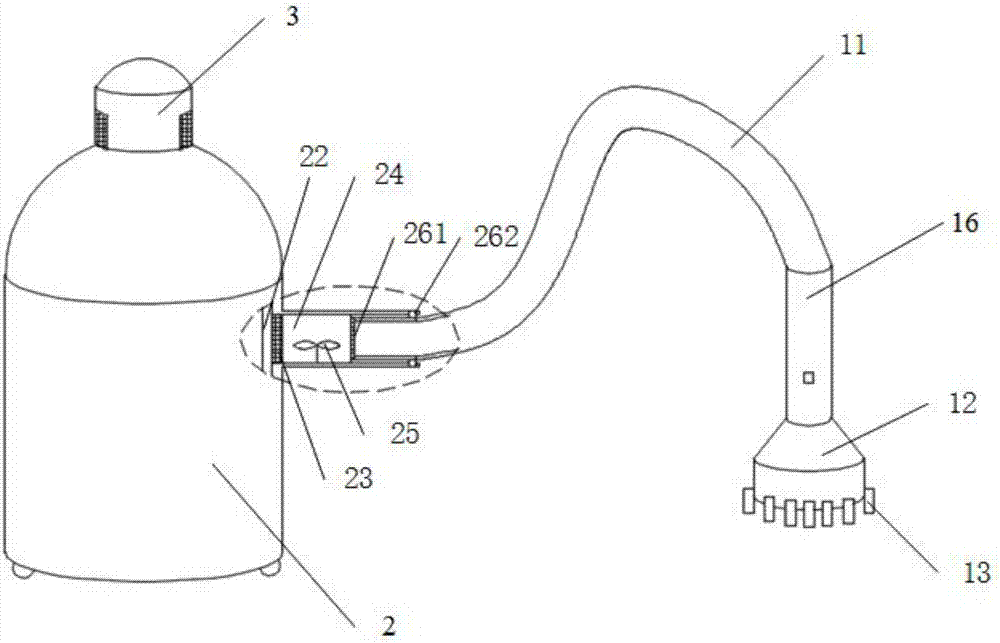

[0028] See figure 1 , Is a schematic diagram of the structure of a vacuum cleaner in a spinning workshop.

[0029] The vacuum cleaner of the spinning workshop provided by this application includes: a dust collection device 1, a dust collection device 2, and a power device 3;

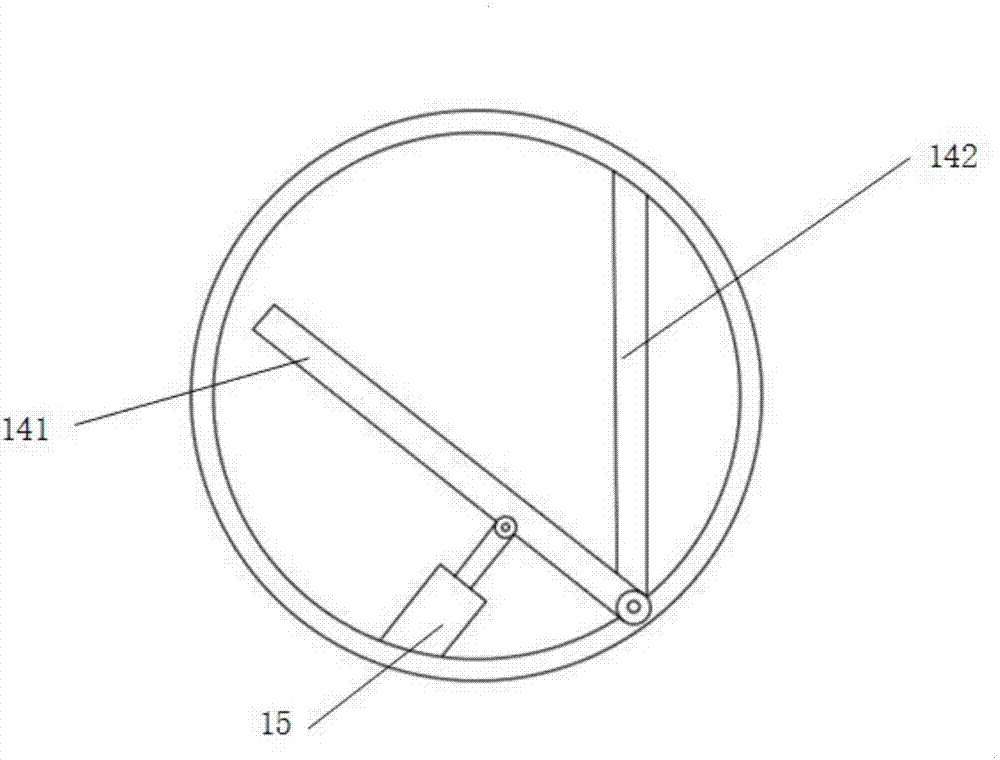

[0030] The dust suction device 1 includes a dust suction pipe 11 and a cleaning joint 12 arranged at one end of the dust suction pipe 11. A number of columnar anti-blocking strips 13 are evenly arranged on the edge of the end surface of the cleaning joint 12; inside the cleaning joint 12 A shearing mechanism 14 is also provided. The shearing mechanism 14 includes a movable blade 141 connected to the air cylinder 15 and a static blade 142 hinged to the movable blade 141, and the static blade 142 is fixed on the housing inside the cleaning joint 12.

[0031] The dust collection device 1 is used to provide a cleaning joint 12 that prevents clogging of fiber materials in the spinning workshop, so as to operate a va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com