Grain grinding device

A crushing device and grain technology, applied in the direction of grain processing, etc., can solve the problems of difficult operation and maintenance, bacteria breeding, large volume, etc., and achieve the effect of convenient maintenance and cleaning, and stable uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

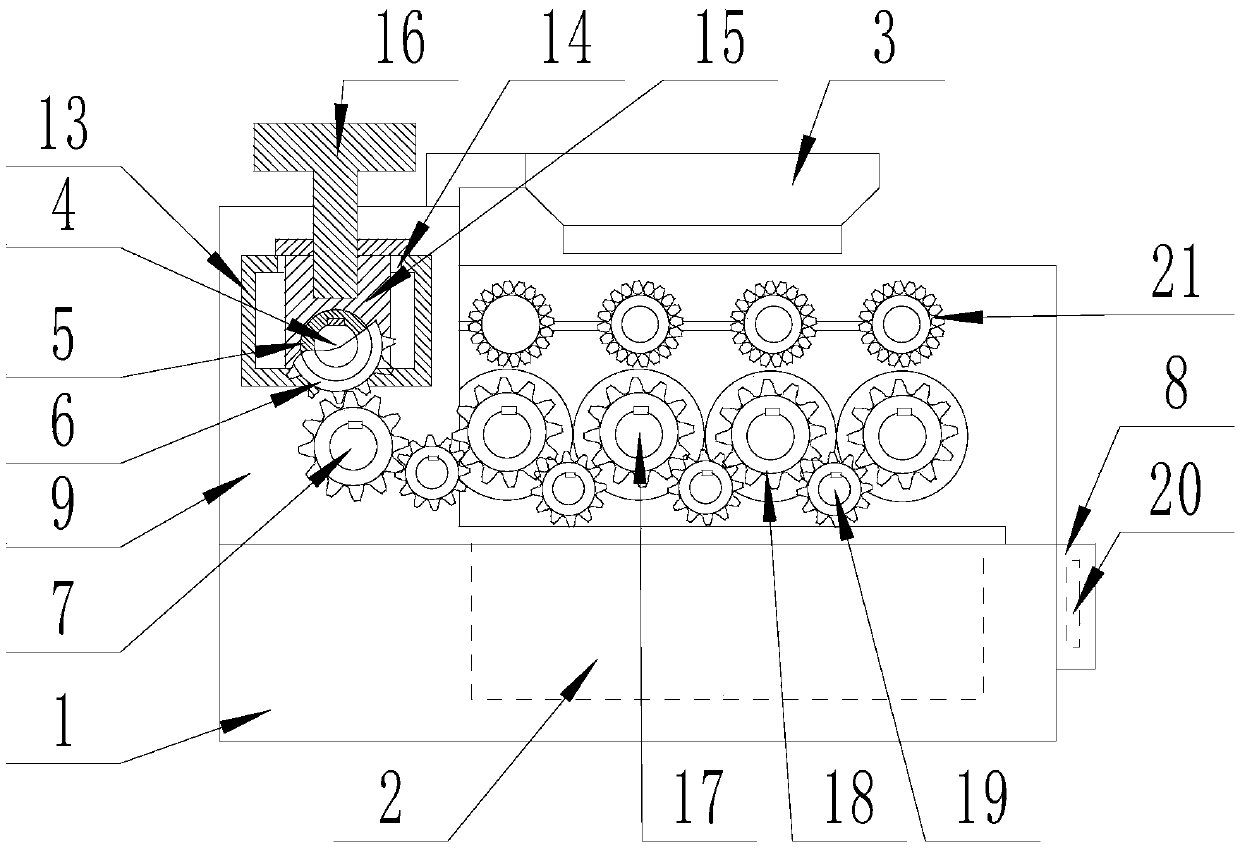

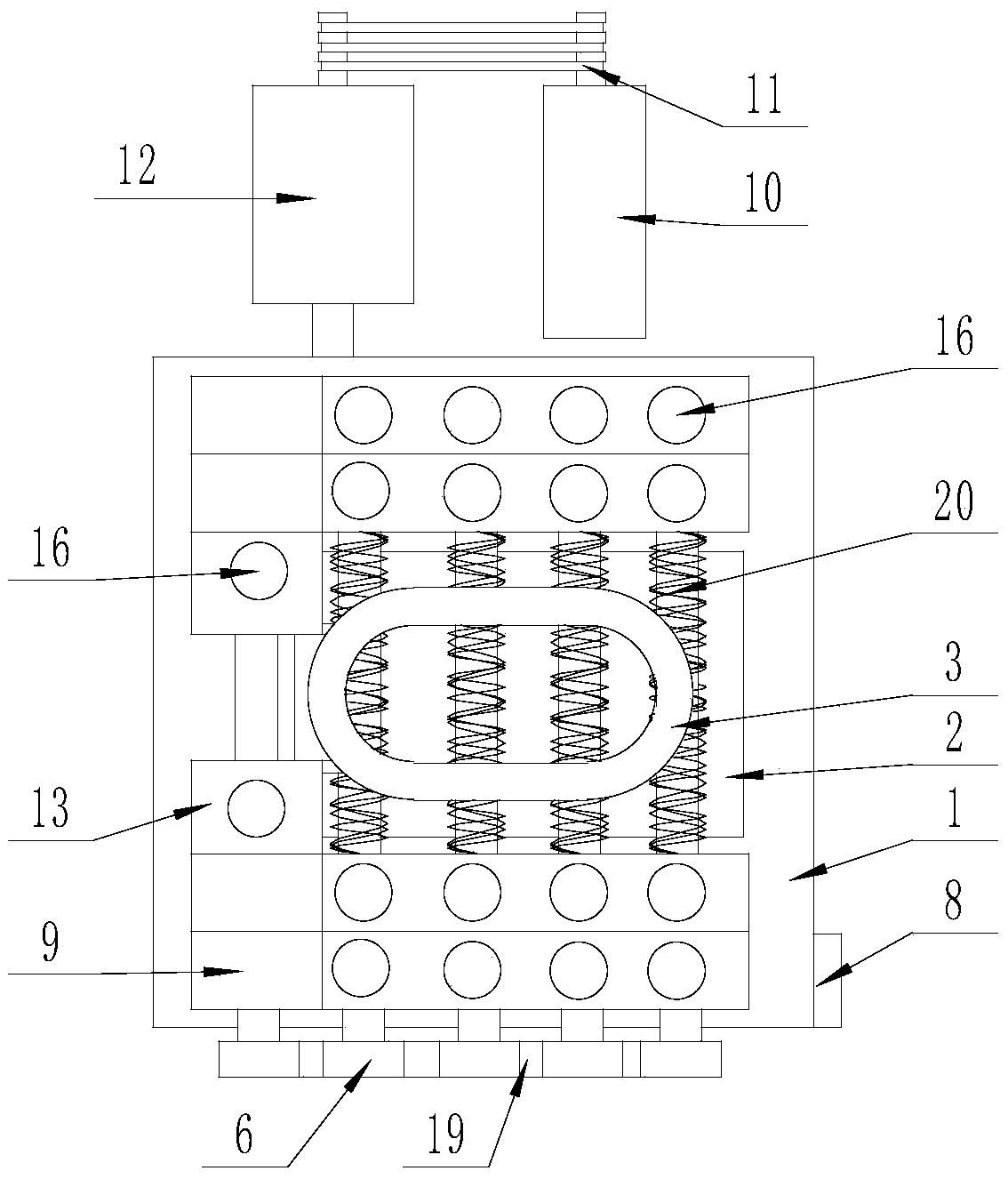

[0018] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a grain crushing device includes a workbench (1) and a groove (2) arranged on the workbench (1), a grain storage funnel (3) is arranged above the groove (2), and the The left and right sides of the workbench (1) are respectively provided with wheel frame groups, and the two wheel frame groups are provided with crushing units, and the crushing units are overlapped with the grooves (2) on the workbench (1), so that The front and rear sides of the workbench (1) are provided with drive units that drive the movement of the crushing unit. The crushing unit is composed of a driving crushing mechanism and a driven crushing mechanism arranged on the wheel frame group. The driving crushing mechanism is The driving roll pressing upper mandrel (4) connected with the two wheel frame groups, the stone mill rolling sleeve (5) sleeved on the driving rolling upper man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com