Corrugating device for steel strip and aluminum strip

A technology of embossing and aluminum strip, which is applied in the field of longitudinal sheath production, can solve the problems of aluminum strip or steel strip breaking, accumulation, and production line speed asynchrony of embossing speed, etc., and achieve the effect of flexible adjustment and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

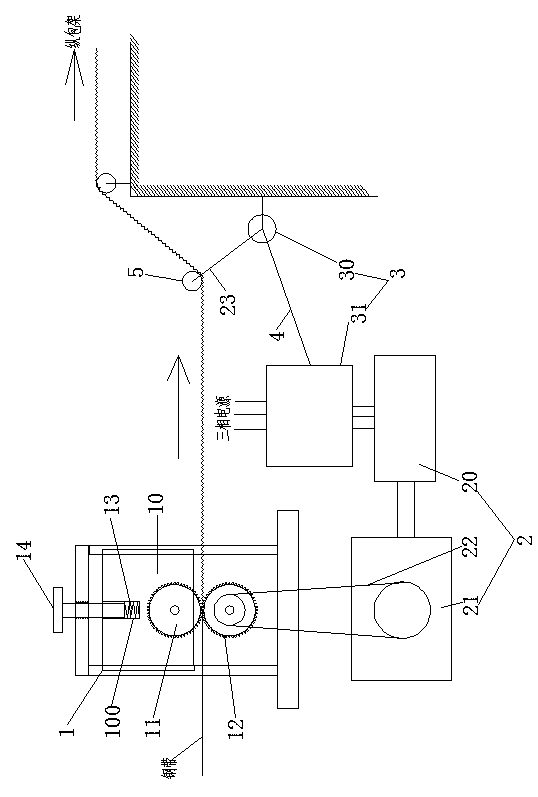

[0009] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0010] see figure 1 , the embodiment of the present invention includes: an embossing device for steel strip and aluminum strip, including: an embossing frame 1, a driving mechanism 2 and an electric control system 3, and a slider 10 is arranged in the embossing frame 1 , upper roll 11 and lower roll 12, described slide block 10 is arranged on the upper half in embossing stand 1, and described lower roll 12 is arranged on the lower half in embossing stand 1, and described upper roll 11 Fixed on the slider 10, a screw hole 100 is set in the upper middle of the slider 10, a spring 13 is installed in the hole of the screw hole 100, and an adjusting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com