Anhydrous stemming for blast furnace

A waterless blast furnace mud and blast furnace technology, applied in the field of refractory materials for blast furnaces, can solve problems such as difficulty in meeting industrialized production, affecting the health of operators, and escaping harmful gases. Conducive to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

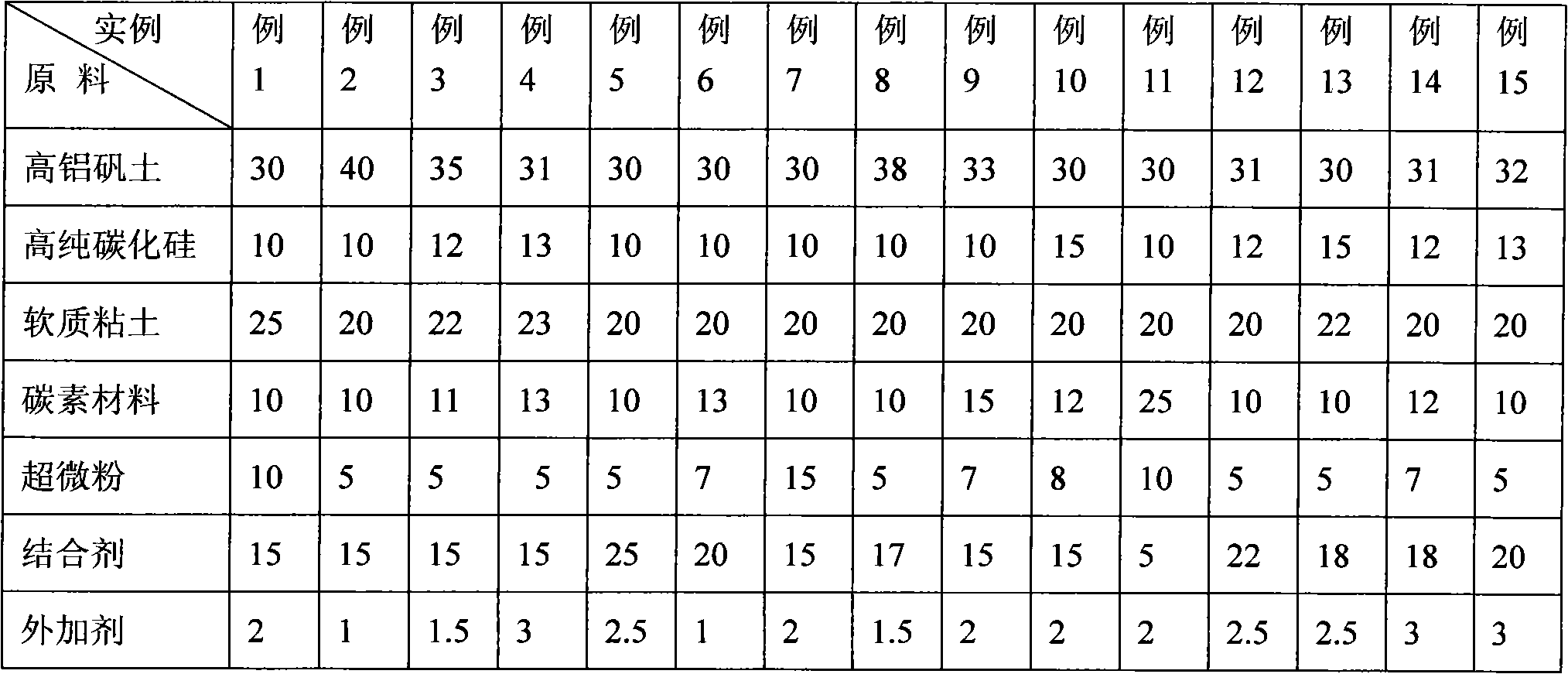

[0016] Embodiment 1: Anhydrous taphole mud for blast furnaces, the raw material formula is shown in Table 1, and in weight percent, 30% of high alumina bauxite, 10% of high-purity silicon carbide, 25% of soft clay, 10% of carbon material, super 10% micropowder, 15% medium-temperature coal tar as a binder; add metal silicon powder additive (ie admixture) accounting for 2% of the total weight of the above-mentioned raw materials.

[0017] Among them, the purity of high-purity silicon carbide is more than 97%, and the particle size is required to pass 200 mesh sieve; the ultrafine powder is Al 2 o 3 , SiC, the mixing ratio of the two is 1:3-4, the particle size of the superfine powder is required to pass through a 325 mesh sieve, and the purity of SiC is more than 97%; the carbon material is graphite; the particle size of the metal silicon powder is required to pass through a 325 mesh sieve.

[0018] Production method: Weigh each raw material, mix and stir evenly, cover and seal...

Embodiment 2~15

[0019] Examples 2-15: The raw material formula of anhydrous taphole clay is shown in Table 1, and the particle size requirement and production method of the raw material are the same as in Example 1, and will not be repeated.

[0020] The carbon material in the embodiment of the present invention is graphite, which can also be replaced by pitch or metallurgical coke.

[0021] Table 1: Components of anhydrous taphole mud for blast furnaces in various examples (in weight percent, %).

[0022]

[0023] Table 2: the performance index of product in the embodiment of the present invention

[0024] serial number

[0025] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com