push nailer

A nailer and pressing technology, applied in nailing tools, manufacturing tools, etc., can solve the problem of easy access to the gap between the firing needle and the firing needle cannula, and achieve the benefits of disassembly and maintenance, simple assembly, and improved performance. The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

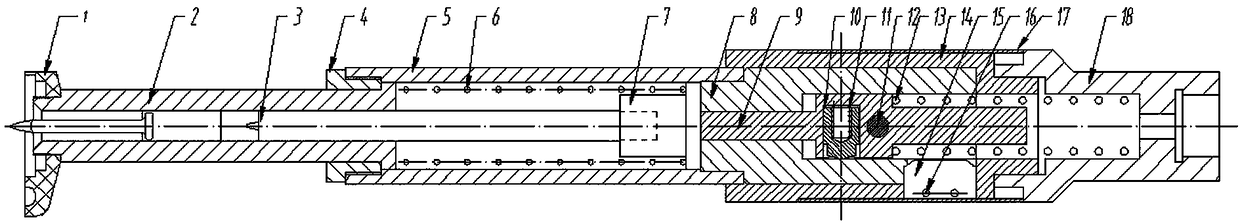

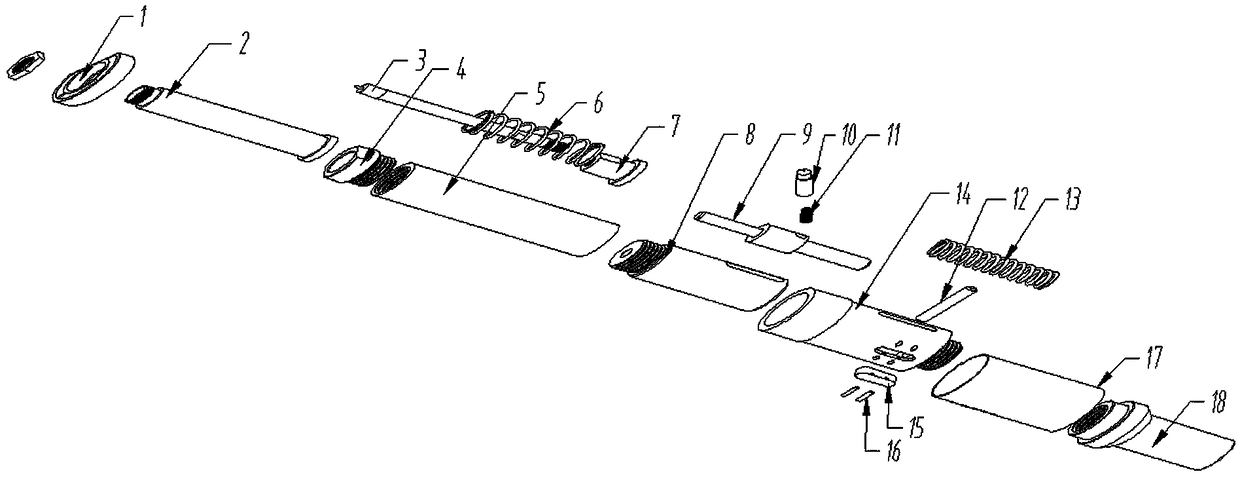

[0038]A push-type nail shooter, including a firing mechanism and a firing mechanism, the firing mechanism includes a firing pin 10, a firing pin compression spring 11, a positioning pin 12, a firing column compression spring 13, a sliding sleeve 14, a firing piece 15, a fastening Pin 16, bushing 17, connecting sleeve 18, firing seat 8 and firing column 9 arranged in firing seat 8, said firing seat 8 is arranged in sliding sleeve 14, and said firing seat 8 and sliding sleeve 14 are provided with There is a waist hole, and the waist hole on the firing seat 8 corresponds to the waist hole on the sliding sleeve 14; the sliding sleeve 14 is connected with the firing piece 15 through the fastening pin 16, and the connecting sleeve 18 is screwed to the sliding sleeve 14. connected, the bushing 17 is sleeved on the sliding sleeve 14 through the connecting sleeve 18; the firing column 9 is provided with an annular boss, and the annular boss is provided with a blind hole and a through ho...

Embodiment 2

[0042] A push-type nail shooter, including a firing mechanism and a firing mechanism, the firing mechanism includes a firing seat 8 and a firing column 9 arranged in the firing seat 8, the firing mechanism includes a gun barrel 2, a gun barrel fixing sleeve 5, Barrel compression spring 6 and firing pin 3, described gun barrel 2 is slidably sleeved on one end of gun barrel fixing sleeve 5, and the other end of described gun barrel fixing sleeve 5 is fixedly sleeved on percussion seat 8, and described firing pin 3 includes a hammer head, a rod body 21 and a seat body 7. The hammer head and the seat body 7 are connected as a whole through the rod body 21. The hammer head is located in the barrel 2, and the seat body 7 is located at the firing end of the firing column 9. The barrel compression spring 6 is sheathed on the rod body 21 , and the barrel compression spring 6 is located between the barrel 2 and the base 7 .

[0043] In this embodiment, the hammer head and the seat body ...

Embodiment 3

[0045] A push-type nail shooter, including a firing mechanism and a firing mechanism, the firing mechanism includes a firing seat 8 and a firing column 9 arranged in the firing seat 8, the firing mechanism includes a gun barrel 2, a gun barrel fixing sleeve 5, Barrel compression spring 6 and firing pin 3, described gun barrel 2 is slidably sleeved on one end of gun barrel fixing sleeve 5, and the other end of described gun barrel fixing sleeve 5 is fixedly sleeved on percussion seat 8, and described firing pin 3 includes a hammer head, a rod body 21 and a seat body 7. The hammer head and the seat body 7 are connected as a whole through the rod body 21. The hammer head is located in the barrel 2, and the seat body 7 is located at the firing end of the firing column 9. The barrel compression spring 6 is sheathed on the rod body 21 , and the barrel compression spring 6 is located between the barrel 2 and the base 7 .

[0046] In this embodiment, the hammer head includes a main ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com