Smelting method for medium coke used in large bell-less blast furnace in high proportion

A smelting method and bell-less technology, which is applied in the smelting field of large-scale bell-less blast furnaces where a high proportion of medium coke is used, can solve the problems such as no positive proposal for a high proportion of medium coke smelting method, and achieve long-term stability. , the effect of eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

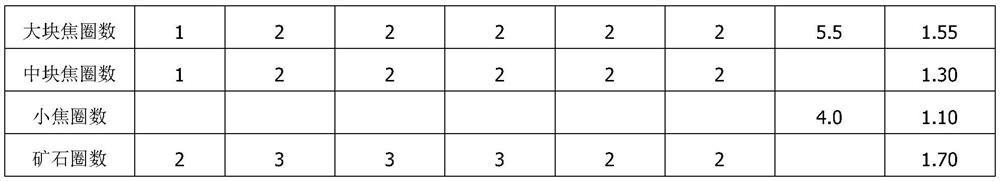

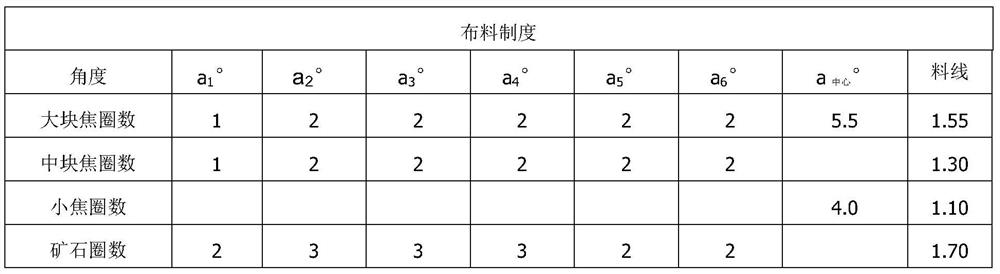

[0024] When the blast furnace uses 270Kg / t of bulk coke, 80Kg / t of medium coke (the proportion of medium coke accounts for 22.8% of the coke entering the furnace), and 58.60t / batch iron batch smelting, the specific countermeasures are as follows:

[0025] 1. Small focus cloth parameter selection (S 中 is the number of medium block batches in each cycle, S 总 is the total number of ore coke batches in each cycle, S 大 is the number of bulk coke batches per cycle, P 中 is the medium batch weight, P 大 is the bulk batch weight, P T Batch weight of small focus, Q 批 is the iron content of each batch of ore, a is the proportion of central coke, K 中 is the focal ratio of the middle block, K 大 is the bulk focal ratio):

[0026] ①, take S 中 = 1, S 总 ==8 (take an even number, not including the number of small focus batches), then S 大 =8÷2-1=3;

[0027] ②, P 中 =K 中 ×Q 批 ×S 总 ÷2÷S 中 ÷1000=80×58.60×8÷2÷1÷1000=18.76t / batch.

[0028] ③, P 大 =(K 大 ×Q 批 ×S 总 ÷2÷1000-P T )÷S 大...

Embodiment 2

[0042] When the blast furnace uses a large coke ratio of 250Kg / t, a medium coke ratio of 100Kg / t (the medium coke ratio accounts for 28.6% of the furnace coke ratio), and batch iron 58.60t / batch smelting, the specific countermeasures are as follows:

[0043] 1. Small focus cloth parameter selection (S 中 is the number of medium block batches in each cycle, S 总 is the total number of ore coke batches in each cycle, S 大 is the number of bulk coke batches per cycle, P 中 is the medium batch weight, P 大 is the bulk batch weight, P T Batch weight of small focus, Q 批 is the iron content of each batch of ore, a is the proportion of central coke, K 中 is the focal ratio of the middle block, K 大 is the bulk focal ratio):

[0044] ①, take S 中 = 1, S 总 ==6 (take an even number), then S 大 =6÷2-1=2;

[0045] ②, P 中 = K 中 ×Q 批 ×S 总 ÷2÷S 中 ÷1000=100×58.60×6÷2÷1÷1000=17.58t / batch.

[0046] ③, P 大 =(K 大 ×Q 批 ×S 总 ÷2÷1000-P T )÷S 大 =(250×58.60×8÷2÷1000-5.2)÷2=19.38t / batch. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com