Distribution method for stabilizing central airflow of blast furnace

A technology for distribution and blast furnace, which is applied to the distribution field of stabilizing the airflow in the center of the blast furnace, can solve the problems such as the deterioration of the blast furnace index, the influence of the stability of the blast furnace condition, and the imprecise placement of the charge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

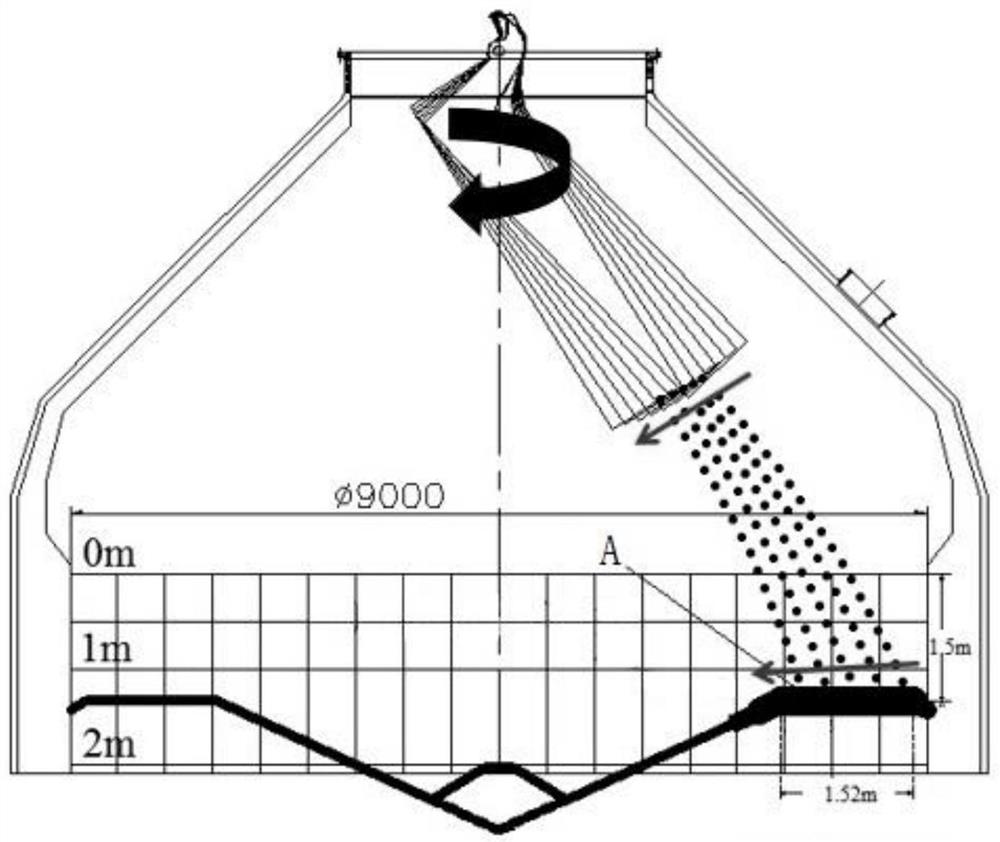

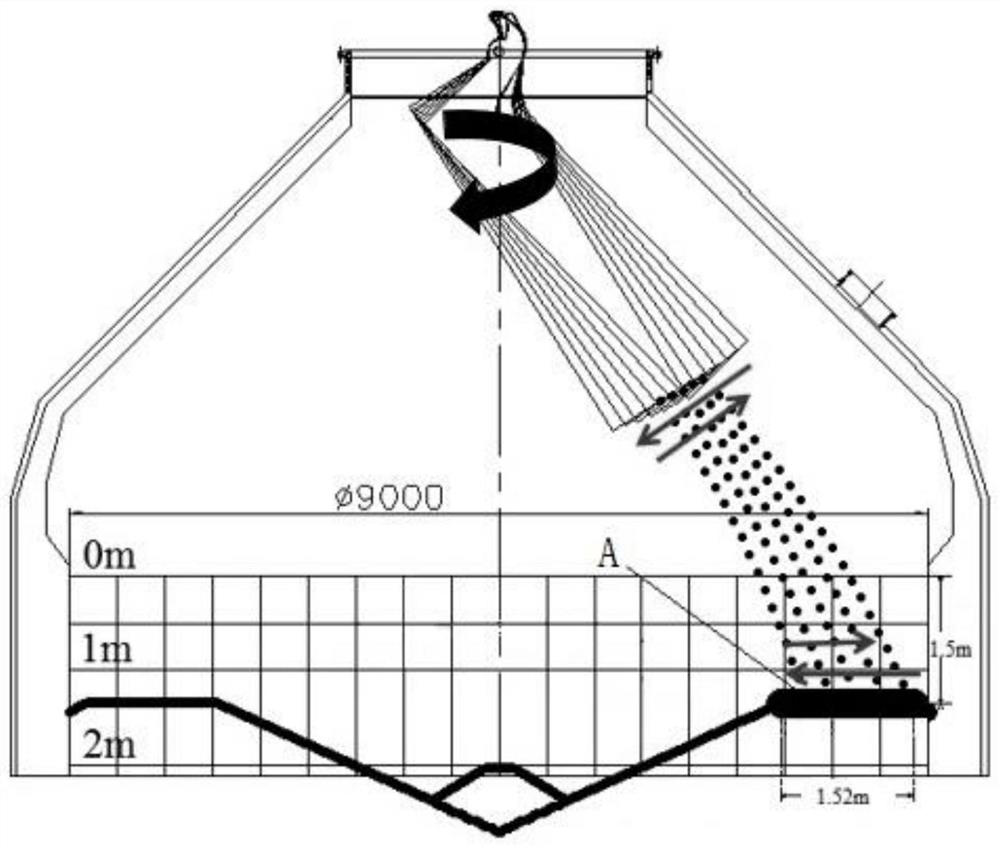

[0032] Embodiment 1 adopts the ore distribution method described in the present invention, and the distribution matrix of ore is Its working principle is: after the ore is distributed on the mine platform, the distribution chute will tilt back from the minimum gear to the middle gear, and then continue to distribute materials, so as to prevent a small amount of ore from entering the central non-mine area during the downward inclination of the distribution chute. Simulated material surface A such as figure 2 As shown, the ore on the mining platform has no slipping phenomenon.

Embodiment 2

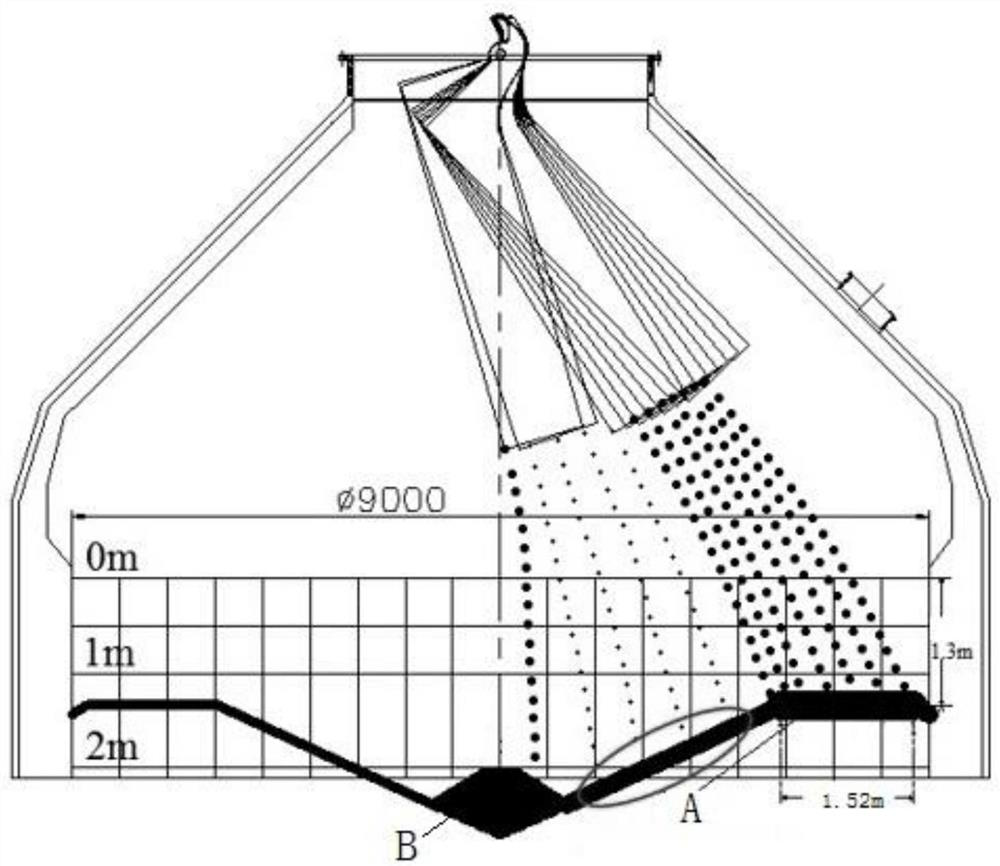

[0034] The coke distribution matrix that embodiment 2 adopts is Its working principle is: the material chute closes the throttle valve at the minimum gear position after the coke cloth is finished on the coke platform to stop the material distribution, the material distribution chute continues to tilt down to the gear corresponding to the center coke, and then opens the throttle valve to continue the material distribution, and the remaining coke (Central coke) is placed in the center of the blast furnace to avoid placing coke on the ring belt between the sub-center and the center coke gear, reduce the size of the coke stack ring in the center of the blast furnace material surface, and improve the accuracy of the center coke amount, thereby stabilizing Blast furnace center airflow. Simulated material surface A such as Figure 4 As shown, the coke did not slip to the ring zone between the sub-center and the center coke gear.

[0035] Such as Figure 5 As shown, in Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com