Double-tire steering axle of engineering machinery

A construction machinery and steering axle technology, applied in the field of double-tire steering axle connection structure, can solve the problems of reduced driver comfort, oil leakage failure of steering cylinder, and reduced tire service life, so as to improve driving safety and prolong service life , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

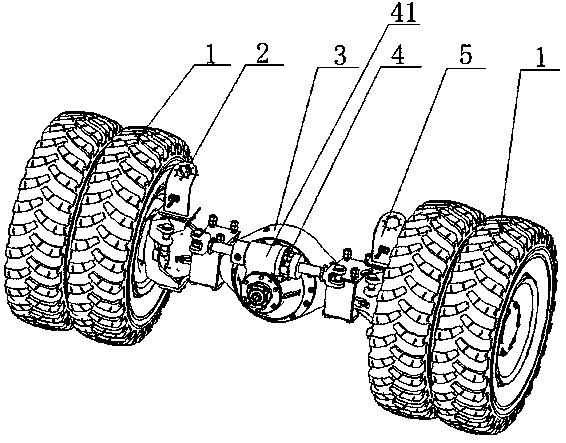

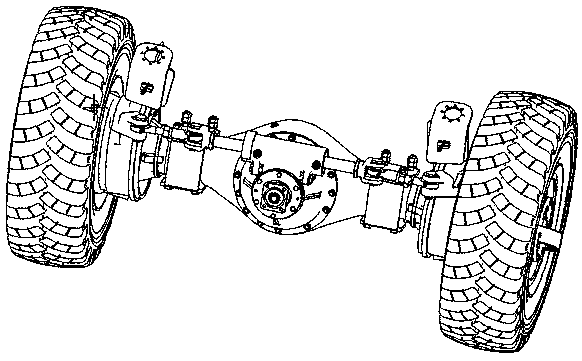

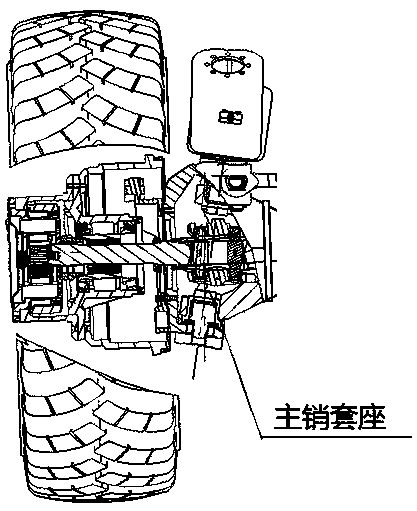

[0020] Embodiment: the two sides of the steering axle housing 3 are equipped with a left-turning arm frame 2 and a right-turning arm frame 5, and a pair of double tires 1 are installed on the left-turning arm frame 2 and the right-turning arm frame 5 through the kingpin and the sleeve respectively. The design of the tire steering axle cancels the inclination angle, that is, the inclination angle of the kingpin and the camber angle of the tire; after changing to a double tire, the total width of the tire remains unchanged, the axle housing and half shaft are shortened, the structure is compact, and the left and right swing angle of the front axle is larger. There is an installation sleeve 41 for the steering cylinder 4 on the steering axle housing 3. Insert the steering cylinder 4 into the installation sleeve 41. There are bolt holes on the wall of the sleeve 41. The installation steps on the side of the steering cylinder 4 and the installation sleeve 41 Cooperate with the end f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com