A group of compounds for stabilizing the reduction potential and dyeing performance of sulfur dyeing systems and methods of use thereof

A sulfur dye and dyeing system technology, applied in the field of textile dyeing, can solve the problems of color fluctuation, damage to electronic components, high price, etc., and achieve the effects of color depth improvement, stability improvement, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] According to the experimental scheme designed in Table 1, the dyeing solution was prepared according to the experimental methods (1), (2), (3), and (4), and the reduction potential was tested and dyed. The reduction potential and the color index of the fabric are shown in Table 2. Show.

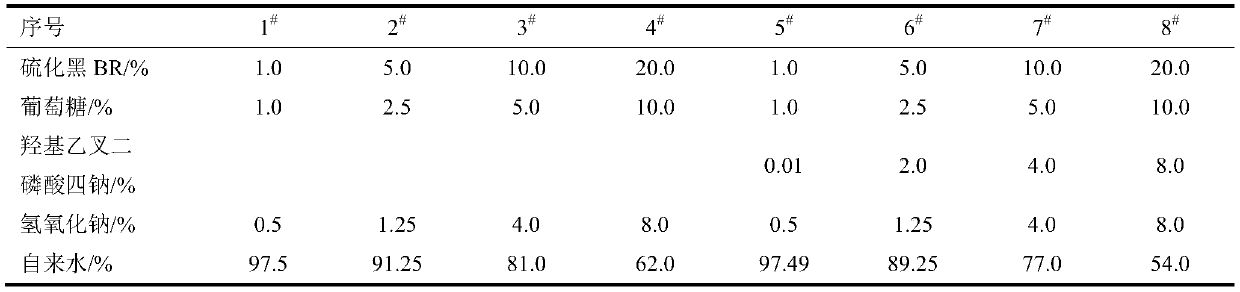

[0057] Table 1. The weight ratio of each component in the dyeing system based on different dye concentrations

[0058]

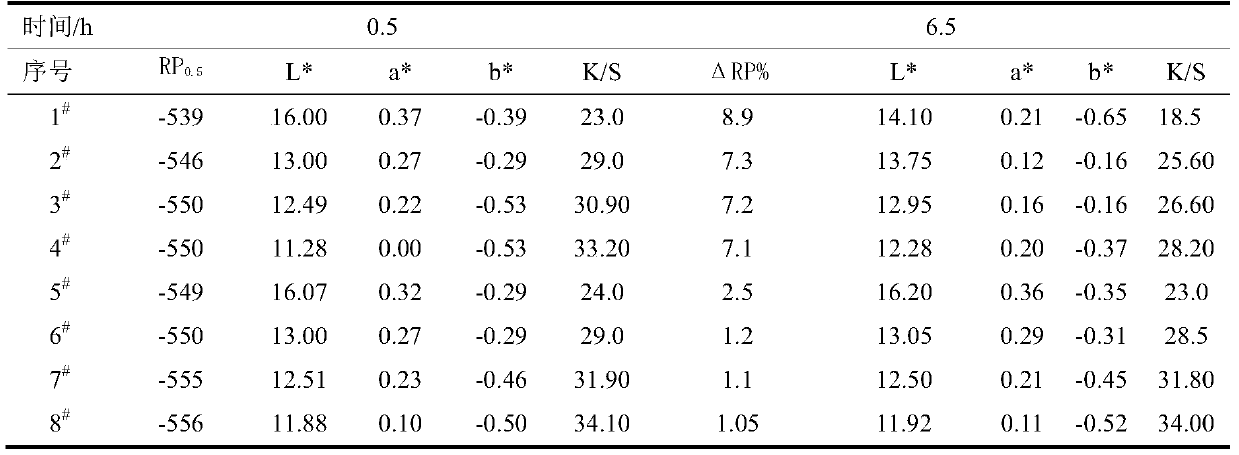

[0059] Table 2 Reduction potential values of dyeing systems based on different dye concentrations and color performance index values after dyeing

[0060]

[0061] Oxidation-reduction potential can measure the effectiveness of changing properties between chemical substances due to electron exchange, and is used to reflect the macroscopic oxidation-reduction properties of all substances in aqueous solution. If the potential is positive, it means that the solution shows certain oxidative properties, and if it is negative, it means that the solution shows red...

Embodiment 2

[0065] Glucose is as the reductant of sulfur black BR, tetrasodium hydroxyethylidene diphosphate and tetrasodium aminotrimethylene phosphonate are as added components According to the experimental scheme designed in table 3, according to experimental methods (1), (2), ( 3), (4) Prepare the dyeing solution, test the reduction potential and carry out dyeing, the reduction potential and the color index of the fabric are shown in Table 4.

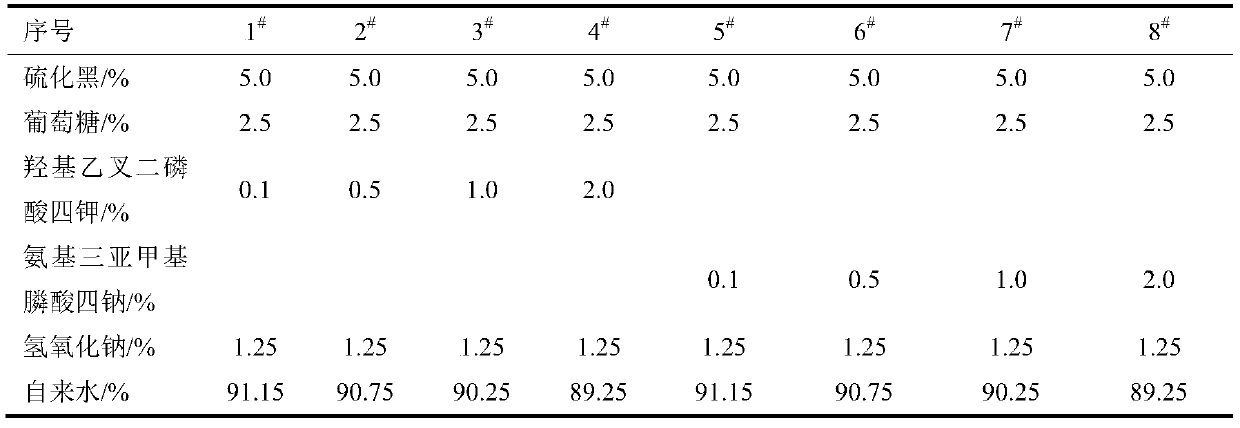

[0066] Table 3. The weight ratio of each component in the dyeing system with different concentrations of organic phosphate

[0067]

[0068] Table 4. Adding different concentrations of organophosphates to the reduction potential value of the dyeing system and the color performance index value after dyeing

[0069]

[0070] As can be seen from Table 3, under the same amount of dye, glucose and sodium hydroxide, 1 # ~4 # The amount of tetrapotassium hydroxyethylidene diphosphate added was increased from 0.1% to 2.0%. When the dosage is 0...

Embodiment 3

[0074] Glucose is as the reductant of sulfur black BR, sodium ethylenediamine tetramethylene phosphonate and heptasodium diethylene triamine pentamethylene phosphonate are as added components, according to the experimental scheme designed in table 5, according to experimental method (1 ), (2), (3), (4) Prepare the dyeing solution, test the reduction potential and dye it, the reduction potential and the color index of the fabric are shown in Table 6.

[0075] Table 5. The weight ratio of each component in the dyeing system with different concentrations of organic phosphate

[0076]

[0077] Table 6. Adding different concentrations of organophosphates to the reduction potential value of the dyeing system and the color performance index value after dyeing

[0078]

[0079] As can be seen from Table 6, under the same amount of dye, glucose and sodium hydroxide, 1 # ~4 # The amount of sodium ethylenediamine tetramethylene phosphonate added was increased from 0.1% to 2.0%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com