Patents

Literature

43results about How to "Shade stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dedicated dye for dyeing blend fabric and mixed fabric

The present invention relates to a kind of special dyestuff applied in mixing fabric and interweaving fabric dyeing, mixed by anion dyestuff, cation dyestuff and surface active agent. The weight proportion of anion and cation dyestuff is 5 - 95 : 5 - 95, the surface active agent is 1% - 200% of the sum of anion and cation dyestuff; the anion dyestuff is selected from acid dyestuff, weak acid dyestuff, neutral dyestuff, active dyestuff or direct dyestuff; the cation dyestuff is selected from cation dye or alkali dyestuff; the surface active agent is selected from fatty mellow polyethyleneoxide ether, alkyl mellow polyethyleneoxide sulfuric ester from the esterification reaction of average add and strong sulfuric acid, the methylene double sodium naphthalenesulfonate added levelling agent O or alkyl phenol polyethyleneoxide ether OP-10. The dyestuff can effectively prevent the interaction of different dyestuff components to form compound or such phenomenon as sedimentation, which can make mixing spinning and interweaving fabrics whose dyeing technologic conditions mutually conflicts as fur / nitrile and cotton / nitrile realize the dyeing technics of One Bath One Step method.

Owner:DONGWU DYE SUZHOU

Polyester/sorona mixed fabric disperse dye one-bath process dyeing method

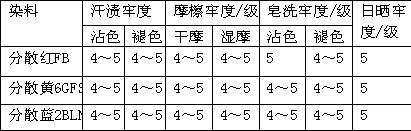

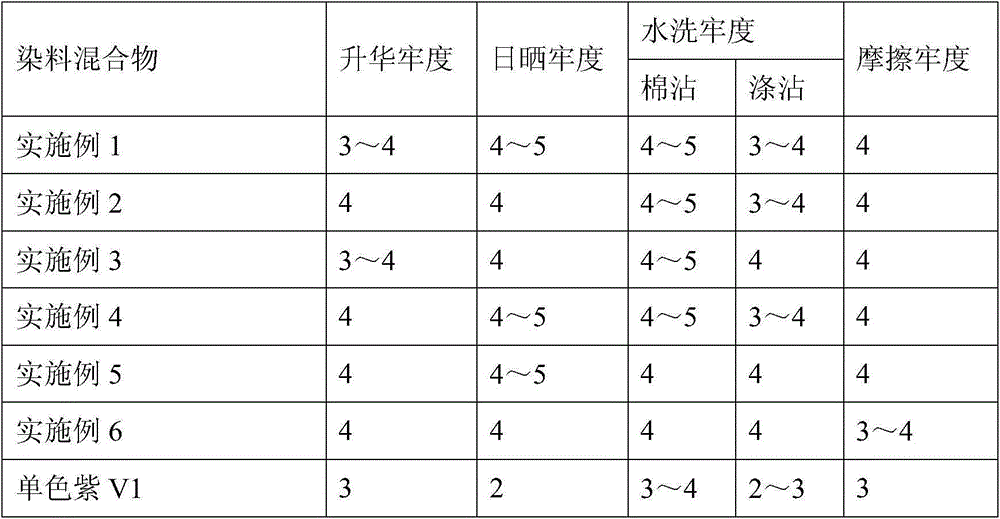

InactiveCN103215831AImprove qualityShade stabilityDry-cleaning apparatus for textilesDyeing processDisperse dyeColour fastness

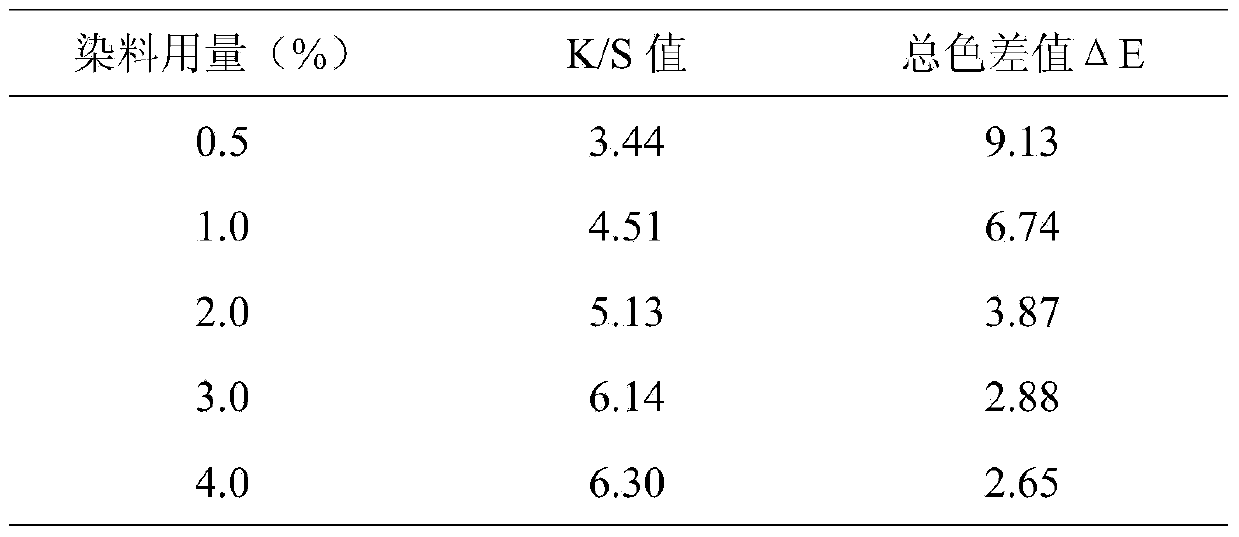

The invention relates to a polyester / sorona mixed fabric disperse dye one-bath process dyeing method. According to the determined optimal dyeing process of polyester / sorona mixed fabric, the dye dosage is greater than or equal to 2% (owf), the pH value is 5.5, the dyeing time is 50 minutes, the dyeing temperature is 110 DEG C, and the carrier dosage is 1.5g / L. The result indicates that the dyeing method can obtain a product with stable color light, good homochromatism and high color fastness; and the process is simple, the time is short, and the production cost is low.

Owner:JIANGYIN POLYTECHNIC COLLEGE

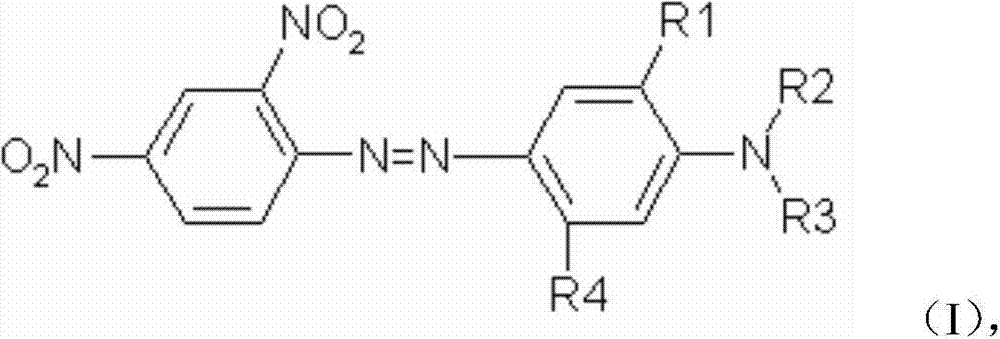

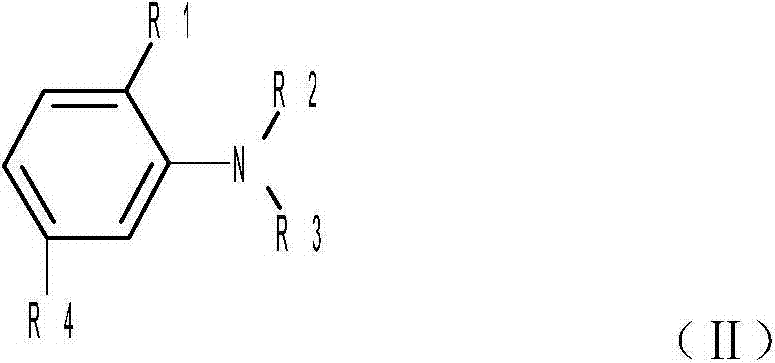

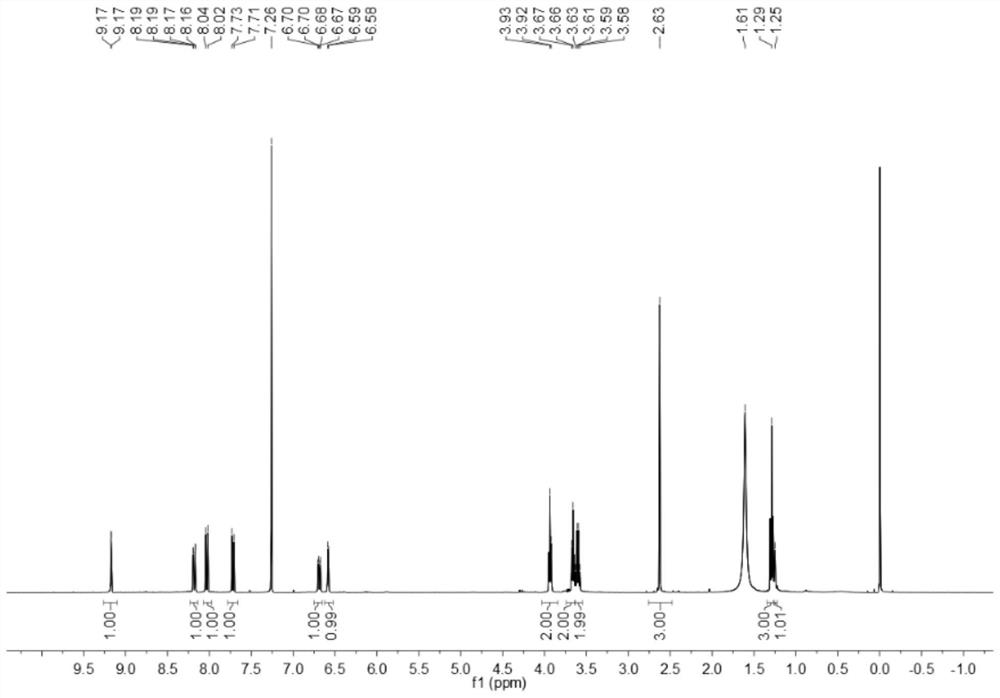

Azo type disperse dye composition synthesis method

ActiveCN103709787AShade stabilityMild crystallization processMonoazo dyesDyeing processDispersion stabilityDisperse dye

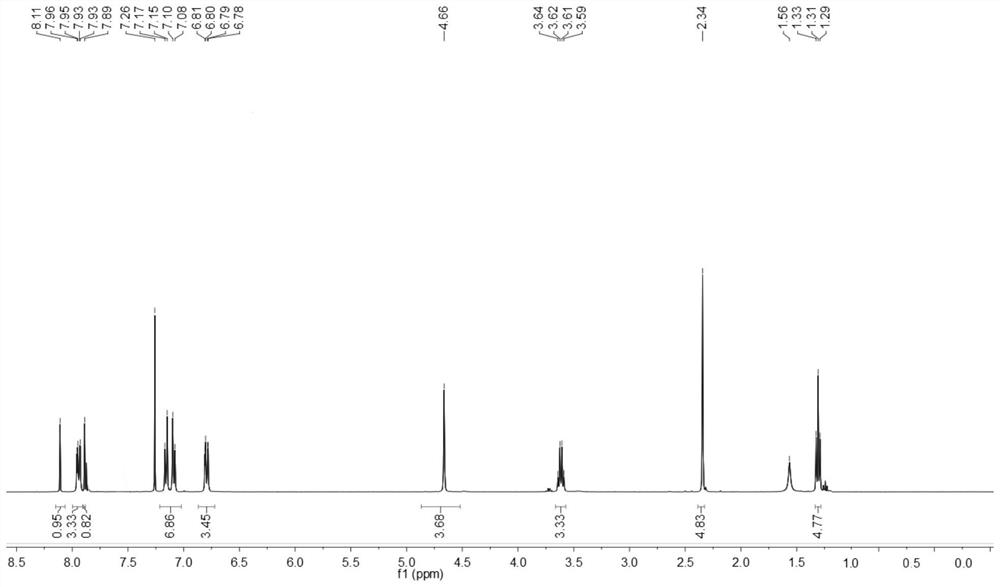

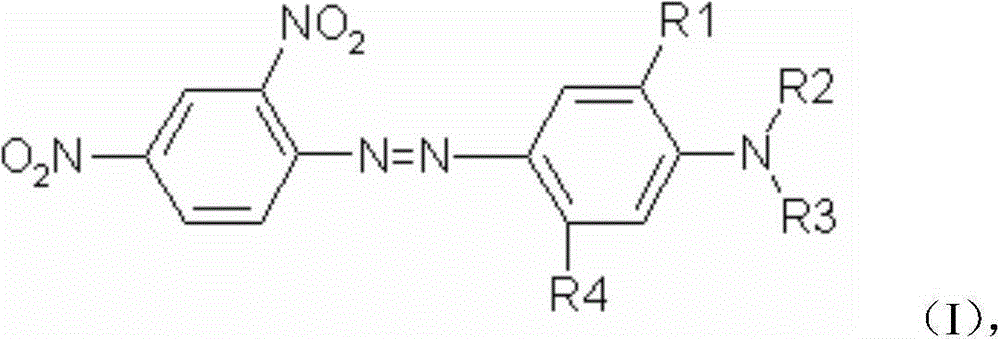

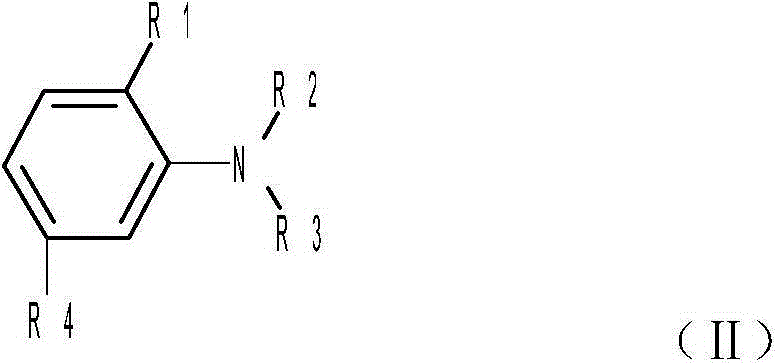

The present invention relates to the technical field of disperse dyes, and provides an azo type disperse dye composition synthesis method so as to solve the problem of not ideal light fastness of the single color variety due to 2,4-dinitroaniline. The synthesis method comprises that: a diazo component 2,4-dinitroaniline of various components in the desired mixture concurrently reacts in the same diazotization device, various coupling components of the mixed dye are coupled in the same coupling device through a plurality of coupling manners according to the ratio requirement with the diazo during coupling, the obtained coupling solution can be subjected to a temperature increase crystal transformation treatment before entering a filter if necessary so as to make the crystal form of the obtained dye be stable, and pressure filtration is performed to directly obtain the dye mixture with the required ratio. According to the present invention, the light fastness problem is solved, the crystal transformation process is mild, and the high temperature dispersion stability, the low temperature dispersion stability and the chromatic light of the dye are stable.

Owner:ZHEJIANG JIHUA GROUP +1

Modified non-woven fabric as well as preparation method and use method thereof

ActiveCN106758212AHigh color fastnessHigh fastnessOther chemical processesWater contaminantsWastewaterNonwoven fabric

The invention discloses modified non-woven fabric as well as a preparation method and a use method thereof. The modified non-woven fabric is prepared from 1-6wt% of ionic liquid, 8-20wt% of a reactive cation modifier and 1-6wt% of inorganic strong alkali based on the weight of the non-woven fabric. The modified non-woven fabric provided by the invention can effectively absorb or adsorb free anionic dyes in dyeing waste liquid or water washing liquor obtained after dyeing, thus increasing the washing efficiency, improving the performance of the washed fabric and reducing the washing temperature; furthermore, a soaping agent does not need to be added, and the pollution level of the waste water is remarkably reduced.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

Active dye cold pad fixation method

InactiveCN106978743ASolve the problem of alkali hydrolysisShade stabilityLiquid/gas/vapor removalTextile treatment machine arrangementsFixation methodAqueous solution

The invention discloses an active dye cold pad fixation method. The method comprises dipping a fabric into a padding liquor, drying the fabric, dipping the fabric into a base rolling liquid, carrying out rolling, carrying out stacking at the normal temperature, carrying out unrolling, and carrying out water washing. The dye is an active dye aqueous solution. Compared with the conventional active cold pad fixation process, the method provided by the invention is free of mixing of the base liquid and dye and putting of the base liquid and dye into a rolling tank so that the problem that the active dye is easily hydrolyzed in the presence of a base in cold pad fixation is solved, the use amount of the active dye is reduced, batch difference is small, color light influence is small and color light is stable. Water and dye are supplied before pad dyeing and base rolling and the dyeing process is smooth and stable.

Owner:WUXI HAIJIANG PRINTING & DYEING

Technology using vaccinium bracteatum plant dye for dyeing of black blue real silk

InactiveCN105369654AWidely distributedAchieve plantingNatural dyesDyeing processVaccinium bracteatumWater baths

The present invention relates to a technology using a vaccinium bracteatum plant dye for dyeing of real silk, the technology includes 60 DEG C water bath extraction of the vaccinium bracteatum plant dye and low temperature environmental-friendly dyeing, the dyeing is as follows: wetting real silk, squeezing to dry, putting the real silk into the plant dye with the bath ratio of 1:20 to 1: 30, adding a mordant or not, heating the water bath to 50-75 DEG C at a heating rate of 1.5 DEG C / min for thermal insulation dyeing for 1-2h; taking a dyeing cup out, standing at room temperature for 7-8h; after the dyeing, steaming the real silk at the temperature of 100-103 DEG C for 10-15min, after washing with water, boiling with soap at 90-100 DEG C for 5-10min, and finally drying at 50-60 DEG C. The obtained real silk has a rare black blue color and special natural flower and plant fresh scent.

Owner:JIANGYIN POLYTECHNIC COLLEGE

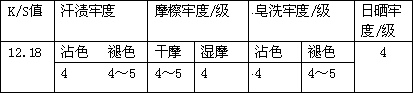

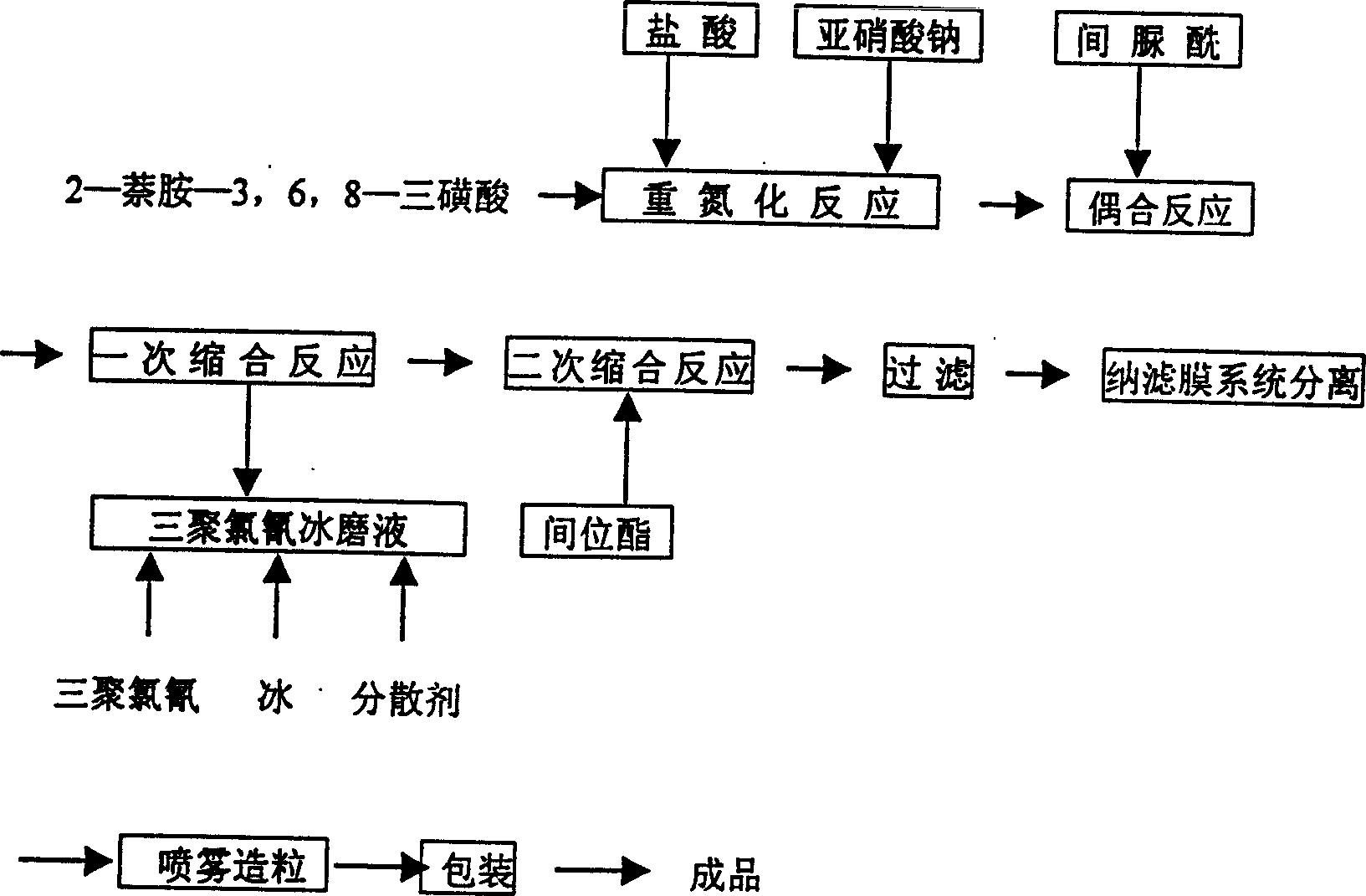

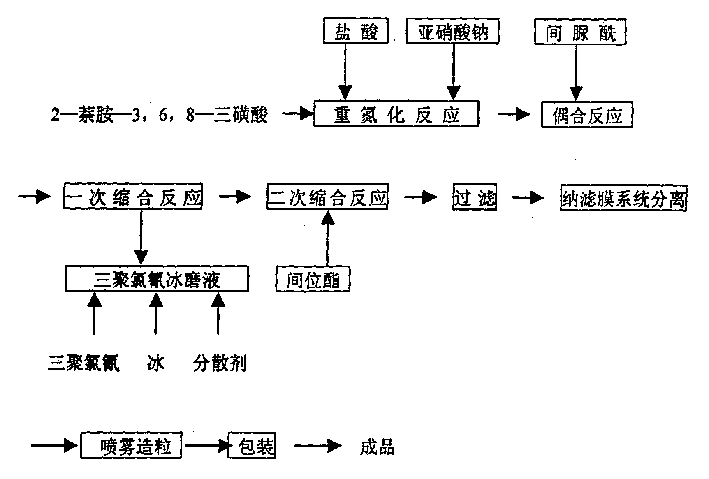

Process for preparing low-salt high-strength active yellow dye

The low-salinity and high-strength active yellow dye is prepared with 2-naphthylamine-3, 6, 8-trisulfonic acid as material and through diazotization and condensation. The present invention features the addition of dispersant in the first condensation, the addition of meta-ester in the second condensation, nano filtering film technology for material liquid separation, pressurized spraying pelletizing and drying and less "three waste" exhaust in the production process. The produced active yellow dye has low salinity, high strength, high color fixation, and other advantages.

Owner:马朝亮

Dark colored reactive dye with high fixation rate

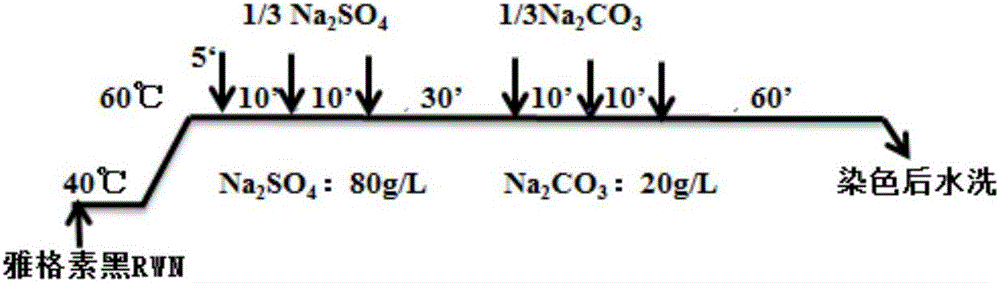

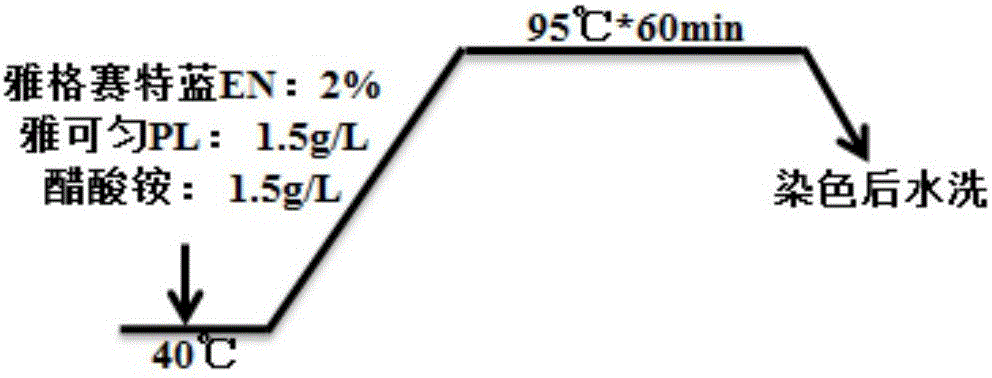

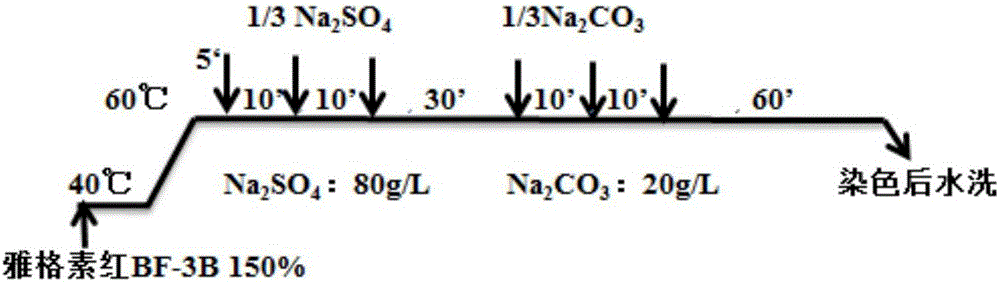

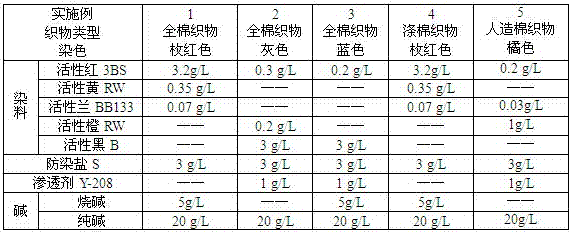

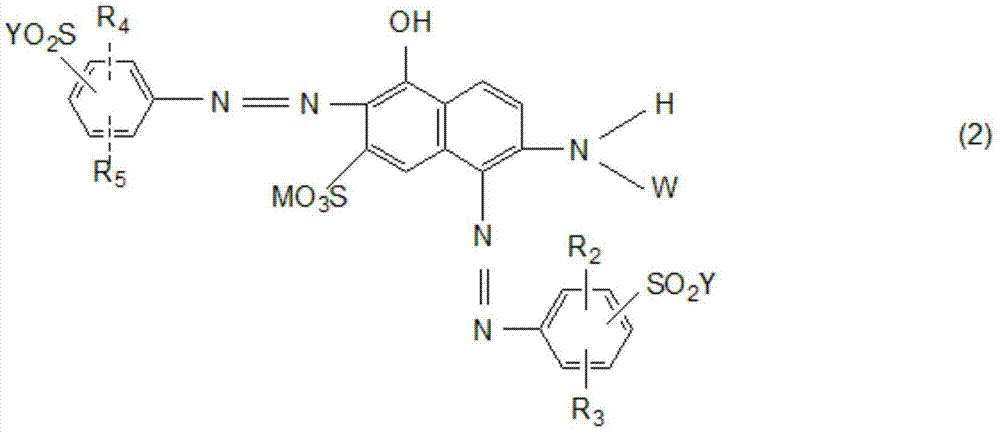

The invention relates to a dark colored reactive dye with high fixation rate, belonging to the technical field of chemical dyestuff. The dark colored reactive dye consists of dark blue, red and yellow reactive dyes. The dye is characterized by comprising dark blue, red and yellow components in structures shown in general formulae. The three-primary-color reactive dye comprises the following components in ratio by weight: dark blue: red: orange=(50-80):(6-25):(6-20). The dark colored reactive dye provided by the invention is applicable to dyeing natural fibers such as cotton, hemps and regenerated fibers and is also applicable to dyeing protein fibers and polyamide fibers. The textile fibers can be in various forms such as fibers, yarns, fabrics or knitted goods. Dip dyeing means that the dyed object is absorbed in a dye bath with an appointed formula and then is fixed by alkali treatment, wherein the dyeing and fixing temperature is 50-70 DEG C. The leveling property of the dye is better promoted, the three components are good in compatibility, the colored light in a dyeing process is relatively stable, and the dye has good pitch-black degree.

Owner:褚平忠

Method for enhancing alkali resistance and oxidation resistance of benzoisothiazole disperse dyes

ActiveCN111995879AIncrease brightnessBright colorMonoazo dyesDyeing processDisperse dyeTextile technology

The invention discloses a method for enhancing alkali resistance and oxidation resistance of benzoisothiazole disperse dyes, and belongs to the technical field of textiles. The method starts from thestructural design of the dye; an azo alkali-resistant disperse dye taking the benzoisothiazole as a diazo component is synthesized; different groups are introduced into the coupling component to enhance the alkali resistance and oxygen bleaching resistance of the heterocyclic azo disperse dye, so that a series of benzoisothiazole disperse dyes with alkali resistance and oxidation resistance strength difference gradients are obtained; the disperse dye capable of meeting the requirements of a polyester-cotton blended fabric bleached cotton and disperse dyeing polyester one-bath process or a polyester fabric alkali deweighting and disperse dyeing one-bath process is determined, and a reference can be provided for the structural design of alkali-resistant and oxidation-resistant disperse dyes.

Owner:QINGDAO UNIV +1

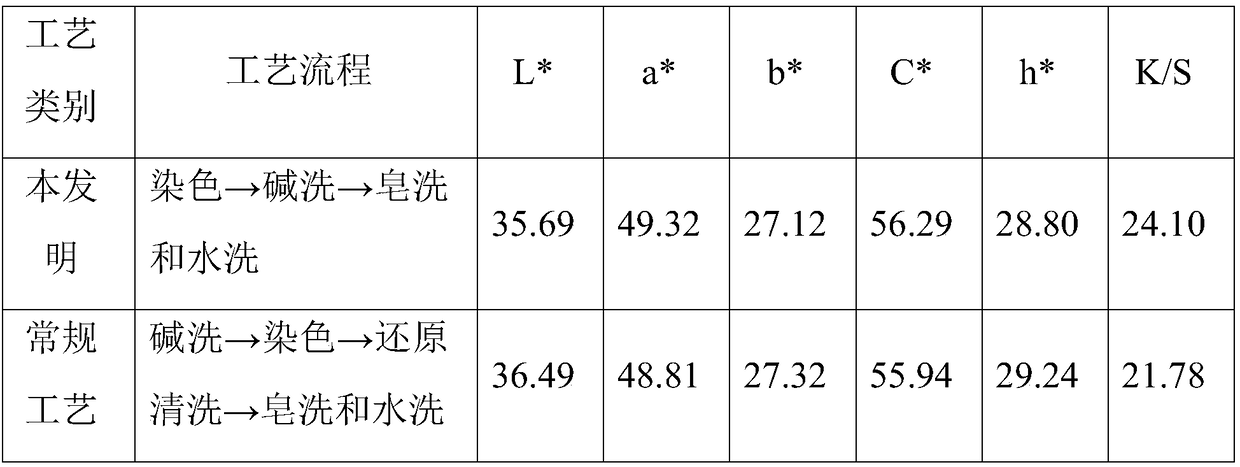

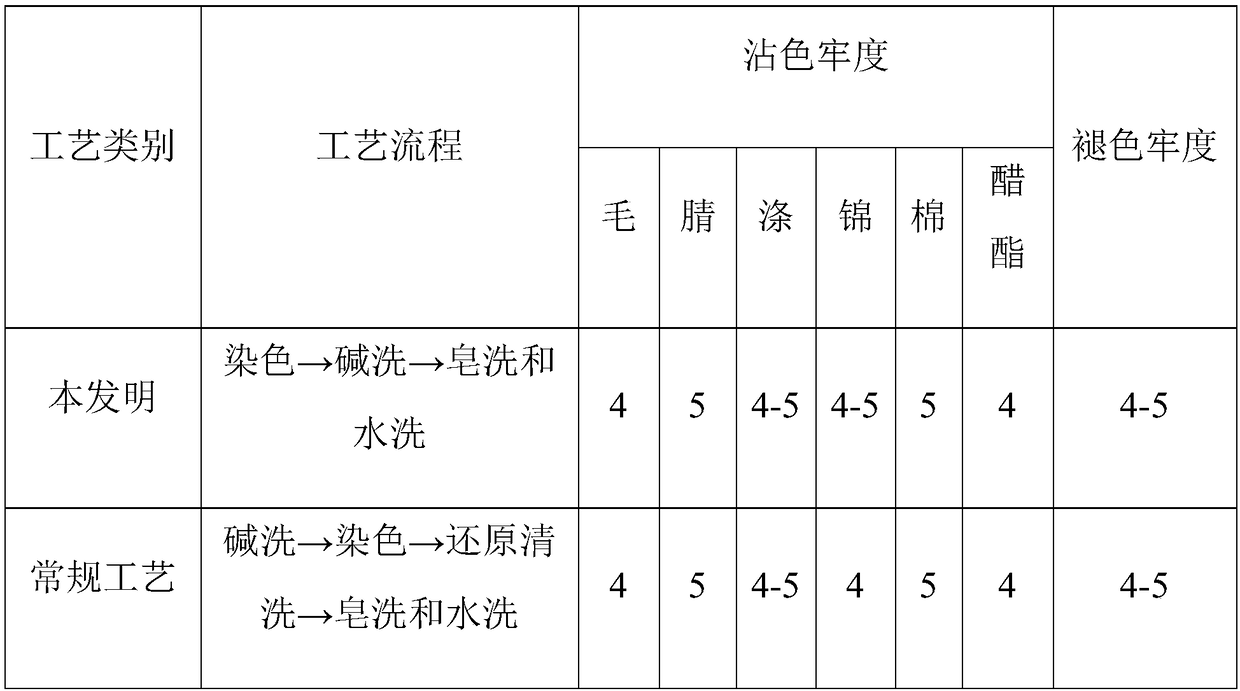

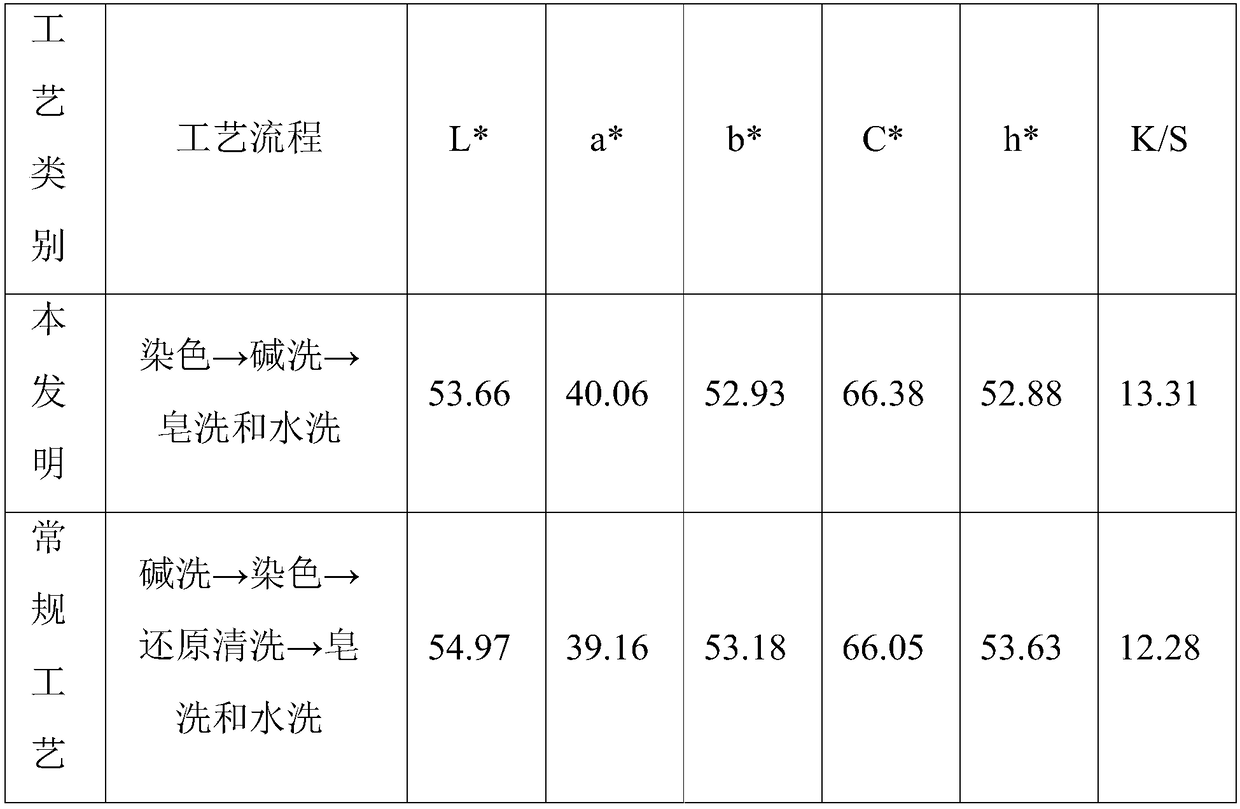

Terylene fabric dispersive dyeing non-reduction cleaning technology

ActiveCN108589329AShade stabilityExcellent color fastness to washingDyeing processEngineeringTextile dyeing

The invention relates to the field of textile dyeing and finishing treatment, and concretely relates to a terylene fabric dispersive dyeing non-reduction cleaning technology. A high alkali-resistant dispersive dye is used for dyeing the terylene fabric, an alkaline solution is used for dyeing the terylene fabric, and soaping and washing can be carried out. The terylene fabric dispersive dyeing non-reduction cleaning technology does not require a reducing agent for reduction cleaning on dyeing terylene fabric, and can effectively remove floated color and color spot on the surface of the fabric,the dyed fabric can obtain the stable colored light and excellent washable color fastness, the technology is simplified and is more environmentally friendly, and reduces the enterprise cost, and increases the enterprise benefit.

Owner:PENGLAI JIAXIN DYES & CHEM

Dye for terylene fabric embossing and manufacturing technique thereof

The invention discloses a dye for terylene fabric embossing, which is prepared by the following components by weight percentage: 80% to 90% disperse red BLSF, 0.5% to 2% 3B red, and 8% to 18% diffusat MF. The invention also provides a manufacturing technique of the dye. The invention has the advantages of stable color tone, bright color, firmness, high dye uptake, environment friendliness, and safety.

Owner:韩耀君

Dye for polyester fabric and production process of dye

The invention discloses a dye for polyester fabric and a production process of the dye. The dye is prepared from the following raw materials in percent by weight: 70%-90% of disperse violet SE-BL; 0.2%-2% of disperse red 3B and 8%-28% of dispersing agent MF. The dye disclosed by the invention has the characteristics of stable color and light, bright color, high dyeing rate, strong fastness, good washing fastness, environmental friendliness and safety.

Owner:浙江山川科技股份有限公司

Digital printing process for polyester fabric

InactiveCN110195361AShade stabilityBright colorWrinkle resistant fibresGrip property fibresPolyesterEngineering

The invention discloses a digital printing process for a polyester fabric. The process comprises the following steps that a digital printing thickner is prepared; a pretreatment agent is prepared; thepolyester fabric is cleaned by adopting deionized water, dried, and then placed in the pretreatment agent in S2, dipping is carried out twice, rolling is carried out twice, then the polyester fabricis taken out and dried to obtain a pretreated fabric; then sizing treatment is performed on the surface of the pretreated polyester fabric in S3 through the thickner obtained in S1; after the surfaceof the pretreated polyester fabric is sized, the pretreated polyester fabric is sent into a hot press, and the fabric is placed in a high-temperature high-pressure environment for hot pressing; the hot-pressed fabric in S5 is dried. A printing thickner colorant has stable colored light, bright color, a high color yield, a clear printing outline and good washing fastness and rubbing fastness, and is environmentally friendly and safe; the use of the pretreatment agent on the fabric can improve the mechanical properties of the fabric; the whole process is simple to operate, has a good printing effect and low cost, and the obtained pattern effect is exquisite and beautiful.

Owner:苏州市彩旺纺织整理有限公司

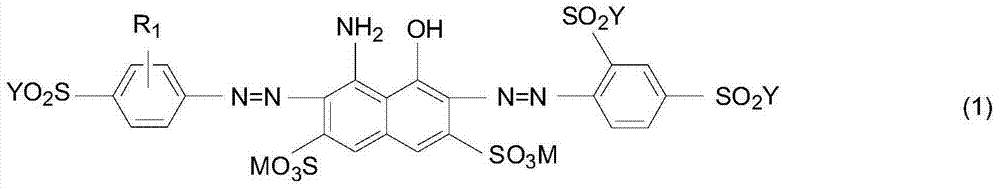

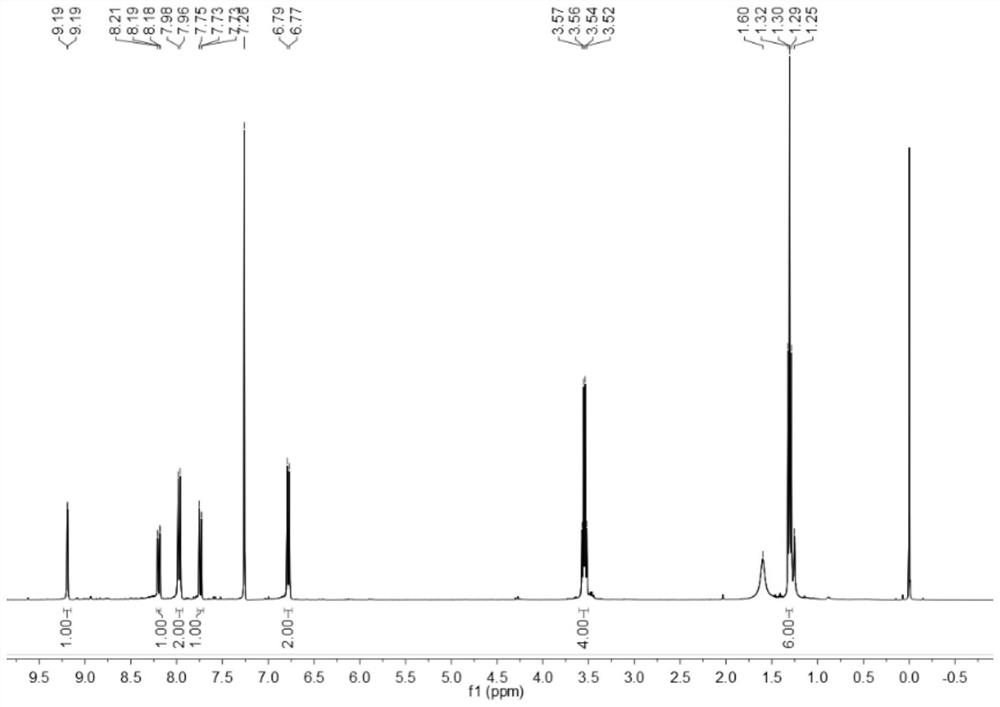

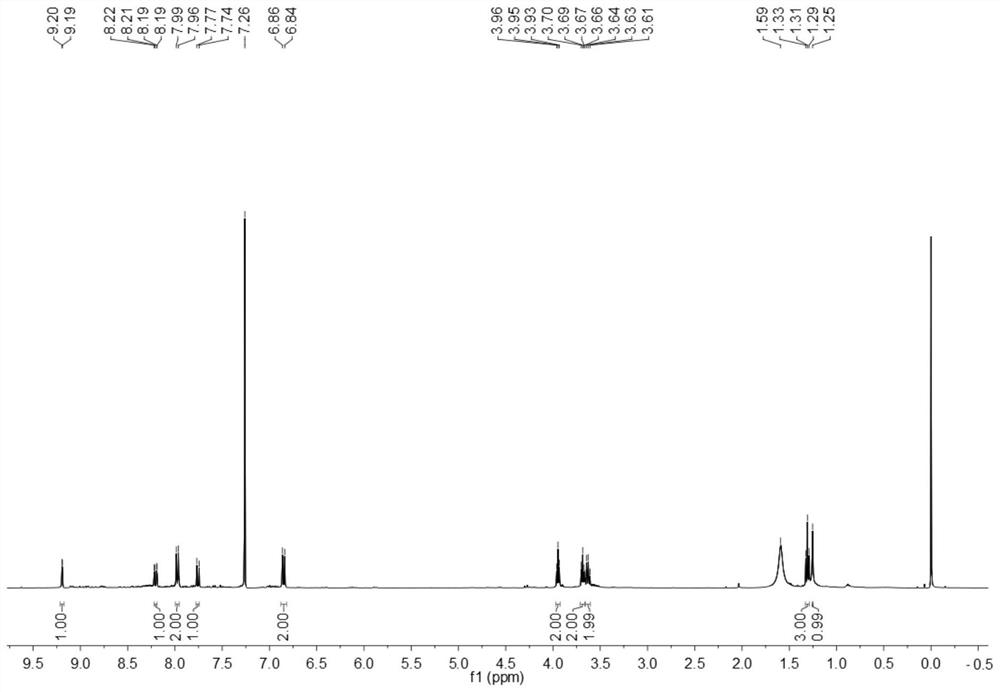

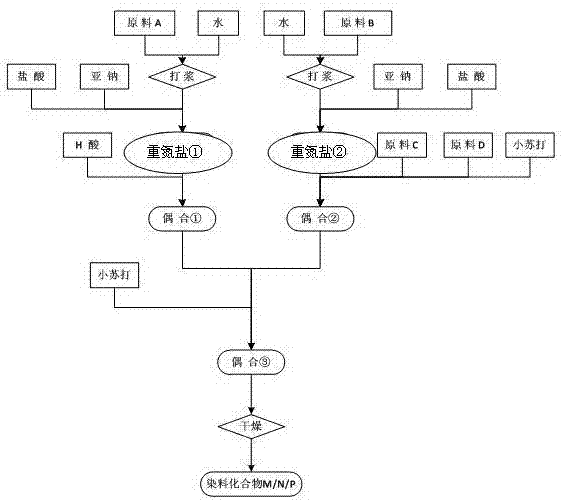

Synthesis method of black active dyestuff compound

The invention relates to a synthesis method of a black active dyestuff compound and belongs to the field of dyestuff chemistry. The synthesis method comprises the following steps: preparing a raw material A shown as a formula 1 into a first coupling solution; preparing a raw material B shown as a formula 2 into second diazonium salt and preparing the second diazonium salt, a raw material C shown as a formula 3 and a raw material D shown as a formula 4 into a second coupling solution under the condition that baking soda is added; mixing the first coupling solution and the second coupling solution; carrying out third coupling reaction and drying to obtain the black active dyestuff compound. The synthesis method of the black active dyestuff compound, provided by the invention has comprehensive advantages in the aspects of equipment, manpower, reaction time, product quality and the like when being compared with a former technology; the reaction time is greatly shortened to 8h to 14h; a synthesized black dyestuff has stable quality and good reproducibility; the yield of a product is 2 percent to 3 percent higher than that of a former mixture technology; reaction steps are reduced so that the occupied rate of reaction equipment is low; meanwhile, post-treatment procedures and equipment are saved, so that the defects of more mixture reaction equipment and great blending working amount are overcome.

Owner:SHANGHAI WANDE CHEM

Dye for polyester textures and production process thereof

The invention discloses a dye for polyester textures and a production process thereof. The dye is prepared from the following raw materials in percentage by weight: 20% to 30% of dispersing brilliant red F-3BS, 10% to 20% of dispersing red FB, and 50% to 70% of dispersing agent MF. The dye has the advantages that the color and the light are stable, the color is bright, the dyeing rate is high, the fastness is high, the washable effect is high, and the environment-friendly effect and safety are realized.

Owner:浙江山川科技股份有限公司

Coloring agent for pure cotton fabric dyeing and printing and production process thereof

The invention discloses a coloring agent for pure cotton fabric dyeing and printing and a production process thereof. The coloring agent for pure cotton fabric dyeing and printing is prepared from the following raw materials in percentage by weight: 70 to 80 percent of reactive red GB, 10 to 20 percent of reactive brilliant red and 10 to 20 percent of anhydrous sodium sulphate. The coloring agent for pure cotton fabric dyeing and printing has the characteristics of stable color light, bright color, high dyeing rate, high fastness, good washable effect, environmental protection and safety.

Owner:南通隆彩纺织科技有限公司

Dispersing agent for dyeing of polyester fabrics and production process thereof

The invention discloses a dispersing agent for the dyeing of polyester fabrics and a production process thereof. The dispersing agent for the dyeing of the polyester fabrics is prepared from the following components in percentage by weight: 20 to 30 percent of disperse blue 2BLN, 0.01 to 0.05 percent of disperse turquoise blue S / GL, 30 to 40 percent of disperse blue SE / 5R, 0.004 to 0.008 percent of disperse yellow 8GFF and 30 to 40 percent of dispersing agent MF. The dispersing agent for the dyeing of the polyester fabrics and the production process thereof have the characteristics of stable chromatic light, bright color, high fastness, high dyeing rate, environmental friendliness and safety.

Owner:浙江山川科技股份有限公司

Coloring agent used for dyeing and printing polyester cotton and pure cotton fabric and production process thereof

The invention discloses a coloring agent used for dyeing and printing polyester cotton and a pure cotton fabric and a production process thereof. The coloring agent is prepared from the following raw materials in parts by weight: 0.018-0.08 part of disperse blue 2BLN, 0.1-0.3 part of disperse violet HFRL, and 90-100 parts of brightener CPS-D. The coloring agent disclosed by the invention has the advantages of stable color tone, bright color, high dyeing rate, high fastness, good washing-resisting effect, environmental protection and safety.

Owner:浙江山川科技股份有限公司

Method for enhancing alkali resistance and oxidation resistance of benzothiazole disperse dyes

The invention discloses a method for enhancing alkali resistance and oxidation resistance of benzothiazole disperse dyes, and belongs to the field of disperse dyes. According to the method, four diazocomponents and eight coupling components are adopted to design and synthesize 28-branch thiazole heterocyclic azo disperse dyes, so that the alkali resistance and the oxidation resistance of the disperse dyes are enhanced. The synthesized disperse dyes are subjected to structure confirmation, and the alkali resistance, the oxidation resistance and other dyeing properties of the disperse dyes aretested. According to the method for enhancing the alkali resistance and the oxidation resistance of the benzothiazole disperse dyes, the relationship between the dye structure and the alkali resistance and the oxidation resistance is clear, the disperse dyes with excellent alkali resistance and oxidation resistance are obtained, and the dyeing property is stable under the dyeing condition of 10g / Lsodium hydroxide or 5g / L hydrogen peroxide. The dyes can be applied to bleaching and dyeing one bath of polyester cotton and decrement dyeing one bath of polyester, short-process dyeing and finishingprocessing is achieved, and huge ecological benefits and economic benefits are generated.

Owner:QINGDAO UNIV +1

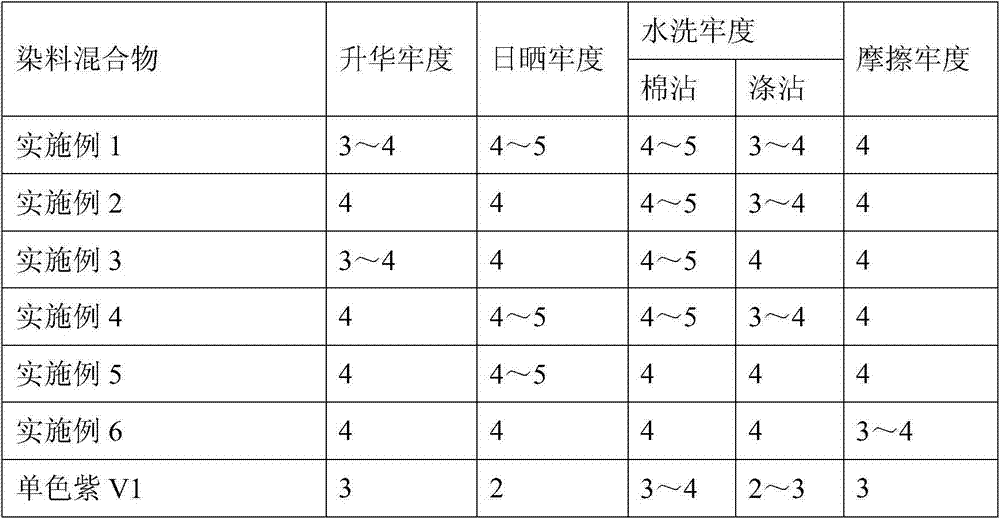

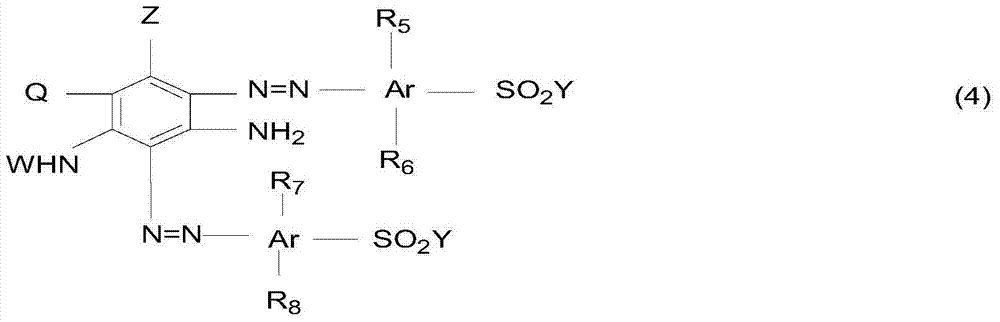

Disperse grey dye composition

PendingCN113025076AHigh dyeing consistencyShade stabilityOrganic dyesDyeing processPolymer chemistryDisperse dye

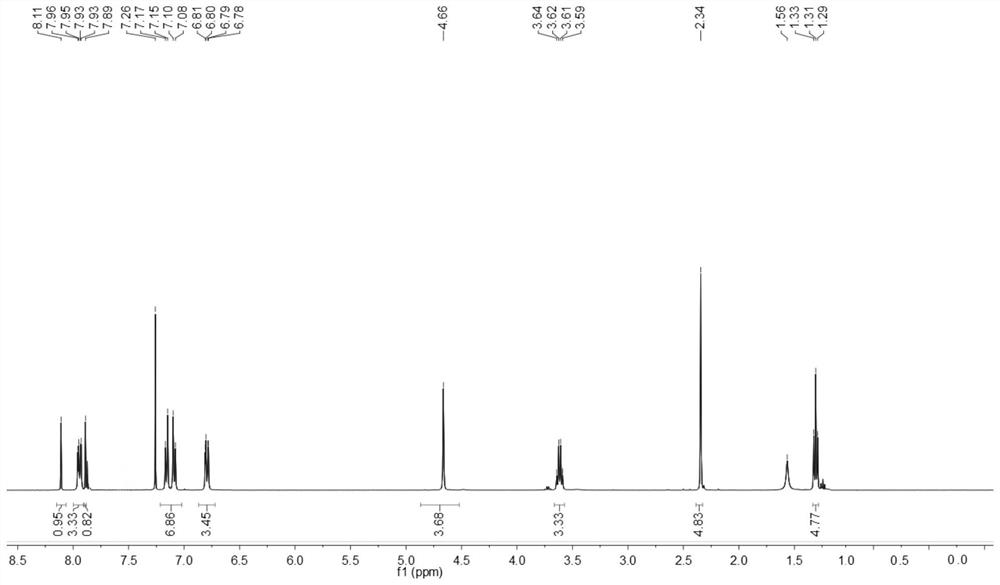

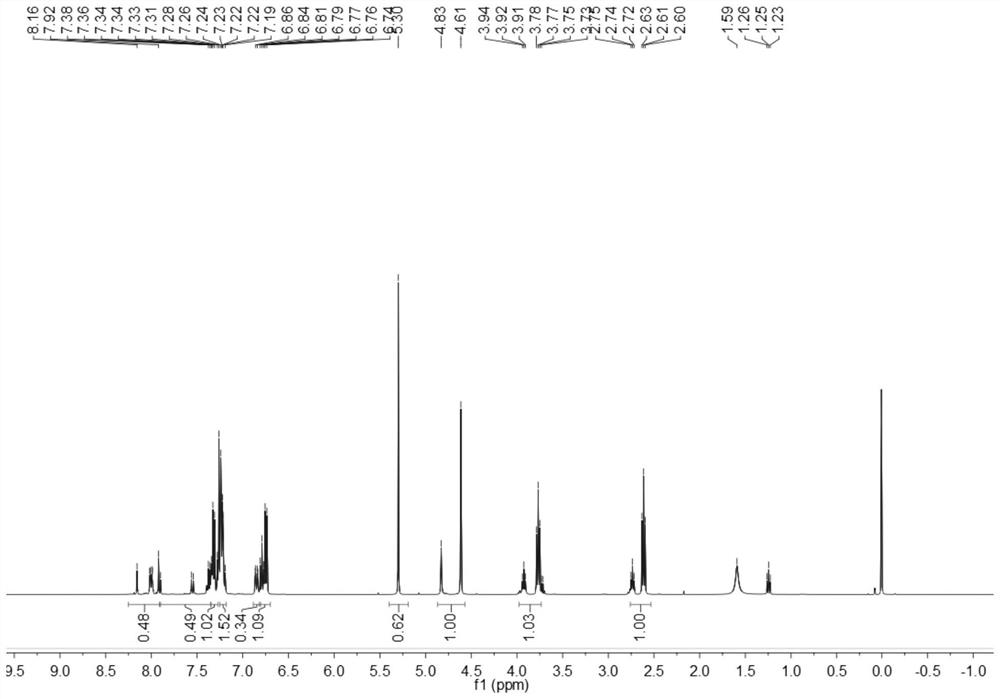

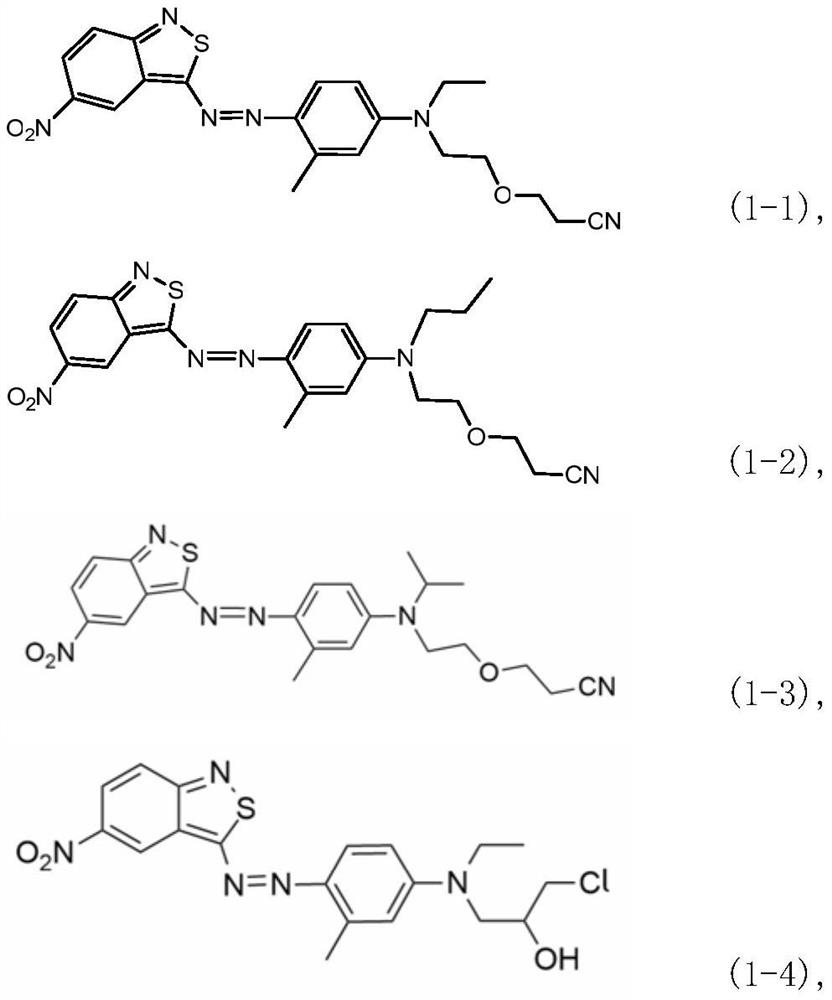

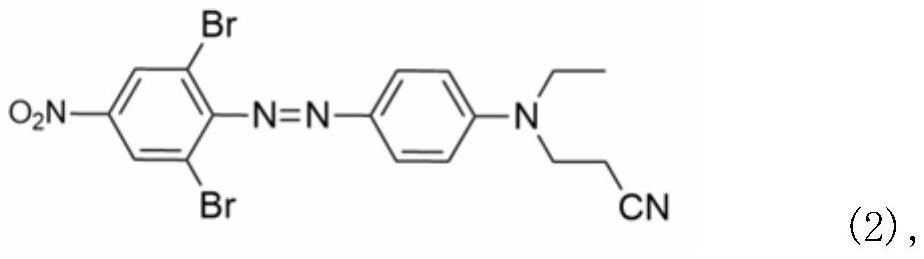

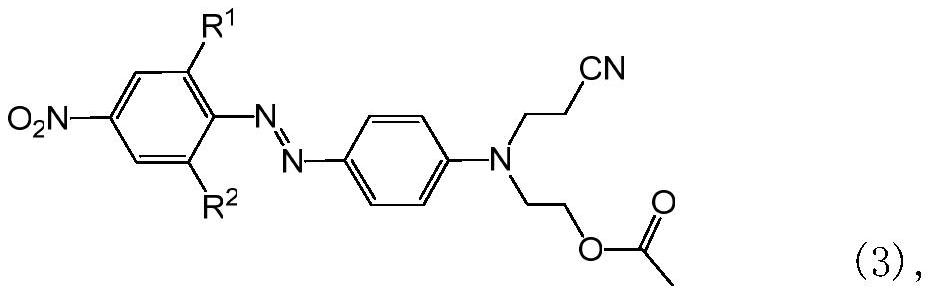

The invention discloses a disperse grey dye composition, and belongs to the technical field of disperse dye compositions. The composition is characterized by comprising the following components in percentage by weight: a component A which is one or more of compounds shown as a formula (1-1), a formula (1-2), a formula (1-3) and a formula (1-4); a component B which is a compound as shown in a formula (2); a component C which is a compound as shown in a formula (3); and a component D which is one or more of compounds as shown in a formula (4). Compared with common disperse grey dye compositions, the disperse grey dye composition disclosed by the invention is high in coloring consistency and good in compatibility in a dyeing process, does not generate dyeing defects even if dyeing interruption is caused by a failure in the dyeing process, and is particularly suitable for a short-process rapid dyeing process.

Owner:浙江昱泰科技有限公司

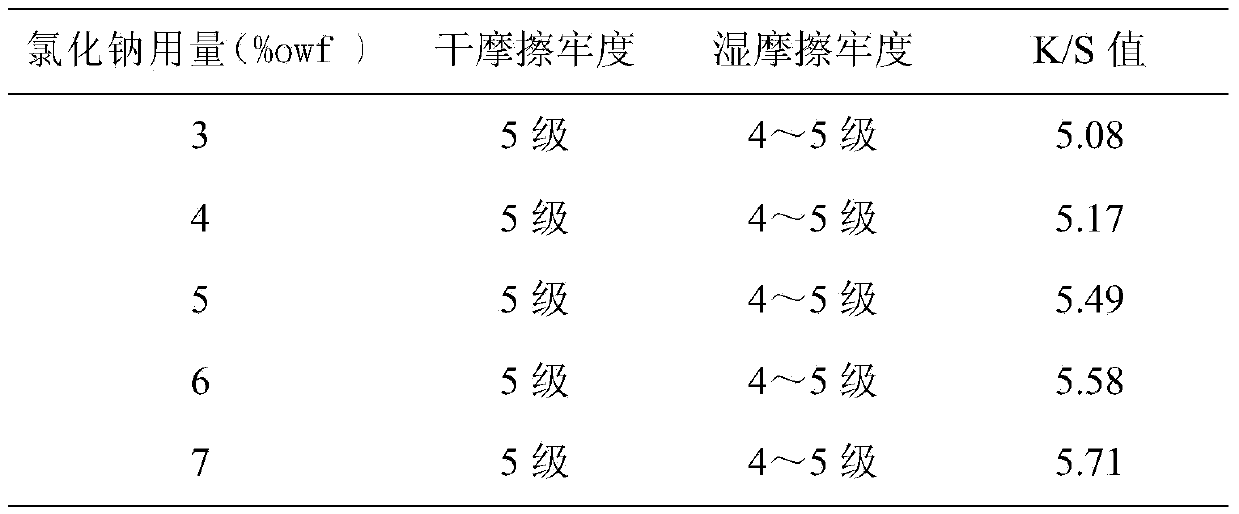

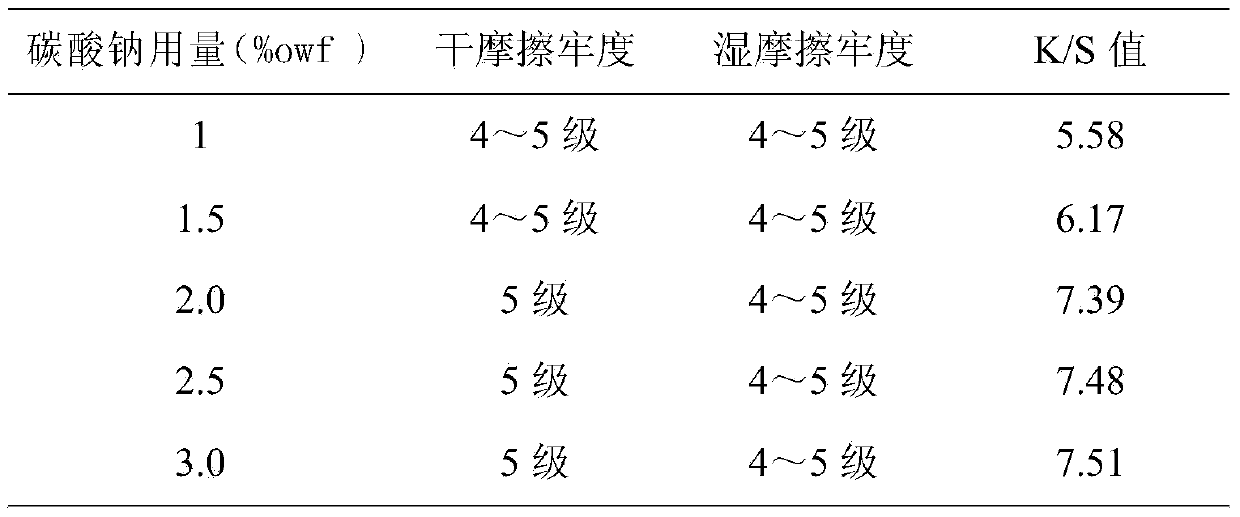

Hemp and denim active dye and dyeing technology

The invention provides a hemp and denim active dye and a dyeing technology. The dye is prepared from active yellow 3RS, sodium chloride, sodium carbonate, polyvinylamine and a penetrant TR. The dye and the dyeing technology are high in reproducibility, high in stability and high in dry and wet fastness; after being dyed, a fabric has a high fixation rate and is full in chromaticity and bright in color. Multiple practices prove that a yarn sample is finally very close to that supplied by a customer; meanwhile, dyeing is quite stable; the sizing percentage is proper, and the cloth machine efficiency is over 95 percent; a final denim product is extremely close to a sample supplied by the customer in the style, the color and the quality, and the enzyme wash and stone grinding effect of the final denim product is almost the same with that of the sample supplied by the customer.

Owner:浙江丝之美服饰染整有限公司

Pure cotton textile dyeing and printing dye and production technology of the same

ActiveCN102391682AShade stabilityBright colorsOrganic dyesDyeing processComposite materialPolymer chemistry

The invention discloses a pure cotton textile dyeing and printing dye and a production technology of the same. The pure cotton textile dyeing and printing dye is prepared by the following materials in percent by weight: 70%-80% of active black BMGB; 10%-20% of reactive brilliant blue BR and10%-20% of anhydrous sodium sulphate. The pure cotton textile dyeing and printing dye has the characteristics of being stable in color light, bright in color, high in dye-uptake, strong in fastness, excellent in washing resisting effect and environment-friendly and safe.

Owner:晋江市浪潮服装工贸有限公司

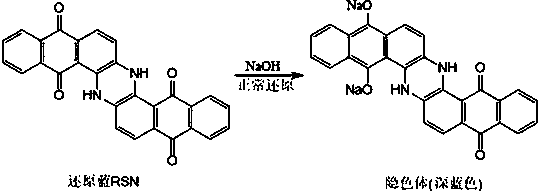

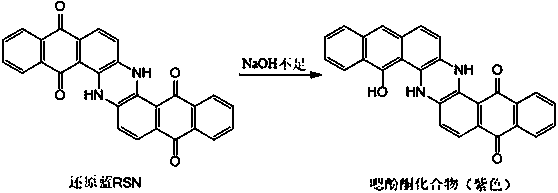

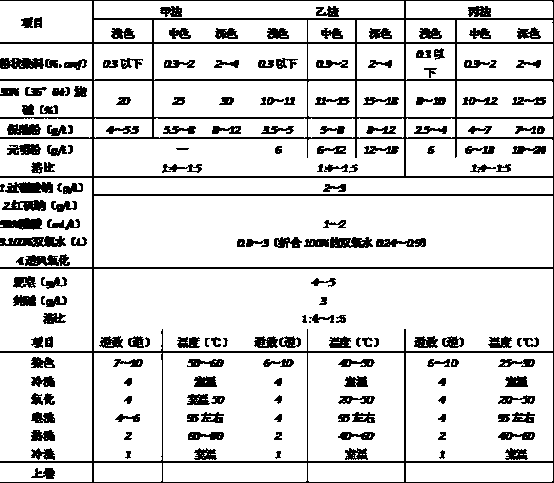

Batch dyeing method to dye cotton fabrics with vat dyes under enhanced oxidation and zero soaping

The invention relates to a batch dyeing method to dye cotton fabrics with vat dyes under enhanced oxidation and zero soaping and belongs to the technical field of printing and dyeing. The technical problem to be solved is to provide a batch dyeing method with vat dyes under enhanced oxidation and zero soaping. The batch dyeing method to dye cotton fabrics with vat dyes under enhanced oxidation andzero soaping comprises the steps of after mercerizing and before dyeing entry for dry fabric, performing all-in bath reduction, carrying out jig dyeing and vat treating, oxidizing, cold washing, hotwashing, cold washing, and rolling. An oxidizing liquid includes 1-7 g / L OF 100% hydrogen peroxide; a reducing liquid includes 3.2-12 g / L of 100% caustic soda, 3-12 g / L of 85% sodium hydrosulfite and-24 g / L of sodium sulfate. The oxidation parameters of the traditional process are adjusted, oxidation is enhanced, soaping is omitted, the process route is shortened, benefit is improved, and the cost is lowered.

Owner:SHANXI CAIJIA PRINTING & DYEING

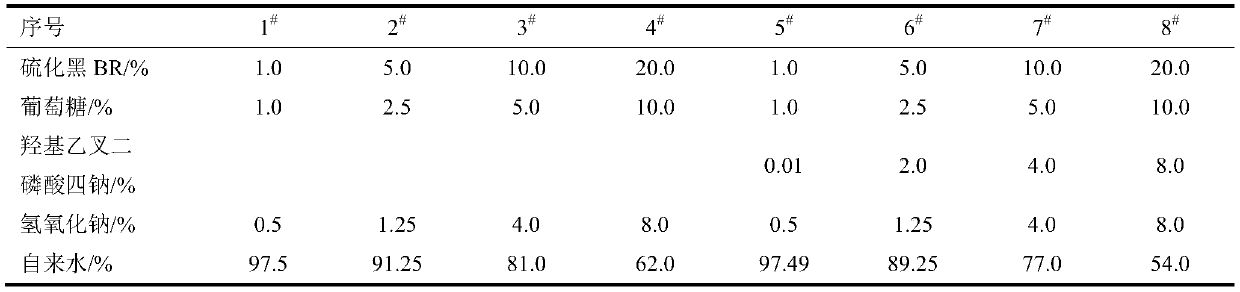

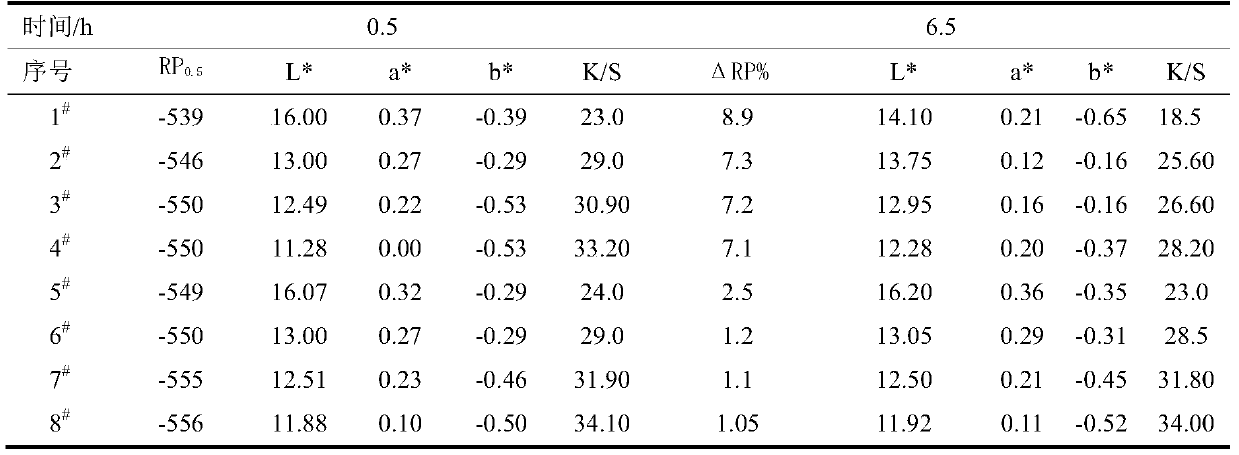

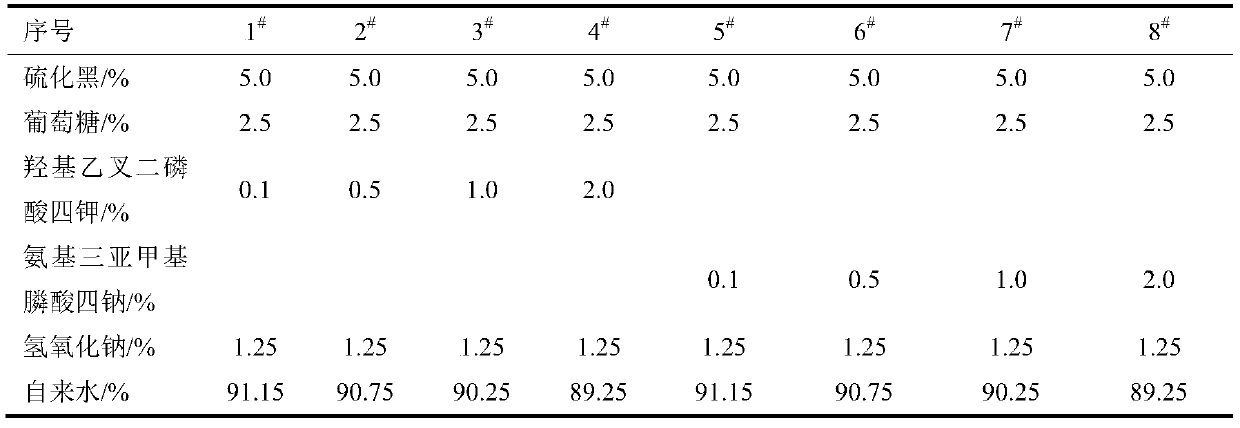

A group of compounds for stabilizing the reduction potential and dyeing performance of sulfur dyeing systems and methods of use thereof

The invention relates to a group of compounds for stabilizing the reduction potential and the dyeing performance of a sulfur dye dyeing system, and a use method thereof. 0.1-20.0 wt% of an organophosphate compound is added to a sulfur dye / glucose / sodium hydroxide system, and then the obtained system is used for sulfur dye dyeing. A sulfur dye forms a soluble leuco compound under the reduction effect of a glucose / sodium hydroxide system, cellulose fibers are dyed with the soluble leuco compound, and the organophosphate compound is added to effectively stabilize the reduction potential in the reduction system and realize the stability of the dyeing performance. Compared with organophosphate-free reduction systems, the reduction system reduces the reduction potential reduction rate after 6 hprolongation at 90 DEG C to 1-2% from 6-8%, improves the color depth by 20% or more, basically keeps the color tone and the dye depth of a fabric basically stable. An effective way is provided for solving environmental pollution in the dyeing process of the sulfur dye and realizing the continuous and stable industrial application of glucose in the dyeing process.

Owner:石家庄美施达生物化工有限公司

Pure cotton textile dyeing and printing dye and production technology of same

The invention discloses a pure cotton textile dyeing and printing dye and a production technology of the same. The pure cotton textile dyeing and printing dye is prepared by the following materials in percent by weight: 70%-80% of active black BMGB; 10%-20% of reactive brilliant blue BR and10%-20% of anhydrous sodium sulphate. The pure cotton textile dyeing and printing dye has the characteristics of being stable in color light, bright in color, high in dye-uptake, strong in fastness, excellent in washing resisting effect and environment-friendly and safe.

Owner:晋江市浪潮服装工贸有限公司

A kind of synthetic method of azo type disperse dye composition

ActiveCN103709787BShade stabilityMild crystallization processMonoazo dyesDyeing processDispersion stabilityDisperse dye

The present invention relates to the technical field of disperse dyes, and provides an azo type disperse dye composition synthesis method so as to solve the problem of not ideal light fastness of the single color variety due to 2,4-dinitroaniline. The synthesis method comprises that: a diazo component 2,4-dinitroaniline of various components in the desired mixture concurrently reacts in the same diazotization device, various coupling components of the mixed dye are coupled in the same coupling device through a plurality of coupling manners according to the ratio requirement with the diazo during coupling, the obtained coupling solution can be subjected to a temperature increase crystal transformation treatment before entering a filter if necessary so as to make the crystal form of the obtained dye be stable, and pressure filtration is performed to directly obtain the dye mixture with the required ratio. According to the present invention, the light fastness problem is solved, the crystal transformation process is mild, and the high temperature dispersion stability, the low temperature dispersion stability and the chromatic light of the dye are stable.

Owner:ZHEJIANG JIHUA GROUP +1

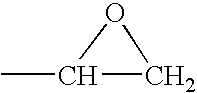

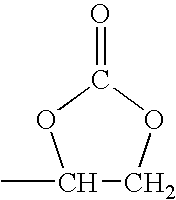

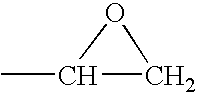

Method for producing coatings from coating materials that can be cured by the action of heat or actinic radiation

InactiveUS8147923B2Improve scratch resistanceStable to overbakePretreated surfacesPolyurea/polyurethane coatingsMethacrylatePolymer science

Owner:BASF COATINGS GMBH +1

Colorant for digital printing of polyester fabric and production technique thereof

The invention discloses a colorant for digital printing of polyester fabric, comprising, by weight, 60-80% of disperse red, 8-15% of disperse pink, 5-15% of a dispersing agent, 2-5% of a dye leveler,2-5% of an anti-wrinkle softener, and 1-5% of an irrigation inhibitor. The invention also discloses a production technique of the colorant, characterized by comprising the steps of (1) adding cold water into a vat; (2) adding the dye leveler and the irrigation inhibitor into the vat; (3) adjusting PH via glacial acetic acid; (4) after first heating, adding the disperse red No. 60, the disperse pink BG and the dispersing agent, and maintaining; (5) continuing to perform heating, maintaining the temperature, and performing color matching. The colorant has the advantages of good chromatic stability and bright color, high color yield, clear outline of printed patterns, good water fastness and friction fastness, and good environmental friendliness and safety.

Owner:浙江瑞灿科技有限公司

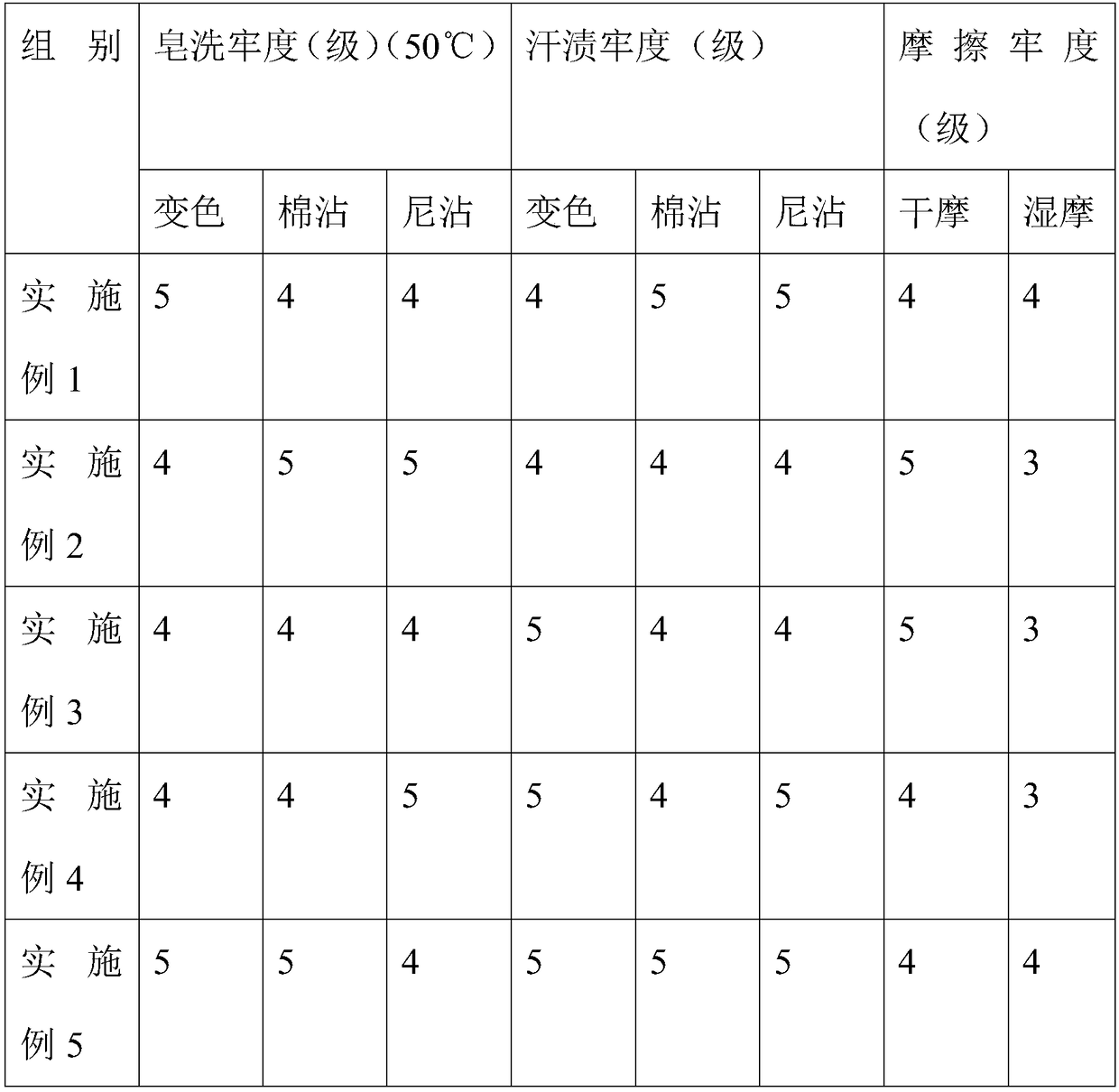

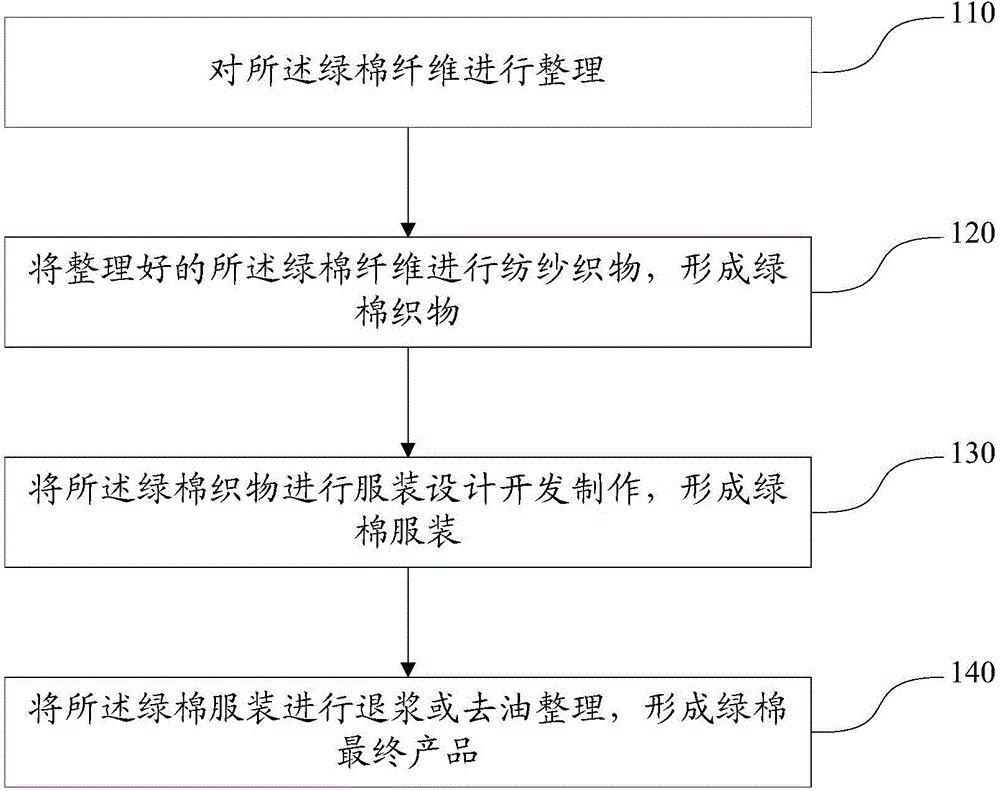

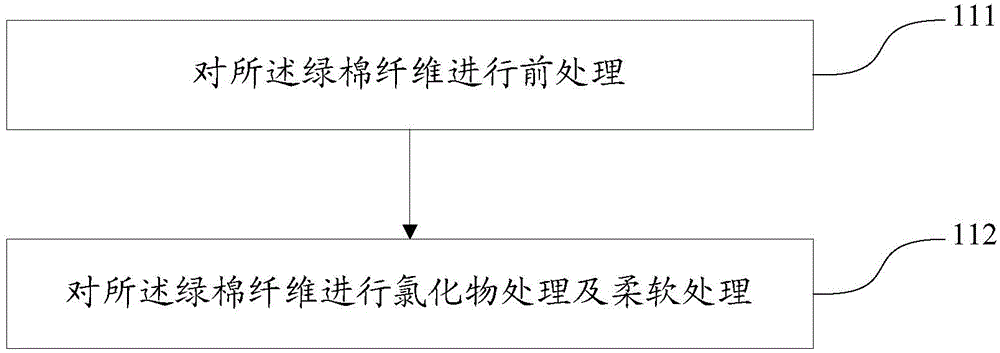

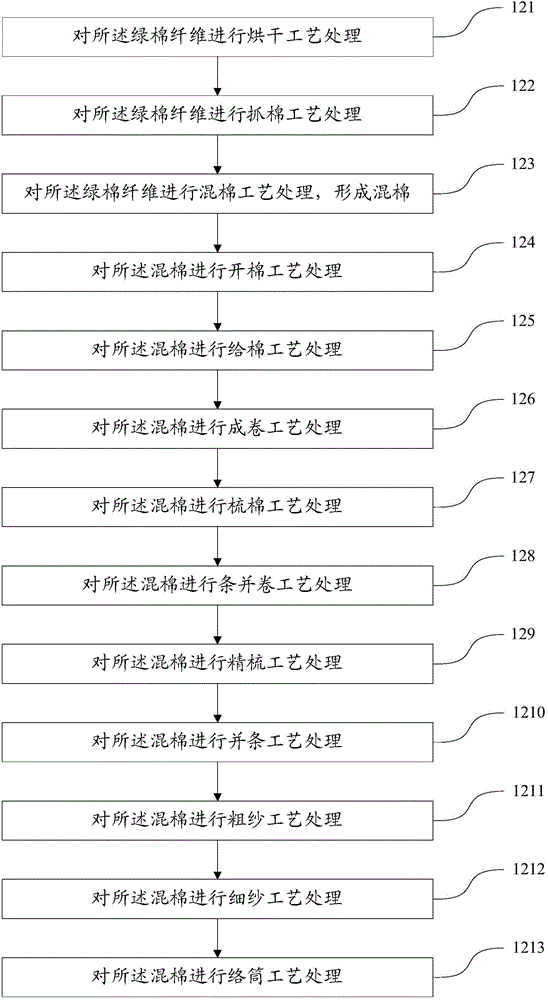

A kind of processing method of green cotton fiber

ActiveCN103628313BShade stabilityWeaken influenceDry-cleaning apparatus for textilesYarnTextile technologyFiber

Owner:BEIJING GUANGHUA TIMES TEXTILE & CLOTHING CO LTD

Dichloro-substituted benzothiazole disperse dye with high alkali resistance and high oxygen bleaching resistance

ActiveCN113913027AIncrease brightnessBright colorMonoazo dyesTextile/flexible product manufactureDisperse dyePolymer science

The invention discloses a dichloro-substituted benzothiazole disperse dye with high alkali resistance and high oxygen bleaching resistance, and belongs to the field of disperse dyes. According to the invention, 28 thiazole heterocyclic azo disperse dyes are designed and synthesized by adopting 4 diazo components and 8 coupling components, so that the alkali resistance and oxidation resistance of the disperse dyes are enhanced. The structure of the synthesized disperse dye is confirmed, and the alkali resistance, oxidation resistance and other dyeing properties of the disperse dye are tested. According to the method for enhancing alkali resistance and oxidation resistance of the benzothiazole disperse dye provided by the invention, the relationship between the dye structure and the alkali resistance and oxidation resistance is defined, the disperse dye with excellent alkali resistance and oxidation resistance is obtained, and the dyeing performance is stable under the dyeing condition of 10 g / L sodium hydroxide or 5 g / L hydrogen peroxide. The dye can be applied to bleaching and dyeing one-bath of polyester cotton and decrement dyeing one-bath of polyester, short-process dyeing and finishing processing is realized, and huge ecological benefits and economic benefits are generated.

Owner:QINGDAO UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com