Process for preparing low-salt high-strength active yellow dye

A yellow dye, high-strength technology, applied in azo dyes, organic dyes, monoazo dyes, etc., can solve the problems of low technological content, low added value, low price, etc., and achieve short drying time and stable color light , the effect of generating less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

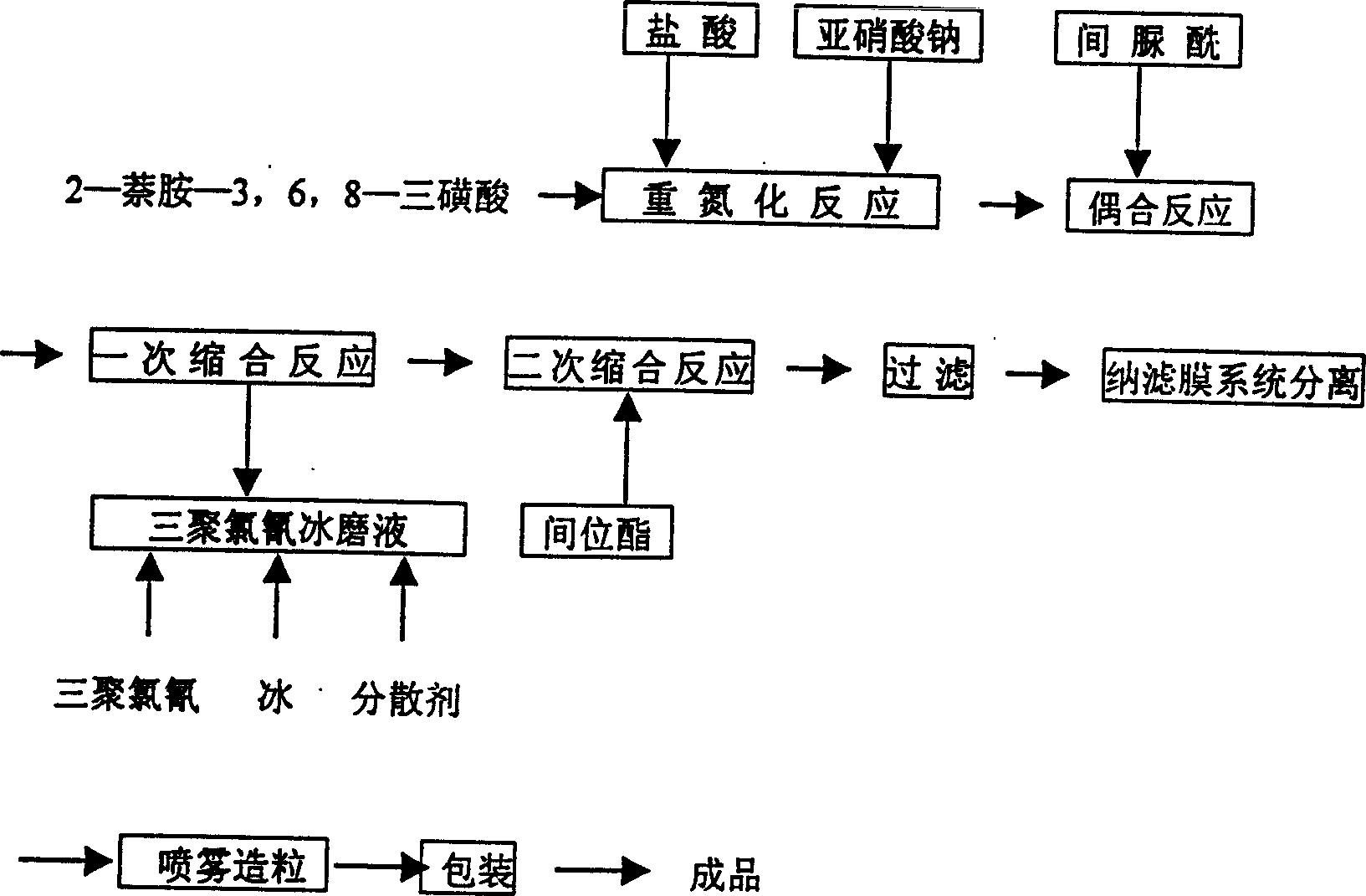

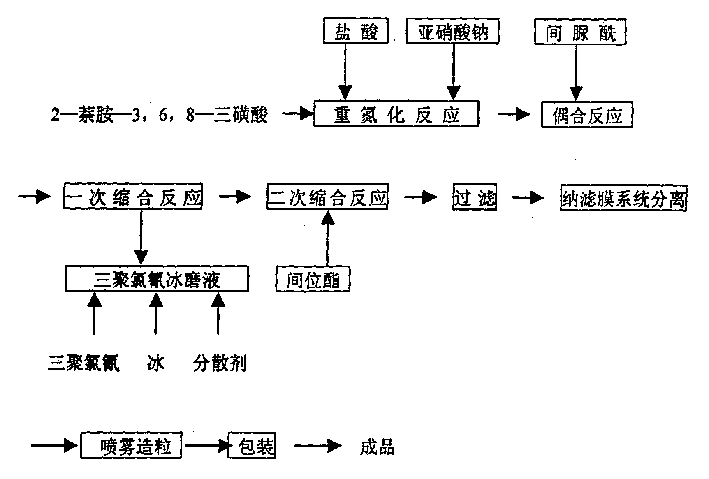

Method used

Image

Examples

Embodiment 1

[0035] Add 105kg of 100% 2-naphthylamine-3,6,8-trisulfonic acid into the diazotization reaction tank, add 25kg of 100% hydrochloric acid, 18.8kg of sodium nitrite, and react for 1 hour at 5°C to obtain diazonium For the salt solution, the diazonium salt solution was added to (100% m-urea) 40.2kg m-urea solution for coupling reaction, the pH of the solution was adjusted to 5 with soda ash, the temperature was controlled below 20°C, and the reaction was maintained for 3 hours to obtain coupling solution.

[0036] In the condensation reaction tank, add 50 kg of cyanuric chloride, disperse 0.8 kg of sodium 1.4-dibutylnaphthalene-6-sulfonate, and carry out ice grinding for 1 hour with an appropriate amount of ice, and then add the coupling liquid to the cyanuric chloride ice grinding liquid Carry out a condensation reaction in a medium temperature, control the temperature below 15°C, control the pH value to 4-7, keep the reaction for 3 hours, then add 76kg of 100% meta-ester to the...

Embodiment 2

[0037] Embodiment 2 This embodiment includes the following steps:

[0038] a. Dissolution and diazotization of 2-naphthylamine-3,6,8-trisulfonic acid

[0039] First, 160 kg of quantitative arylamine 2-naphthylamine-3,6,8-trisulfonic acid industrial product is added in an antiseptic reaction pot, 90 kg of excess hydrochloric acid is added, and then quantitative sodium nitrite solution is added for diazotization reaction. At the same time, the induced draft fan was turned on to recover the gas. During the sodium addition process, the starch potassium iodide test paper was kept slightly blue and the Congo red test paper was blue. Under these conditions, the diazo solution was prepared for 1 hour.

[0040] b. Coupling reaction

[0041] Take 40kg of m-urea, slowly add it to the diazo solution, and ensure that the temperature of the material is below 20°C, and the feeding time is 20 minutes. After the addition, slowly adjust the pH to 5 with a soda ash solution, that is, it is advi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com