Modified non-woven fabric as well as preparation method and use method thereof

A non-woven and modified technology, applied in chemical instruments and methods, textiles and papermaking, dyeing methods, etc., can solve the problems of small dye adsorption, unsatisfactory application effect, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In a preferred embodiment, the preparation method of modified nonwoven fabric of the present invention comprises the following steps:

[0035] a) preparing a water treatment solution containing an ionic liquid, a reactive cationic modifier and a strong inorganic base;

[0036] b) impregnating the non-woven fabric in the water treatment solution; and

[0037] c) drying or drying at 60-90°C.

[0038]In a preferred embodiment, the water treatment liquid used in the method of the present invention contains 1-5 g / L ionic liquid, 3-15 g / L reactive cationic modifier and 1-10 g / L inorganic strong base, preferably It contains 2-5 g / l ionic liquid, 5-15 g / l reactive cationic modifier and 3-10 g / l sodium hydroxide.

[0039] In a preferred embodiment, the method for absorbing free anionic dyes in the dyeing waste liquid or dyed washing liquid of the present invention comprises the following steps:

[0040] i) provide the modified non-woven fabric of the present invention;

[00...

Embodiment 1

[0056] Immerse 5 grams of viscose non-woven fabric in the modified working solution. The working solution is: 1-allyl-3-methylimidazolium chloride: 2 g / L, 4-chloro-s-triazine-2, 6-Di-p-benzylamine quaternary ammonium salt: 8 g / L, NaOH: 2 g / L, the working solution used was 75 ml; treated at 65°C for 40 min, and dried to obtain the modified non-woven fabric 1.

[0057] Dyeing example 1:

[0058] Take 10 grams of two identical pure cotton knitted bleached cloths, and dye them according to the following process:

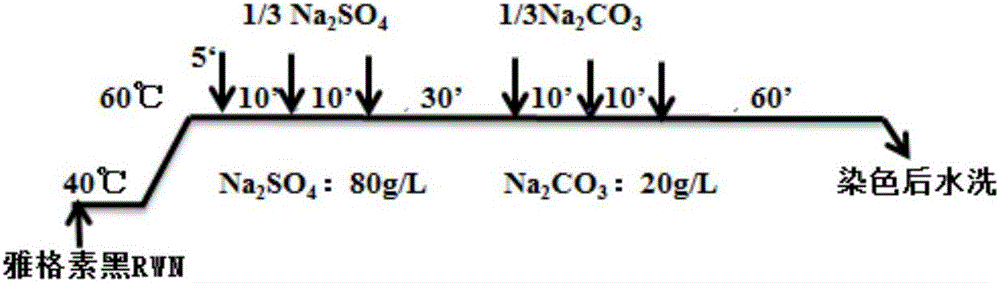

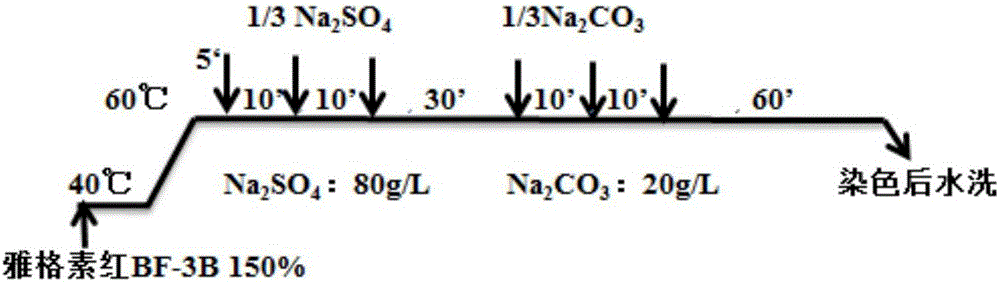

[0059] Take 0.6 grams of reactive dye Argosol black RWN, put it into 100ml water at 40°C, stir evenly, put it into pure cotton knitted bleached cloth, heat it up to 60°C, keep it warm, divide it into three times after 5 minutes, each time at an interval of 10 minutes, and add 8.0 g Na 2 SO 4 , after continuing to keep warm for 30 minutes, add 2.0g Na 2 CO 3 , continue to keep warm for 60 minutes, then stop, take out the fabric, and obtain the dyed pure cotton knitte...

Embodiment 2

[0068] Immerse 5 grams of cotton non-woven fabric in the modified working solution. The working solution is: sodium N-allylpyridinium sulfite: 3 g / L, chlorinated polyepichlorohydrin trimethylammonium salt: 5 g / L, NaOH: 5 g / L, the dosage of the working solution is 75 ml; treat at 80°C for 30 min, and obtain the modified non-woven fabric 2;

[0069] Dyeing example 2:

[0070] Take 10 grams of two identical nylon knitted fabrics and dye them according to the following process:

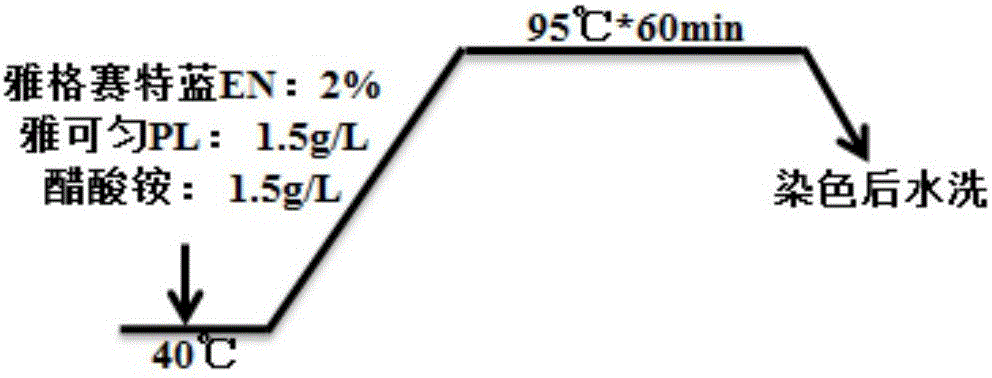

[0071] Take the acid dye Jagset Blue N-R: 0.2g, Accordion PL: 0.15g, ammonium acetate: 0.15g, add it into 100ml water at 40°C, raise the temperature to 95°C at 2°C / min, keep it warm for 60min, and then stop the dyeing. The nylon knitted fabric is taken out to obtain the dyed nylon knitted fabric and the dyed residue.

[0072] Contrast washing example 2:

[0073] The dyed fabric in dyeing example 2→washing in hot water (75°C*15min)→soaping (Accord SW-PA: 3g / L, 60°C*15min)→warm water washing (60°C*15min)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com