Terylene fabric dispersive dyeing non-reduction cleaning technology

A disperse dyeing technology for polyester fabrics, applied in dyeing methods, textiles and papermaking, etc., can solve the problems of destroying dyes, achieve the effects of reducing enterprise costs, omitting reduction cleaning steps, and excellent color fastness to washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

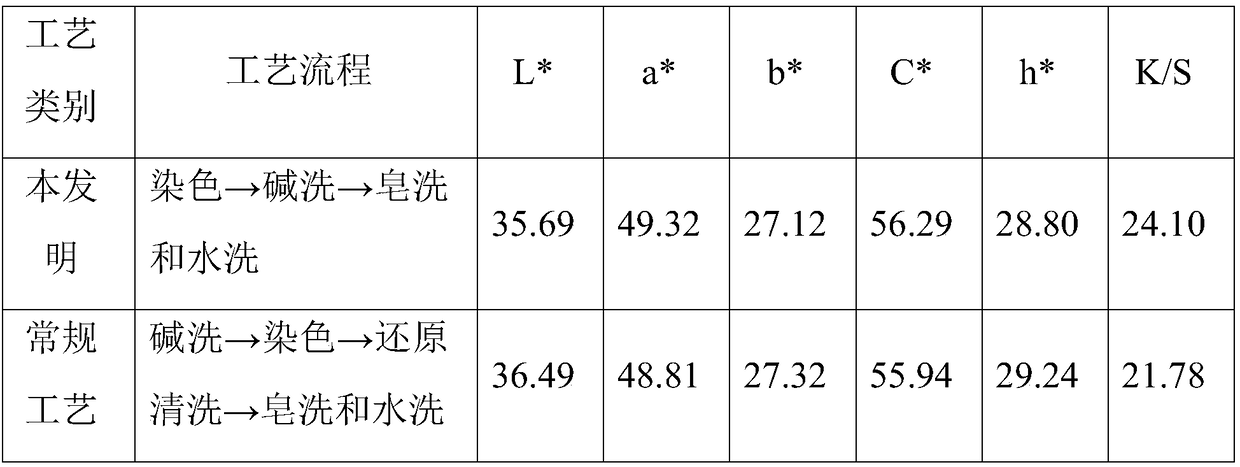

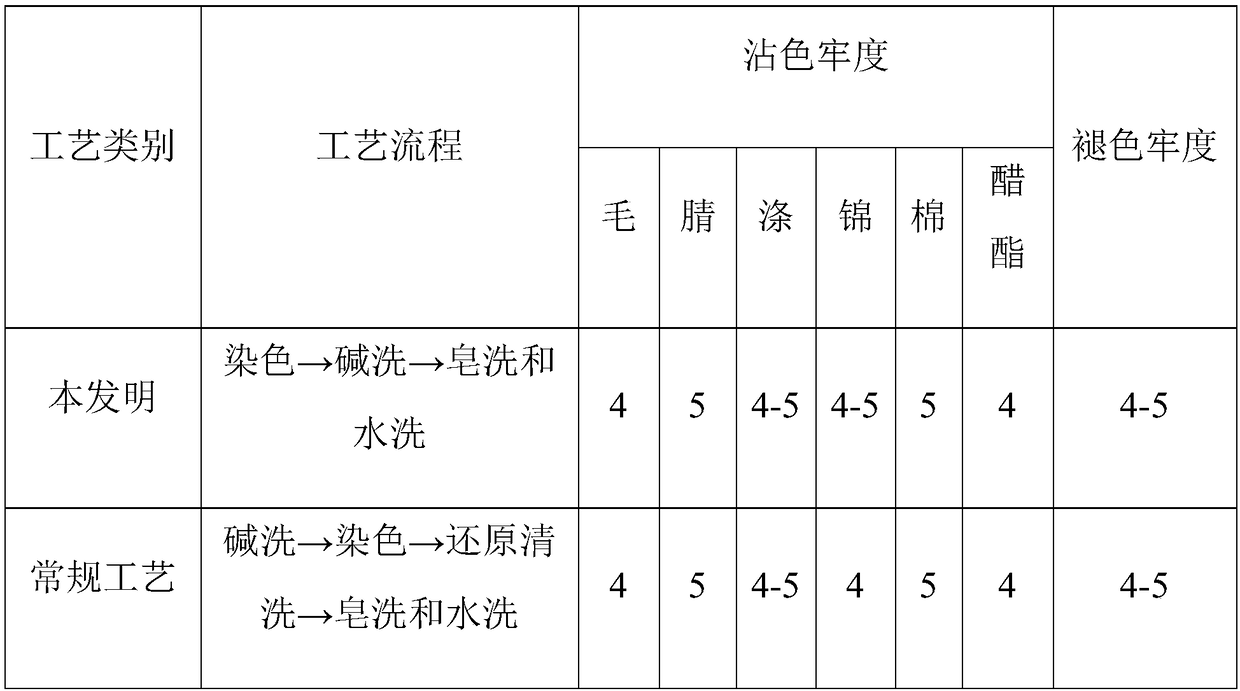

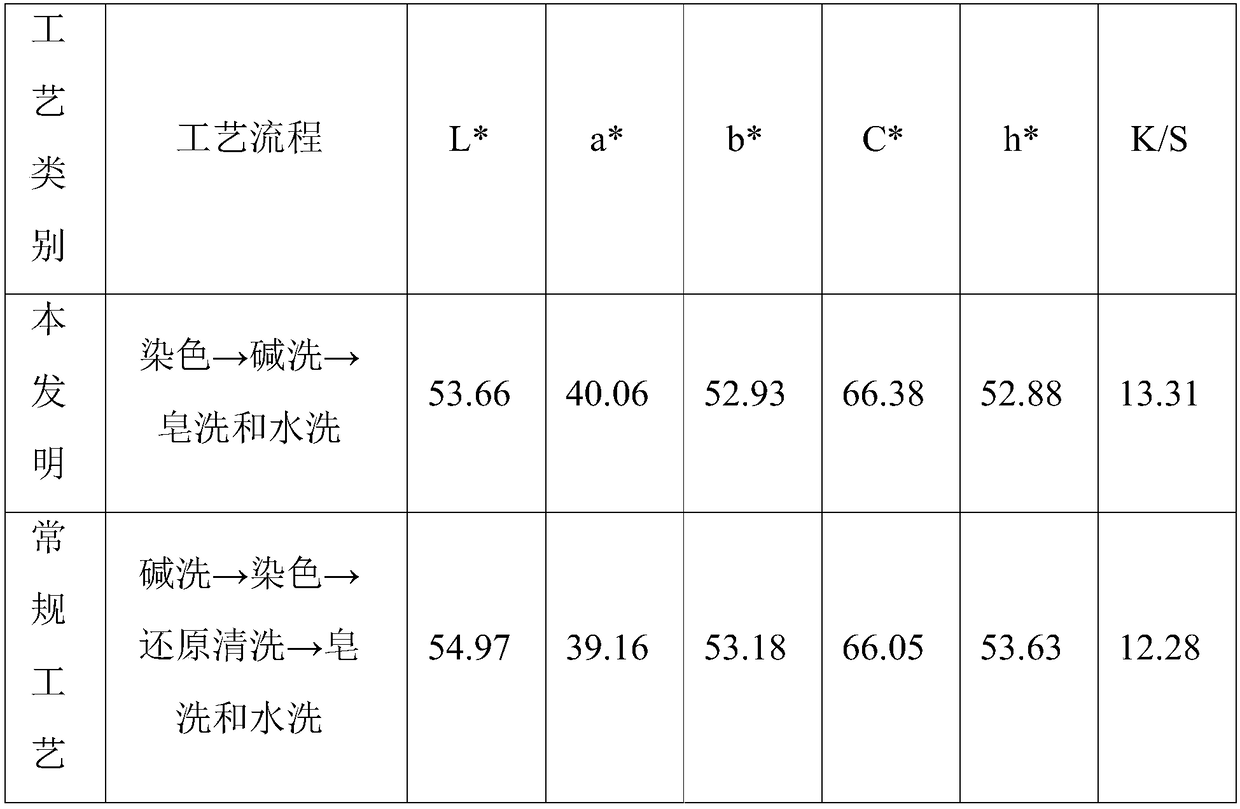

[0048] Disperse scarlet HA-G dyed polyester knitted fabric

[0049] The polyester fabric dispersion dyeing non-reduction cleaning process provided by the present invention includes the following steps:

[0050] (1) High temperature and high pressure dyeing of polyester knitted fabric: the amount of dye is 2% of the weight of the fabric, and the leveling agent is 1g / L (NICCASUNSOLT 7000Z, Zhejiang Rihua Chemical Co., Ltd.); it is formulated according to the weight ratio of dye liquor to fabric at 10:1 The dye liquor is heated on a high temperature and high pressure dyeing machine at a temperature of 1°C / min to 100°C for 10 minutes; then at a heating rate of 1°C / min to 130°C for 30 minutes; after dyeing, the temperature is lowered at a cooling rate of 4°C / min Discharge the dye solution when the temperature is below 80℃.

[0051] (2) Alkaline washing of dyed polyester knitted fabric: Inject 2.5g / L of caustic soda solution into the dyeing vat. The weight ratio of caustic soda solution t...

Embodiment 2

[0065] Disperse scarlet HA-G dyed polyester knitted fabric

[0066] The polyester fabric dispersion dyeing non-reduction cleaning process provided by the present invention includes the following steps:

[0067] (1) High temperature and high pressure dyeing of polyester knitted fabrics: the amount of dye is 0.1% of the weight of the fabric, and the leveling agent is 0.5g / L (NICCA SUNSOLT 7000Z, Zhejiang Rihua Chemical Co., Ltd.); the weight ratio of dye liquor to fabric is 30: 1 Prepare the dye solution, heat up to 70°C at 0.5°C / min on a high-temperature and high-pressure dyeing machine, and hold for 20 minutes; then heat up to 105°C at a heating rate of 0.5°C / min and hold for 60 minutes; after dyeing, cool down at 4°C / min The temperature is lowered to below 80°C and the dye liquor is discharged.

[0068] (2) Alkaline washing of dyed polyester knitted fabric: inject 0.5g / L of caustic soda solution into the dyeing vat, the weight ratio of caustic soda solution to the fabric is 30:1, h...

Embodiment 3

[0077] Disperse scarlet HA-G dyed polyester knitted fabric

[0078] The polyester fabric dispersion dyeing non-reduction cleaning process provided by the present invention includes the following steps:

[0079] (1) High-temperature and high-pressure dyeing of polyester knitted fabric: the amount of dye is 10% of the weight of the fabric, and the leveling agent is 3g / L (NICCASUNSOLT 7000Z, Zhejiang Rihua Chemical Co., Ltd.); it is formulated according to the weight ratio of dye liquor to fabric of 3:1 Dye liquor, heat up to 100°C at 4°C / min on a high-temperature and high-pressure dyeing machine for 5 minutes; then heat up to 135°C at a heating rate of 4°C / min for 30 minutes; after dyeing, cool down at a cooling rate of 4°C / min Discharge the dye solution when the temperature is below 80℃.

[0080] (2) Alkaline washing of dyed polyester knitted fabric: Inject 20g / L of caustic soda solution into the dyeing vat. The weight ratio of caustic soda solution to the fabric is 3:1. The temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com