Patents

Literature

38results about How to "Excellent color fastness to washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

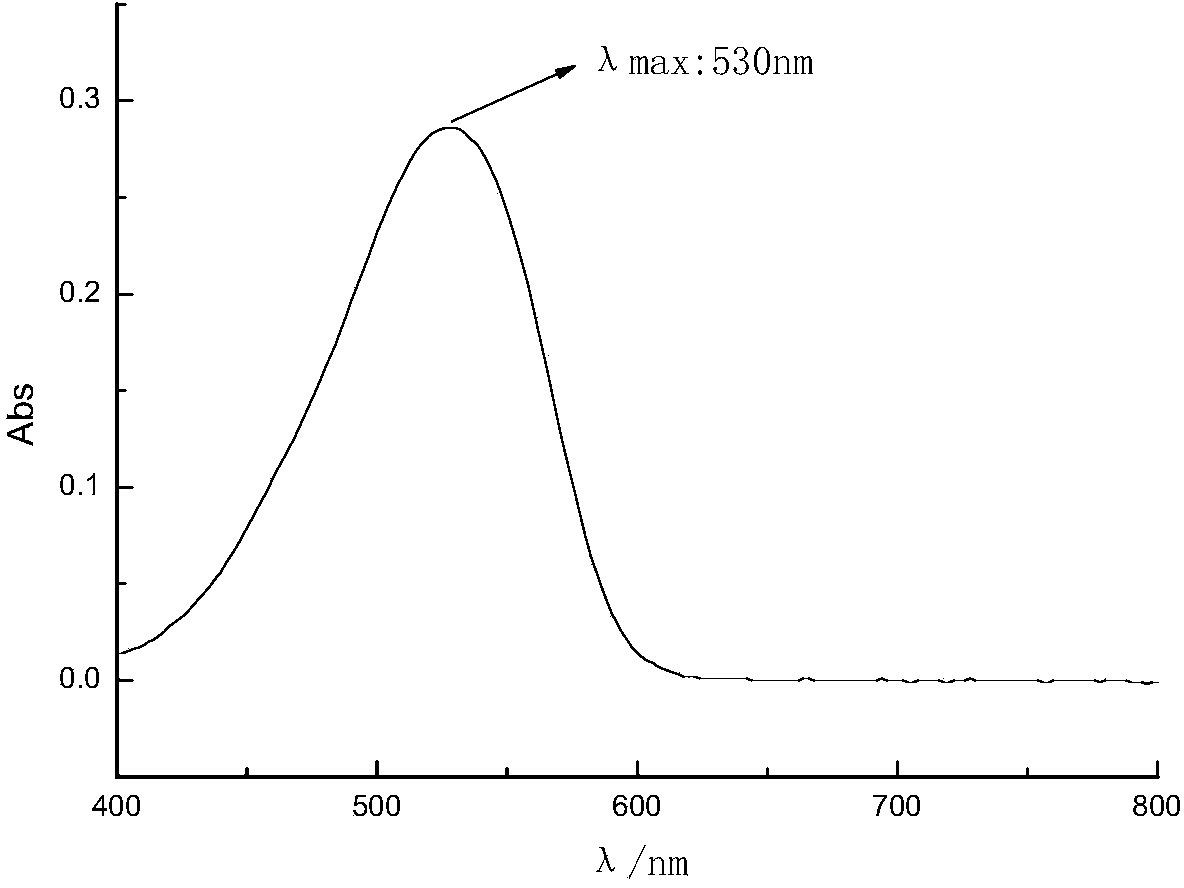

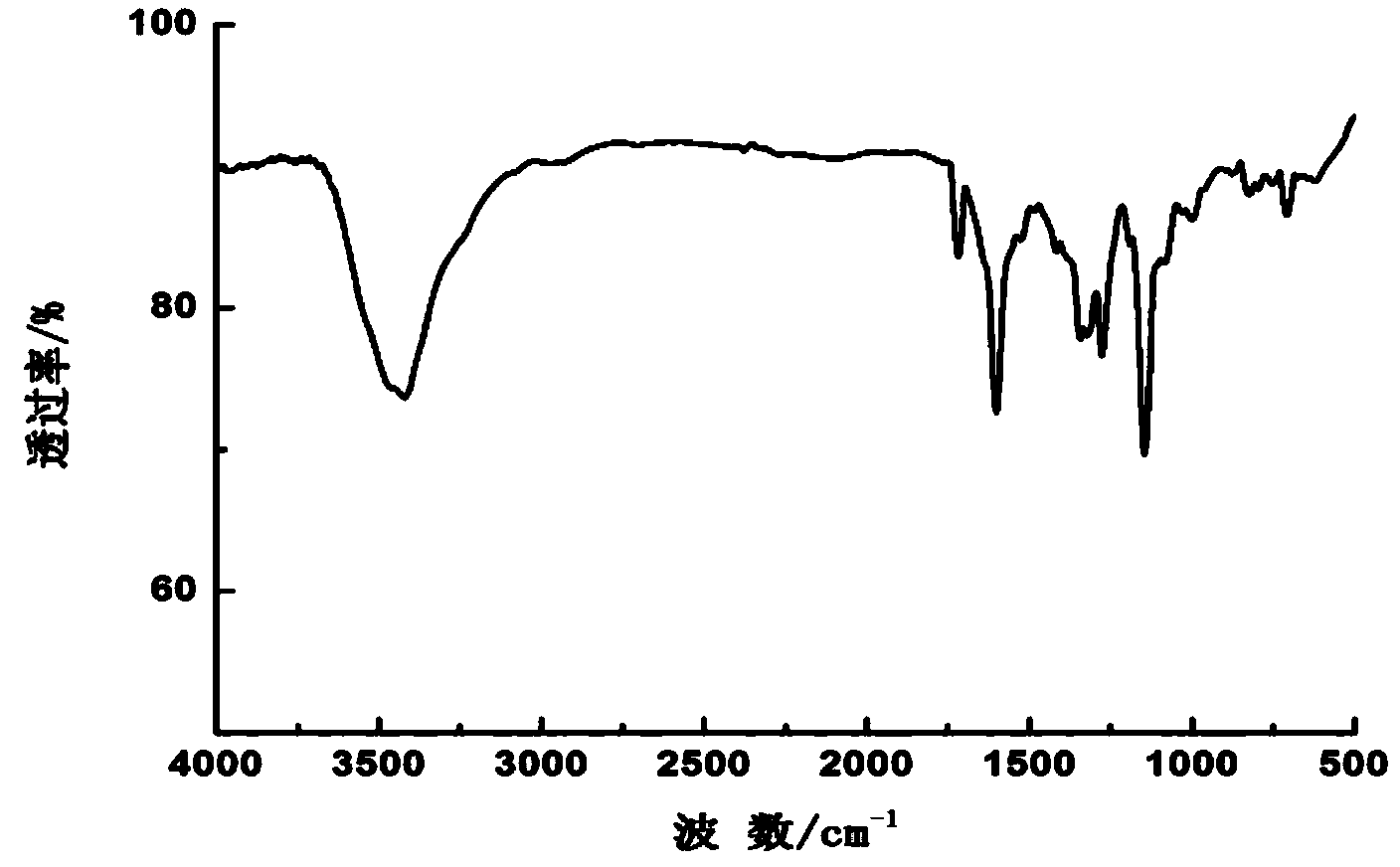

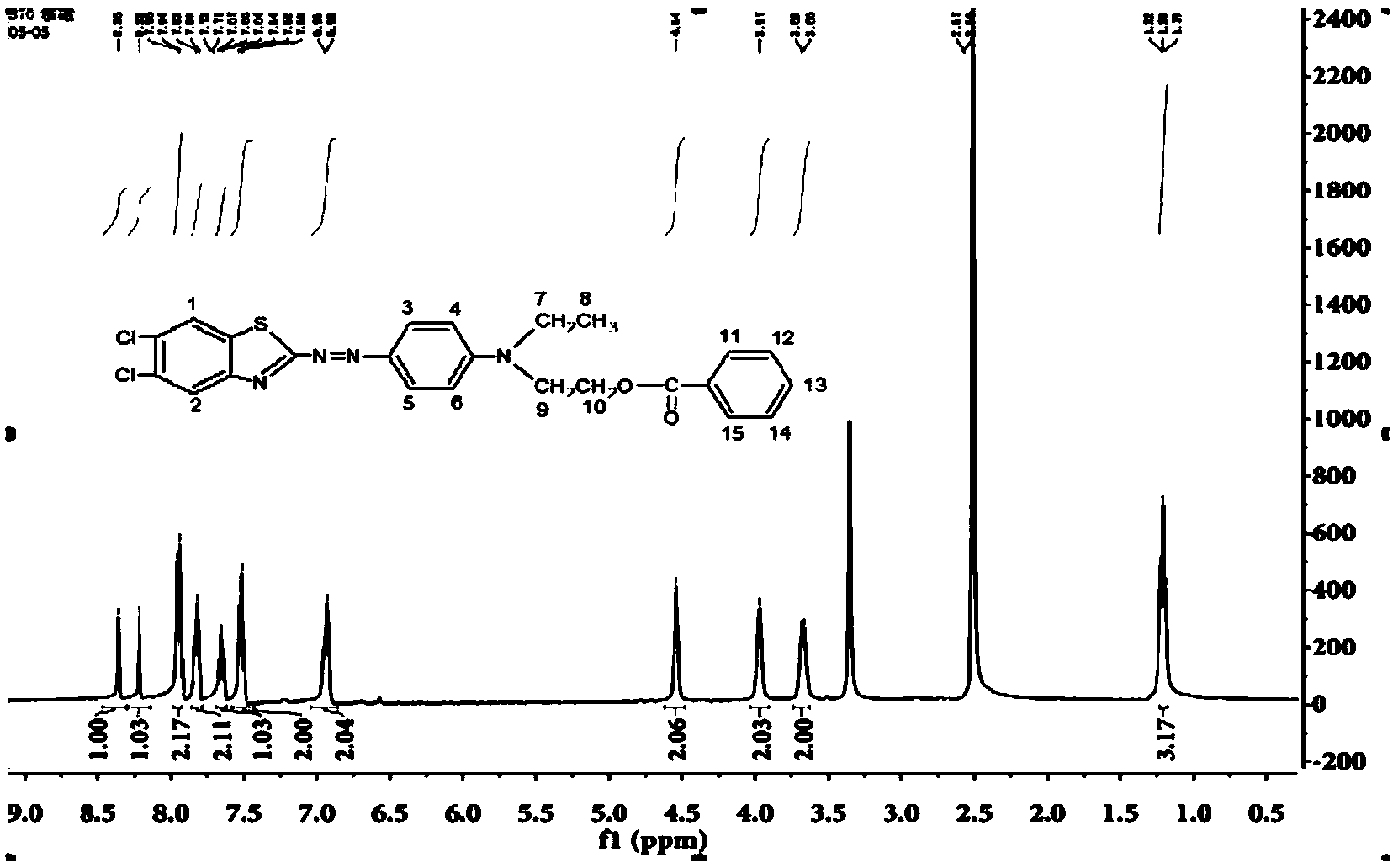

Red thiazole heterocyclic disperse dye compound containing benzoate group and preparation and application thereof

InactiveCN104231659AShort processEmission reductionMonoazo dyesDyeing processDisperse dyeAcetic acid

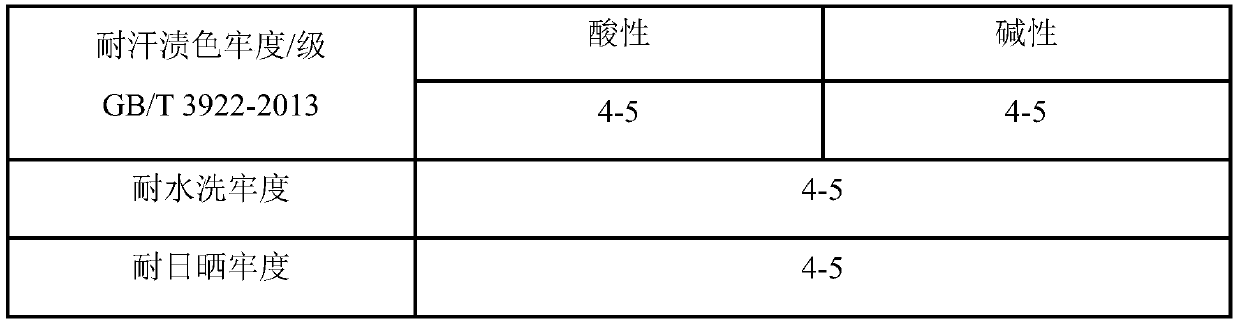

The invention relates to a red thiazole heterocyclic disperse dye compound containing benzoate group and preparation and an application thereof. The general formula of the disperse dye compound is shown in the specification. The compound is prepared by the following steps: dissolving a coupling component in acetic acid; then cooling to 0-5 DEG C; then, dropwise adding a diazo component; reacting at the temperature till the diazo component disappears; filtering; washing; and drying to obtain the compound. The compound is applied to a red disperse dye. The dye provided by the invention is simple in synthetic process and can be used for dyeing polyester fabrics in a pH range of 4-13, and the dyed fabric is full in color phase. The compound is excellent in color fastness to sunlight, color fastness to sublimation and color fastness to washing and is a high-fastness red disperse dye which can be suitable for wide pH dyeing.

Owner:俞杏英 +1

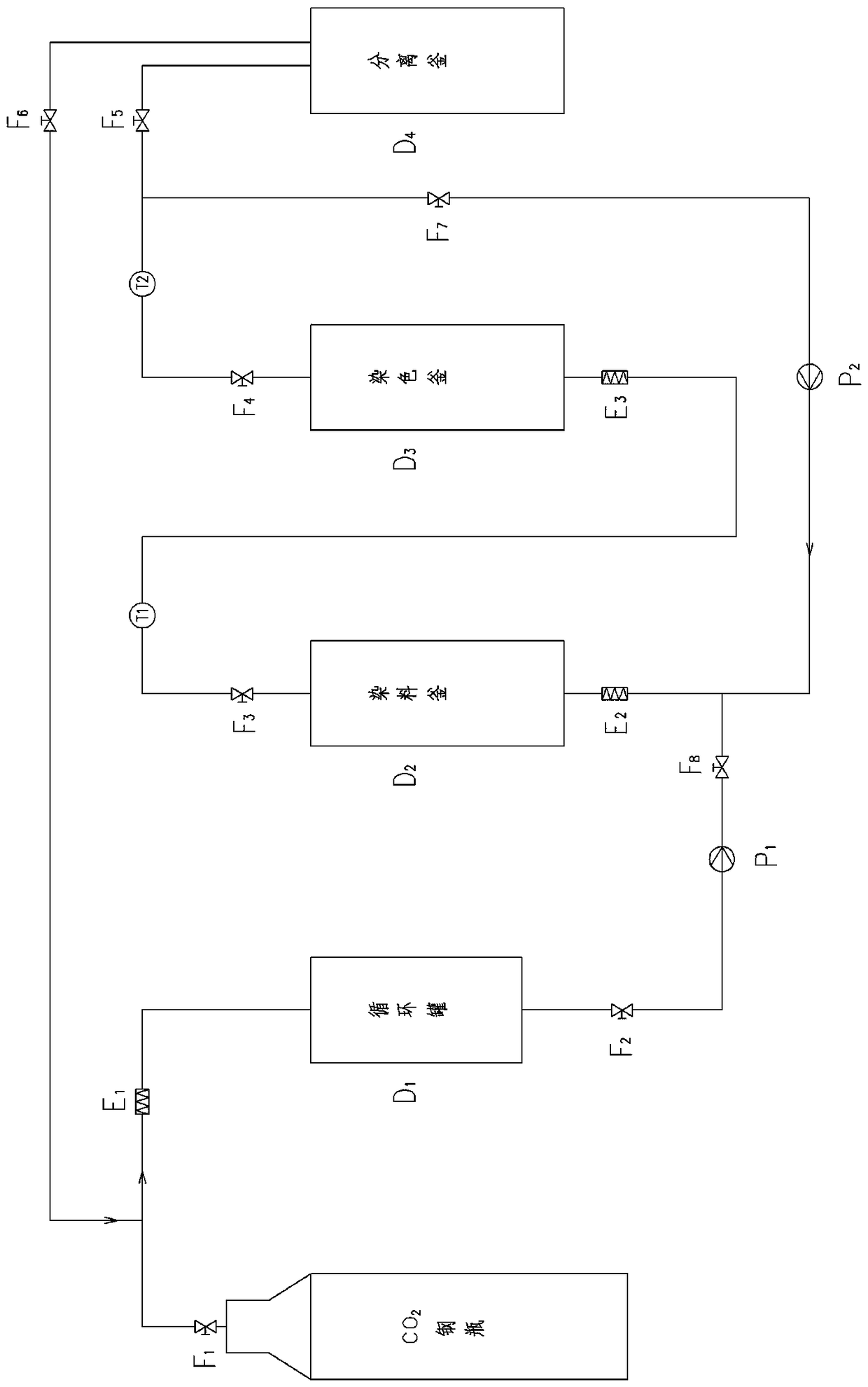

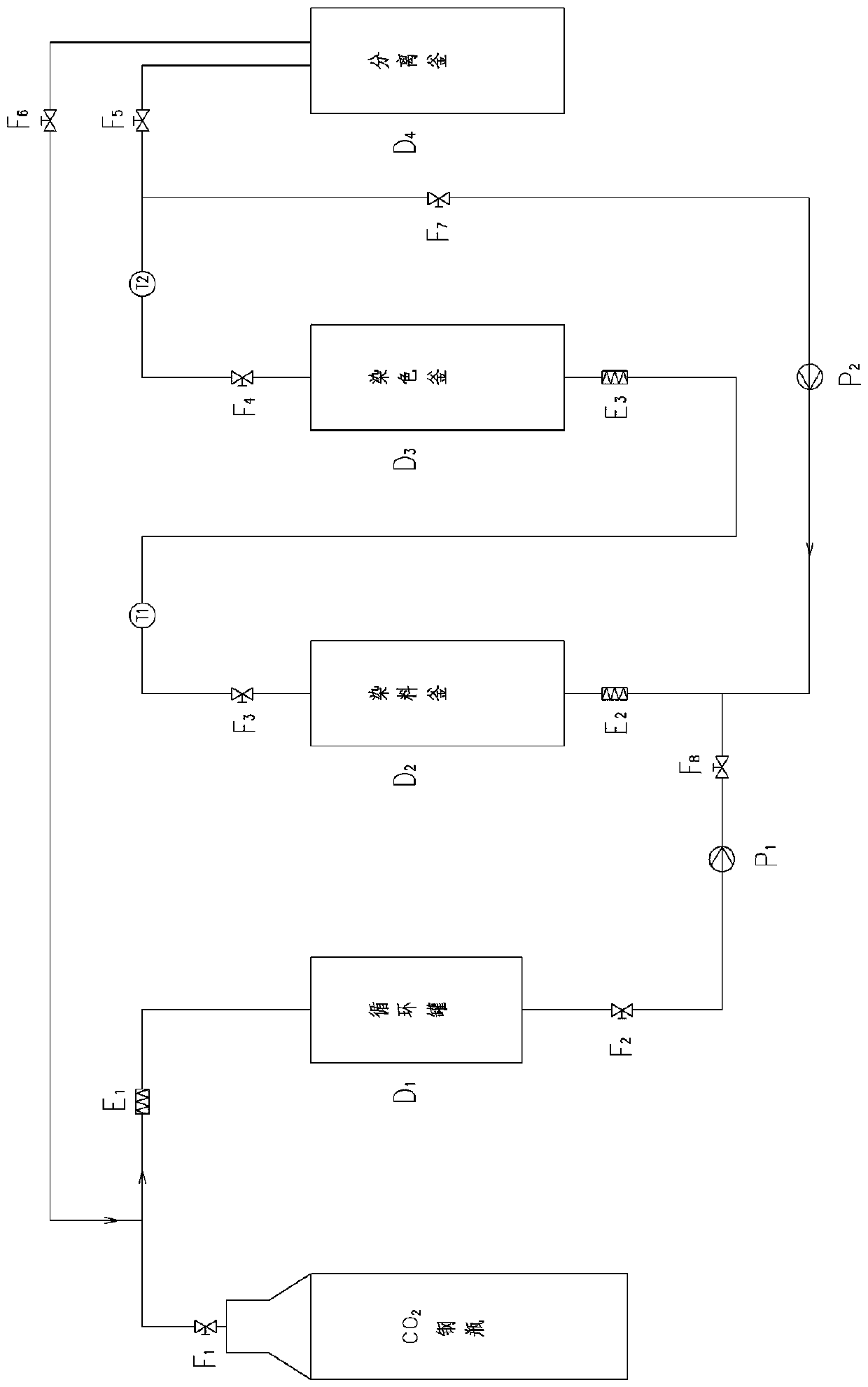

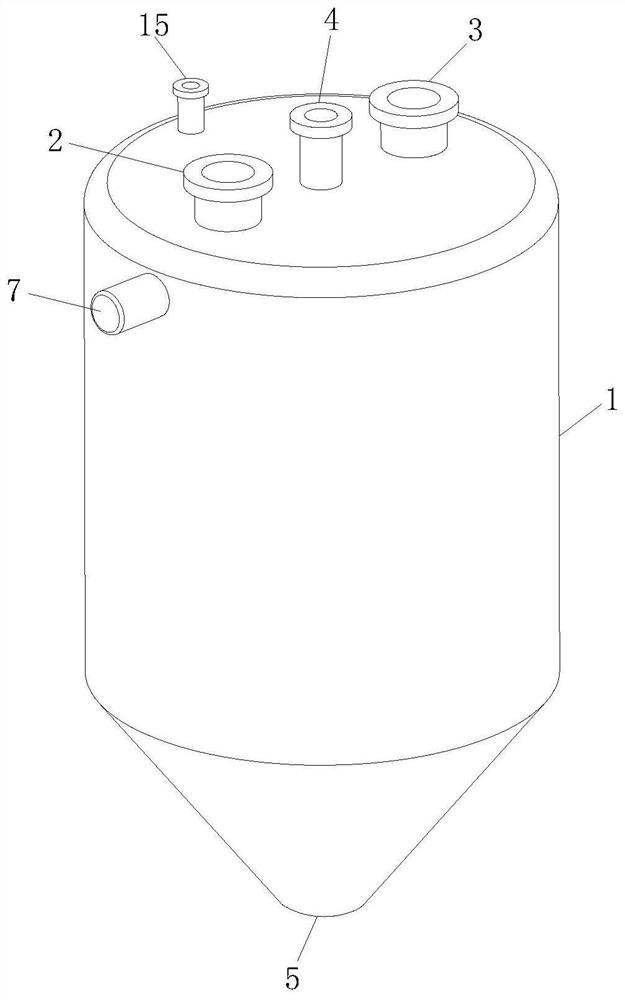

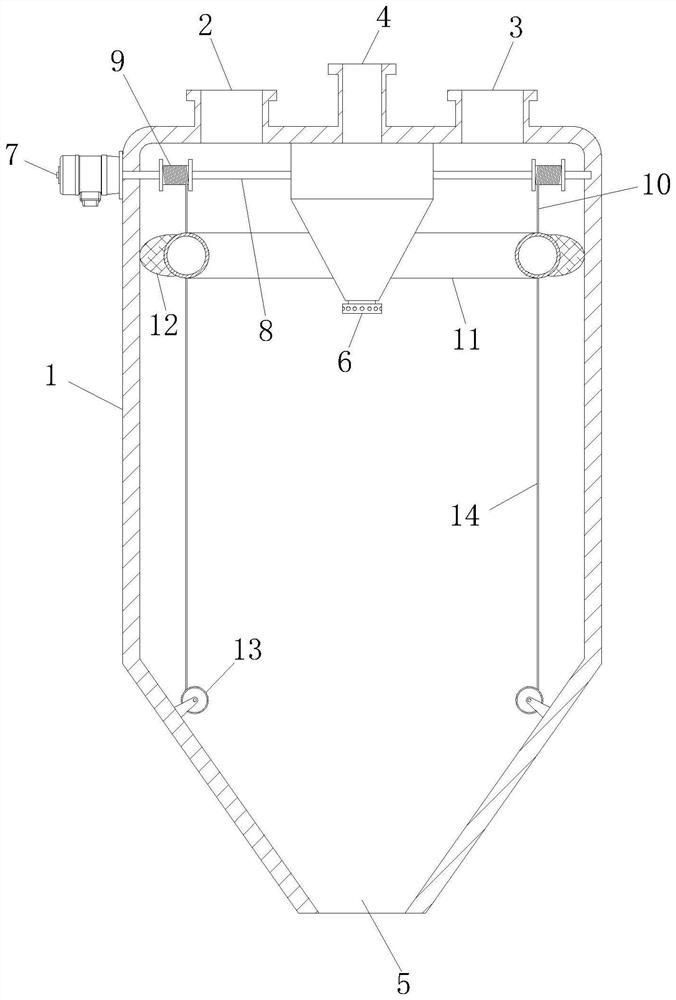

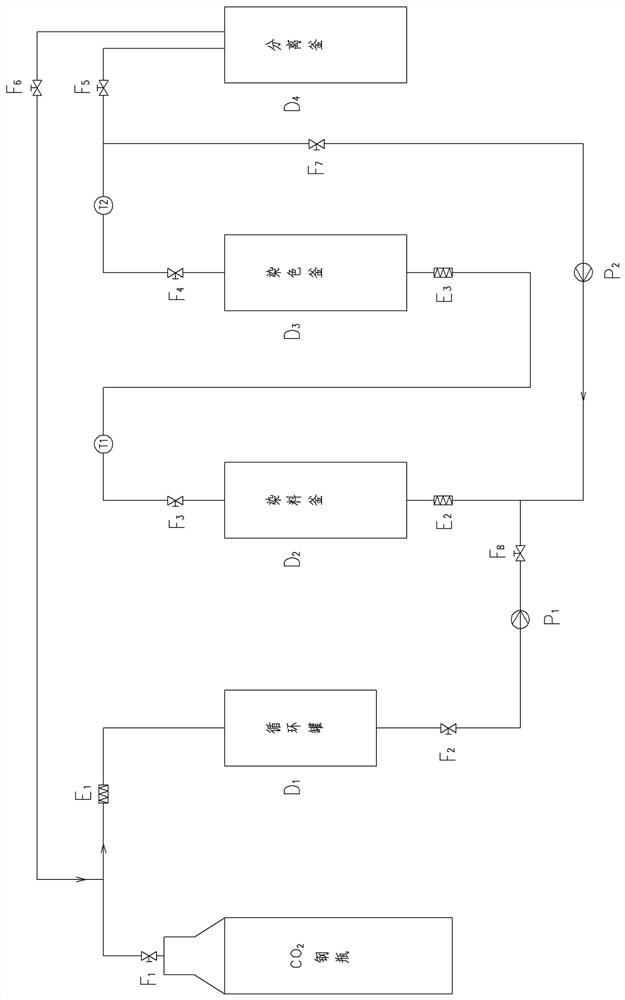

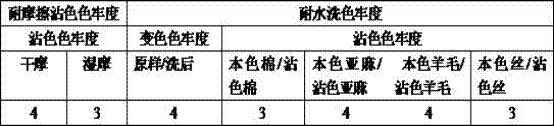

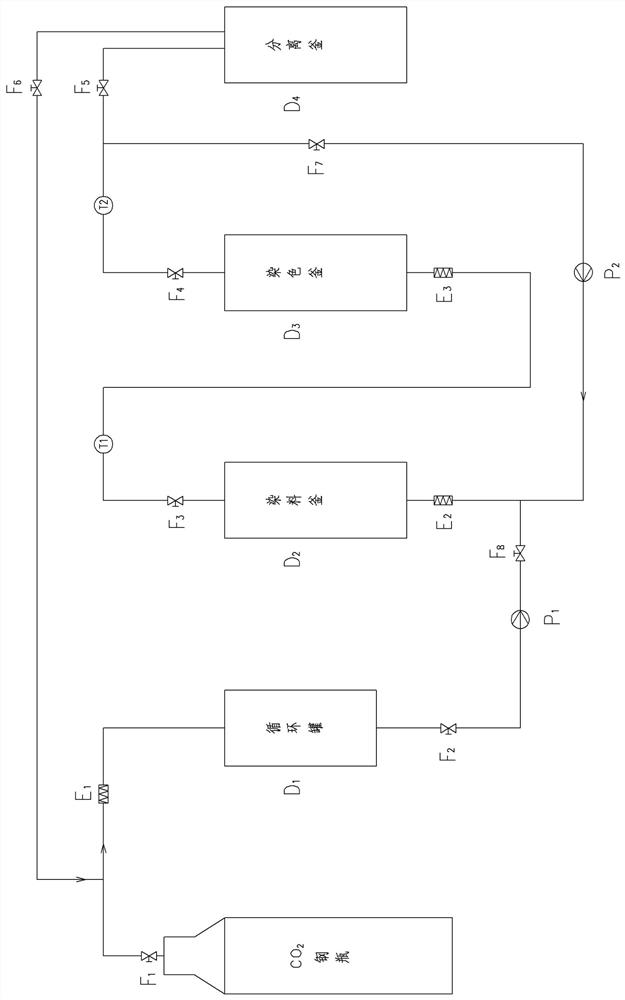

Supercritical CO2 fluid dye composition for textile, dyeing system and method

ActiveCN108086022AGood compatibilityReal-time detection of scale changesDyeing processCarbon dioxide cylinderDisperse dye

The invention belongs to the technical field of anhydrous dyeing of textile and particularly relates to a dyeing technology of textile in a supercritical CO2 fluid with three-primary color disperse dye. At least two of the three-primary color dye including C.I. disperse red 140, C.I. disperse yellow and C.I. disperse blue 56 are mixed in any ratio. All the disperse dyes are well compatible, are suitable to be used for supercritical CO2 fluid dying and can be combined to dye textile in various colors. The dyeing system of the composition comprises a CO2 steel cylinder, a booster pump, a dye kettle, a dyeing kettle and a separation kettle which are sequentially connected. A circulating pump is also arranged between a fluid outlet of the dyeing kettle and a fluid inlet of the dye kettle. Online detection is adopted in the dyeing process of the supercritical CO2 fluid, the proportion change of the three-primary color dye can be detected in real time, and competitive dyeing phenomenon can be avoided.

Owner:亚临界(上海)技术有限公司

Supercritical CO2 fluid natural textile dye composition as well as dyeing system and method thereof

ActiveCN107904986AGood compatibilityReal-time detection of scale changesDyeing processCarbon dioxide cylinderGardenia

The invention belongs to the technical field of water-free dyeing of textiles and particularly relates to a technique for dyeing textiles through a three-primary-color natural dye in supercritical CO2fluid. The three-primary-color natural dye is prepared by mixing at least two of radix salviae miltiorrhizae red pigments, turmeric yellow pigments and gardenia blue pigments according to an arbitrary ratio. All the natural dyes are high in compatibility, are applicable to supercritical CO2 fluid dyeing, and can be combined for dyeing the textiles with various colors. A dyeing system comprises acarbon dioxide steel cylinder, a boosting pump, a dye kettle, a dyeing kettle and a separation kettle which are successively connected with each other; a circulation pump is arranged between a fluid outlet of the dyeing kettle and a fluid inlet of the dye kettle; on-line detection is used in the dyeing process of the supercritical CO2 fluid; the ratio change of the three-primary-color dye can be detected in real time; the phenomenon of competitive dyeing is avoided.

Owner:亚临界(上海)技术有限公司

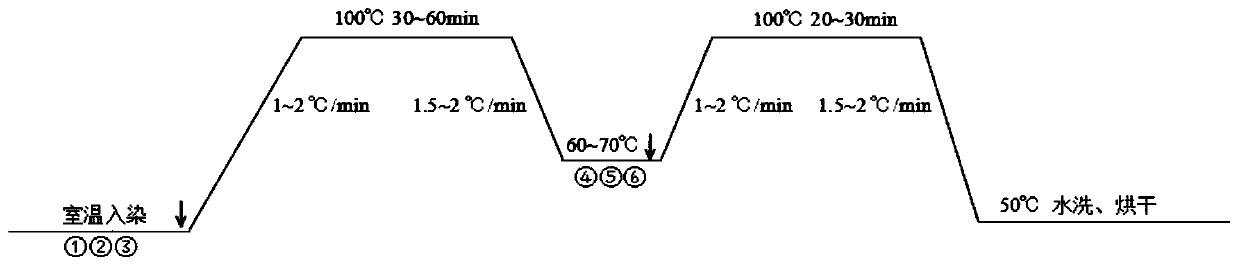

Dyeing method of nylon/spandex blended fabric

ActiveCN111535057AReduce processing stepsExcellent color fastness to washingDyeing processDisperse dyeAcetic acid

The invention relates to a dyeing method of a nylon / spandex blended fabric. The method comprises the following steps: pretreating the nylon / spandex blended fabric; then carrying out dyeing in the samebath, adding an acid dye, a leveling agent and acetic acid in the dyeing process, adjusting the pH value, carrying out heating, heat preservation and dyeing, adding a disperse dye, a dispersing agentand ammonium sulfate after cooling, adjusting the pH value, and carrying out heating, heat preservation, dyeing, cooling and water washing; and carrying out color fixation. According to the method, an acid dye and a disperse dye are used for one-bath two-step dyeing, the process is simple, and large-scale production can be realized by adopting conventional dyeing equipment.

Owner:DONGHUA UNIV +1

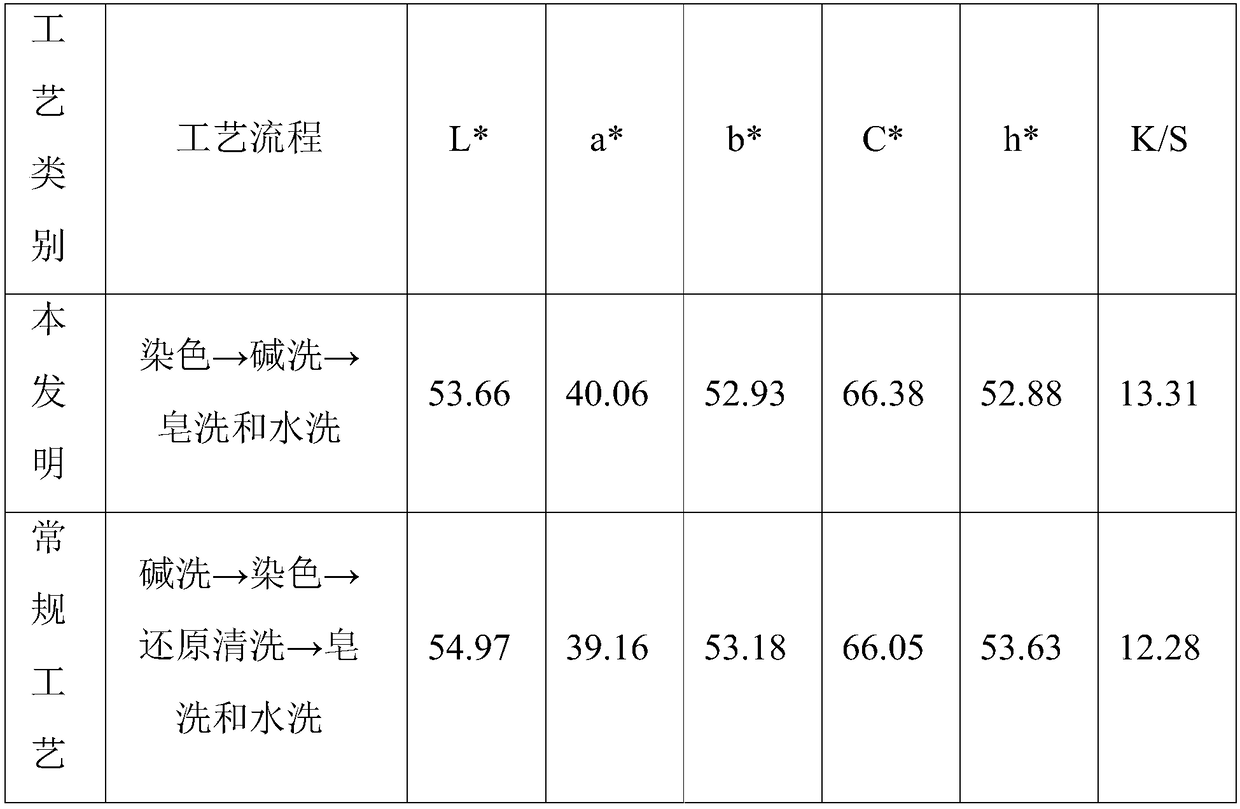

Terylene fabric dispersive dyeing non-reduction cleaning technology

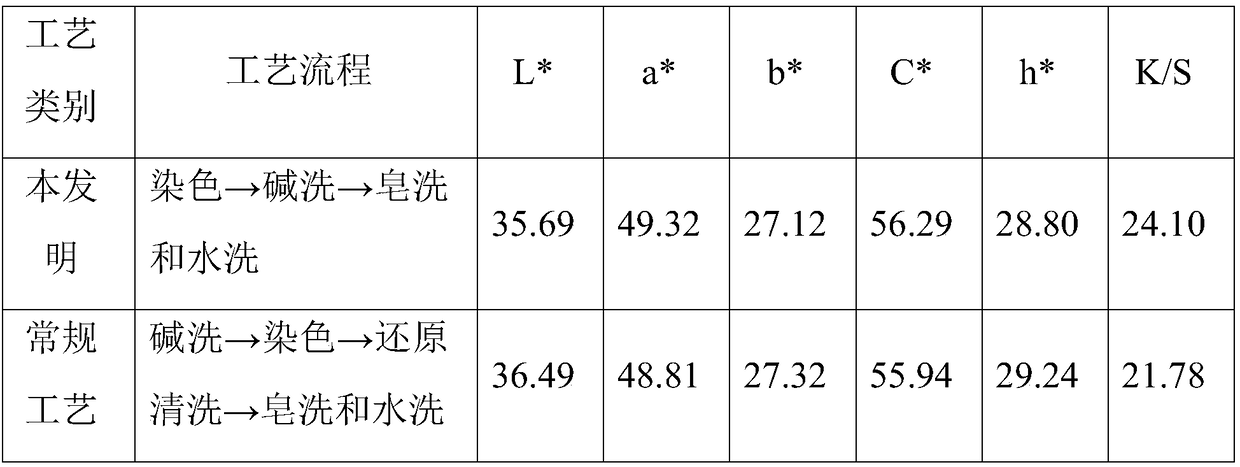

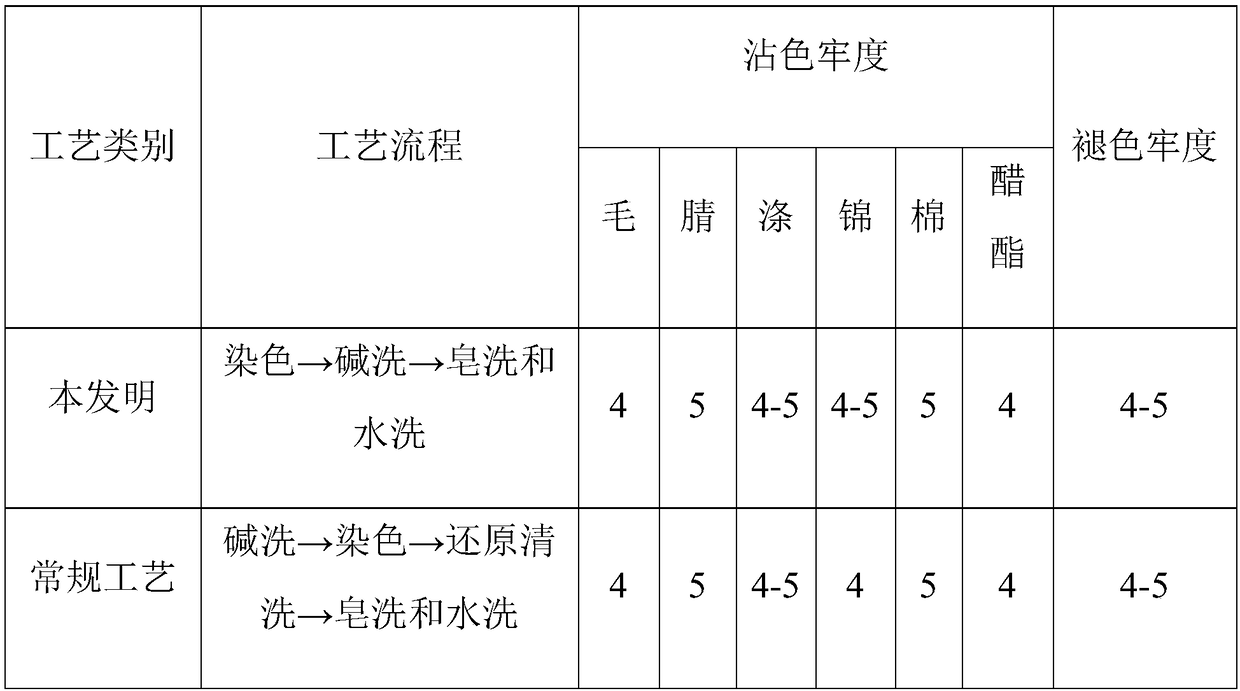

ActiveCN108589329AShade stabilityExcellent color fastness to washingDyeing processEngineeringTextile dyeing

The invention relates to the field of textile dyeing and finishing treatment, and concretely relates to a terylene fabric dispersive dyeing non-reduction cleaning technology. A high alkali-resistant dispersive dye is used for dyeing the terylene fabric, an alkaline solution is used for dyeing the terylene fabric, and soaping and washing can be carried out. The terylene fabric dispersive dyeing non-reduction cleaning technology does not require a reducing agent for reduction cleaning on dyeing terylene fabric, and can effectively remove floated color and color spot on the surface of the fabric,the dyed fabric can obtain the stable colored light and excellent washable color fastness, the technology is simplified and is more environmentally friendly, and reduces the enterprise cost, and increases the enterprise benefit.

Owner:PENGLAI JIAXIN DYES & CHEM

Dyeing method of wool fiber top

InactiveCN106337299AExcellent light fastnessGood dyeing uniformityDyeing processDimethyl formamideN-methyldiethanolamine

The invention discloses a dyeing method of wool fiber top, comprising the following steps: 1) successively adding tristyrylphenol polyoxyelhylene ether sulfonate, acryloyloxyethyltrimethyl ammonium chloride, polyvinylpyrrolidone, dimethyl formamide and vegetable dye into a dye vat and successively pouring deionized water, uniformly stirring and heating to 45 DEG C; 2) successively pouring N-methyldiethanolamine, linear alklybezene sulfonates, magnesium sulfate and nitrilotriacetic acid, continuously stirring until the materials are fully and uniformly mixed, and heating to 60 DEG C; 3) immersing top into the dye vat for 50 min; 4) drying the immersed top at 85 DEG C; 5) immersing the dried top in clear water and rinsing for 50 min; and 6) taking the rinsed top out of the clear water and naturally airing. The top dyed by the above method has excellent color fastness and has good dyeing uniformity and has no dyeing defect.

Owner:常熟市新华源有色毛条厂

Dyeing method for blended fabric

InactiveCN106320012AExcellent color fastness to chlorine bleachingExcellent color fastness to washingDyeing processSulfonateTriethylenetetramine

The invention discloses a dyeing method for blended fabric. The method comprises the steps of 1) adding magnesium sulfate, diglycolamidic acid, carboxymethylcellulose, HACC and vegetable dyes in deionized water in sequence, mixing even and heating to 55oC; 2) Adding tetrasodium glutamate diacetate, alkyl sodium sulfonate, triethylenetetramine, mica powder in sequence, and mixing even, heating to 65oC; 3) Soaking the fabric in the dye vat for 25min; 4) Drying the soaked fabric at 80oC; 5) Soaking the dried fabric in clean water and rinsing for 25min; and 6) Getting out the rinsed fabric and make it dry naturally. The dyed fabric is excellent in color fastness and good in dyeing uniformity, free of color tone.

Owner:常熟市华谊织造有限公司

Dyeing method for sofa fabrics

InactiveCN106368001AExcellent color fastness to perspirationExcellent water fastnessDyeing processPhosphateFatty alcohol

The invention discloses a dyeing method for sofa fabrics. The dyeing method includes the steps: 1) sequentially adding dimethyl formamide, N-methyl diethanol amine, sodium hexametaphosphate, magnesium sulfate and vegetable dyes into a dye vat, sequentially adding deionized water, uniformly mixing, and heating to 55 DEG C; 2) sequentially adding iminodiacetic acid, isomeric fatty alcohol polyoxyethylene ether phosphate, chitosan quaternary ammonium salt and sodium ethylene diamine tetraacetate, continuing to mix until sufficiently and uniformly blending is achieved, and heating to 65 DEG C; 3) soaking the fabrics in the dye vat for 35 minutes; 4) drying the soaked fabrics at the temperature of 80 DEG C; 5) soaking the dried fabrics in clear water to wash for 35 minutes; 6) taking out the washed fabrics to naturally dry. The fabrics dyed by the method have excellent color fastness and are good in dyeing uniformity and free from dyeing defects.

Owner:SUZHOU XIN GE HOUSEHOLD PROD CO LTD

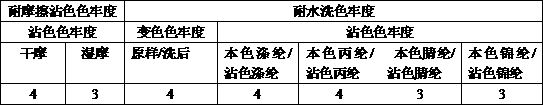

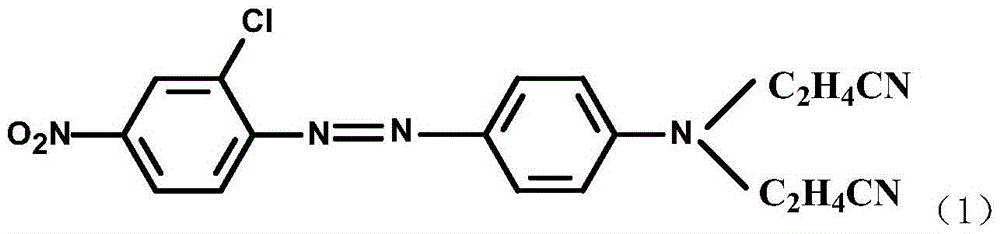

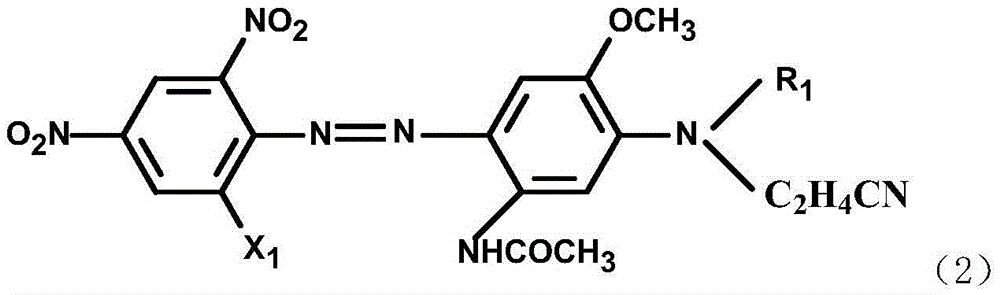

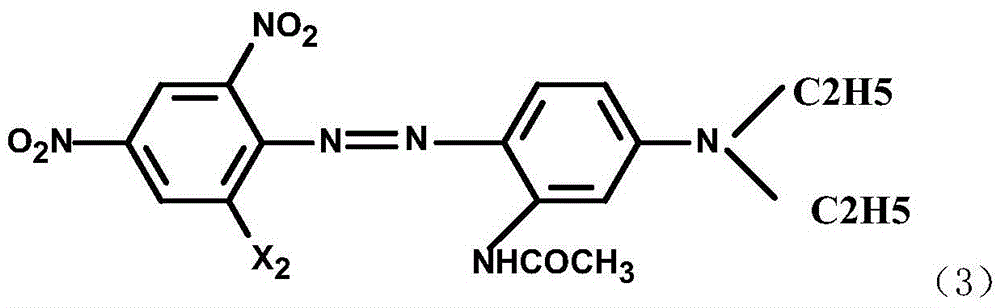

Disperse dye composition and disperse dye and preparation method and application thereof

The invention discloses a dye composition and a disperse dye and its preparation method and application. The dye composition comprises a compound as shown in the formula (1) and at least one compound as shown in the formula (2) and formula (3). The disperse dye contains the disperse dye composition and an auxiliary material. The preparation method of the disperse dye comprises the following steps: mixing various dye components, and carrying out particlization treatment in the presence of the auxiliary material by a sand mill or a grinding machine; or respectively carrying out particlization treatment on the various dye components in the presence of the auxiliary agent by a sand mill or a grinding machine, and mixing. The prepared disperse dye is suitable for dyeing and printing of fabric, has good compatibility, is low-cost, has little pollution and is a disperse dye with good cost performance. In the formula (2), X1 is Br or Cl, and R1 is H or C2H5. In the formula (3), X2 is Cl or Br.

Owner:太湖亚太精化有限公司

Dyeing method of spandex fabric

InactiveCN106381727AExcellent color fastness to perspirationExcellent water fastnessDyeing processAcetic acidSulfonate

The invention discloses a dyeing method of spandex fabric, comprising the following steps: 1) successively adding dibutyl phthalate, diisocyanate, polypropylene glycol, butyl peroxybenzoate and vegetable dye into 1 part of deionized water in a dye vat, uniformly stirring, and heating to 55 DEG C; 2) successively pouring glycine, diisooclyl maleate sulfonate, acrylic acid ester and tetrasodium glutamate diacetate, continuously stirring until the materials are fully and uniformly mixed, and heating to 65 DEG C; 3) immersing the fabric in the dye vat for 35 min; 4) drying the immersed fabric at 80 DEG C; 5) rinsing the dried fabric in clear water for 35 DEG C; and 6) taking the rinsed fabric out of the clear water and naturally airing. The dyed fabric has excellent color fastness and good dyeing uniformity and has no dyeing defect.

Owner:SUZHOU XIN GE HOUSEHOLD PROD CO LTD

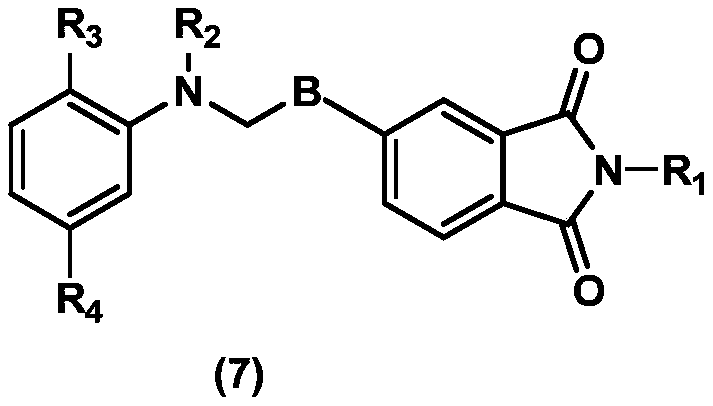

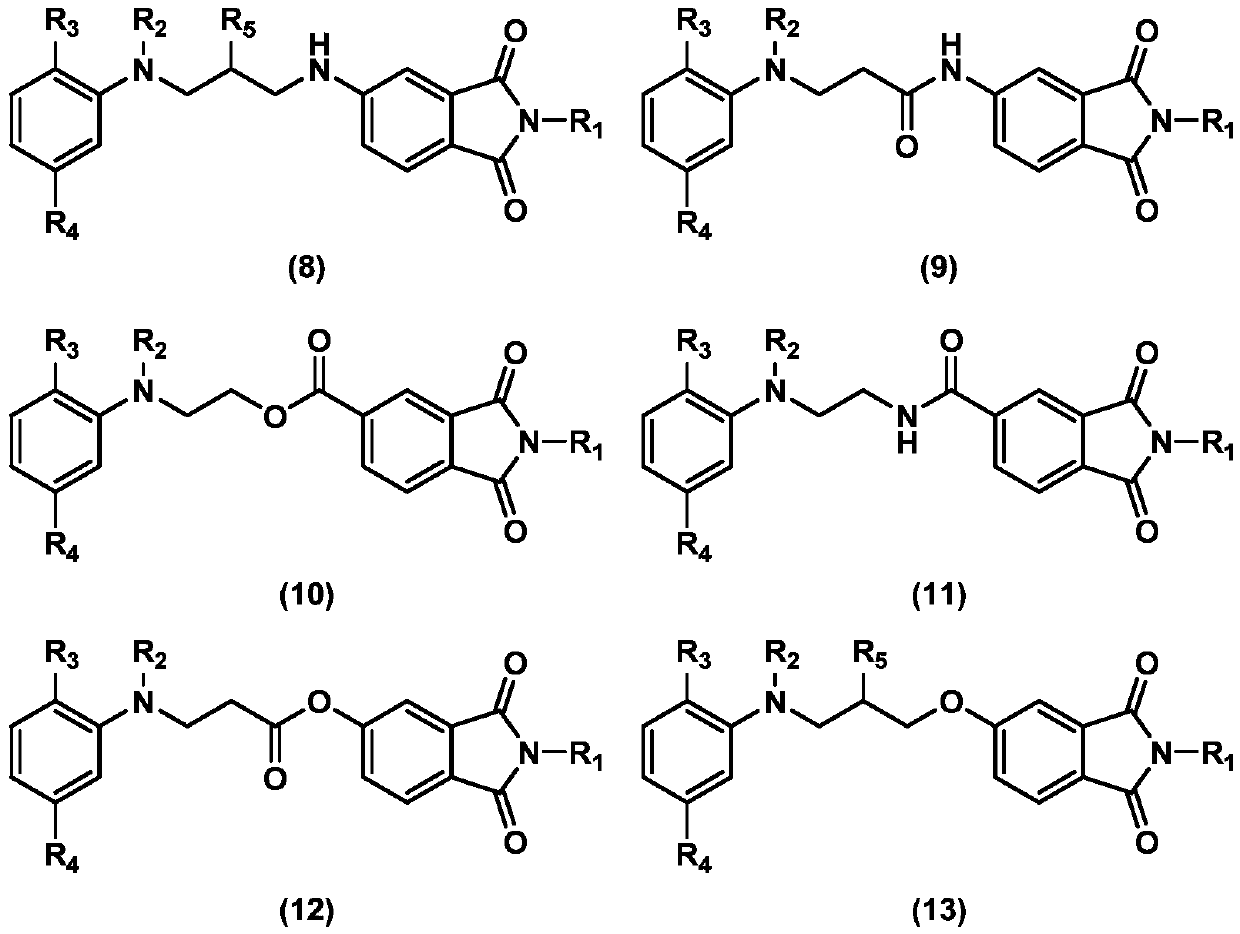

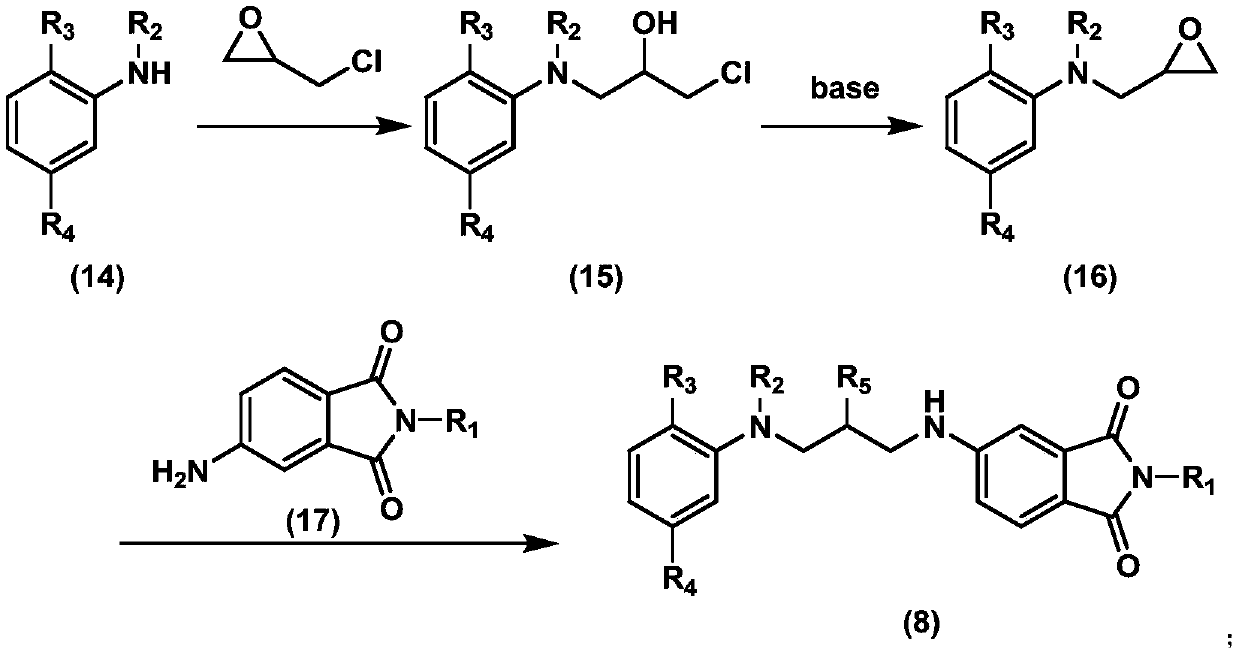

Coupling component containing phthalimide structure, and preparation method and application of coupling component

PendingCN111303005ADifferent applicabilityIncrease intermolecular forcesMonoazo dyesOrganic chemistryPolyesterImide

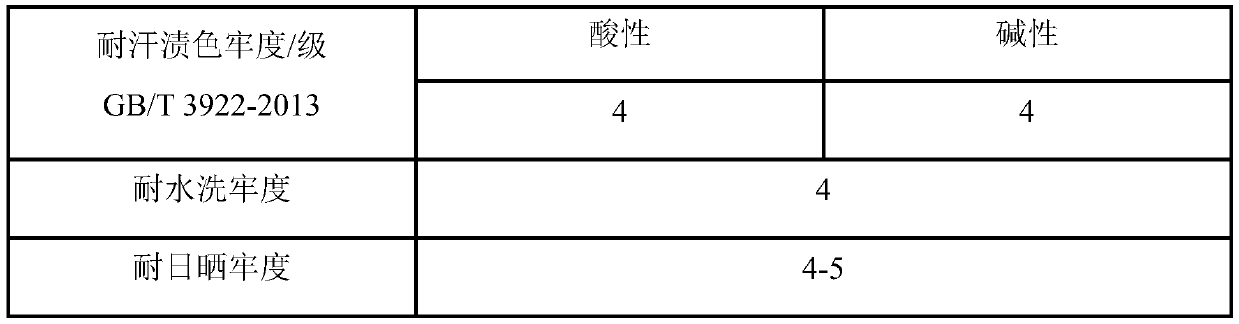

The invention discloses a coupling component containing a phthalimide structure, and a preparation method and application of the coupling component. The structural formula of the coupling component isas shown in a formula (7). The prepared coupling component containing the phthalimide structure belongs to novel coupling components containing phthalimide; the phthalimide structure is introduced through connection with a substituent group on a phthalimide benzene ring, and the nitrogen atoms of imide can be connected to different substituent groups R1, so a dye is allowed to have different application performances and excellent color fastness to washing. Meanwhile, only an alkali washing process is used after a polyester fabric is dyed, so carcinogenic aromatic amine generated by decomposing azo groups under the condition of reduction cleaning of sodium hydrosulfite is prevented from being released into sewage, the treatment burden of washing sewage is reduced, and high environmental protection performance is achieved.

Owner:乌海青石化学有限公司

Method for dyeing PV pile fabric

InactiveCN106245358AExcellent color fastness to rubbingGood dyeing uniformityDyeing processDiethylenetriamineEthylenediamine

The invention discloses a method for dyeing a PV pile fabric. The method comprises the following steps: (1) sequentially adding tea polyphenols, diethylenetriamine, ethylene glycol, a maleate-acrylate copolymer and vegetable dyes into a dye vat, successively adding deionized water into the dye vat, uniformly stirring, and heating the dye vat to the temperature of 45 DEG C; (2) then, sequentially adding ethylenediamine, iso-tridecanol polyoxyethylene ether, an N-vinyl pyrrolidone / acrylamide copolymer and 2-acrylic acid amide-2-methylpropanesulfonic acid into the dye vat, continuing stirring until the mixture is uniformly mixed thoroughly, and heating the dye vat to the temperature of 60 DEG C; (3) soaking the fabric in the dye vat for 45 minutes; (4) baking the soaked fabric at the temperature of 85 DEG C; (5) submerging the baked fabric in clean water, and rinsing for 45 minutes; (6) taking out the rinsed fabric, and naturally drying the fabric in the air. According to the method, the dyed fabric has excellent color fastness, is good in dyeing uniformity and is free of uneven dyeing.

Owner:常熟市绮丽家纺有限公司

Shu velveteen fabric dyeing method

InactiveCN106320013AExcellent color fastness to washingGood dyeing uniformityDyeing processN-butyl acrylateTitanium dioxide

The invention discloses a Shu velveteen fabric dyeing method. The Shu velveteen fabric dyeing method comprises the following steps: 1) polyethylene glycol fatty acid ester, borax, polyacrylic acid, dimethylamine and a vegetable dye are added to deionized water in a dye vat sequentially, and the materials are stirred uniformly and heated to 45 DEG C; 2) then alkyl polyglucoside, sodium alkyl ester sulfosuccinate, n-butyl acrylate and titanium dioxide are fed sequentially, and the materials are stirred continuously until the materials are mixed sufficiently and uniformly and are heated to 60 DEG C; 3) the fabric is soaked in the dye vat for 40 min; 4) the soaked fabric is dried at 85 DEG C; 5) the dried fabric is soaked in clear water and rinsed for 40 min; 6) the rinsed fabric is taken out and aired naturally. The fabric dyed with the method has excellent color fastness and dyeing evenness and is free of colored spots.

Owner:SUZHOU YUHUA BUSINESS MANAGEMENT CO LTD

Dyeing method for PV fabric

InactiveCN106320009AGood light fastnessExcellent color fastness to perspirationDyeing processPhosphateClean water

The invention discloses a dyeing method for PV fabric. The method comprises the steps of 1) Adding epichlorohydrin, ferrous sulfate, sodium hexametaphosphate, dimethylamine and vegetable dyes in sequence in deionized water, then mixing even and heating to 55oC; 2) Adding poly(acrylic acid-co-maleic acid), isomeric 13 - dodecanol polyoxyethylene ether phosphate and ODPA in sequence and continue to mix to even mixing, and heat to 65oC; 3) Soaking fabric in the dye vat for 30min; 4) Drying the soaked fabric at 80oC; 5) Soaking the dried fabric in clean water and rinsing for 30min; 6) Getting out the rinsed fabric and make it dry naturally. The dyed fabric is excellent in color fastness and good in dyeing uniformity, free of color tone.

Owner:常熟市通惠织造有限公司

Dyeing process capable of increasing fixation rate of textiles

InactiveCN108716147AReduce energy consumptionImprove dyeing effectDyeing processPolyesterEnergy conservation

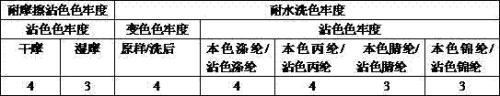

The invention provides a dyeing process capable of increasing fixation rate of textiles. The dyeing process includes A, pre-dyeing treatment, B, dyeing treatment and C, post-dyeing treatment. The dyeing process has the advantages that the one-bath dyeing method integrates a cotton dyeing process with a terylene dyeing process; according to the one-bath two-step method, cotton is dyed at a low temperature, and terylene is dyed at a high temperature, so that feasibility of the one-bath dyeing method is improved, technological steps are simplified greatly, consumption of energy such as water andsteam is reduced, technological consumed time is shortened, and energy conservation, emission reduction and production efficiency improvement are realized; proper components and ratios of dyestuff andaids are selected according to the one-bath dyeing method, optimal technological steps and parameters (time and temperature) are combined, and accordingly, the dyeing effect of fabrics is improved greatly; polyester-cotton fabrics dyed and finished by the one-bath dyeing method have high color fastness to washing, insolation, friction, water and perspiration; dyeing uniformity is achieved, and dyeing defects are avoided.

Owner:RUGAO ZHOUQIN CLOTHING CO LTD

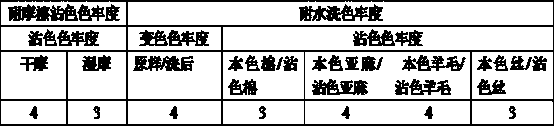

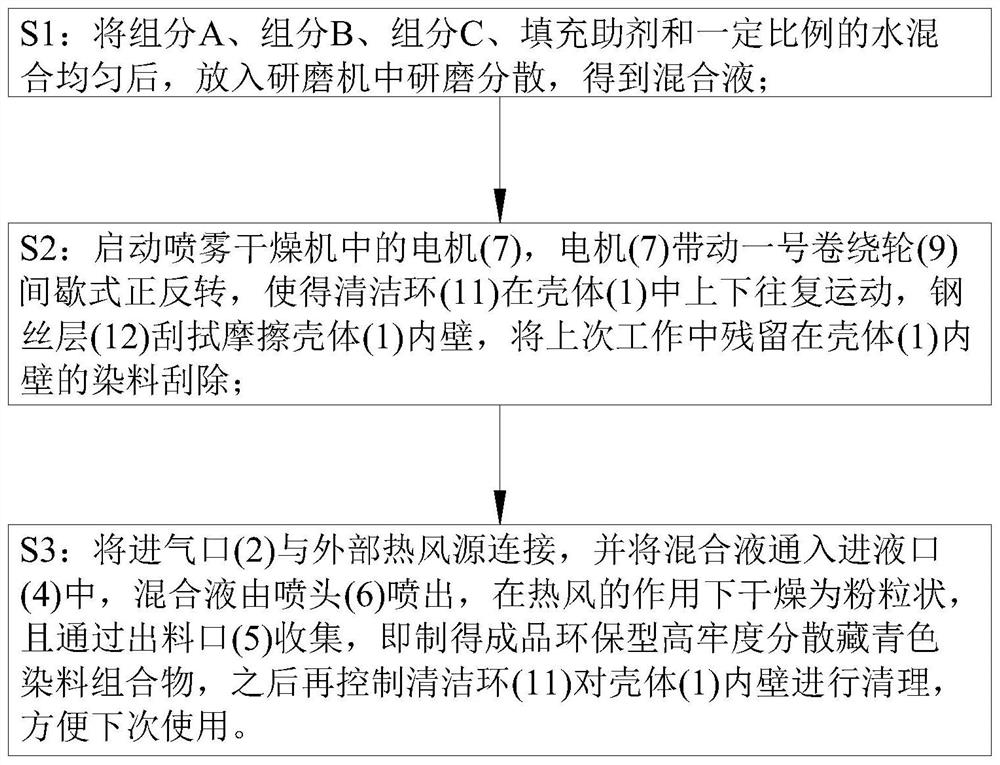

Environment-friendly high-fastness disperse navy blue dye composition and preparation method thereof

ActiveCN113621252AHigh exhaustion rateIncrease profitEvaporator accessoriesOrganic dyesTextile printerColour fastness

The invention belongs to the technical field of fine chemical engineering, and particularly relates to an environment-friendly high-fastness disperse navy blue dye composition and a preparation method thereof. The dye composition comprises, by weight, 20-42 parts of a component A, 29-51 parts of a component B, 46-65 parts of a component C, and 70-210 parts of a filling aid. The dye composition does not contain forbidden aromatic amines, sensitization and carcinogenic dyes, chlorophenol, organochlorine carriers, quinoline and other components harmful to human health, meets the OEKO-TEX Standard 100 indexes of textiles, has high environmental protection property, improves the compatibility of the dyes and improves the exhaustion rate and utilization rate of the dyes through compounding and addition of the dyes with different structures, meanwhile, the dyeing or printing soaping residual liquid is clear, the treatment difficulty of printing and dyeing wastewater is reduced, and the dye is good in lifting power and excellent in water soaking, sublimation and soaping color fastness.

Owner:菲诺染料化工(无锡)有限公司

Quilt cover fabric dyeing method

InactiveCN106400532AExcellent color fastness to perspirationExcellent water fastnessDyeing processAlcoholSulfate

The invention discloses a quilt cover fabric dyeing method. The method comprises the steps of: 1) adding calcium sulfate, aspartic acid, sodium polyacrylate, titanium dioxide and vegetable dyes into deionized water in a dye vat in order, stirring the substances evenly, and performing heating to 55DEG C; 2) then adding beta-alanine, secondary alcohol ethoxylate, sodium silicate and ferrous sulfate, further conducting stirring until the substances are fully and evenly mixed, and performing heating to 65DEG C; 3) soaking the fabric in the dye vat for 35min; 4) drying the well soaked fabric at 80DEG C; 5) immersing the dried fabric in clear water and performing rinsing for 35min; and 6) taking out the rinsed fabric and conducting natural airing. According to the method provided by the invention, the dyed fabric has excellent color fastness and good dyeing uniformity, and is free of dyeing defect.

Owner:SUZHOU XIN GE HOUSEHOLD PROD CO LTD

Pine needle fleece fabric dyeing method

InactiveCN106320014AExcellent color fastness to washingGood dyeing uniformityDyeing processTriethylenetetramineDyeing

The invention discloses a pine needle fleece fabric dyeing method. The pine needle fleece fabric dyeing method comprises the following steps: 1) ethylene carbonate, glacial acetic acid, hydroxypropyl cellulose, triethylenetetramine and a vegetable dye are added to deionized water in a dye vat sequentially, and the materials are stirred uniformly and heated to 45 DEG C; 2) then sodium glycinate, sodium sulfamate, acryloyloxyethyltrimethyl ammonium chloride and polyurethane are fed sequentially, and the materials are stirred continuously until the materials are mixed sufficiently and uniformly and are heated to 60 DEG C; 3) the fabric is soaked in the dye vat for 40 min; 4) the soaked fabric is dried at 85 DEG C; 5) the dried fabric is soaked in clear water and rinsed for 40 min; 6) the rinsed fabric is taken out and aired naturally. The fabric dyed with the method has excellent color fastness and dyeing evenness and is free of colored spots.

Owner:SUZHOU YUHUA BUSINESS MANAGEMENT CO LTD

Wool fabric dyeing method

InactiveCN106337301AExcellent color fastness to chlorine bleachingExcellent color fastness to washingDyeing processTetramineALLYL SUCROSE

The invention discloses a wool fabric dyeing method, which comprises: 1) sequentially pouring hexamethoxymethylmelamine, maleic acid, polyacrylic acid, dinitroso pentamethylene tetramine and a plant dye into deionized water in a dyeing vat, uniformly stirring, and heating to a temperature of 55 DEG C; 2) sequentially adding iminodipropionic acid, tributyl phosphate, hexanediamine and methacrylic acid diethyl amino ethyl ester, continuously stirring until completely and uniformly mixing, and heating to a temperature of 65 DEG C; 3) soaking a fabric for 25 min in the dying vat; 4) drying the soaked fabric at a temperature of 80 DEG C; 5) immersing the dried fabric in clear water, and rinsing for 25 min; and 6) taking out the rinsed fabric, and carrying out natural air drying. According to the present invention, the dyed fabric has advantages of excellent color fastness, good dyeing uniformity, and no dyeing spot.

Owner:常熟市华谊织造有限公司

Dyeing method of coral velvet fabric

InactiveCN106367998AGood light fastnessExcellent color fastness to perspirationDyeing processEpoxyPhenol

The invention discloses a dyeing method of a coral velvet fabric. The dyeing method includes the steps of: 1) successively adding polyurethane, fumaric acid, sodium silicate, acryloyl chloride, and a plant dye to deionized water in a dye vat, and stirring the mixture uniformly and heating the mixture to 55 DEG C; 2) successively adding ferrous sulfate, fatty alcohol-polyoxyethylene ether, epoxy chloropropane and tristyryl phenol polyoxyethylene ether sulfonate, continuously stirring the mixture until the components are fully mixed, and heating the mixture to 65 DEG C; 3) soaking the fabric in the dye vat for 30 min; 4) drying the soaked fabric at 80 DEG C; 5) rinsing the dried fabric in clear water for 30 min; and 6) naturally air-drying the rinsed fabric. The dyed fabric has excellent color fastness, good dyeing uniformity and is free of non-uniform dyeing.

Owner:常熟市通惠织造有限公司

supercritical co 2 Fluid natural textile dye composition and dyeing method

ActiveCN107904986BGood compatibilityReal-time detection of scale changesDyeing processNatural dyeTextile dye

The invention belongs to the technical field of water-free dyeing of textiles and particularly relates to a technique for dyeing textiles through a three-primary-color natural dye in supercritical CO2fluid. The three-primary-color natural dye is prepared by mixing at least two of radix salviae miltiorrhizae red pigments, turmeric yellow pigments and gardenia blue pigments according to an arbitrary ratio. All the natural dyes are high in compatibility, are applicable to supercritical CO2 fluid dyeing, and can be combined for dyeing the textiles with various colors. A dyeing system comprises acarbon dioxide steel cylinder, a boosting pump, a dye kettle, a dyeing kettle and a separation kettle which are successively connected with each other; a circulation pump is arranged between a fluid outlet of the dyeing kettle and a fluid inlet of the dye kettle; on-line detection is used in the dyeing process of the supercritical CO2 fluid; the ratio change of the three-primary-color dye can be detected in real time; the phenomenon of competitive dyeing is avoided.

Owner:亚临界(上海)技术有限公司

Dyeing method of flannel fabric

InactiveCN106320005AExcellent color fastness to rubbingExcellent color fastness to washingDyeing processColour fastnessTriethanolamine

The invention discloses a dyeing method of flannel fabric. The dyeing method comprises the following steps: 1) sequentially adding sodium sulfate, ammonia water, sodium hexametaphosphate, hydantoin and vegetable dye into deionized water, uniformly stirring, and heating to 45 DEG C; 2) then sequentially putting methylallylamine hydrochloride, sodium alkyl benzene sulfonate, triethanolamine and a monomer containing tertiary amino, further stirring until the substances are fully and uniformly mixed, and heating to 60 DEG C; 3) soaking the fabric in a dyeing vessel for 45 minutes; 4) drying the soaked fabric at the temperature of 85 DEG C; 5) immersing the dried fabric into clean water and rinsing for 45 minutes; and 6) taking out the rinsed fabric, and naturally airing. The dyed fabric has excellent colour fastness, dyeing uniformity is good, and no dyeing defect is produced.

Owner:常熟市绮丽家纺有限公司

Method for dyeing plush fabric

InactiveCN106368002AExcellent color fastness to washingExcellent color fastness to dry cleaningDyeing processTetramineDiethylenetriamine

The invention discloses a method for dyeing plush fabric. The method comprises the following steps that 1, o-phthalimide, sodium hexametaphosphate, Arabic gum powder, diethylenetriamine and vegetable dyes are sequentially added into a dye vat, deionized water is put into the dye vat, is the materials are stirred to be uniform, and the mixture is heated to 45 DEG C; 2, phenoxyethanol, igepon T and isobornyl methacrylate and dinitroso pentamethylene tetramine are sequentially put into the dye vat, the mixture continues to be stirred to be fully mixed to be uniform, and the mixture is heated to 60 DEG C; 3, fabric is soaked in the dye vat for 40 minutes; 4, the soaked fabric is dried at the temperature of 85 DEG C; 5, the dried fabric is soaked in clear water to be rinsed for 40 minutes; 6, the rinsed fabric is taken out to be naturally aired. The dyed fabric has excellent color fastness and is good in dyeing uniformity and free of color stains.

Owner:SUZHOU YUHUA BUSINESS MANAGEMENT CO LTD

Method for dyeing polar fleece fabric

InactiveCN106337292AExcellent color fastness to rubbingGood dyeing uniformityDyeing processChemistryEthylenediaminetetra(methylenephosphonic)acid

The invention discloses a method for dyeing a polar fleece fabric, and the method comprises the following steps: 1) adding copper sulfate, hexamethylenediamine, hexyldecanol, sodium ethylenediamine tetramethylene phosphonate and a plant dye in turn into deionized water in a dyeing vat, stirring well, and heating to 45 DEG C; 2) in turn adding fatty alcohol polyoxyethylene ether, alkyl sodium sulfonate, polyethylene glycol (peg) and 1-dimethyl diallyl ammonium chloride, continuing to stir until even mixing, and heating at 60 DEG C; 3) soaking the fabric for 45 minutes in the dyeing vat; 4) drying the soaked fabric at 85 DEG C; 5) dipping the dried fabric into clean water for rinsing for 45 minutes; and 6) taking the rinsed fabric for drying in air naturally. The dyed fabric has excellent color fastness and good dyeing uniformity, and is free of dyeing defects.

Owner:常熟市绮丽家纺有限公司

Dyeing method for acrylic top

InactiveCN106320008AGood light fastnessExcellent color fastness to washingDyeing processMethacrylateSodium metasilicate

The invention discloses a dyeing method for acrylic top, comprising the steps of 1) add secondary alcohol ethoxylate, triallylamine, sodium metasilicate, diethyl amino ethyl methacrylate and vegetable dyes into the deionized water, mix the water and heat it to 4oC; 2) add sodium of polyaspartic acid, sodium dodecyl sulfate, zinc stearate and Alpha-aminopropionic acid, keep mixing util the solution is mixed evenly and heat the solution to 60oC; 3) dip the wool top in the dye vat for 50min; 4) dry the soaked wool top at 85oC; 5) wash the dried wool top in clean water for 50min; 6) take out the washed wool top for natural drying. The dyed tops are excellent in color fastness and good in dyeing uniformity, and free of color tone.

Owner:常熟市新华源有色毛条厂

supercritical co for textiles 2 Fluid dye composition and dyeing system and method

ActiveCN108086022BGood compatibilityReal-time detection of scale changesDyeing processDisperse dyeDisperse yellow

The invention belongs to the technical field of anhydrous dyeing of textile and particularly relates to a dyeing technology of textile in a supercritical CO2 fluid with three-primary color disperse dye. At least two of the three-primary color dye including C.I. disperse red 140, C.I. disperse yellow and C.I. disperse blue 56 are mixed in any ratio. All the disperse dyes are well compatible, are suitable to be used for supercritical CO2 fluid dying and can be combined to dye textile in various colors. The dyeing system of the composition comprises a CO2 steel cylinder, a booster pump, a dye kettle, a dyeing kettle and a separation kettle which are sequentially connected. A circulating pump is also arranged between a fluid outlet of the dyeing kettle and a fluid inlet of the dye kettle. Online detection is adopted in the dyeing process of the supercritical CO2 fluid, the proportion change of the three-primary color dye can be detected in real time, and competitive dyeing phenomenon can be avoided.

Owner:亚临界(上海)技术有限公司

Dyeing method of bar-shaped plush fabric

InactiveCN106381728AExcellent color fastness to perspirationExcellent water fastnessDyeing processPhosphateEthyl ester

The invention discloses a dyeing method of bar-shaped plush fabric. The dyeing method comprises the following steps: 1) successively adding 2-(diethylamino)ethyl methacrylate, poly(aspartic acid), sodium tripolyphosphate, zinc stearate and vegetable dye into deionized water in a dye vat, uniformly stirring and heating to 55 DEG C; 2) successively pouring nitrilotriacetic acid, aliphatic isoalcohol phosphate, dicyandiamide and chitosan, continuously stirring until the materials are fully and uniformly mixed, and heating to 65 DEG C; 3) immersing fabric in the dye vat for 35 min; 4) drying the immersed fabric at 80 DEG C; 5) immersing the dried fabric in clear water and rinsing for 35 min; and 6) taking out the rinsed fabric and naturally airing. The dyed fabric has excellent color fastness and good dyeing uniformity, but has no dyeing defect.

Owner:SUZHOU XIN GE HOUSEHOLD PROD CO LTD

Dyeing method of bubble cashmere fabric

InactiveCN106381729AExcellent color fastness to washingExcellent color fastness to dry cleaningDyeing processEthylenediaminePyrophosphate

The invention discloses a dyeing method of a bubble cashmere fabric, wherein the dyeing method comprises the following steps: 1) successively adding octadecyl dimethylamine, sodium sulfate, sodium pyrophosphate, ammonia water and a plant dye into deionized water in a dyeing vat, stirring evenly, and heating to 45 DEG C; 2) then successively adding sodium ethylenediamine tetramethylene phosphonate, sodium alpha-olefin sulfonate, methylallylamine hydrochloride and zinc stearate, continuing to stir to fully and evenly mix, and heating to 60 DEG C; 3) soaking a fabric in the dyeing vat for 40 minutes; 4) drying the soaked fabric at the temperature of 85 DEG C; 5) immersing the dried fabric into clear water, and rinsing for 40 minutes; and 6) taking out the rinsed fabric, and naturally air-drying. The dyed fabric has the advantages of excellent color fastness, good dyeing uniformity, and no color spots.

Owner:SUZHOU YUHUA BUSINESS MANAGEMENT CO LTD

Dyeing method of coral velvet fabric

InactiveCN106400534AExcellent color fastness to washingGood dyeing uniformityDyeing processSodium polyacrylateChemistry

The invention discloses a dyeing method of a coral velvet fabric. The dyeing method comprises 1) orderly adding polyoxyethylene fatty amine, powdered sodium carbonate, sodium polyacrylate, monomethylamine and a plant dye into deionized water in a dye vat, carrying out uniform stirring and heating the mixture to a temperature of 45 DEG C, 2) orderly adding hydantoin, sodium alkyl naphthalenesulfonate, polyalkylene polyamine and blocked isocyanate into the mixture, carrying out stirring for full mixing and heating the mixture to 60 DEG C, 3) soaking a fabric in the dye vat for 40 minutes, 4) drying the soaked fabric at a temperature of 85 DEG C, 5) immersing the dried fabric in clear water and carrying out rinsing for 40 minutes, and 6) taking out the rinsed fabric and carrying out natural air-drying. The dyed fabric has excellent color fastness and good dyeing uniformity and prevents color mixing.

Owner:SUZHOU YUHUA BUSINESS MANAGEMENT CO LTD

Method for dyeing loop-raised fabric

InactiveCN106337293AExcellent color fastness to rubbingGood dyeing uniformityDyeing processSodium polyacrylateDiethylenetriamine

The invention discloses a method for dyeing a loop-raised fabric, and the method comprises the following steps: 1) adding sodium hexametaphosphate, diethylenetriamine, sodium polyacrylate, sodium amino acetic acid and a plant dye in turn into deionized water in a dyeing vat, stirring well, and heating to 45 DEG C; 2) in turn adding Isobornyl methacrylate, secondary alkyl sodium sulfate, dimethylformamide and N-methyl diethanolamine, continuing to stir until even mixing, and heating at 60 DEG C; 3) soaking the fabric for 45 minutes in the dyeing vat; 4) drying the soaked fabric at 85 DEG C; 5) dipping the dried fabric into clean water for rinsing for 45 minutes; and 6) taking the rinsed fabric for drying in air naturally. The dyed fabric has excellent color fastness and good dyeing uniformity, and is free of dyeing defects.

Owner:常熟市绮丽家纺有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com