Environment-friendly high-fastness disperse navy blue dye composition and preparation method thereof

A dye composition and an environment-friendly technology, which is applied in the field of environment-friendly high-fastness dispersed navy blue dye composition and its preparation, can solve problems such as endangering human health, achieve reduced processing difficulty, high environmental protection, and improved compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

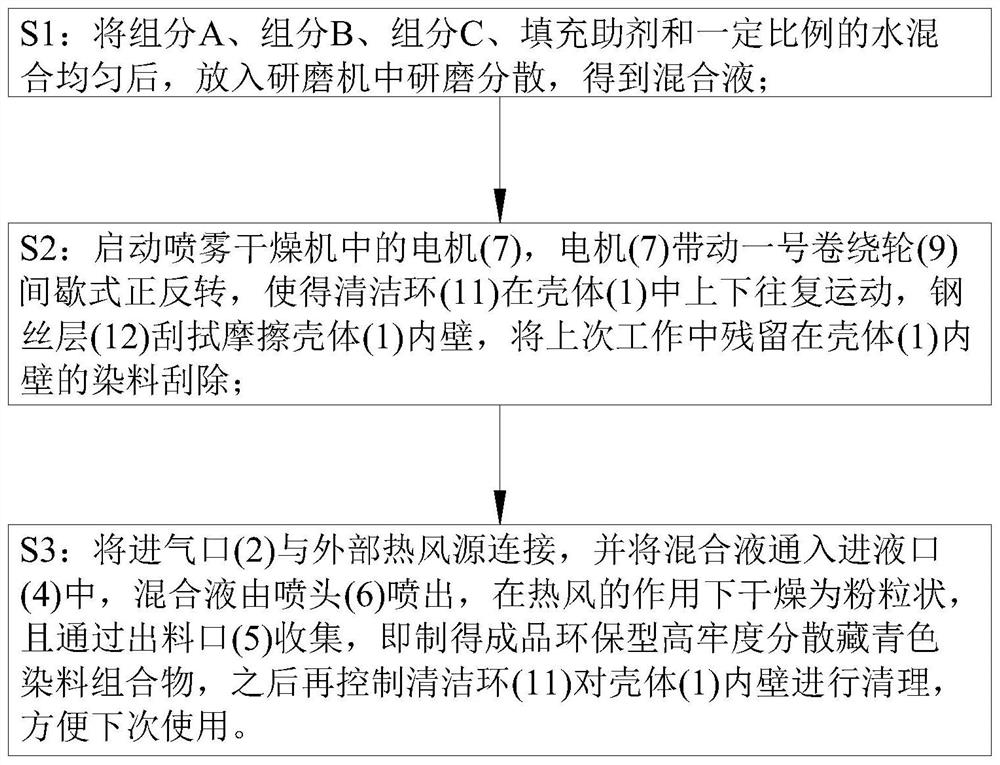

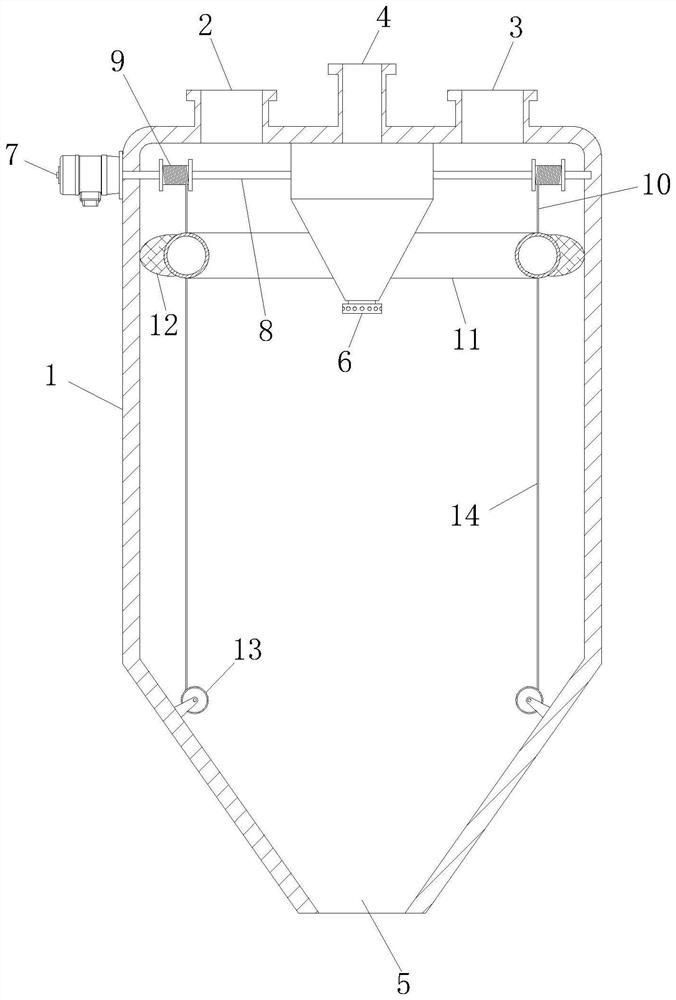

[0060] like Figure 1 to Figure 7 Shown, the preparation method of a kind of environment-friendly type high fastness disperse navy blue dye composition of the present invention, this method is applicable to above-mentioned environment-friendly type high fastness disperse navy blue dye composition, this dye composition adopts following steps to prepare Pick:

[0061] S1: After mixing component A, component B, component C, filling aid and a certain proportion of water, put them into a grinder to grind and disperse to obtain a mixed solution;

[0062] S2: Start the motor 7 in the spray dryer, the motor 7 drives the No. 1 winding wheel 9 to rotate forward and reverse intermittently, so that the cleaning ring 11 reciprocates up and down in the housing 1, and the steel wire layer 12 scrapes and rubs the inner wall of the housing 1, Scrape off the dye remaining on the inner wall of the housing 1 in the previous work;

[0063] S3: Connect the air inlet 2 to an external hot air sourc...

Embodiment 2

[0071] like Figure 8 As shown in Comparative Example 1, as another embodiment of the present invention, the cross-sectional shape of the No. 2 winding wheel 13 is gourd-shaped, and the No. 2 winding wheel 13 is eccentrically arranged with respect to its central axis; The section shape of No. winding wheel 13 is set to gourd shape, can make No. 2 winding wheel 13 in the process of rotation, can drive No. 2 connecting rope 14 to vibrate, cooperates water to drench from No. 2 connecting rope 14 surfaces, thereby improves To the cleaning effect of No. 2 connecting rope 14.

[0072] Offer a chute 28 in the No. 2 winding wheel 13; a counterweight ball 29 is slidably connected in the chute 28; Free sliding, so that the second winding wheel 13 is in the process of rotation, the counterweight ball 29 will slide from one end of the chute 28 to the other end under the effect of its own gravity, and then hit the inner wall of the chute 28, driving the second coil. The winding wheel 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com