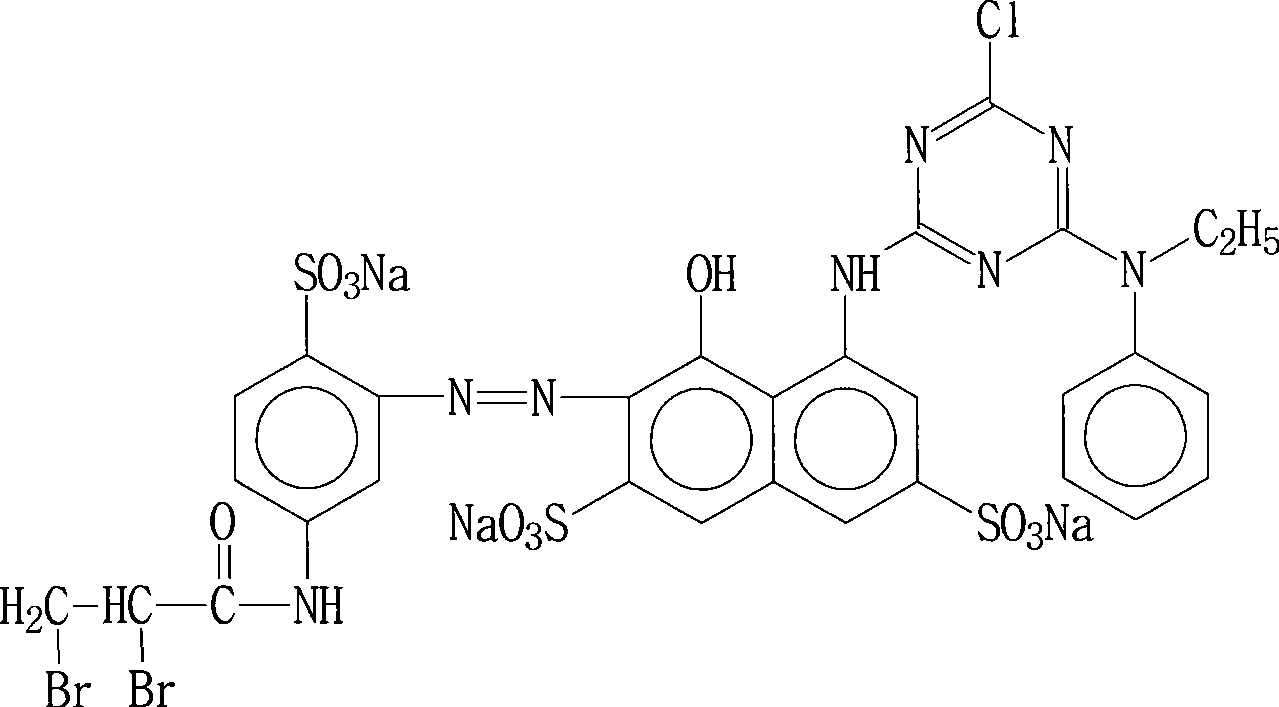

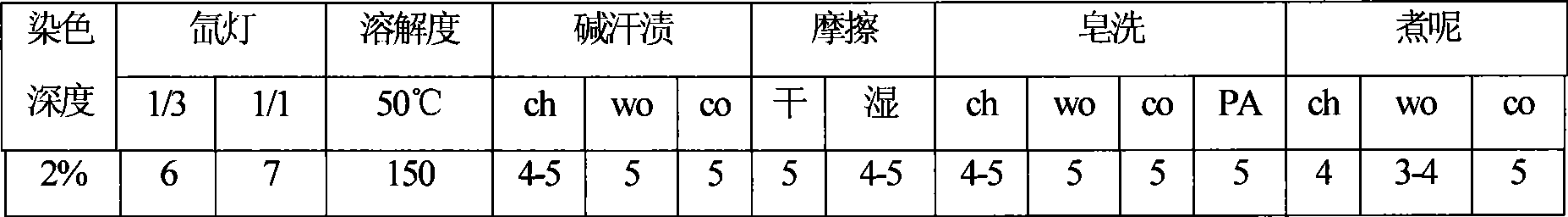

Preparation of red reactive dye for fur

A technology of reactive red and blue, applied in the field of preparation of reactive red GN for wool, can solve the problems of low color yield, large consumption of raw materials, dust pollution, etc., and achieve good reproducibility, improved solubility and high reactivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] a. H-acid dissolution

[0066] Put 3000 liters of bottom water into the enamel tank, add H-acid 375.1Kg, adjust pH=6 with 30% sodium hydroxide solution, make the material completely dissolve and clarify. The volume is 3400 liters, and the mass percentage concentration of the liquid is 11%.

[0067] b. One condensation

[0068]Put into 1500 liters of ice water in the opposite reaction tank, add cyanuric chloride 209.0Kg, make material mix. Control the temperature at 0-5°C, control the pH=2, add the H-acid solution within 45 minutes, then use 10% sodium carbonate to maintain the pH=2, and stir the reaction for 2 hours. The reaction temperature is 0-5°C, and the reaction pH=2. Finally, the end point was detected by TLC aluminum-based silica gel thin-layer plate.

[0069] c. Secondary condensation

[0070] Add 133.1Kg of N-hexylaniline into solution b, keep stirring for 1 hour, heat up to 40°C, maintain pH=6 with 10% sodium carbonate solution, and stir for 1 hour. The...

Embodiment 2

[0096] a. H-acid dissolution

[0097] Put 3000 liters of bottom water into the enamel tank, add H-acid 375.1Kg, adjust pH=7 with 30% sodium hydroxide solution, make the material completely dissolve and clarify. The mass percent concentration of the solution is 11%.

[0098] b. One condensation

[0099] Put into 1500 liters of ice water in the opposite reaction tank, add cyanuric chloride 209.0Kg, make material mix. Control the temperature at 0-5°C, control the pH=2-3, add the H-acid solution within 60 minutes, then use 10% sodium carbonate to maintain the pH=2-3, and stir for 3 hours. The reaction temperature is 0-5°C, and the reaction pH=2-3. Finally, the end point was detected by TLC aluminum-based silica gel thin-layer plate.

[0100] c. Secondary condensation

[0101] Add 133.1Kg of N-hexylaniline to the primary condensate, keep stirring for 1 hour, heat up to 40°C, maintain pH=6 with 10% sodium carbonate solution, and stir for 2 hours. The reaction temperature is 40...

Embodiment 3

[0114] a. H-acid dissolution

[0115] Put 3000 liters of bottom water into the enamel tank, add H-acid 375.1Kg, adjust pH=7 with 30% sodium hydroxide solution, make the material completely dissolve and clarify. The mass percent concentration of the solution is 11%.

[0116] b. One condensation

[0117] Put into 1500 liters of ice water in the opposite reaction tank, add cyanuric chloride 209.0Kg, make material mix. Control the temperature at 0-5°C, control the pH=2-3, add the H-acid solution within 45 minutes, then use 10% sodium carbonate to maintain the pH=2-3, and stir the reaction for 3 hours. The reaction temperature is 0-5°C, and the reaction pH=2-3. Finally, the end point was detected by TLC aluminum-based silica gel thin-layer plate.

[0118] c. Secondary condensation

[0119] Add 133.1Kg of N-hexylaniline to the primary condensate, keep stirring for 1 hour, heat up to 40°C, maintain pH=6 with 10% sodium carbonate solution, and stir for 2 hours. The reaction temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com