Dyeing method of nylon/spandex blended fabric

A technology for blended fabrics and dyeing methods, applied in the field of fabric dyeing, can solve the problems of low fastness to sunlight, washing and perspiration, improve perspiration and washing fastness, excellent color washing fastness, reduce Effects of the yarn processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

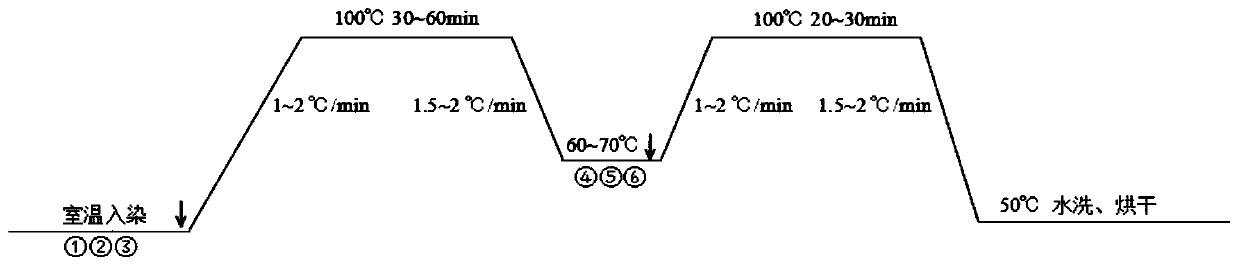

Method used

Image

Examples

Embodiment 1

[0037] First, pre-treat the nylon and spandex blended fabrics provided by Shanghai Jingxuan Garment Co., Ltd., using two-dip and two-rolling. The liquid components are: soda ash 3g / L, hydrosulfite 0.5g / L, JFC 2g / L. Take out and wash with water, soap powder 2g / L, bake at 130°C for 3min, expand and set.

[0038] Next, configure the dye solution: Weak acid brilliant blue RAW 2% o.w.f, leveling agent β-cyclodextrin 3g / L, acetic acid 3g / L, pH adjusted to 5-6, liquor ratio 1:10, feed at room temperature, at 2°C Raise the temperature to 100°C / min, keep it warm for 60min, cool down to 60°C, add disperse blue 2BLN 2% / o.w.f, dispersant NNO 3g / L, ammonium sulfate 3g / L, adjust the pH to 6-7, and use 2 °C / min to 100 °C and keep it warm for 30 min, then cool down to 50 °C at 2 °C / min, take it out, and wash it with water.

[0039] Final color fixation: place the washed fabric in the solution of anionic color-fixing agent DM-2539D (the mass fraction of anionic color-fixing agent DM-2539D is...

Embodiment 2

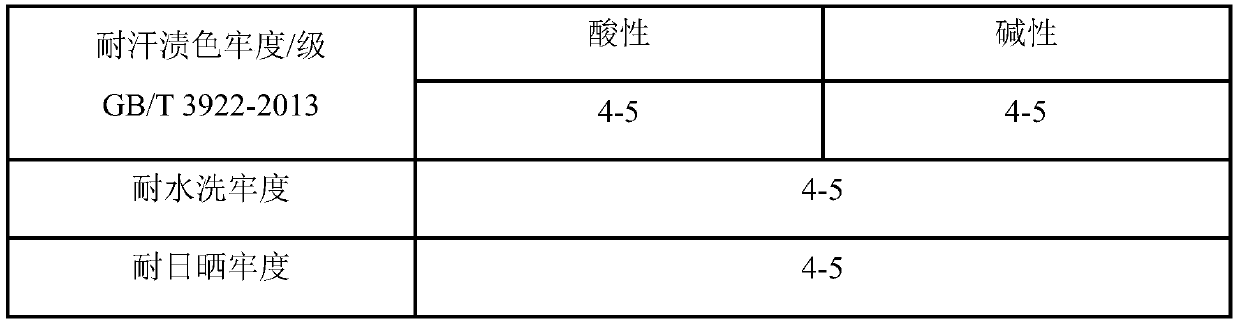

[0043] According to Example 1, the color was fixed only once, the color fixing temperature was 80° C., and the color was fixed for 30 minutes. The rest were the same as in Example 1, and the dyed nylon and spandex blended fabric was obtained, and the performance was tested (results are shown in Table 2).

[0044] Table 2

[0045]

Embodiment 3

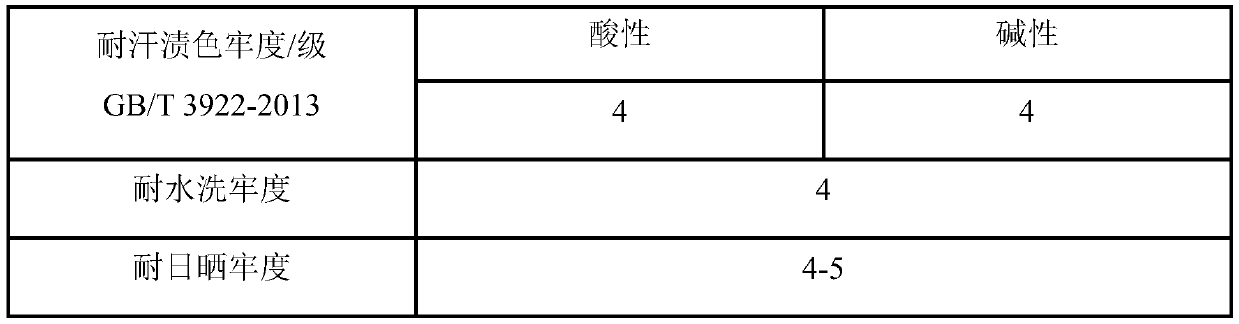

[0047] According to embodiment 1, change disperse dye into disperse blue SE-2R, all the other are identical with embodiment 1, obtain the nylon and spandex blended fabric after dyeing, test performance (results are shown in Table 3).

[0048] table 3

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com