Patents

Literature

36results about How to "Excellent color fastness to rubbing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formula of coating solution and preparation method and application of coating solution

InactiveCN107022295AGood antibacterialImprove mildew resistanceFireproof paintsAntifouling/underwater paintsFiberPolymer science

The invention relates to a formula of a coating solution and a preparation method and application of the coating solution. The coating solution comprises the following raw material ingredients: graphene, polyurethane resin and water, wherein the mass ratio of the graphene to the polyurethane resin to the water is (0.18 to 0.23): 100: (50 to 80). A specific application method comprises the step of coating leather-based fabrics with the coating solution, wherein the leather-based fabrics comprise one or more of knitted fabrics, woven fabrics, non-woven fabrics, ultra-fiber non-woven fabrics and true skin. By adopting the technical scheme provided by the invention, the graphene is compounded into a coating material, so that prepared leather products, particularly leather summer-sleeping mats have excellent functions such as wear resistance, scratch resistance, electrostatic resistance, wave absorbing, bacterial resistance, mildew proofing, UV aging resistance, flame retarding, smoke suppressing, electromagnetic shielding and far-infrared health care; the grade of leather can be comprehensively improved, and the performance of cowhide summer sleeping mats in our country in the aspects of comfortability, durability and mildew proofing and bacterial resistance is improved.

Owner:北欧牧风成都家居用品有限公司

Leather preparation method and application

InactiveCN107164971AExcellent color fastness to rubbingExcellent water vapor absorptionTextiles and paperLeather surface finishingChemistryInfrared

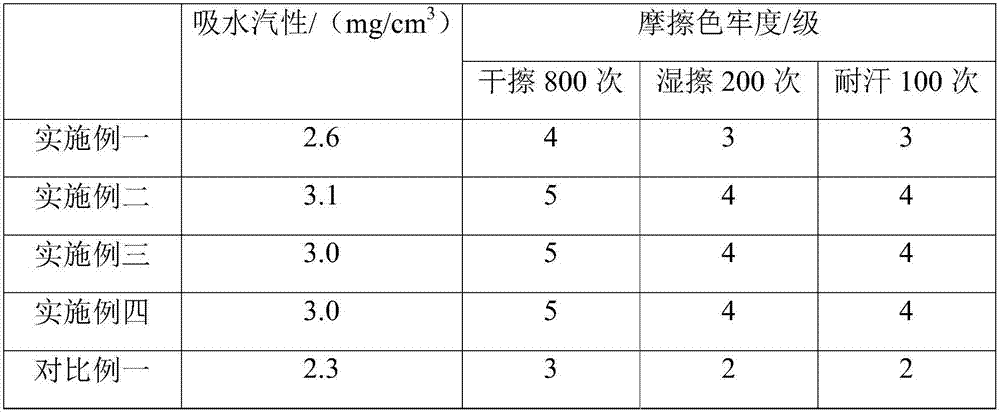

The invention relates to a leather preparation method. The method comprises the following steps: S101, dissolving graphene in an acid solution; and heating for 3-5h under the temperature of 110-130 DEG C; S102, adding a polyethylene acrylate and tourmaline powder to the product obtained in S101; uniformly stirring, and regulating the pH of the product to be 5.8-6.3; S103, adding polyurethane resin and polyvinyl alcohol to the product obtained in S102; uniformly stirring; S104, coating a base leather with the product obtained in S103, so as to obtain the leather. According to the method, the graphene is used as the additive to be applied to the leather preparation process, so that the obtained leather product, in particular a leather bad mat, is outstanding in abrasion and scratching resisting functions, antistatic function, wave absorbing function, bacteria resisting function, mould preventing performance, UV ageing resisting performance, flame resisting and smoke inhibiting performance, electromagnetic shielding function, infrared healthcare function and other function. Therefore, the level of the leather can be comprehensively increased; the comfort, the durability, the mould resistance and the bacteria resistance of national cattlehide bed mats can be improved.

Owner:北欧牧风成都家居用品有限公司

Dyeing method of wool fiber top

InactiveCN106337299AExcellent light fastnessGood dyeing uniformityDyeing processDimethyl formamideN-methyldiethanolamine

The invention discloses a dyeing method of wool fiber top, comprising the following steps: 1) successively adding tristyrylphenol polyoxyelhylene ether sulfonate, acryloyloxyethyltrimethyl ammonium chloride, polyvinylpyrrolidone, dimethyl formamide and vegetable dye into a dye vat and successively pouring deionized water, uniformly stirring and heating to 45 DEG C; 2) successively pouring N-methyldiethanolamine, linear alklybezene sulfonates, magnesium sulfate and nitrilotriacetic acid, continuously stirring until the materials are fully and uniformly mixed, and heating to 60 DEG C; 3) immersing top into the dye vat for 50 min; 4) drying the immersed top at 85 DEG C; 5) immersing the dried top in clear water and rinsing for 50 min; and 6) taking the rinsed top out of the clear water and naturally airing. The top dyed by the above method has excellent color fastness and has good dyeing uniformity and has no dyeing defect.

Owner:常熟市新华源有色毛条厂

Dyeing method for blended fabric

InactiveCN106320012AExcellent color fastness to chlorine bleachingExcellent color fastness to washingDyeing processSulfonateTriethylenetetramine

The invention discloses a dyeing method for blended fabric. The method comprises the steps of 1) adding magnesium sulfate, diglycolamidic acid, carboxymethylcellulose, HACC and vegetable dyes in deionized water in sequence, mixing even and heating to 55oC; 2) Adding tetrasodium glutamate diacetate, alkyl sodium sulfonate, triethylenetetramine, mica powder in sequence, and mixing even, heating to 65oC; 3) Soaking the fabric in the dye vat for 25min; 4) Drying the soaked fabric at 80oC; 5) Soaking the dried fabric in clean water and rinsing for 25min; and 6) Getting out the rinsed fabric and make it dry naturally. The dyed fabric is excellent in color fastness and good in dyeing uniformity, free of color tone.

Owner:常熟市华谊织造有限公司

Dyeing method for sofa fabrics

InactiveCN106368001AExcellent color fastness to perspirationExcellent water fastnessDyeing processPhosphateFatty alcohol

The invention discloses a dyeing method for sofa fabrics. The dyeing method includes the steps: 1) sequentially adding dimethyl formamide, N-methyl diethanol amine, sodium hexametaphosphate, magnesium sulfate and vegetable dyes into a dye vat, sequentially adding deionized water, uniformly mixing, and heating to 55 DEG C; 2) sequentially adding iminodiacetic acid, isomeric fatty alcohol polyoxyethylene ether phosphate, chitosan quaternary ammonium salt and sodium ethylene diamine tetraacetate, continuing to mix until sufficiently and uniformly blending is achieved, and heating to 65 DEG C; 3) soaking the fabrics in the dye vat for 35 minutes; 4) drying the soaked fabrics at the temperature of 80 DEG C; 5) soaking the dried fabrics in clear water to wash for 35 minutes; 6) taking out the washed fabrics to naturally dry. The fabrics dyed by the method have excellent color fastness and are good in dyeing uniformity and free from dyeing defects.

Owner:SUZHOU XIN GE HOUSEHOLD PROD CO LTD

Dyeing method capable of improving dyeing performance of high-elastic nylon 6 fibers

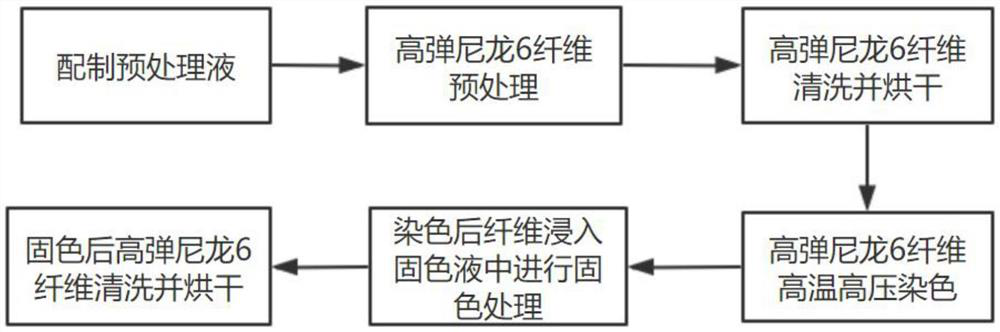

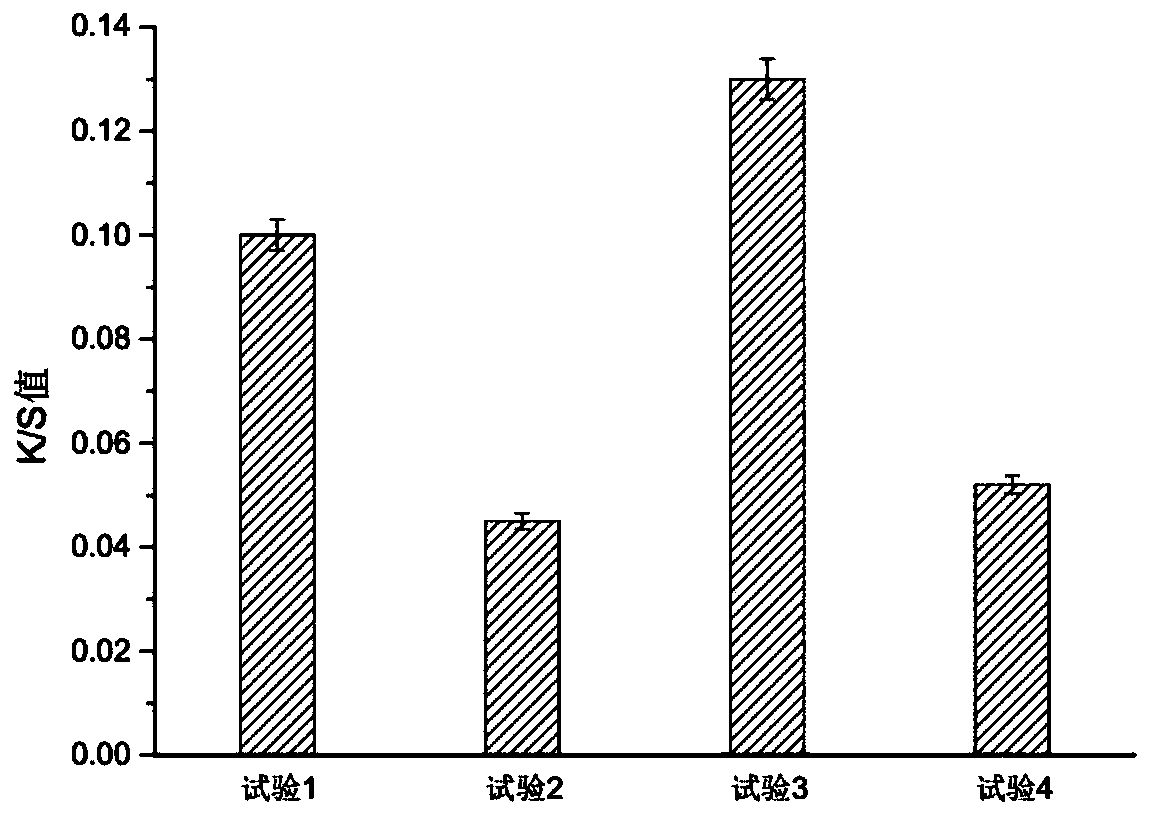

PendingCN113073482AFully dyedImprove color fixationDyeing processColour fastnessEnvironmentally friendly

The invention discloses a dyeing method capable of improving the dyeing performance of high-elastic nylon 6 fibers. The method comprises the steps of dyeing pretreatment, a dyeing process and a color fixing process. According to the dyeing method, the dyeing performance of the high-elastic nylon 6 fibers can be effectively improved, the dyeing rate, the fixation rate, the K / S value and the level dyeing performance of the fibers are remarkably improved, and the washing color fastness, the rubbing color fastness and the light color fastness of fabric are improved. The process is simple and efficient, the usage amount of dye can be remarkably reduced, the method is environmentally friendly, the adopted reagent is efficient in dyeing, bright in color and not prone to fading, and the efficient and lasting dyeing effect can be achieved. On the basis that the dyeing performance of the high-elastic nylon 6 fibers is enhanced, the simplicity, high efficiency and environmental friendliness of the dyeing process are further improved, and wide application of the high-elastic nylon 6 fibers and fabric can be promoted.

Owner:绍兴市柯桥区东纺纺织产业创新研究院

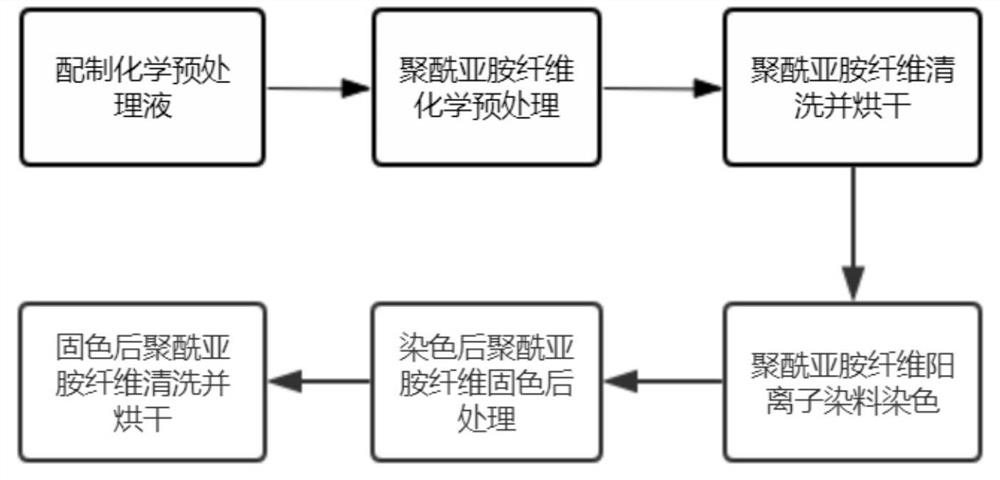

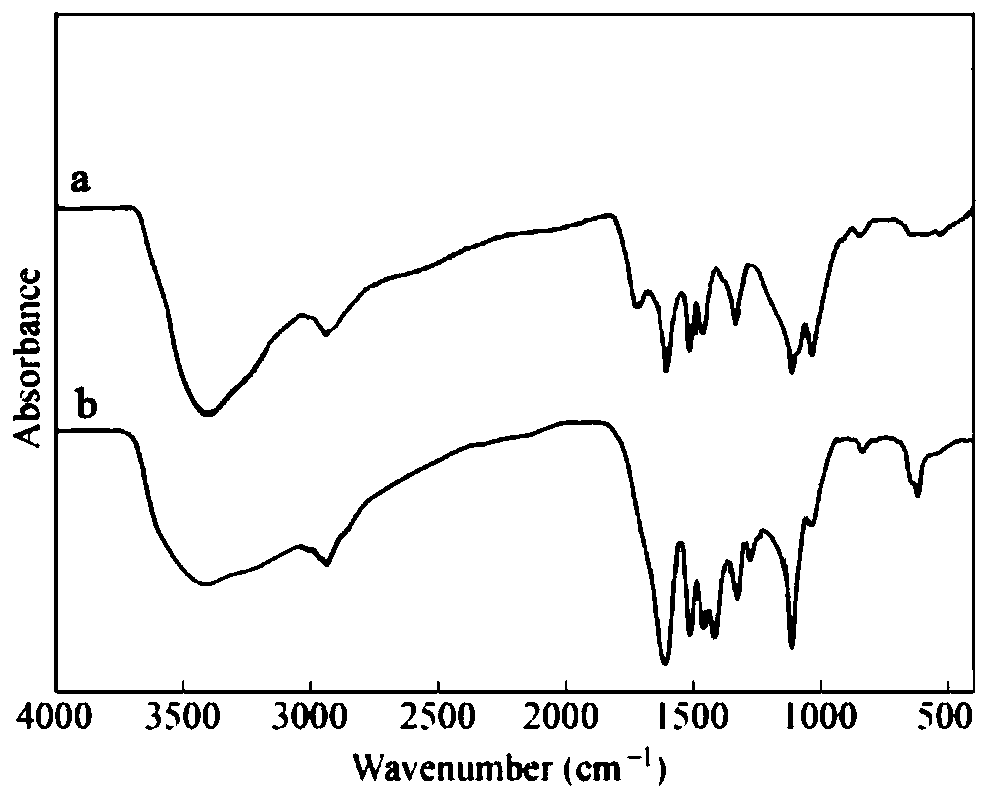

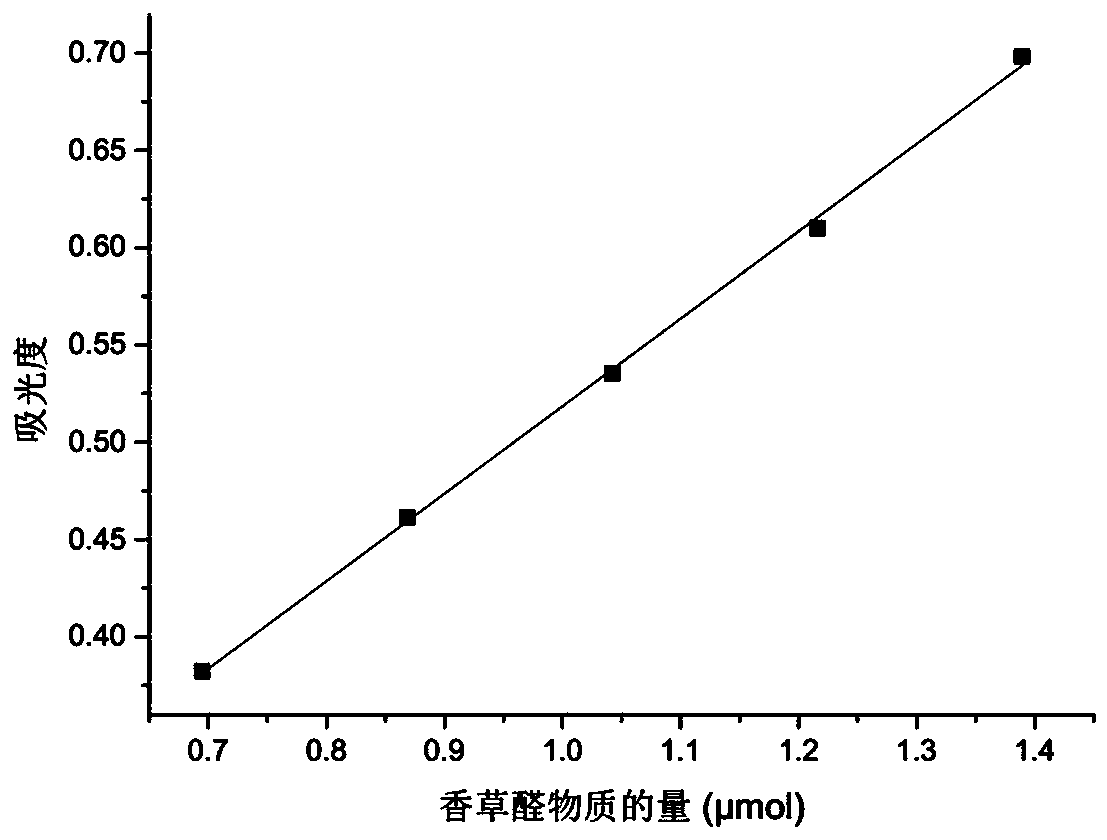

Dyeing method for improving dyeing performance of polyimide fibers

PendingCN113445331AGood leveling effectGood color fastness to washingDyeing processColour fastnessFiber

The invention discloses a dyeing method for improving the dyeing performance of polyimide fibers. The method comprises the steps of pretreatment liquid preparation, fiber pretreatment, fiber dyeing and fiber color fixation. According to the dyeing method provided by the invention, the dyeing performance of the polyimide fibers can be effectively improved, the fiber dye uptake, the fixation rate and the K / S value of the fabric are remarkably improved, and the wet color fastness and the rubbing color fastness of the fabric are improved. The process disclosed by the invention is simple in steps, high in dyeing efficiency, capable of remarkably reducing the use amount of cationic dyes and reducing environmental pollution, green and friendly; the adopted chemical pretreatment process is simple and efficient, and the dyeing performance of the polyimide fibers can be remarkably improved; and the cationic dyes are bright in color and not prone to fading, and the efficient and lasting dyeing effect can be achieved. According to the dyeing method for improving the dyeing performance of the polyimide fibers provided by the invention, on the basis that simple and efficient chemical pretreatment is carried out on the polyimide fibers, the dyeing performance of the polyimide fibers is enhanced, the dyeing efficiency of the dyeing process is further improved, the influence on the mechanical performance of the fibers is small, the environmental friendliness is improved, and wide application of the polyimide fibers and fabrics in the field of clothing can be promoted.

Owner:绍兴市柯桥区东纺纺织产业创新研究院

Dyeing method of spandex fabric

InactiveCN106381727AExcellent color fastness to perspirationExcellent water fastnessDyeing processAcetic acidSulfonate

The invention discloses a dyeing method of spandex fabric, comprising the following steps: 1) successively adding dibutyl phthalate, diisocyanate, polypropylene glycol, butyl peroxybenzoate and vegetable dye into 1 part of deionized water in a dye vat, uniformly stirring, and heating to 55 DEG C; 2) successively pouring glycine, diisooclyl maleate sulfonate, acrylic acid ester and tetrasodium glutamate diacetate, continuously stirring until the materials are fully and uniformly mixed, and heating to 65 DEG C; 3) immersing the fabric in the dye vat for 35 min; 4) drying the immersed fabric at 80 DEG C; 5) rinsing the dried fabric in clear water for 35 DEG C; and 6) taking the rinsed fabric out of the clear water and naturally airing. The dyed fabric has excellent color fastness and good dyeing uniformity and has no dyeing defect.

Owner:SUZHOU XIN GE HOUSEHOLD PROD CO LTD

Dyeing method for PV fabric

InactiveCN106320009AGood light fastnessExcellent color fastness to perspirationDyeing processPhosphateClean water

The invention discloses a dyeing method for PV fabric. The method comprises the steps of 1) Adding epichlorohydrin, ferrous sulfate, sodium hexametaphosphate, dimethylamine and vegetable dyes in sequence in deionized water, then mixing even and heating to 55oC; 2) Adding poly(acrylic acid-co-maleic acid), isomeric 13 - dodecanol polyoxyethylene ether phosphate and ODPA in sequence and continue to mix to even mixing, and heat to 65oC; 3) Soaking fabric in the dye vat for 30min; 4) Drying the soaked fabric at 80oC; 5) Soaking the dried fabric in clean water and rinsing for 30min; 6) Getting out the rinsed fabric and make it dry naturally. The dyed fabric is excellent in color fastness and good in dyeing uniformity, free of color tone.

Owner:常熟市通惠织造有限公司

Denim continuous dyeing method

ActiveCN111118924A4.0 dry resistance4.0 Color fastness to wet rubbingDyeing processDenimCotton fibre

The invention provides a denim continuous dyeing method, and belongs to the technical field of fabric processing. The denim contains cotton fibers, and the continuous dyeing method comprises the following steps of carrying out pretreatment on the denim by a solution containing a penetrating agent and caustic soda, and performing water washing for 2-3 times; carrying out modification treatment on the denim obtained in the step 1 by a dyeing assistant; and carrying out dyeing on the denim by a dyeing liquor containing a natural mineral dye by adopting a twice-dipping and twice-rolling method, and performing color fixing and dying. By adoption of the method, continuous dyeing of the denim is realized by the natural mineral dye, the obtained denim has relatively high K / S value, high level dyeing property and excellent color fastness to rubbing, and the water washing residual liquid chrominance after hot water washing is relatively low. According to the method, the dyeing rate and color fixing rate of the natural mineral dye are improved by a dispersant, damage to the fibers in the dyeing process is lowered, and the gloss and softness of the denim are improved.

Owner:邢台恒进纺织有限公司

Dyeing process capable of increasing fixation rate of textiles

InactiveCN108716147AReduce energy consumptionImprove dyeing effectDyeing processPolyesterEnergy conservation

The invention provides a dyeing process capable of increasing fixation rate of textiles. The dyeing process includes A, pre-dyeing treatment, B, dyeing treatment and C, post-dyeing treatment. The dyeing process has the advantages that the one-bath dyeing method integrates a cotton dyeing process with a terylene dyeing process; according to the one-bath two-step method, cotton is dyed at a low temperature, and terylene is dyed at a high temperature, so that feasibility of the one-bath dyeing method is improved, technological steps are simplified greatly, consumption of energy such as water andsteam is reduced, technological consumed time is shortened, and energy conservation, emission reduction and production efficiency improvement are realized; proper components and ratios of dyestuff andaids are selected according to the one-bath dyeing method, optimal technological steps and parameters (time and temperature) are combined, and accordingly, the dyeing effect of fabrics is improved greatly; polyester-cotton fabrics dyed and finished by the one-bath dyeing method have high color fastness to washing, insolation, friction, water and perspiration; dyeing uniformity is achieved, and dyeing defects are avoided.

Owner:RUGAO ZHOUQIN CLOTHING CO LTD

Quilt cover fabric dyeing method

InactiveCN106400532AExcellent color fastness to perspirationExcellent water fastnessDyeing processAlcoholSulfate

The invention discloses a quilt cover fabric dyeing method. The method comprises the steps of: 1) adding calcium sulfate, aspartic acid, sodium polyacrylate, titanium dioxide and vegetable dyes into deionized water in a dye vat in order, stirring the substances evenly, and performing heating to 55DEG C; 2) then adding beta-alanine, secondary alcohol ethoxylate, sodium silicate and ferrous sulfate, further conducting stirring until the substances are fully and evenly mixed, and performing heating to 65DEG C; 3) soaking the fabric in the dye vat for 35min; 4) drying the well soaked fabric at 80DEG C; 5) immersing the dried fabric in clear water and performing rinsing for 35min; and 6) taking out the rinsed fabric and conducting natural airing. According to the method provided by the invention, the dyed fabric has excellent color fastness and good dyeing uniformity, and is free of dyeing defect.

Owner:SUZHOU XIN GE HOUSEHOLD PROD CO LTD

Pine needle fleece fabric dyeing method

InactiveCN106320014AExcellent color fastness to washingGood dyeing uniformityDyeing processTriethylenetetramineDyeing

The invention discloses a pine needle fleece fabric dyeing method. The pine needle fleece fabric dyeing method comprises the following steps: 1) ethylene carbonate, glacial acetic acid, hydroxypropyl cellulose, triethylenetetramine and a vegetable dye are added to deionized water in a dye vat sequentially, and the materials are stirred uniformly and heated to 45 DEG C; 2) then sodium glycinate, sodium sulfamate, acryloyloxyethyltrimethyl ammonium chloride and polyurethane are fed sequentially, and the materials are stirred continuously until the materials are mixed sufficiently and uniformly and are heated to 60 DEG C; 3) the fabric is soaked in the dye vat for 40 min; 4) the soaked fabric is dried at 85 DEG C; 5) the dried fabric is soaked in clear water and rinsed for 40 min; 6) the rinsed fabric is taken out and aired naturally. The fabric dyed with the method has excellent color fastness and dyeing evenness and is free of colored spots.

Owner:SUZHOU YUHUA BUSINESS MANAGEMENT CO LTD

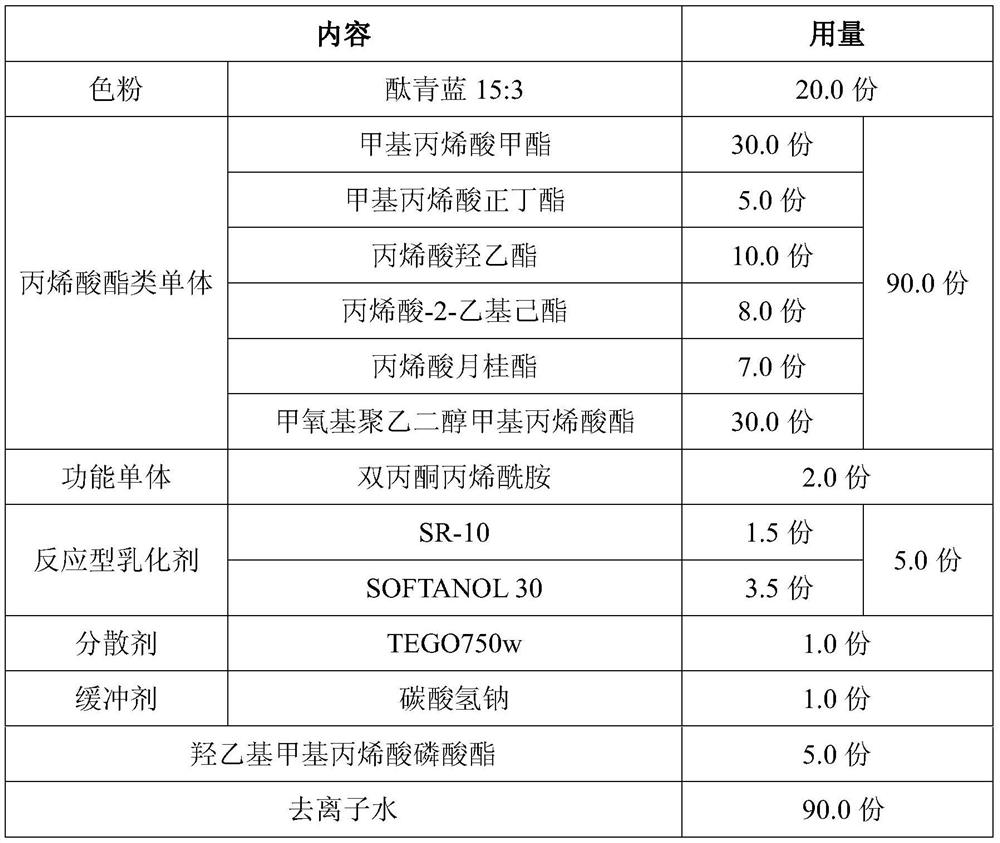

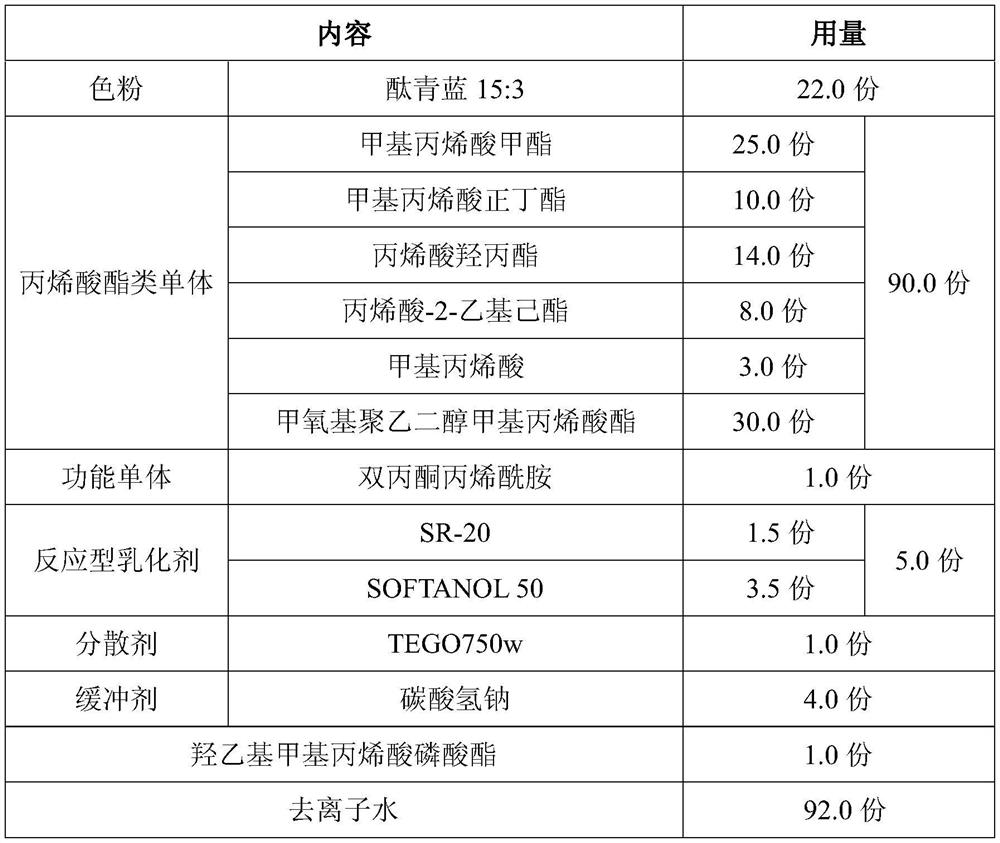

Coating processing technology for imitated oily frosted leather

PendingCN112725545AUniform particlesHigh affinityWax coatingsLeather stretching/tensioningPhospholipidChlorinated paraffins

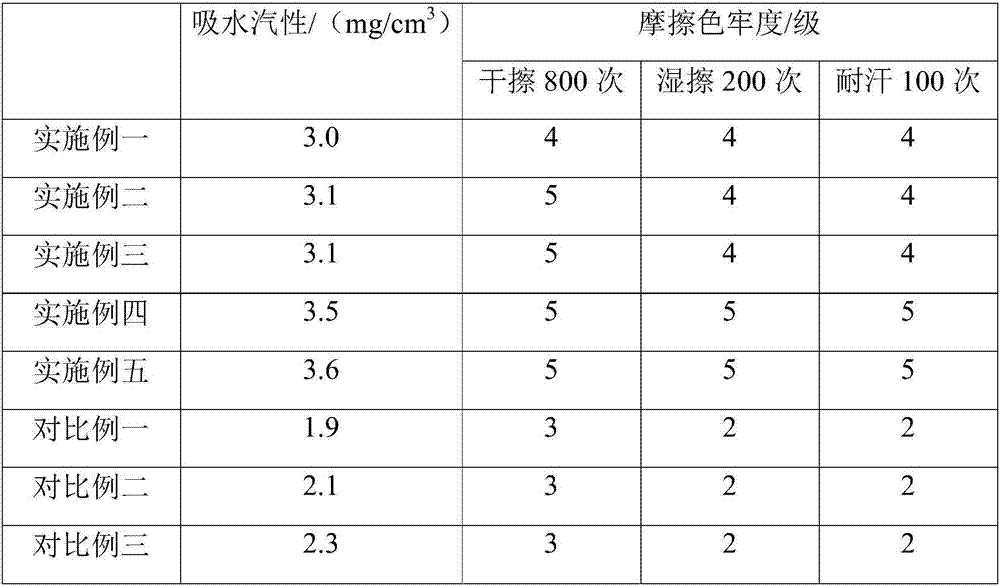

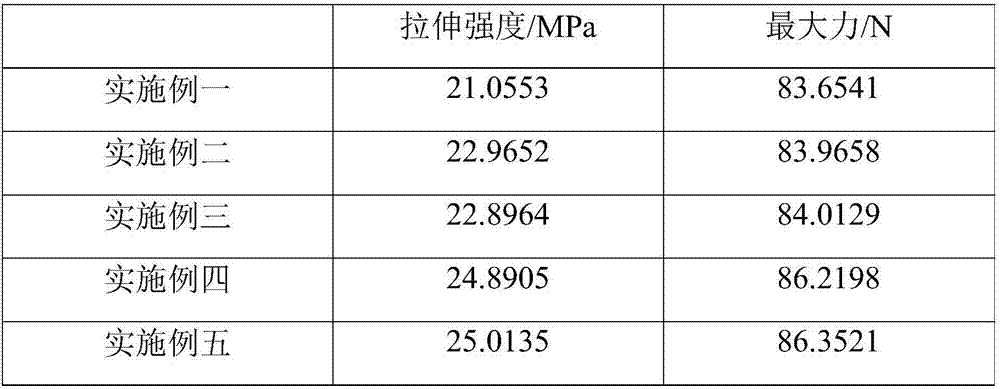

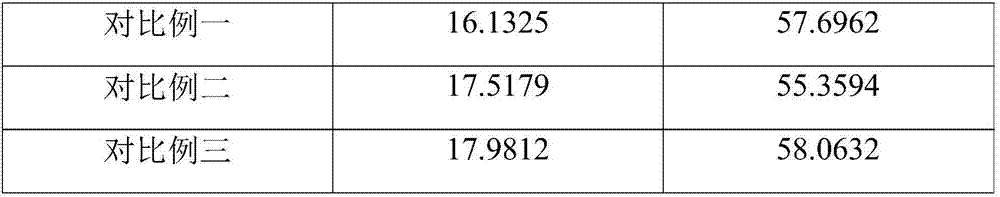

The invention discloses a coating processing technology for imitated oily frosted leather. The coating processing technology comprises the following steps of carrying out drying and finishing on crust leather, carrying out roller coating of grease, carrying out standing, carrying out ironing with a sand roller, carrying out pre-priming-coating, carrying out priming coating, carrying out ironing with a smooth roller, carrying out floating coating, carrying out top coating, carrying out standing, carrying out ironing with the smooth roller, carrying out ironing with a pore roller, carrying out ironing with the smooth roller and carrying out surface treatment so as to obtain the finished leather, wherein the grease used in the process of roller coating of the grease is prepared from 100-125 parts of water, 75-80 parts of mixed emulsion of sulfated synthetic grease and phospholipid, 20-25 parts of chlorinated paraffin and 100-125 parts of penetrant. According to the coating processing technology, the finished leather has the frosted touch feeling, is high in oiliness feeling, good in air permeability and perspiration performance and soft and full in leather body, the comfortable and natural genuine leather feeling and excellent hygienic performance of natural leather are better highlighted, and leather products such as shoes, boots, bags and suitcases and sofas made of the finished leather are attractive, elegant and noble and belong to high-quality products in the leather products; and meanwhile, excellent rubbing color fastness is achieved, and the dry rubbing resistance, the wet rubbing resistance and the sweat rubbing resistance can all reach the fourth level or above.

Owner:XINGYE LEATHER TECH CO LTD

Wool fabric dyeing method

InactiveCN106337301AExcellent color fastness to chlorine bleachingExcellent color fastness to washingDyeing processTetramineALLYL SUCROSE

The invention discloses a wool fabric dyeing method, which comprises: 1) sequentially pouring hexamethoxymethylmelamine, maleic acid, polyacrylic acid, dinitroso pentamethylene tetramine and a plant dye into deionized water in a dyeing vat, uniformly stirring, and heating to a temperature of 55 DEG C; 2) sequentially adding iminodipropionic acid, tributyl phosphate, hexanediamine and methacrylic acid diethyl amino ethyl ester, continuously stirring until completely and uniformly mixing, and heating to a temperature of 65 DEG C; 3) soaking a fabric for 25 min in the dying vat; 4) drying the soaked fabric at a temperature of 80 DEG C; 5) immersing the dried fabric in clear water, and rinsing for 25 min; and 6) taking out the rinsed fabric, and carrying out natural air drying. According to the present invention, the dyed fabric has advantages of excellent color fastness, good dyeing uniformity, and no dyeing spot.

Owner:常熟市华谊织造有限公司

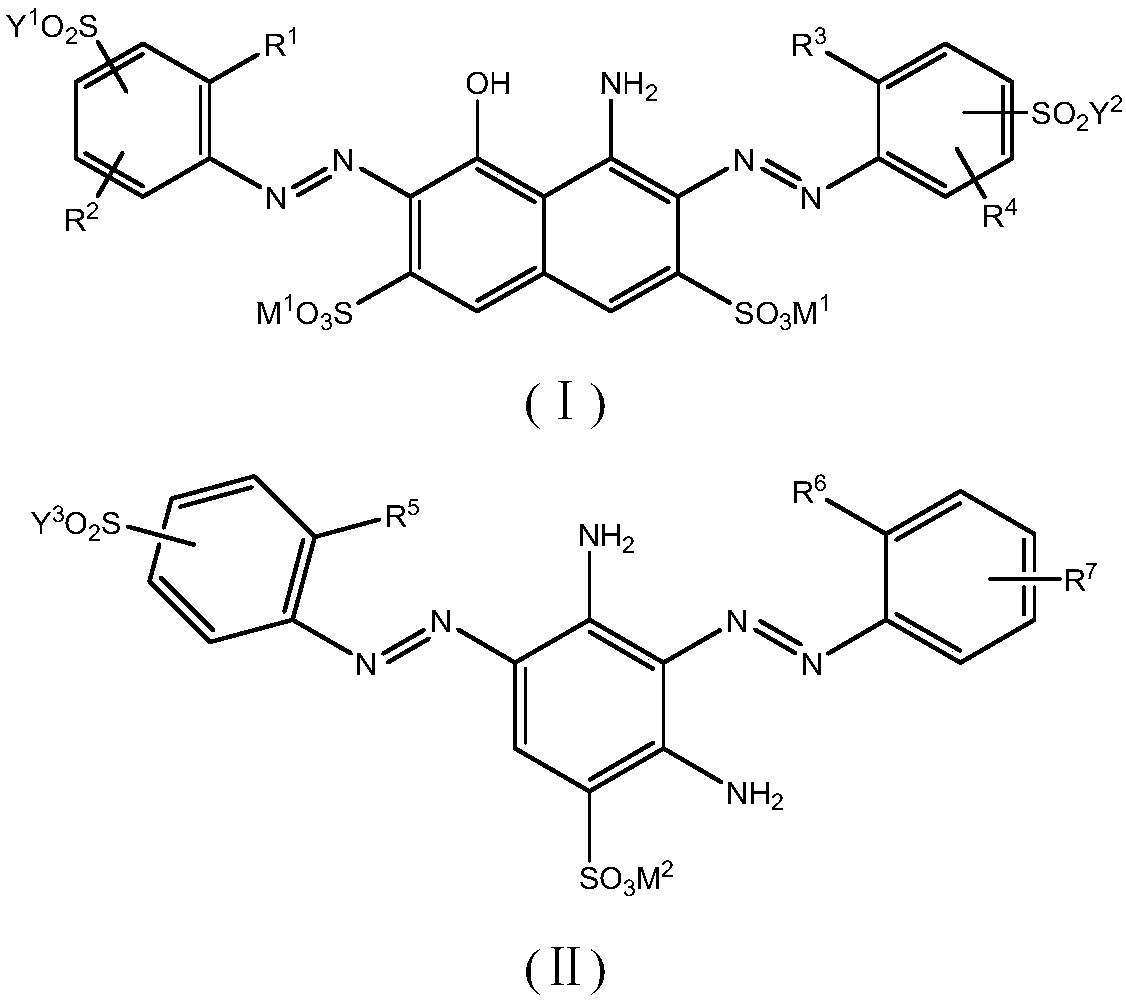

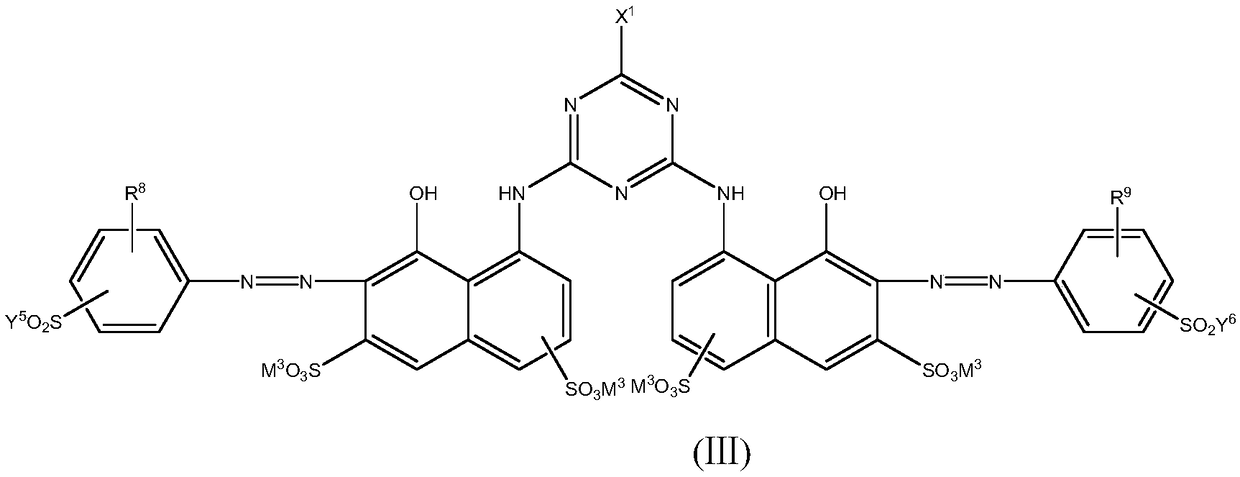

Dark reactive dye composition and dye product

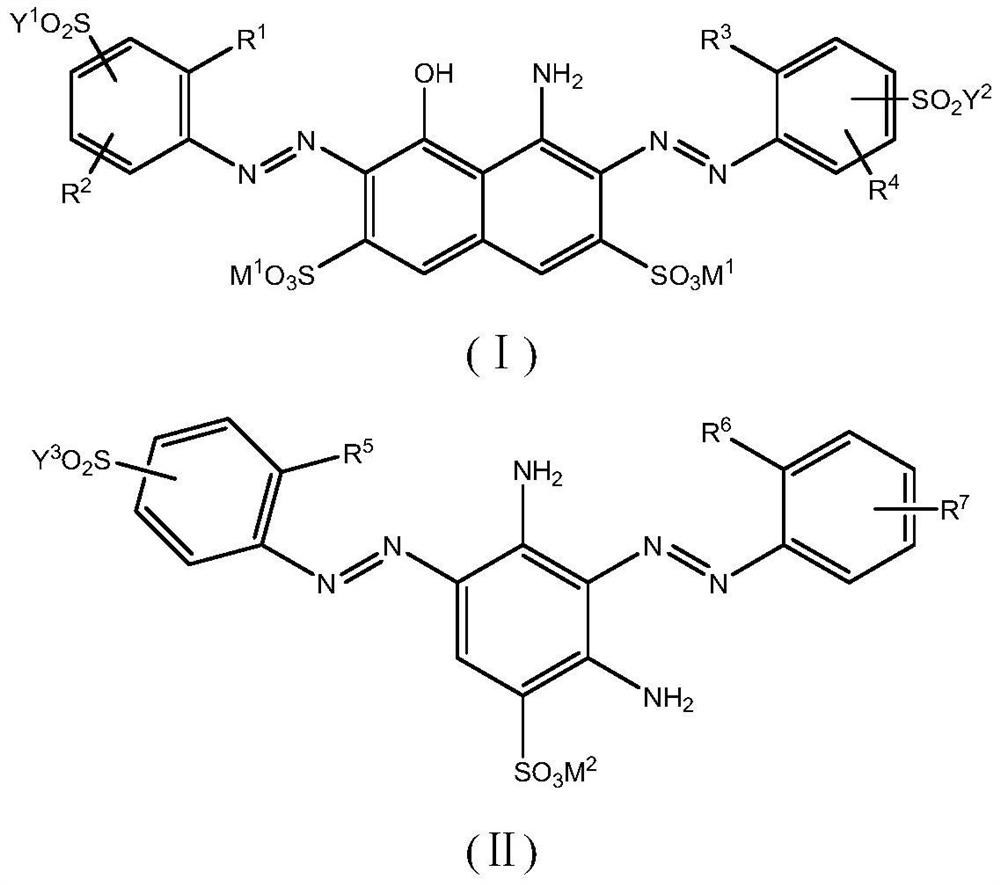

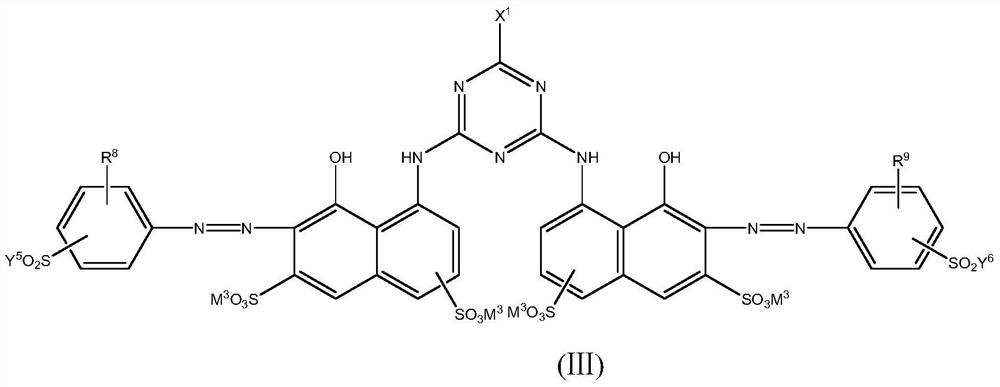

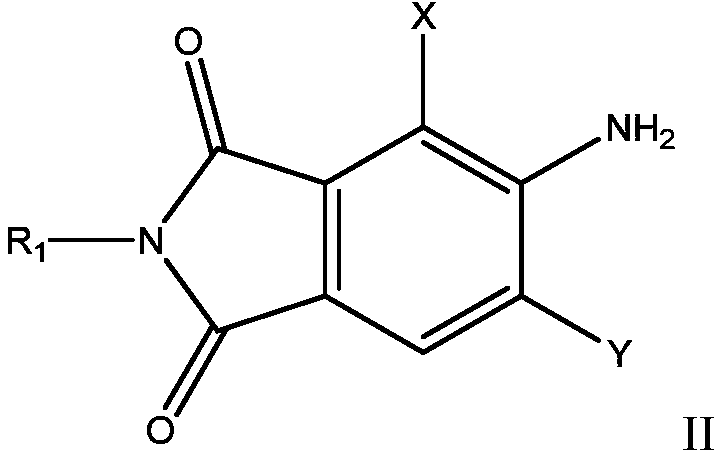

ActiveCN109370255AEasy to liftGood color fixation rateOrganic dyesDyeing processReactive dyeSolubility

The invention discloses a dark reactive dye composition and a dye product. The composition is prepared from the following components in percentage by mass: 10-90 percent of a component A, 5-85 percentof a component B and 5-30 percent of a component C, based on total mass of the components A, B and C, wherein the component A is selected from at least one dye compound as shown in a formula (I), thecomponent B is selected from at least one dye compound as shown in a formula (II), the component C is selected from at least one dye compound as shown in a formula (III). A dark reactive dye productcontains the dark reactive dye composition. The dark reactive dye composition and the dye product have good solubility, are easy to wash, cannot be easily stained during washing, and have the characteristics of excellent compatibility, good dyeing depth, excellent fixation rate and excellent fastness.

Owner:ZHEJIANG KEYONG CHEM CO LTD +1

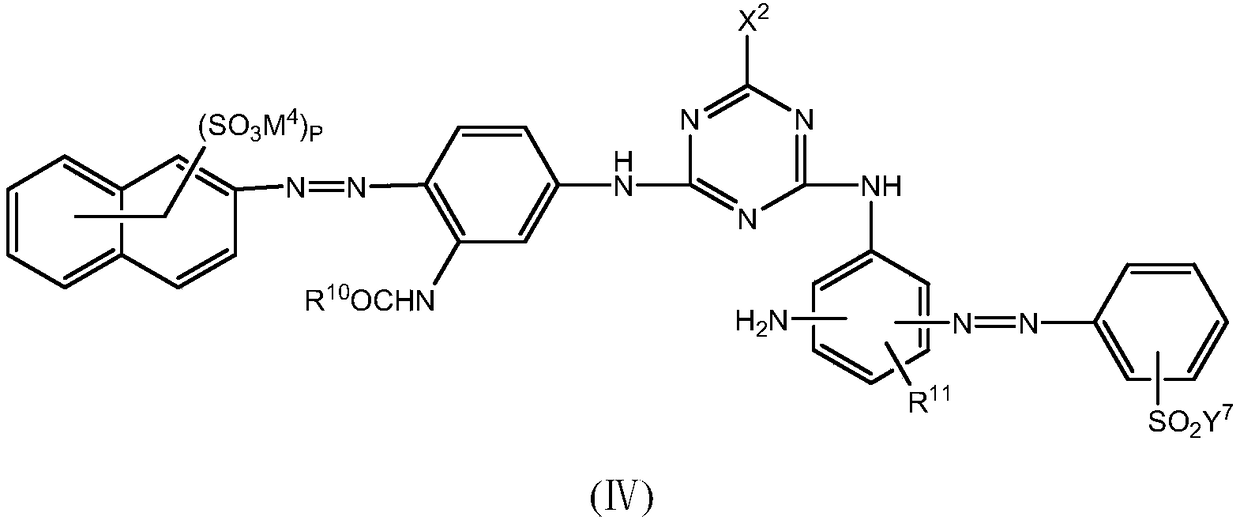

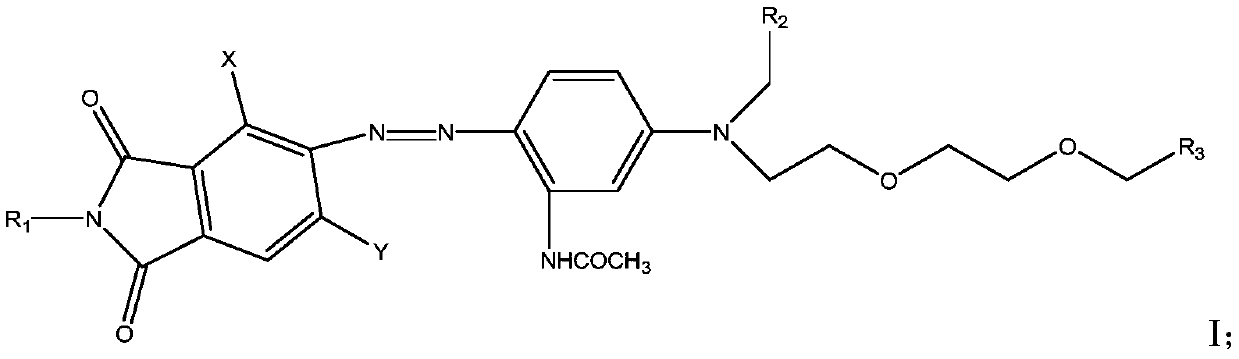

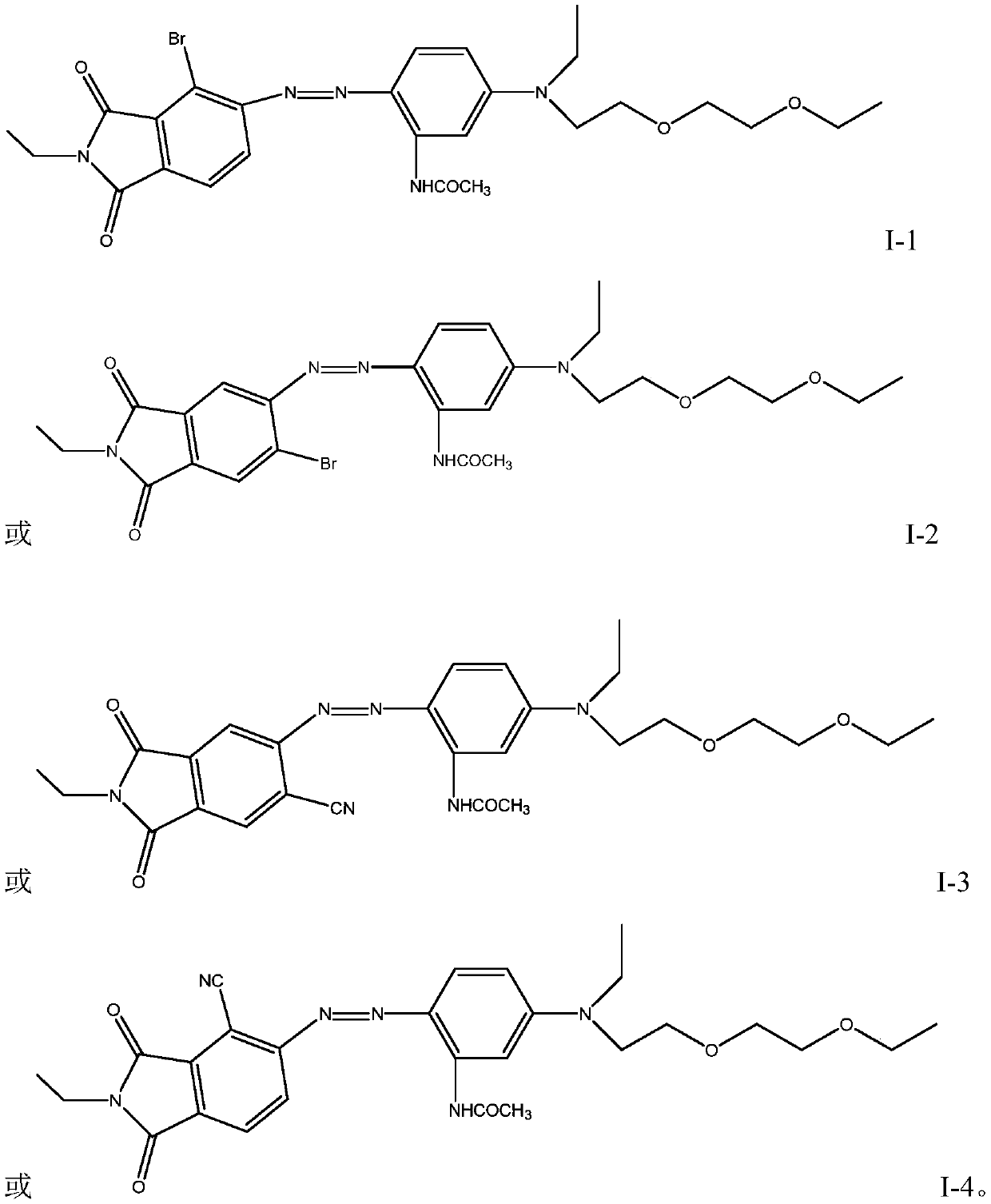

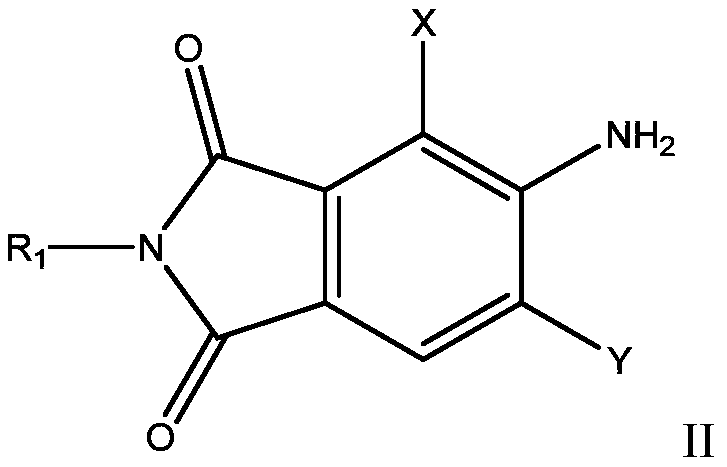

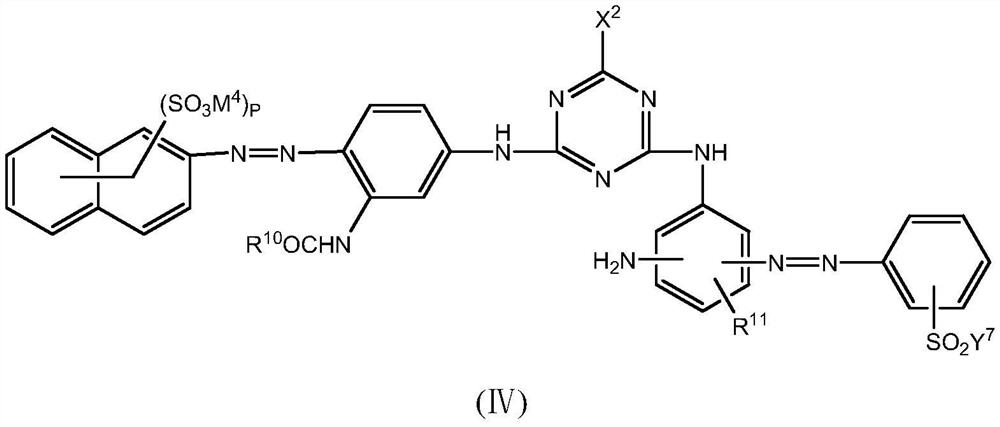

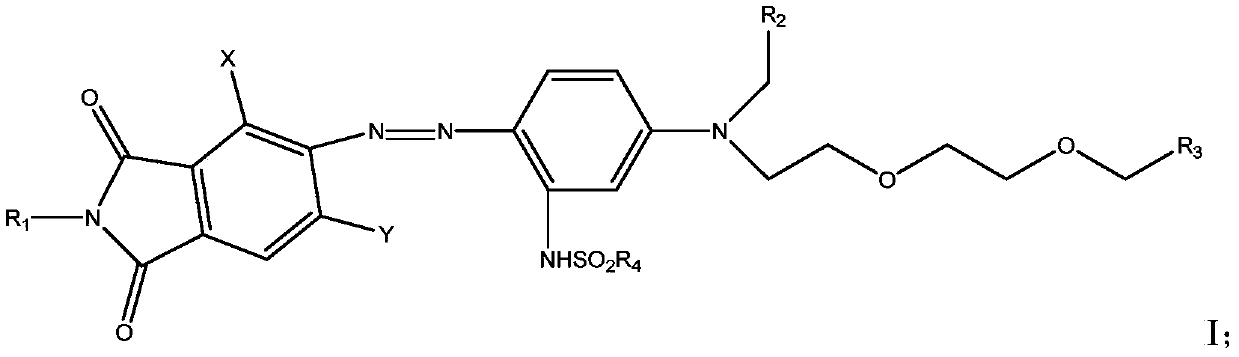

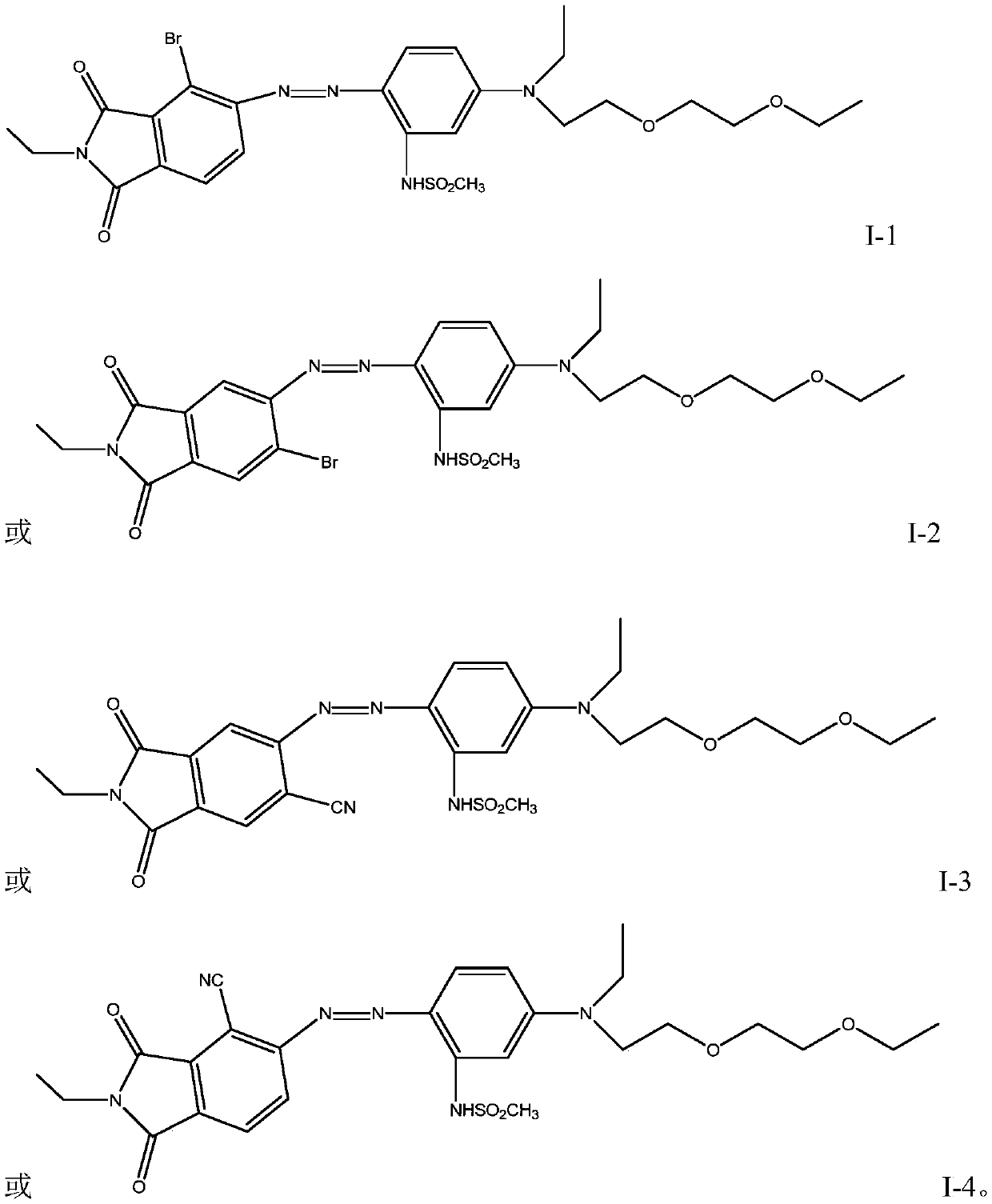

A kind of azo dye compound containing acetamide group and its preparation method and application

ActiveCN109054429BExcellent sweat resistanceExcellent color fastness to rubbingMonoazo dyesDyeing processTextile printerColour fastness

Owner:ZHEJIANG WANFENG CHEM

Method for dyeing PV pile fabric

InactiveCN106245358AExcellent color fastness to rubbingGood dyeing uniformityDyeing processDiethylenetriamineEthylenediamine

The invention discloses a method for dyeing a PV pile fabric. The method comprises the following steps: (1) sequentially adding tea polyphenols, diethylenetriamine, ethylene glycol, a maleate-acrylate copolymer and vegetable dyes into a dye vat, successively adding deionized water into the dye vat, uniformly stirring, and heating the dye vat to the temperature of 45 DEG C; (2) then, sequentially adding ethylenediamine, iso-tridecanol polyoxyethylene ether, an N-vinyl pyrrolidone / acrylamide copolymer and 2-acrylic acid amide-2-methylpropanesulfonic acid into the dye vat, continuing stirring until the mixture is uniformly mixed thoroughly, and heating the dye vat to the temperature of 60 DEG C; (3) soaking the fabric in the dye vat for 45 minutes; (4) baking the soaked fabric at the temperature of 85 DEG C; (5) submerging the baked fabric in clean water, and rinsing for 45 minutes; (6) taking out the rinsed fabric, and naturally drying the fabric in the air. According to the method, the dyed fabric has excellent color fastness, is good in dyeing uniformity and is free of uneven dyeing.

Owner:常熟市绮丽家纺有限公司

Antibacterial warm-keeping fabric and preparation method thereof

InactiveCN112342671AImprove wearing comfortFeel goodWeft knittingBiochemical fibre treatmentYarnFiber

The invention discloses antibacterial warm-keeping fabric and a preparation method thereof. The preparation method includes the following steps: performing opening, cotton scutching, carding and residual impurity removal on EKS fibers with cross-shaped cross sections, silver ion antibacterial spandex, sisal fibers and Thermocool fibers, and mixing the fibers to prepare cotton slivers; mixing the cotton slivers for two times fully mix the fibers, and carrying out automatic spooling to prepare blended yarn; performing rewinding, pre-shrinking and qualitative treatment on the bamboo fiber filaments, and seamlessly knitting the blended yarn and the bamboo fiber filaments into gray fabric; dyeing the gray fabric, and drying the gray fabric after dehydrating; and carrying out cross-linking finishing by using a hydrophilic finishing agent, drying, carrying out soft tentering, pre-shrinking, carrying out steam setting after calendering. Through detection, according to GB / T3922-2013, the colorfastness to acid perspiration is level 4-5, and the soaping fastness is level 4-5; according to GB / T3920-2008, the rubbing fastness is level 4-5; and according to GB / T3922-2013, and the color fastnessto alkali perspiration is level 4-5.

Owner:义乌市鼎莎针织有限公司

Dyeing method of coral velvet fabric

InactiveCN106367998AGood light fastnessExcellent color fastness to perspirationDyeing processEpoxyPhenol

The invention discloses a dyeing method of a coral velvet fabric. The dyeing method includes the steps of: 1) successively adding polyurethane, fumaric acid, sodium silicate, acryloyl chloride, and a plant dye to deionized water in a dye vat, and stirring the mixture uniformly and heating the mixture to 55 DEG C; 2) successively adding ferrous sulfate, fatty alcohol-polyoxyethylene ether, epoxy chloropropane and tristyryl phenol polyoxyethylene ether sulfonate, continuously stirring the mixture until the components are fully mixed, and heating the mixture to 65 DEG C; 3) soaking the fabric in the dye vat for 30 min; 4) drying the soaked fabric at 80 DEG C; 5) rinsing the dried fabric in clear water for 30 min; and 6) naturally air-drying the rinsed fabric. The dyed fabric has excellent color fastness, good dyeing uniformity and is free of non-uniform dyeing.

Owner:常熟市通惠织造有限公司

Dyeing method of flannel fabric

InactiveCN106320005AExcellent color fastness to rubbingExcellent color fastness to washingDyeing processColour fastnessTriethanolamine

The invention discloses a dyeing method of flannel fabric. The dyeing method comprises the following steps: 1) sequentially adding sodium sulfate, ammonia water, sodium hexametaphosphate, hydantoin and vegetable dye into deionized water, uniformly stirring, and heating to 45 DEG C; 2) then sequentially putting methylallylamine hydrochloride, sodium alkyl benzene sulfonate, triethanolamine and a monomer containing tertiary amino, further stirring until the substances are fully and uniformly mixed, and heating to 60 DEG C; 3) soaking the fabric in a dyeing vessel for 45 minutes; 4) drying the soaked fabric at the temperature of 85 DEG C; 5) immersing the dried fabric into clean water and rinsing for 45 minutes; and 6) taking out the rinsed fabric, and naturally airing. The dyed fabric has excellent colour fastness, dyeing uniformity is good, and no dyeing defect is produced.

Owner:常熟市绮丽家纺有限公司

Method for dyeing plush fabric

InactiveCN106368002AExcellent color fastness to washingExcellent color fastness to dry cleaningDyeing processTetramineDiethylenetriamine

The invention discloses a method for dyeing plush fabric. The method comprises the following steps that 1, o-phthalimide, sodium hexametaphosphate, Arabic gum powder, diethylenetriamine and vegetable dyes are sequentially added into a dye vat, deionized water is put into the dye vat, is the materials are stirred to be uniform, and the mixture is heated to 45 DEG C; 2, phenoxyethanol, igepon T and isobornyl methacrylate and dinitroso pentamethylene tetramine are sequentially put into the dye vat, the mixture continues to be stirred to be fully mixed to be uniform, and the mixture is heated to 60 DEG C; 3, fabric is soaked in the dye vat for 40 minutes; 4, the soaked fabric is dried at the temperature of 85 DEG C; 5, the dried fabric is soaked in clear water to be rinsed for 40 minutes; 6, the rinsed fabric is taken out to be naturally aired. The dyed fabric has excellent color fastness and is good in dyeing uniformity and free of color stains.

Owner:SUZHOU YUHUA BUSINESS MANAGEMENT CO LTD

A kind of dark reactive dye composition and dye product

ActiveCN109370255BEasy to liftGood color fixation rateOrganic dyesDyeing processDark colorPhotochemistry

The invention discloses a dark reactive dye composition and a dye product. The composition is prepared from the following components in percentage by mass: 10-90 percent of a component A, 5-85 percentof a component B and 5-30 percent of a component C, based on total mass of the components A, B and C, wherein the component A is selected from at least one dye compound as shown in a formula (I), thecomponent B is selected from at least one dye compound as shown in a formula (II), the component C is selected from at least one dye compound as shown in a formula (III). A dark reactive dye productcontains the dark reactive dye composition. The dark reactive dye composition and the dye product have good solubility, are easy to wash, cannot be easily stained during washing, and have the characteristics of excellent compatibility, good dyeing depth, excellent fixation rate and excellent fastness.

Owner:ZHEJIANG KEYONG CHEM CO LTD +1

Method for dyeing polar fleece fabric

InactiveCN106337292AExcellent color fastness to rubbingGood dyeing uniformityDyeing processChemistryEthylenediaminetetra(methylenephosphonic)acid

The invention discloses a method for dyeing a polar fleece fabric, and the method comprises the following steps: 1) adding copper sulfate, hexamethylenediamine, hexyldecanol, sodium ethylenediamine tetramethylene phosphonate and a plant dye in turn into deionized water in a dyeing vat, stirring well, and heating to 45 DEG C; 2) in turn adding fatty alcohol polyoxyethylene ether, alkyl sodium sulfonate, polyethylene glycol (peg) and 1-dimethyl diallyl ammonium chloride, continuing to stir until even mixing, and heating at 60 DEG C; 3) soaking the fabric for 45 minutes in the dyeing vat; 4) drying the soaked fabric at 85 DEG C; 5) dipping the dried fabric into clean water for rinsing for 45 minutes; and 6) taking the rinsed fabric for drying in air naturally. The dyed fabric has excellent color fastness and good dyeing uniformity, and is free of dyeing defects.

Owner:常熟市绮丽家纺有限公司

Dyeing method for acrylic top

InactiveCN106320008AGood light fastnessExcellent color fastness to washingDyeing processMethacrylateSodium metasilicate

The invention discloses a dyeing method for acrylic top, comprising the steps of 1) add secondary alcohol ethoxylate, triallylamine, sodium metasilicate, diethyl amino ethyl methacrylate and vegetable dyes into the deionized water, mix the water and heat it to 4oC; 2) add sodium of polyaspartic acid, sodium dodecyl sulfate, zinc stearate and Alpha-aminopropionic acid, keep mixing util the solution is mixed evenly and heat the solution to 60oC; 3) dip the wool top in the dye vat for 50min; 4) dry the soaked wool top at 85oC; 5) wash the dried wool top in clean water for 50min; 6) take out the washed wool top for natural drying. The dyed tops are excellent in color fastness and good in dyeing uniformity, and free of color tone.

Owner:常熟市新华源有色毛条厂

Dyeing method of bar-shaped plush fabric

InactiveCN106381728AExcellent color fastness to perspirationExcellent water fastnessDyeing processPhosphateEthyl ester

The invention discloses a dyeing method of bar-shaped plush fabric. The dyeing method comprises the following steps: 1) successively adding 2-(diethylamino)ethyl methacrylate, poly(aspartic acid), sodium tripolyphosphate, zinc stearate and vegetable dye into deionized water in a dye vat, uniformly stirring and heating to 55 DEG C; 2) successively pouring nitrilotriacetic acid, aliphatic isoalcohol phosphate, dicyandiamide and chitosan, continuously stirring until the materials are fully and uniformly mixed, and heating to 65 DEG C; 3) immersing fabric in the dye vat for 35 min; 4) drying the immersed fabric at 80 DEG C; 5) immersing the dried fabric in clear water and rinsing for 35 min; and 6) taking out the rinsed fabric and naturally airing. The dyed fabric has excellent color fastness and good dyeing uniformity, but has no dyeing defect.

Owner:SUZHOU XIN GE HOUSEHOLD PROD CO LTD

Dyeing method of bubble cashmere fabric

InactiveCN106381729AExcellent color fastness to washingExcellent color fastness to dry cleaningDyeing processEthylenediaminePyrophosphate

The invention discloses a dyeing method of a bubble cashmere fabric, wherein the dyeing method comprises the following steps: 1) successively adding octadecyl dimethylamine, sodium sulfate, sodium pyrophosphate, ammonia water and a plant dye into deionized water in a dyeing vat, stirring evenly, and heating to 45 DEG C; 2) then successively adding sodium ethylenediamine tetramethylene phosphonate, sodium alpha-olefin sulfonate, methylallylamine hydrochloride and zinc stearate, continuing to stir to fully and evenly mix, and heating to 60 DEG C; 3) soaking a fabric in the dyeing vat for 40 minutes; 4) drying the soaked fabric at the temperature of 85 DEG C; 5) immersing the dried fabric into clear water, and rinsing for 40 minutes; and 6) taking out the rinsed fabric, and naturally air-drying. The dyed fabric has the advantages of excellent color fastness, good dyeing uniformity, and no color spots.

Owner:SUZHOU YUHUA BUSINESS MANAGEMENT CO LTD

A kind of azo dye compound containing methanesulfonamide group and its preparation method and application

ActiveCN108864732BExcellent sweat resistanceExcellent color fastness to rubbingMonoazo dyesDyeing processTextile printerColour fastness

The invention relates to an azo dyestuff compound containing methanesulfonamide group as well as a preparation method and application thereof. A structural formula of the compound is as follows: a formula is shown in the description. The azo dyestuff compound is applied to dyeing or printing of a hydrophobic material or a blending material containing the hydrophobic material. The compound providedby the invention has excellent perspiration resistance, color fastness to rubbing, water resistance, sublimation resistance and color fastness to bleaching. Even if the dyeing concentration is improved, the color fastness of obtained textiles is very excellent. The dyestuff provided by the invention has good comprehensive performance.

Owner:ZHEJIANG WANFENG CHEM

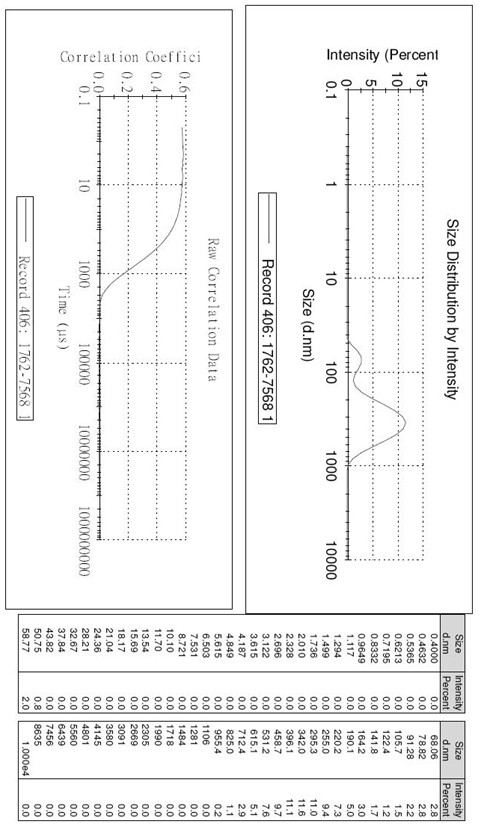

A kind of fiber raw liquid color paste and preparation method thereof

ActiveCN107653704BNovel method of coloring color pasteNovel methodDyeing processColour fastnessFiber

The invention discloses a method for preparing a novel environment-friendly fiber stock solution color paste. The color paste is prepared from pre-emulsion liquid wrapped with pigments, adipic hydrazide aqueous solution and initiator solution as raw materials. When adding monomers and initiator solution The temperature is controlled at 55-60°C, and the reaction is carried out for 4-5 hours after the addition is completed, and the method of batch addition is adopted. The fiber stock liquid color paste obtained by the present invention has more excellent coloring effect, excellent color fastness to light, and color fastness to weathering, and does not require chemical dyeing, tow dyeing or gel dyeing of subsequent fibers or fabrics, and reduces pollution of the environment.

Owner:JIANGSU LYNWON TECH CO LTD

Method for dyeing loop-raised fabric

InactiveCN106337293AExcellent color fastness to rubbingGood dyeing uniformityDyeing processSodium polyacrylateDiethylenetriamine

The invention discloses a method for dyeing a loop-raised fabric, and the method comprises the following steps: 1) adding sodium hexametaphosphate, diethylenetriamine, sodium polyacrylate, sodium amino acetic acid and a plant dye in turn into deionized water in a dyeing vat, stirring well, and heating to 45 DEG C; 2) in turn adding Isobornyl methacrylate, secondary alkyl sodium sulfate, dimethylformamide and N-methyl diethanolamine, continuing to stir until even mixing, and heating at 60 DEG C; 3) soaking the fabric for 45 minutes in the dyeing vat; 4) drying the soaked fabric at 85 DEG C; 5) dipping the dried fabric into clean water for rinsing for 45 minutes; and 6) taking the rinsed fabric for drying in air naturally. The dyed fabric has excellent color fastness and good dyeing uniformity, and is free of dyeing defects.

Owner:常熟市绮丽家纺有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com