Denim continuous dyeing method

A denim and dyeing solution technology, applied in the field of fabric processing, can solve the problems of not being suitable for mass production, high cost, and excessive water consumption, and achieve the effects of low chroma of washing residual liquid, convenient operation, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of dispersant, comprising the following steps:

[0052] Add alkali lignin into an aqueous solution of 8wt% sodium hydroxide at a weight ratio of 1:1.5, stir evenly, then heat up to 72°C, and add 10% formaldehyde by weight of alkali lignin dropwise within 10 minutes under heat preservation , continue to keep warm for 1.5h. Continue to heat up to 95°C, add anhydrous sodium sulfite with 10% weight of alkali lignin, continue to keep warm for 1.5h, cool to room temperature, slowly add epichlorohydrin with 8.2% weight of alkali lignin under ultrasonic stirring state, stop after 2h of reaction Heating, using waste heat to evaporate the remaining unreacted epichlorohydrin, the pH value in the reaction process is 9.0, to obtain a dispersant, which contains the compound shown in formula I,

[0053] In the formula, X=CH 2 SO 3 Na,Y=OCH 3 .

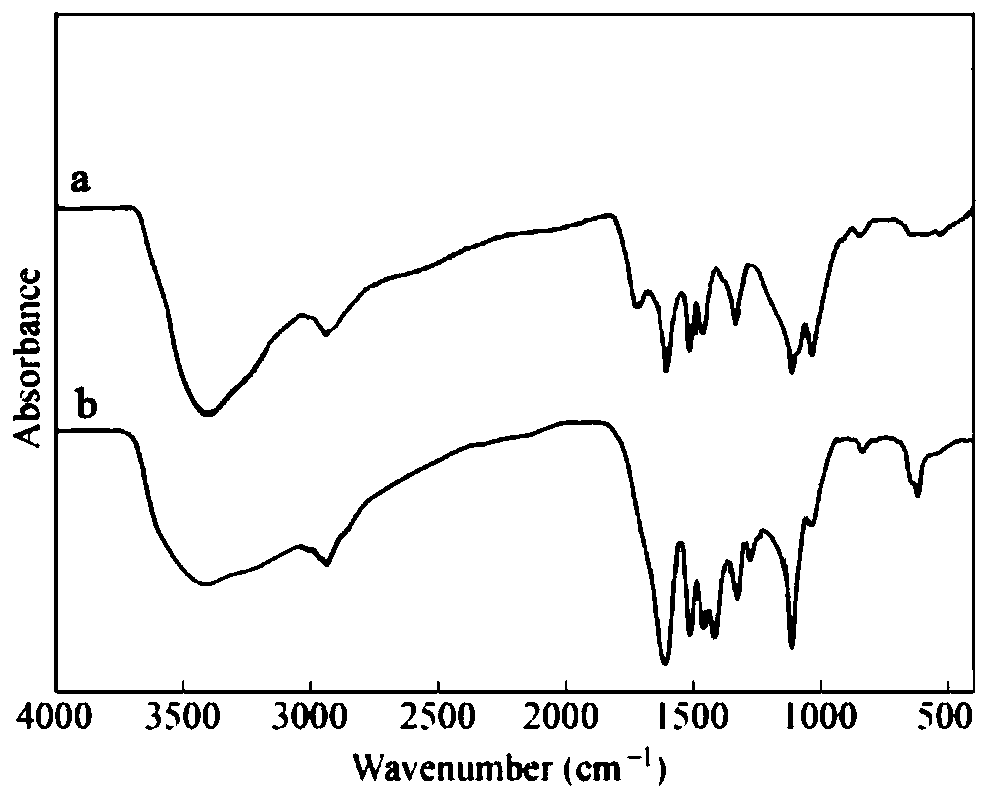

[0054] The infrared spectroscopic analysis of alkali lignin and dispersant was carried out on the Nicolet infrare...

Embodiment 2

[0056] A preparation method of dispersant, comprising the following steps:

[0057] Add alkali lignin into an aqueous solution of 8wt% sodium hydroxide at a weight ratio of 1:1.5, stir evenly, then heat up to 72°C, and add 10% formaldehyde by weight of alkali lignin dropwise within 10 minutes under heat preservation , continue to keep warm for 1.5h. Continue to heat up to 95°C, add anhydrous sodium sulfite with 10% weight of alkali lignin, continue to keep warm for 1.5h, cool to room temperature and slowly add epichlorohydrin with 8.2% weight of alkali lignin under stirring state, stop heating after 2 hours of reaction , using waste heat to evaporate the remaining epichlorohydrin that has not participated in the reaction, and the pH value during the reaction is 9.0 to obtain a dispersant.

Embodiment 3

[0059] A method for continuous dyeing of denim, which contains cotton fibers, the method comprising the following steps:

[0060] Step S1: Arrange the denim in a solution containing 8g / L penetrant JFC and 5g / L caustic soda according to the bath ratio (denim: water) = 1:100 (g / g), pretreat at 80°C for 1 hour, and then Wash twice with water, rinse until the pH value of the rinse solution is 7-7.5;

[0061] Step S2: According to the bath ratio (denim: water) = 1:20 (g / g), the denim obtained in step S2 is arranged in a solution containing 30g / LLINEX SURF Italian auxiliary agent, and modified at 40°C for 30 minutes;

[0062] Step S3: using the method of double dipping and rolling, dyeing the denim obtained in step S3 with the dyeing solution containing 25g / L TR / 0265 Italian natural colored sand dye, the dyeing excess rate is 80%, and the temperature is 50°C; dyeing The back denim was fixed in 30g / L LINEX SUP solution at 60°C for 40min, and then dried at 90°C×3min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com